X Bar R Chart Example

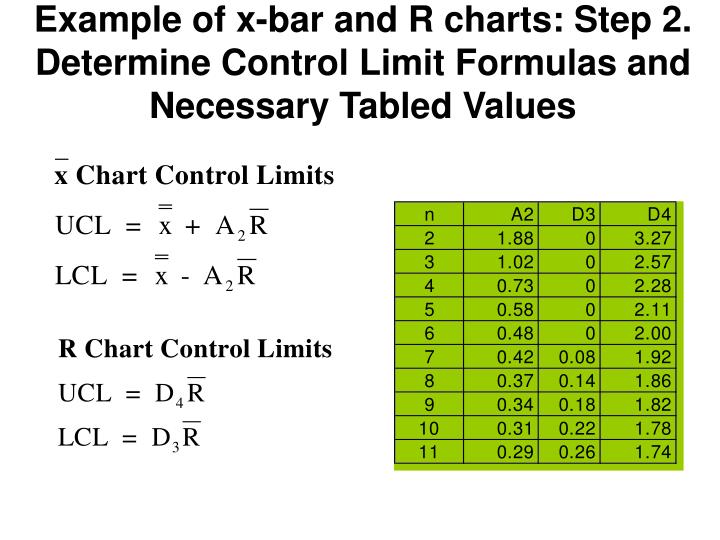

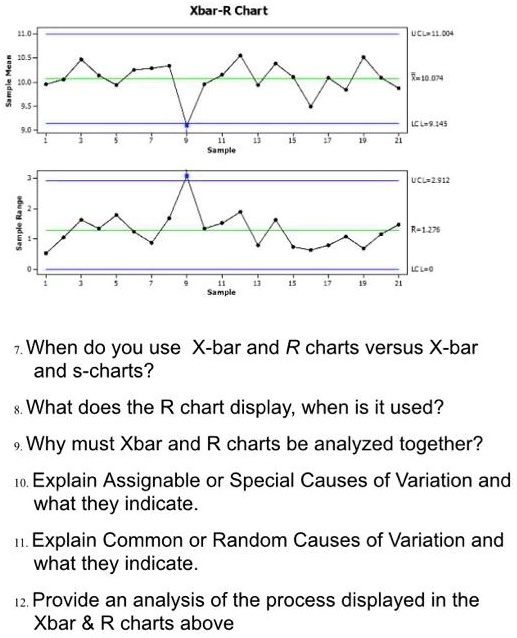

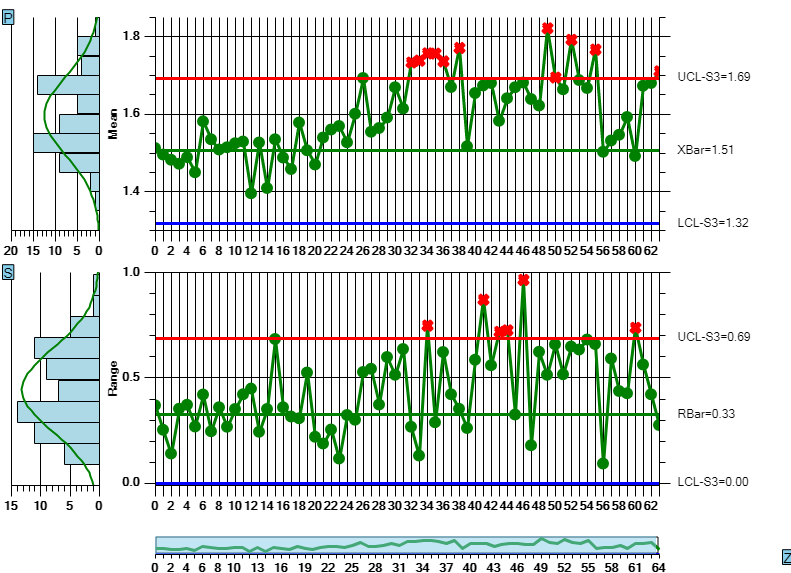

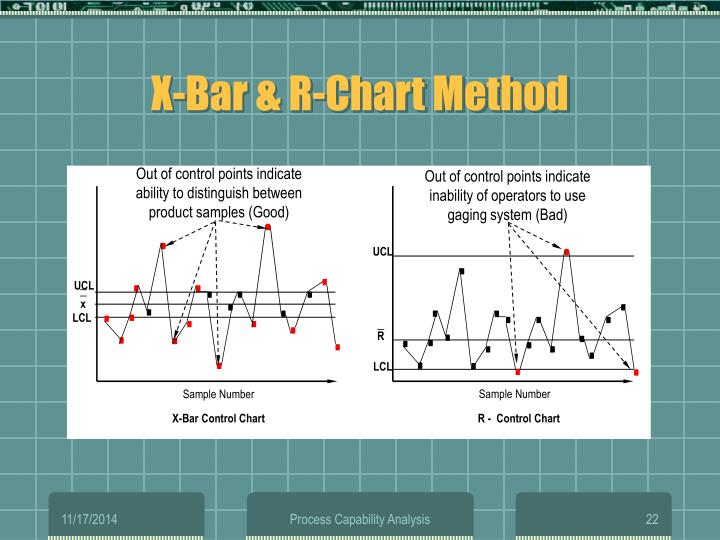

X Bar R Chart Example - Web steps in constructing the xbar chart. Find the mean of each subgroup xbar (1), xbar (2), xbar (3)… xbar (k) and the grand mean of all subgroups using: If the range chart is not in control, the control limits for the \bar { x }. An xbar chart is a graphical representation of the average value of a data set over a period of time. Web the range (r) chart. Plot the data (both the averages and the ranges). A(2) can be found in the following table: When working with an xbar and r chart, we begin with the r chart. Find the ucl and lcl using the following equations: Input your data set into minitab. Web x bar r chart is used to monitor the process performance of continuous data. An xbar chart is a graphical representation of the average value of a data set over a period of time. Three machines manufacture camshafts for three shifts each day. Xbarr chart data usually looks like this: It is actually two plots to monitor the process. You can also use them to collect data from subgroups at set time periods. Three machines manufacture camshafts for three shifts each day. Herein, in this article, we would introduce how to. → many processes can be tracked by this graph like defects, production time, inventory on hand, cost per unit, and other metrics. A(2) can be found in the. A quality engineer at an automotive parts plant monitors the lengths of camshafts. Find the mean of each subgroup xbar (1), xbar (2), xbar (3)… xbar (k) and the grand mean of all subgroups using: Web the range (r) chart. You can also use them to collect data from subgroups at set time periods. Web example of an xbarr chart. Input your data set into minitab. Web steps in constructing the xbar chart. Making a widget, answering a customer call, seating a customer, delivering a pizza, or servicing an appliance. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Web example of an xbarr chart (average and range chart) created by. Xbarr chart data usually looks like this: Determine an appropriate subgroup size and sampling plan. The xbarr chart can help you evaluate the cycle time for almost any process: A(2) can be found in the following table: When working with an xbar and r chart, we begin with the r chart. Find the ucl and lcl using the following equations: Web xbar r charts are often used collectively to plot the process mean (xbar) and process range (r) over time for continuous data. You can also use them to collect data from subgroups at set time periods. Web we have already discussed how to read and establish an accurate method when. When working with an xbar and r chart, we begin with the r chart. Web we have already discussed how to read and establish an accurate method when conducting x bar r charts examinations in previous article. Web steps in constructing the xbar chart. Web xbar r charts are often used collectively to plot the process mean (xbar) and process. You can also use them to collect data from subgroups at set time periods. Three machines manufacture camshafts for three shifts each day. Web we have already discussed how to read and establish an accurate method when conducting x bar r charts examinations in previous article. → many processes can be tracked by this graph like defects, production time, inventory. Web → control _charts measure variation and show it to you graphically and we can easily say whether it is within an acceptable limit or not? When working with an xbar and r chart, we begin with the r chart. Web example of an xbarr chart (average and range chart) created by qi macros. Please let me know if you. Web the range (r) chart. Determine an appropriate subgroup size and sampling plan. Input your data set into minitab. They provide continuous data to determine how well a process functions and stays within acceptable levels of variation. Find the mean of each subgroup xbar (1), xbar (2), xbar (3)… xbar (k) and the grand mean of all subgroups using: Web steps in constructing the xbar chart. Web the range (r) chart. The xbarr chart can help you evaluate the cycle time for almost any process: → many processes can be tracked by this graph like defects, production time, inventory on hand, cost per unit, and other metrics. Three machines manufacture camshafts for three shifts each day. Plot the data (both the averages and the ranges). You can also use them to collect data from subgroups at set time periods. Calculate the average and range for each subgroup. Determine an appropriate subgroup size and sampling plan. Xbarr chart data usually looks like this: Web example of an xbarr chart (average and range chart) created by qi macros. Please let me know if you find it helpful! Making a widget, answering a customer call, seating a customer, delivering a pizza, or servicing an appliance. Herein, in this article, we would introduce how to. An r chart is a type of statistical chart used to monitor the quality of data over time. It is actually two plots to monitor the process mean and the process variation over time and is an example of statistical process control.

PPT X AND R CHART EXAMPLE INCLASS EXERCISE PowerPoint Presentation

SOLVED XbarR Chart WMAA FJO 074 LEIR When do you use Xbar and R

Control Limits for xbar r chart show out of control conditions

XBarR Chart SPC Charts Online

Individuals and Xbar R Control Chart Template

X Bar And R Chart

Xbar and R Chart Formula and Constants The Definitive Guide

X Bar R Chart Control Chart How To Make X Bar R Chart In Excel How My

Control Limits for Individual Sample Yields limits that differ from

X Bar R Chart Template Chart Examples

The Engineer Measures Five Camshafts From Each Machine During Each Shift.

Input Your Data Set Into Minitab.

Find The Ucl And Lcl Using The Following Equations:

When Working With An Xbar And R Chart, We Begin With The R Chart.

Related Post: