Wood Bandsaw Blade Tpi Chart

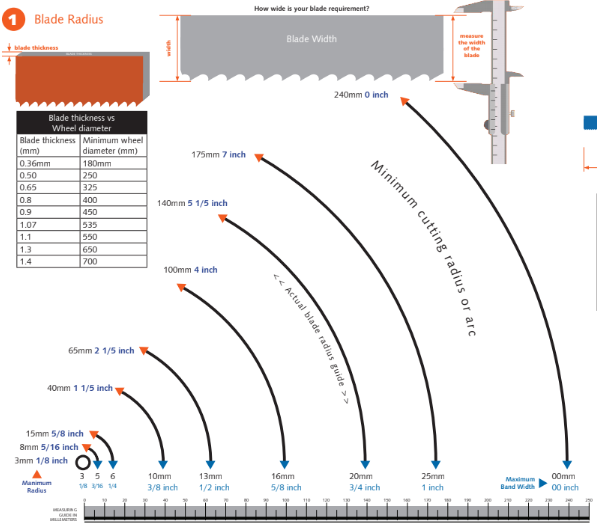

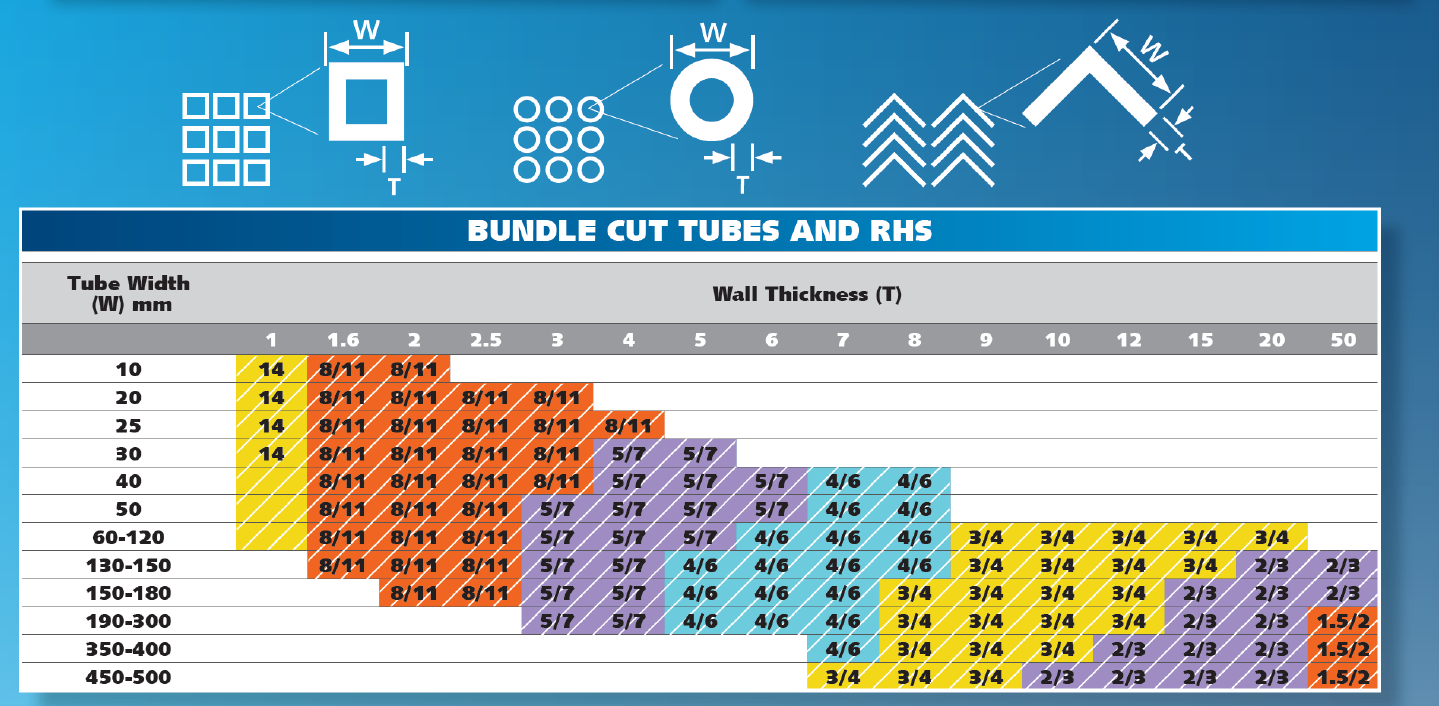

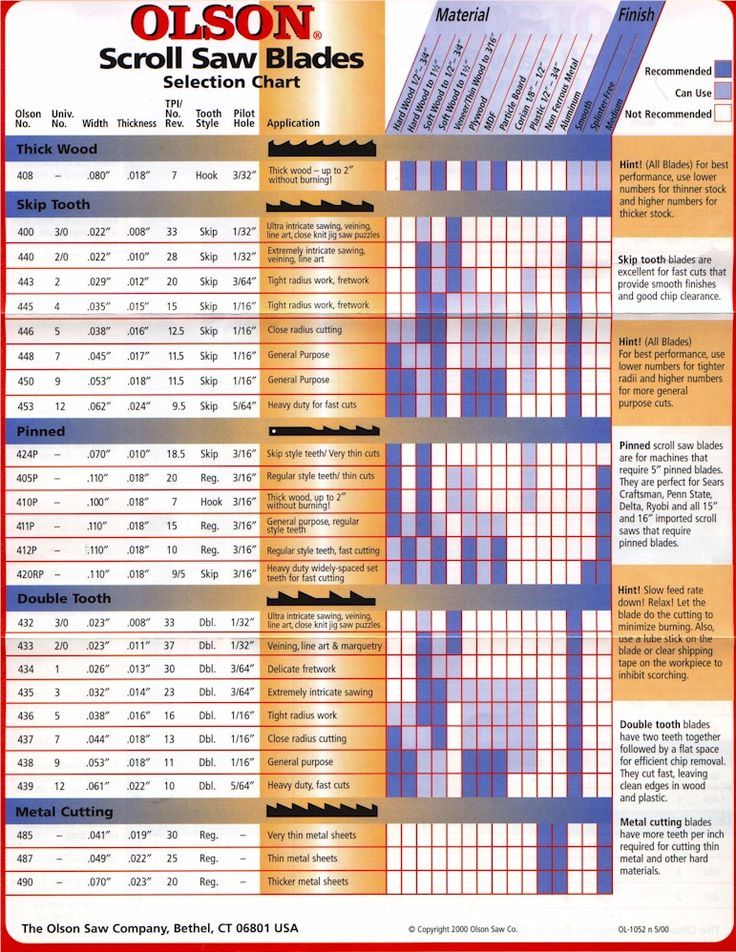

Wood Bandsaw Blade Tpi Chart - It’s important to note when deciding on the right tpi that at least three teeth must be in your work piece. To achieve a smoother, more refined cut choose a blade that has more tpi. High tpi configurations should be used on thinner materials and may require a reduced material feed rate through the blade. When transitioning to blade width, select a wider blade for enhanced stability, especially when dealing with thicker wood stock. Web increased cutting rates are obtained by using a coarser tooth pitch, higher saw speed and faster rate of feed. Web the best surface finish is produced by fine tooth pitch, high saw speed and slow feed rate. Manually measuring the blade length. Different cutting applications require varying tpi for optimal performance. Opt for a higher tpi blade (e.g., 14. If you have neither, please call us for advice. Web when selecting a bandsaw blade, the tooth per inch (tpi) is a critical factor to consider. Web tpi is arguably the most important decision when selecting a band saw blade. Web the best surface finish is produced by fine tooth pitch, high saw speed and slow feed rate. Web view our tpi charts in the links below. The chart. Web a band saw blade with 6 to 10 tpi is good general purpose blade. Maximum blade life is achieved by selecting a medium pitch blade, slow saw speed and medium rate feed. Most resaw blades feature a low tpi configuration. Web view our tpi charts in the links below. A finer tooth saw blade setting — 18 to 32. Maximum blade life is achieved by selecting a medium pitch blade, slow saw speed and medium rate feed. Increased cutting rates are obtained by using a coarser tooth pitch, higher saw speed and faster rate of feed. Determine the smallest radius curve that will be cut on your workpiece and use the corresponding blade width. This helps prevent clogging and. Web view our tpi charts in the links below. Web when selecting a bandsaw blade, the tooth per inch (tpi) is a critical factor to consider. For working with blocks of wood, particularly if you’re considering the use of carbon blades, there’s a range of considerations. Here is an introductory guide in identifying different parts of a bandsaw mill blade. Find by model or blade length. Maximum blade life is achieved by selecting a medium pitch blade, slow saw speed and medium rate feed. Opt for a higher tpi blade (e.g., 14. For softer woods, choose a lower tpi blade, enhancing chip removal efficiency. Manually measuring the blade length. Web the best surface finish is produced by fine tooth pitch, high saw speed and slow feed rate. Here is an introductory guide in identifying different parts of a bandsaw mill blade and how to choose a blade profile that is best suited for your sawing application. When transitioning to blade width, select a wider blade for enhanced stability, especially. Web choosing the correct blade width the number of teeth per inch (tpi) is important in obtaining the finish desired and the proper feed rate.a coarse tooth blade (2, 3 tpi) should be used for resawing wood and cutting thicker stock up to 8″.a fine toothed blade (18 to 32 tpi) should be used for thinner metals and plastics under. Web what is the proper blade teeth per inch (tpi) or pitch? Web understanding teeth per inch (tpi) measuring bandsaw blade length. For harder materials like metal: Move up to the correct material size next to the chart. For cutting stocks up to 8″ and above: Move up to the correct material size next to the chart. Web in addition to sawmill blade material, understanding the geometry and terminology of sawmill blade profiles is important. What this refers to is the number of teeth located on the blade. Web thicker materials require a low tpi blade, but may be fed through the blade at a higher. Web band saw tooth size (teeth per inch) is determined by the size and type of material to be cut and the desired finish. The chart below, developed by starrett®, offers guidelines for tpi selection based on material thickness. Web increased cutting rates are obtained by using a coarser tooth pitch, higher saw speed and faster rate of feed. For. Using the bandsaw blade length chart. Find by model or blade length. Wood/soft materials tpi chart (carbon) wood/soft materials tpi chart (bimetal) metals tpi char t (carbon) metals tpi chart (bimetal) order my bandsaw blade. Web what is the proper blade teeth per inch (tpi) or pitch? The chart below, developed by starrett®, offers guidelines for tpi selection based on material thickness. Begin with the wood type; The easy bandsaw blade selector. The most obvious piece of information you need to know is “how long is my blade?” this should be on the spec label on your machine, or in the instruction book. Web a band saw blade with 6 to 10 tpi is good general purpose blade. Web when selecting a bandsaw blade, the tooth per inch (tpi) is a critical factor to consider. Web view our tpi charts in the links below. Increased cutting rates are obtained by using a coarser tooth pitch, higher saw speed and faster rate of feed. Manually measuring the blade length. Web thicker materials require a low tpi blade, but may be fed through the blade at a higher feed rate. For working with blocks of wood, particularly if you’re considering the use of carbon blades, there’s a range of considerations. Use the chart below as a guide when choosing a blade for curve cutting.

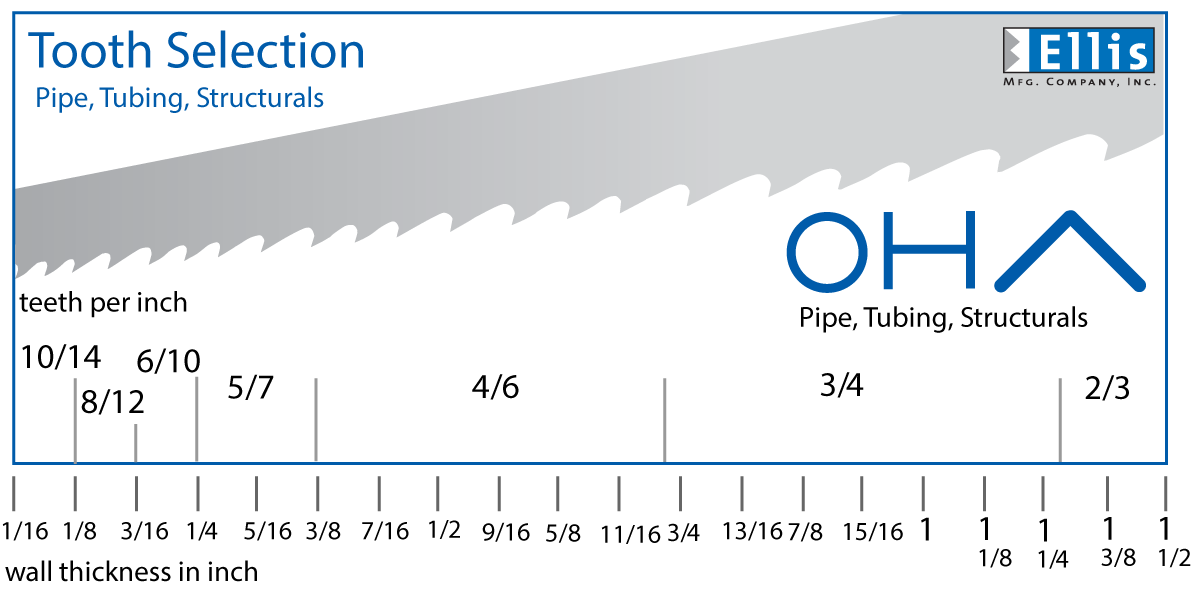

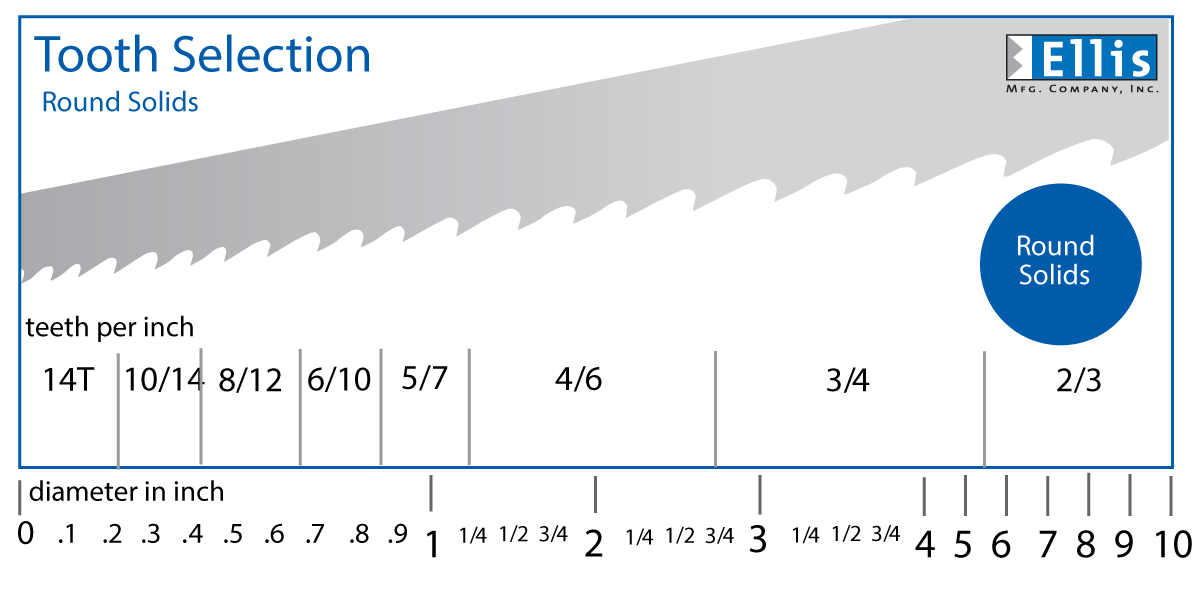

Band Saw Blade Tooth Selection Ellis Mfg, Inc.

Bandsaw Blade Radius Chart

Band Saw Blades Ellis Mfg, Inc.

M42 Wood Bandsaw Blades Size UK Guide Tpi Chart Tension for Various

The Ultimate Bandsaw Blade TPI Guide

How to select a band saw blade for maximum productivity

1425mm (56 1/8") x 1/4" (6mm) Wide Wood Cutting Bandsaw Blades (1425 mm

Wood Bandsaw Blade Tpi Chart

Bandsaw Blade Selection Guide

The Ultimate Bandsaw Blade TPI Guide

Opt For A Higher Tpi Blade (E.g., 14.

For Softer Materials Like Wood And Plastics:

When It Comes To Choosing The Appropriate Bandsaw Blade.

For Softer Woods, Choose A Lower Tpi Blade, Enhancing Chip Removal Efficiency.

Related Post: