Sealed Power Piston Ring Gap Chart

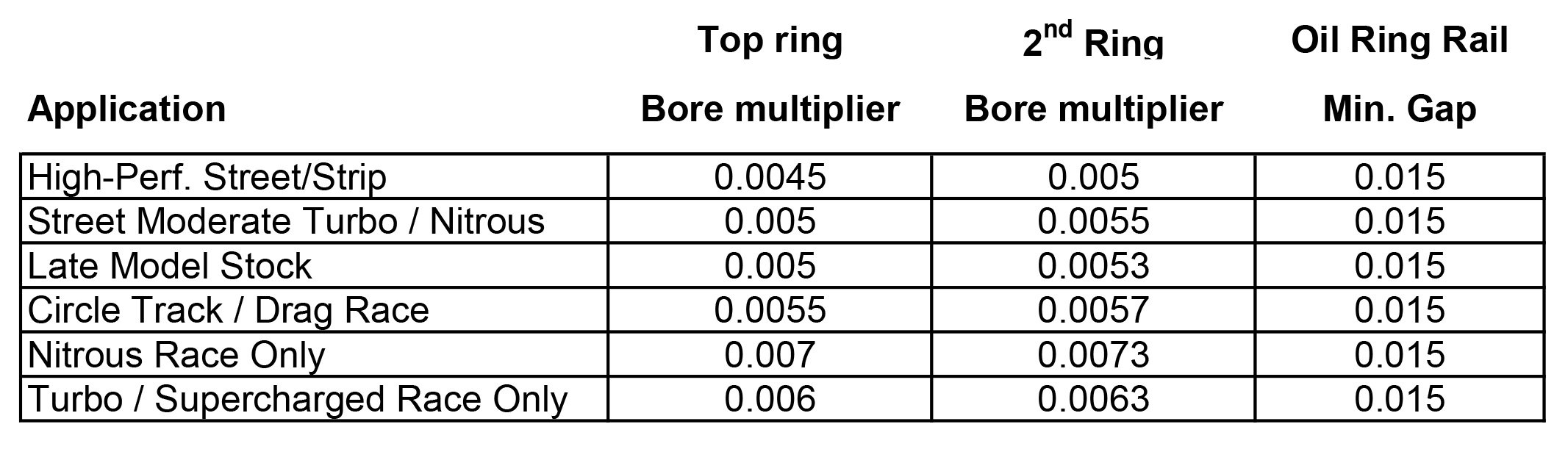

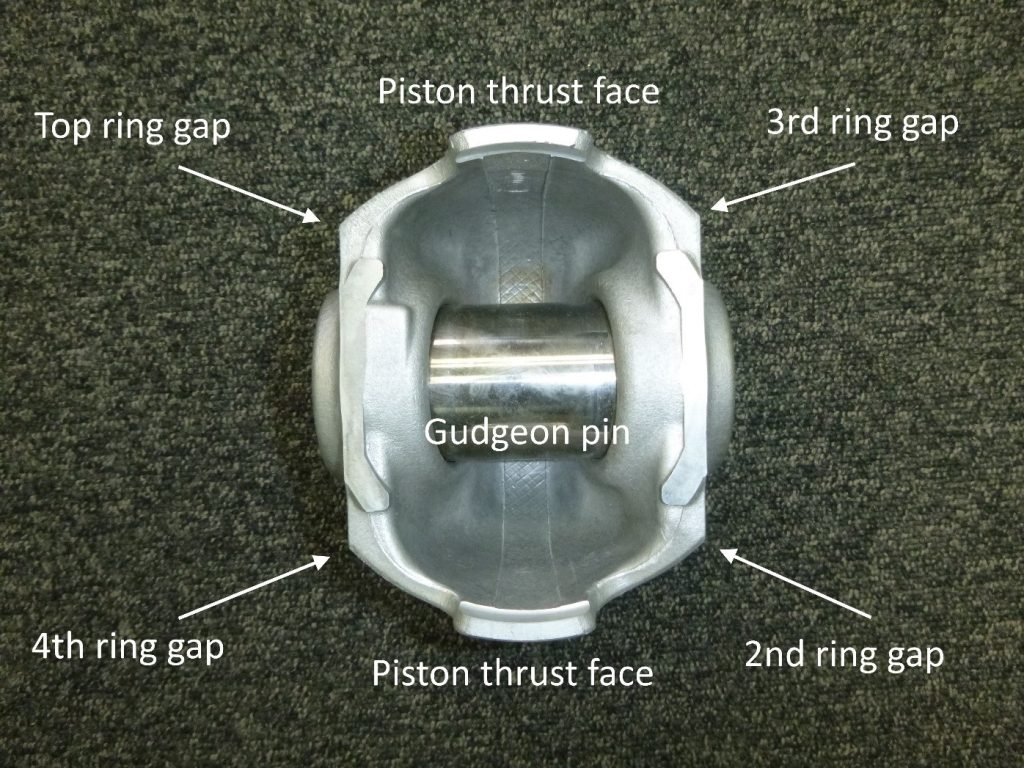

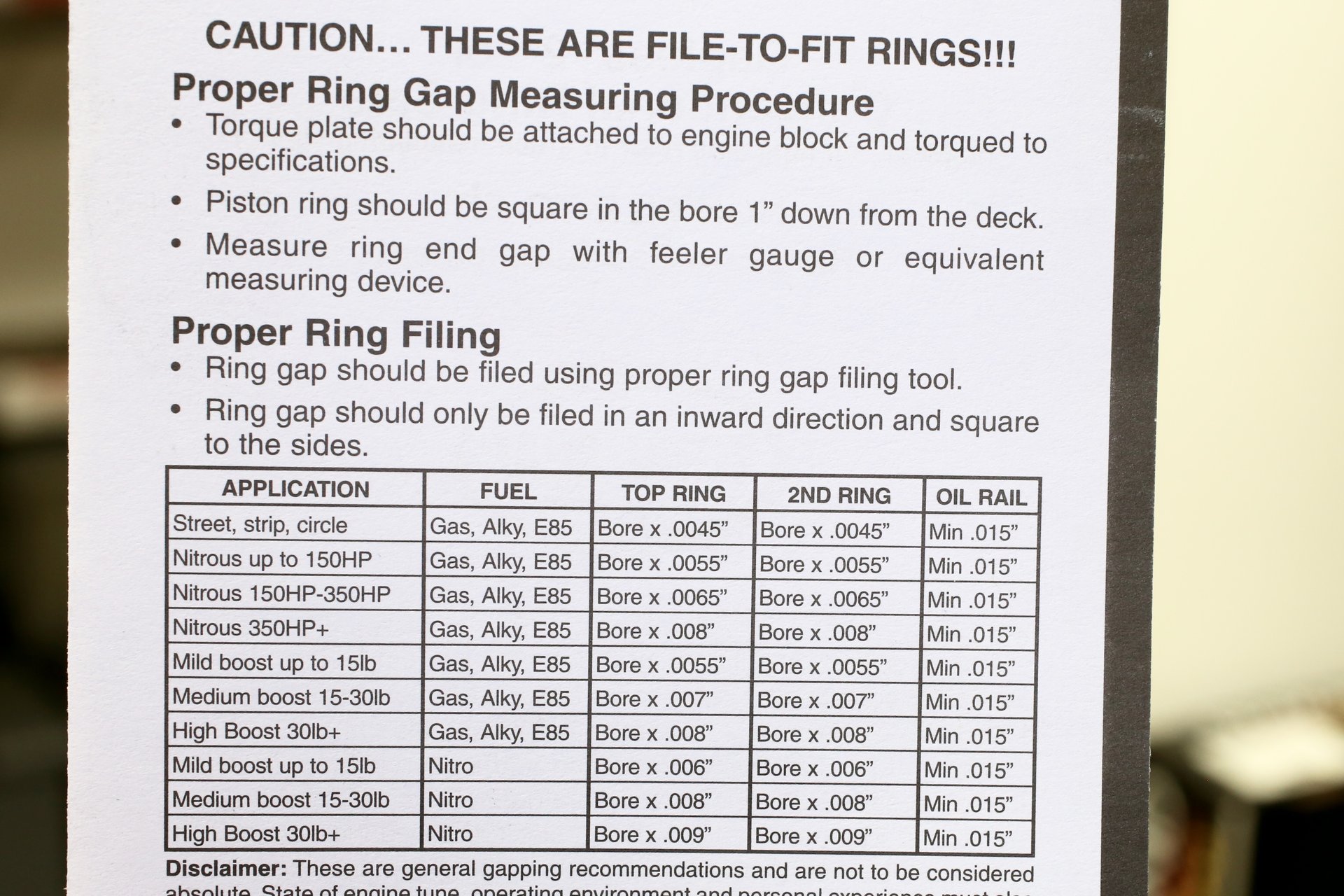

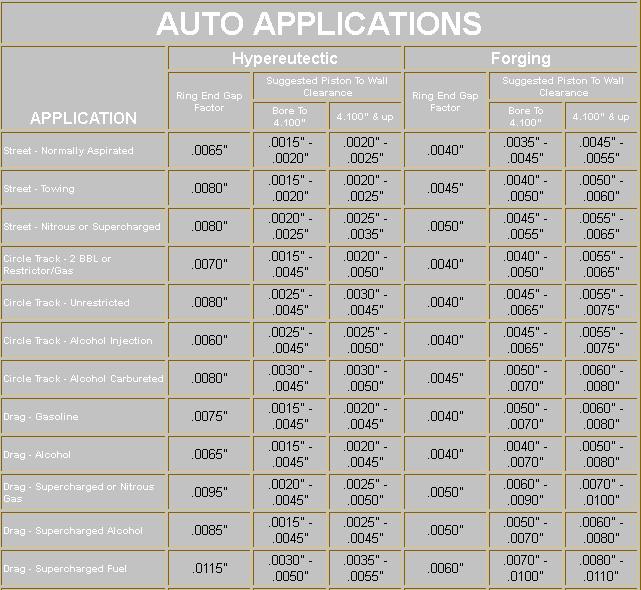

Sealed Power Piston Ring Gap Chart - When a loose fit engine is desired the rigid skirt design of the kb piston allows the builder a choice without fear of piston damage. Properly clocking piston rings when they are installed will keep things running and sealing as they should. If the ring's end surfaces. Web the following is a recommended gap chart for conventional (gap style) rings from total seal piston rings: Pulling, racing and daily driver apps. Web the following chart indicates the specifications for compression ring gap as outlined by the sae (society of automotive engineers) as standards for the automotive piston ring manufacturers. Cylinder should be free of any taper. The end gap refers to the clearance between the two ends of the piston ring when installed into the cylinder bore. Today’s performance piston designs are moving the top compression ring higher for optimal performance. They are carefully selected for the best combination of top, second and oil control. Pulling, racing and daily driver apps. Is there a measurable power difference between these two gaps? Web the following chart indicates the specifications for compression ring gap as outlined by the sae (society of automotive engineers) as standards for the automotive piston ring manufacturers. Today’s performance piston designs are moving the top compression ring higher for optimal performance. This creates. Technical sales representative, kevin studaker from total seal piston rings takes you through the basic steps for gapping a piston ring with our power ring. A common practice in performance applications is file fitting piston end gaps to a precise end gap using slightly oversized rings. Web basic rule of thumb for n/a engines without nitrous is.0045 to.0050 inch of. Your hypereutectic performance piston will expand less than typical cast or forged pistons. State of engine tune, operating environment, and personal experience should also be considered. Today’s performance piston designs are moving the top compression ring higher for optimal performance. Most performance ring sets are available in file fit (+.005”) oversizes. Web the following is a recommended gap chart for. Setting custom ring end gaps can be accomplished easily enough. Web the gap that you create in the top ring is to accommodate the maximum expansion that you anticipate the top ring requiring. Web this means that once installed, they’re good to go. Web total seal® piston rings | performance piston ring manufacturer. Cylinder should be free of any taper. That is a huge difference in the gap as compared to the production ring package. Web total seal® piston rings | performance piston ring manufacturer. Technical sales representative, kevin studaker from total seal piston rings takes you through the basic steps for gapping a piston ring with our power ring. The second ring gap should always be larger then the. In seeking for the optimum end gap for your particular engine, choose the proper application in the chart and gap the rings to the high limit. They are carefully selected for the best combination of top, second and oil control. Web basic rule of thumb for n/a engines without nitrous is.0045 to.0050 inch of gap, per inch of bore diameter. The idea is to run a slightly larger gap for the second ring to prevent a pressure buildup between the top and second ring. What's your piston ring application? This creates even higher operating temperatures, therefore requiring a larger top compression ring end. Not only is piston rings what we do—it’s all we do. In seeking for the optimum end. Total seal notes that these are general gapping recommendations and should not be considered absolute. Web the ring gap position on the piston is a critical thing to pay attention to when assembling an engine. We don’t manufacture other engine parts because that would only take us away from what we do best. That is a huge difference in the. Today’s performance piston designs are moving the top compression ring higher for optimal performance. Web a close fitting piston rocks less, supports the rings better, and seals the engine for maximum power. Pulling, racing and daily driver apps. Ring sets and custom piston rings for every type of competition. Is there a measurable power difference between these two gaps? Web total seal® piston rings | performance piston ring manufacturer. Web to find the proper ring end gap, multiply your bore size by the ring end gap factor listed on the chart (i.e., street naturally aspirated 4.000” bore x.0065” gap factor =.026” total top ring end gap). When a loose fit engine is desired the rigid skirt design of the. 360 views 1 year ago. A common practice in performance applications is file fitting piston end gaps to a precise end gap using slightly oversized rings. Since your gap is already larger than the je recommendation, this is not ideal, but acceptable. Web ring end gap should be measured with the ring square in the bore on a fresh hone. Custom rings for your vintage and restoration build. In worn cylinders, make sure that ring gaps are checked at bottom of ring travel. Ring sets and custom piston rings for every type of competition. This is very critical to understand, as the top ring is responsible for holding in compression. This creates even higher operating temperatures, therefore requiring a larger top compression ring end. Your hypereutectic performance piston will expand less than typical cast or forged pistons. The idea is to run a slightly larger gap for the second ring to prevent a pressure buildup between the top and second ring. Sealed power® piston ring sets are designed to minimize cylinder leakage and provide maximum oil control. The second ring gap should always be larger then the top ring gap in order to relieve pressure between the two rings. Web this means that once installed, they’re good to go. Not only is piston rings what we do—it’s all we do. The end gap refers to the clearance between the two ends of the piston ring when installed into the cylinder bore.

Blueprint Series The How And Why Of Setting Piston Ring End Gap

Piston Ring Gap Placement GM Square Body 1973 1987 GM Truck Forum

Repair Guides Engine Mechanical Components Piston & Ring

Repair Guides Engine Mechanical Pistons And Connecting Rods

Piston ring gap chart. Greg Clark Flickr

Bartech Marine Drop in engine power due to piston ring gap positioning

How to FileFit and Install Piston Rings

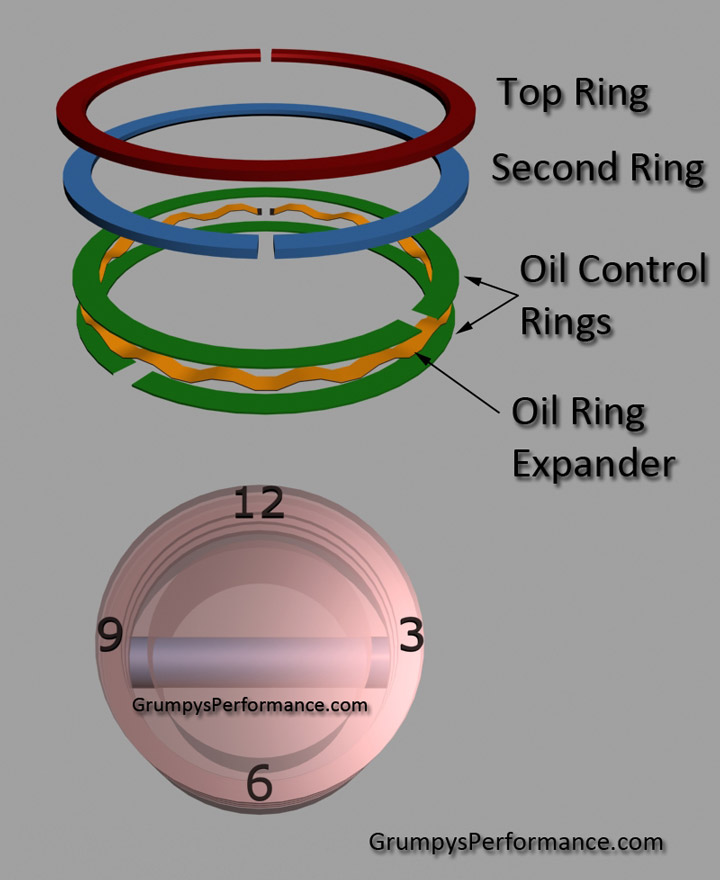

installing rings in piston grooves Grumpys Performance Garage

ring gapping and basic piston ring info YOULL NEED Grumpys

Sealed Power Standard Gap PlasmaMoly Piston Ring Sets R9904 Free

Web Basic Rule Of Thumb For N/A Engines Without Nitrous Is.0045 To.0050 Inch Of Gap, Per Inch Of Bore Diameter For The Top Ring And.0055 To.0060 Per Inch Of Bore Diameter For The Second Ring.

Web In The Last Video Of The Series, Lake Speed Jr.

They Are Carefully Selected For The Best Combination Of Top, Second And Oil Control.

Web The Gap That You Create In The Top Ring Is To Accommodate The Maximum Expansion That You Anticipate The Top Ring Requiring.

Related Post: