Wood Veneer Patterns

Wood Veneer Patterns - Plain slicing is the method most commonly used to produce veneers for architectural flush doors. Using a very short nap roller, roll the contact cement onto the area of the substrate that will be covered by a single panel of the veneer. Different wood grains include bird's eye, fiddleback, pommel and crossfire etc. Along with color and type of wood, figure plays a strong part into the veneer that is chosen. Hardwood edging for a veneered box, part 1. Web to discuss your requirements or get answers to all your questions about the different types of veneers across celebrated wood species, call us at +91 11 4279 1399 or our toll free no.: Figure refers to the surface effect of the grain. As before, tape these strips together edge to edge, square up one end and butt this end against the fence. This allows the designer to control the grain pattern as it progresses around an item or room, often called wood veneer matching. Web patterns and color nuances in veneer are highly prized by wood aficionados because they don’t recur as opposed to how natural wood is processed. Usually, this base material is either a different type of wood, a particle board, or a kind of fiberboard. However, if the designer is aware. The slicing of the flitch is done parallel to a line through the center of the log. When two or more slabs of natural or artificial stone are mirrored to match the pattern, movement, and. The result of this cut will yield mostly cathedral grain patterns and some straight grain. This often causes conflict between designers and manufacturers. The slicing of the flitch is done parallel to a line through the center of the log. Along with color and type of wood, figure plays a strong part into the veneer that is chosen. A series. Architect matt bowles of tenbooks plans to use the veneer in a. Tulips & bees, a 54 x 20. Here are the specific uses of wood veneer: They can be made into luxury bespoke products such as chocolate boxes, wine boxes, luxury soap boxes, tags, spice jars, and so much. Different wood grains include bird's eye, fiddleback, pommel and crossfire. Hardwood edging for a veneered box, part 2. You can also fill out our contact form. They can be made into luxury bespoke products such as chocolate boxes, wine boxes, luxury soap boxes, tags, spice jars, and so much. The slicing of the flitch is done parallel to a line through the center of the log. Architextures (artx), is a. However, if the designer is aware. Web ajiro sunburst provides an elegant sunburst pattern in a classic, hand‑inlaid wood veneer. The slicing of the flitch is done parallel to a line through the center of the log. Every other leaf from a sequentially cut stack is flipped over. Hardwood edging for a veneered box, part 2. Web design by magda kwoczka. Web to discuss your requirements or get answers to all your questions about the different types of veneers across celebrated wood species, call us at +91 11 4279 1399 or our toll free no.: Every other leaf from a sequentially cut stack is flipped over. Sliced veneer (thickness from 0.2 to 5 mm) is made. Along with color and type of wood, figure plays a strong part into the veneer that is chosen. Plain slicing is the method most commonly used to produce veneers for architectural flush doors. Web basic joinery for a veneered box. Crafted with micro‑thin wood on paper backing, ajiro is flexible enough to wrap columns and even turn corners. A series. Wrap up the ebony edging and learn how to separate the box from its lid. This often causes conflict between designers and manufacturers. Web to make a gauge strip for the cherry veneer rectangles, tape together edge to edge the two 3 ⁄ 8 black strips you set aside. Finished in our chicago studio. A beautiful, cost effective and environmentally. Unlock the world of wood veneers and explore a diverse range of. Due to the natural growth of trees, matching and coloring of wood panels is an inexact science. Along with color and type of wood, figure plays a strong part into the veneer that is chosen. 1800 833 0004, or email [email protected]. Different wood grains include bird's eye, fiddleback,. Web patterns and color nuances in veneer are highly prized by wood aficionados because they don’t recur as opposed to how natural wood is processed. Along with color and type of wood, figure plays a strong part into the veneer that is chosen. Here are the specific uses of wood veneer: They can be made into luxury bespoke products such. Due to the natural growth of trees, matching and coloring of wood panels is an inexact science. Web the wood veneer hub caters for all your wall paneling requirements. As before, tape these strips together edge to edge, square up one end and butt this end against the fence. Figure refers to the surface effect of the grain. Hardwood edging for a veneered box, part 2. Thanks to this, it is possible to achieve a solid wood grain pattern, which is very much loved by fans of natural wood. Web wood veneers are defined as thin sheets (from 0.3 to 3 mm) obtained by cutting the logs horizontally. Web patterns and color nuances in veneer are highly prized by wood aficionados because they don’t recur as opposed to how natural wood is processed. A beautiful, cost effective and environmentally sound alternative to traditional wood paneling. Wrap up the ebony edging and learn how to separate the box from its lid. Wrap up the ebony edging and learn how to separate the box from its lid. Web basic joinery for a veneered box. Plain slicing is the method most commonly used to produce veneers for architectural flush doors. Here are the specific uses of wood veneer: Web ajiro sunburst provides an elegant sunburst pattern in a classic, hand‑inlaid wood veneer. Cut and fit precise rabbet joints, then glue up the box in stages.

lostinpattern “ Olivia Salazar Chevron Stripes Wood Wall Art ” Wood

STRIPE Wood veneers from Gustafs Architonic

WALNUT VENEER Wall veneers from Architectural Systems Architonic

VENEERlayouts ImagineGrove Woodworking

Evergreen Maple 11 Veneer Sheets European Walnut Wood Veneers

Evergreen Burmese Teak Veneer Sheets Burman Walnut Wood Veneers

Wood Veneer Patterns Wood veneer, Wood inlay, Veneers

veneer pattern Wood Veneer, Wood Floors, Flooring, Woodworking Shop

485 best Wood, Veneer, Marquetry, Geometric Patterns images on

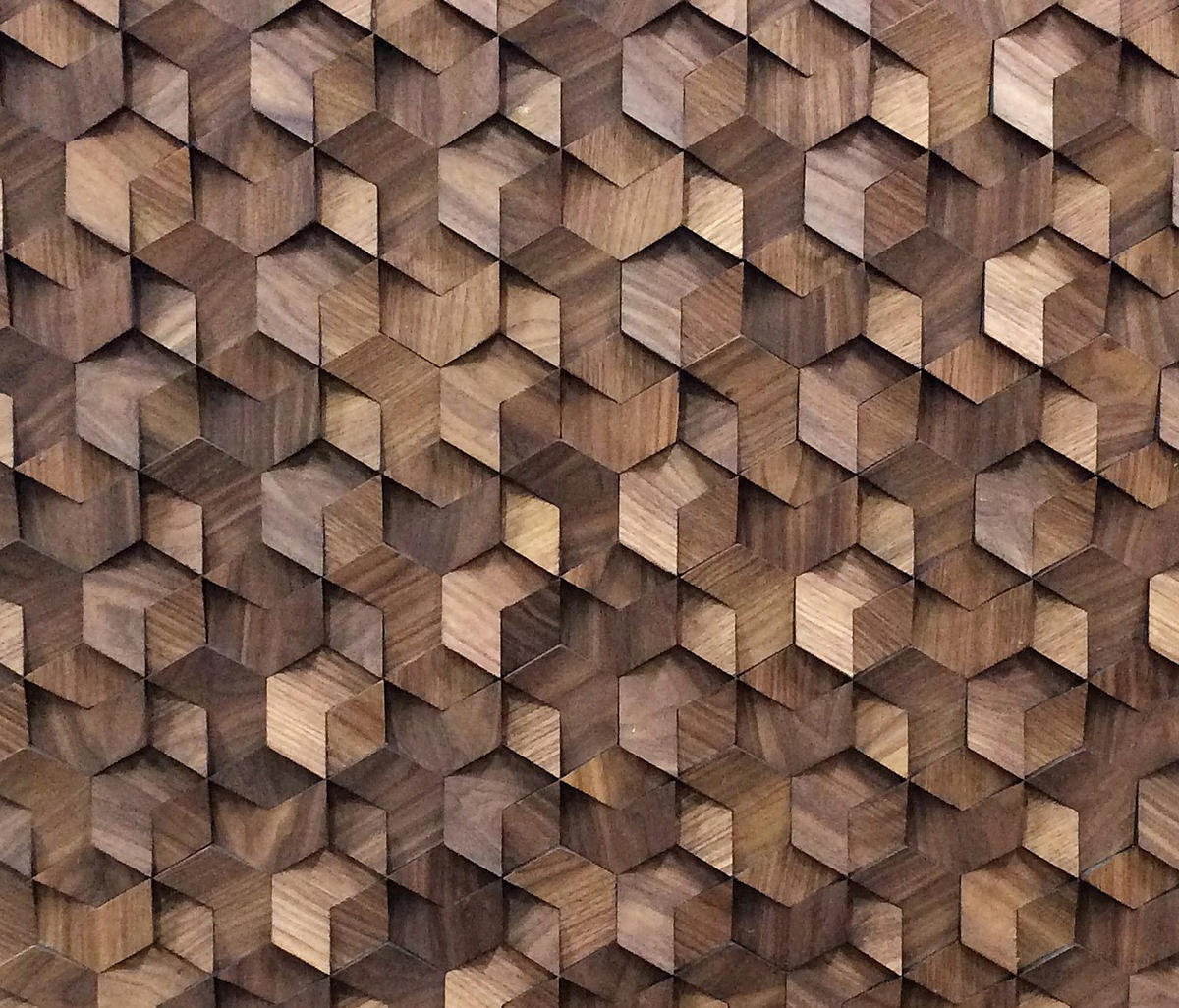

Cube Illusion Wood Veneer Pattern

Every Other Leaf From A Sequentially Cut Stack Is Flipped Over.

You Can Also Fill Out Our Contact Form.

Apply Contact Cement To The Substrate.

Such Veneer Is Produced Mainly From.

Related Post: