Wire Rope Sling Capacity Chart

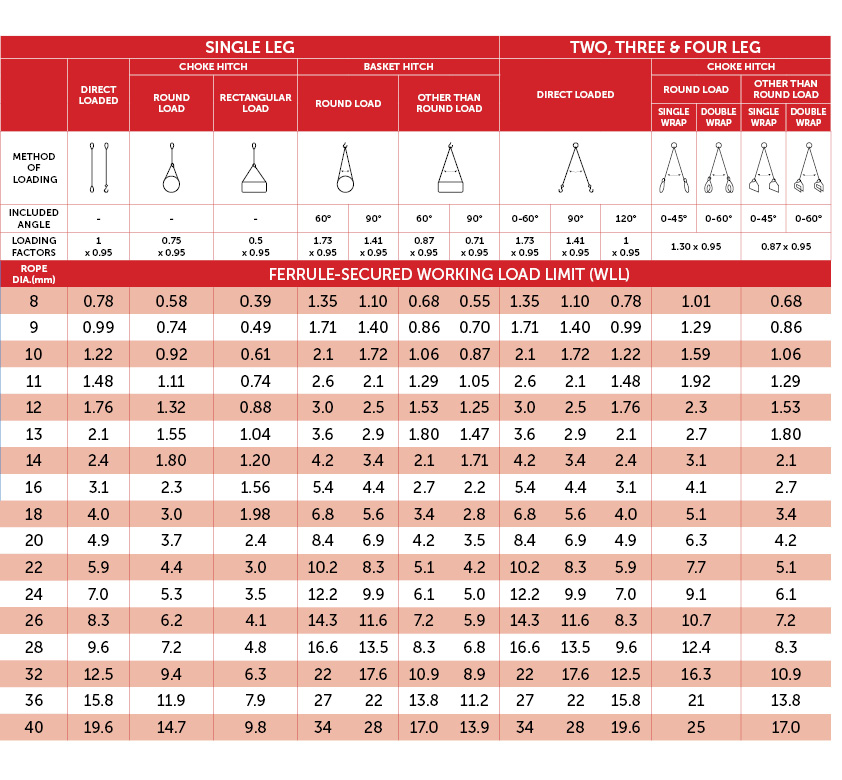

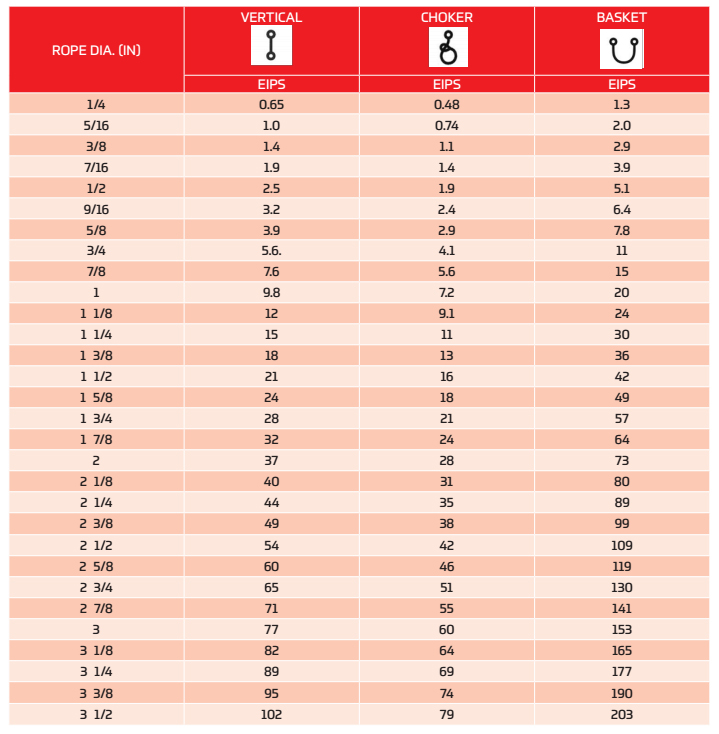

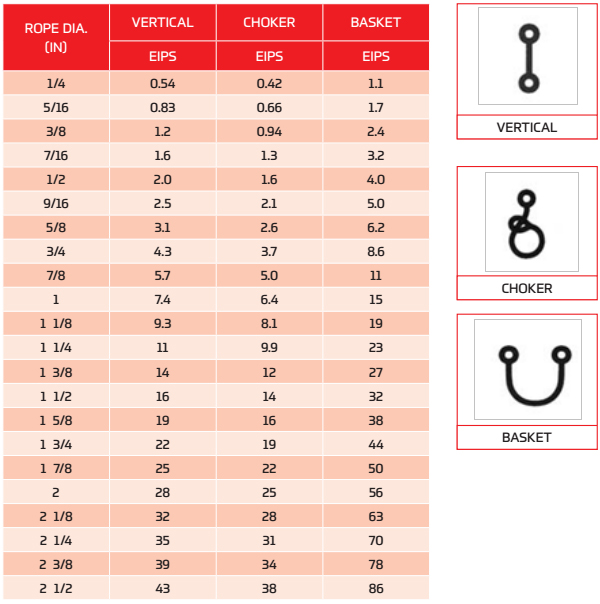

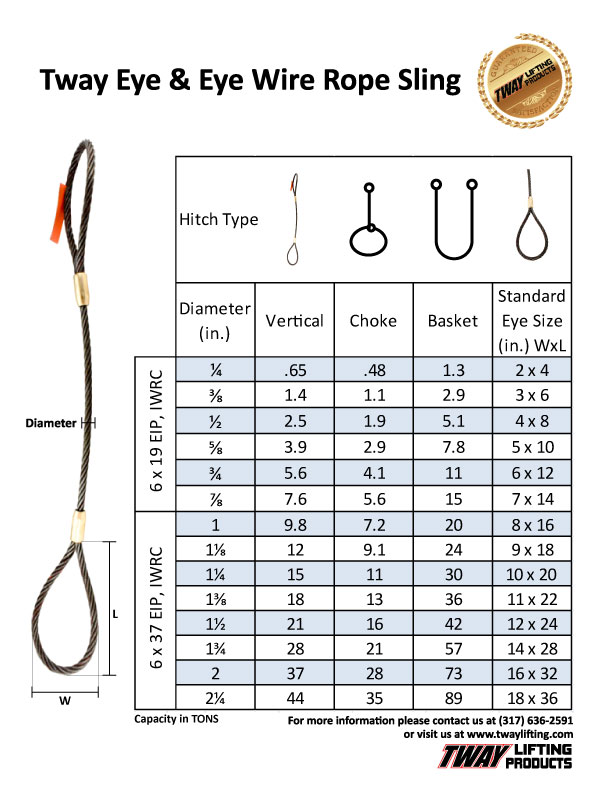

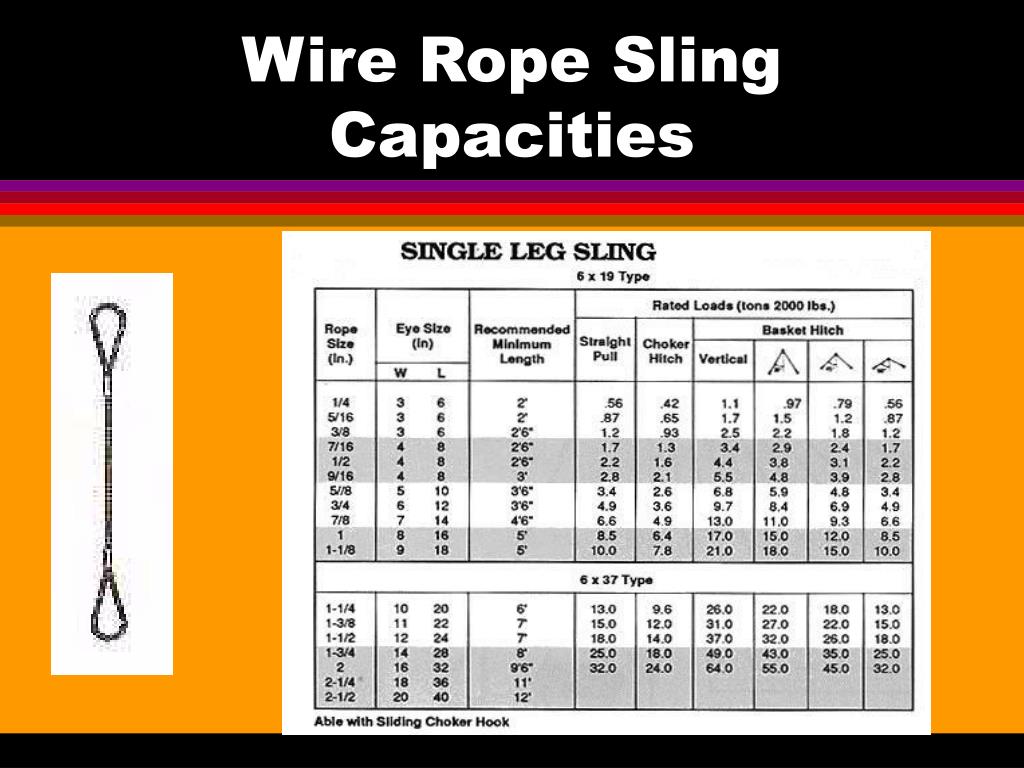

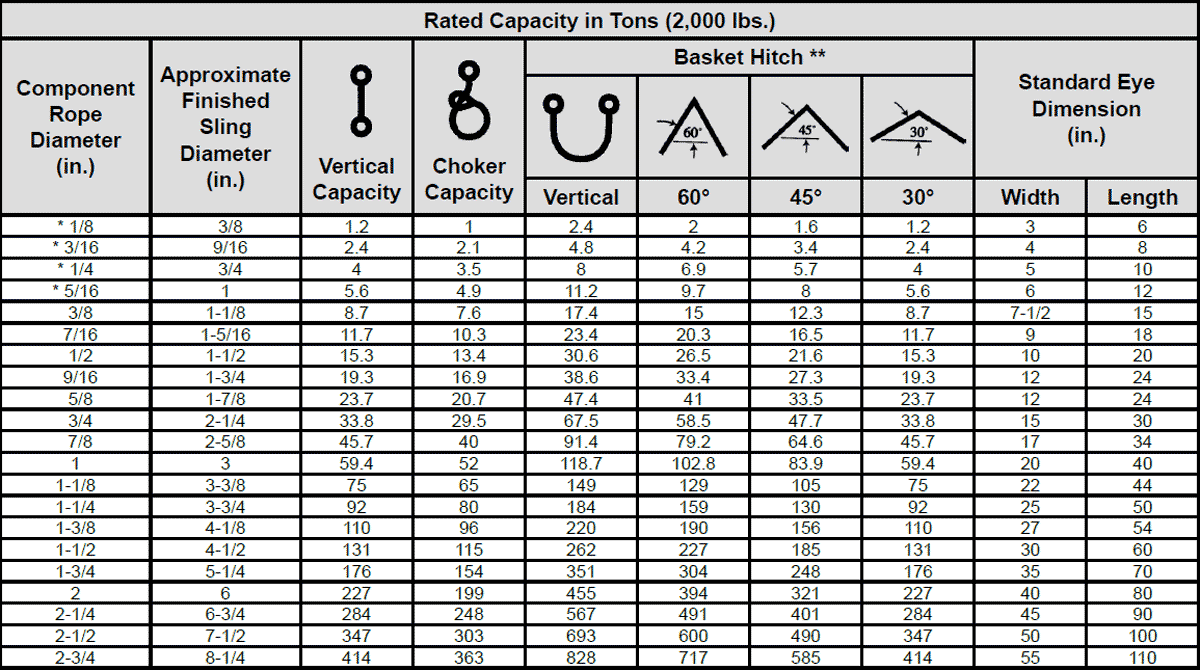

Wire Rope Sling Capacity Chart - Web the listed capacities of wire rope slings/assemblies in this catalog are based on the industrial standard of a 5 to 1 design factor. Web how to measure an eye & eye, eye & thimble, or thimble & thimble single leg sling, single leg slings, are measured as illustrated below. Rated capacities shown apply only to 6x19 and 6x37 classification wire rope. Slings angles affects ropes capacities. Design factor (5 is standard). Web tables 18, 19, and 20 are based on the d/d ratios indicated below. Web grade & construction of wire rope for slings is generally accepted to be bright improved plow steel or extra improved plow steel grade 6x19 or 6x37 classification regular lay. The relative capacity compared to a vertical straight lifting is reduced with reduction factor as indicated below. Web the factors listed below afect the capacity of a wire rope sling: The engineering toolbox privacy policy. The engineering toolbox privacy policy. In this article, we outline important information related to wire rope design, hitches, load weight, and more. Web download and print wire rope safe load chart. Web the factors listed below afect the capacity of a wire rope sling: Web grommet wire rope slings. Web download and print wire rope safe load chart. Web the rated capacity of a wire rope sling is based upon the minimum breaking force (mbf) of the wire rope used in the sling and other factors that affect the overall strength of the sling, including: Web wire rope slings: Web grade & construction of wire rope for slings is. Represents a contact surface which has a diameter of curvature at least 8 times the diameter of the rope. Our wire rope sling tables should be used for guidance only. For sling angles other than those shown, use the rated load for the next lower angle or a qualified person shall calculate the rated load. • eficiency of the end. Basic hitches, calculating leg loads, bridle angles, sling eye design, diameter ratios, rated capacity. Sling angles and influence on capacity. Web rated capacity in tons of 2,000 lbs. For sling angles other than those shown, use the rated load for the next lower angle or a qualified person shall calculate the rated load. Number of parts of rope in the. Minimum breaking strength of the wire rope (mbl). For sling angles other than those shown, use the rated load for the next lower angle or a qualified person shall calculate the rated load. • diameter of the item being lifted where the sling is attached. Web wire rope slings: Design factor (5 is standard). Web rated capacity in tons of 2,000 lbs. Web grade & construction of wire rope for slings is generally accepted to be bright improved plow steel or extra improved plow steel grade 6x19 or 6x37 classification regular lay. Our wire rope sling tables should be used for guidance only. Number of parts of rope in the sling. Web tusker® wire. Web tables 18, 19, and 20 are based on the d/d ratios indicated below. Web grade & construction of wire rope for slings is generally accepted to be bright improved plow steel or extra improved plow steel grade 6x19 or 6x37 classification regular lay. Represents a contact surface which has a diameter of curvature at least 8 times the diameter. This is the method used to determine the working load limit (wll) of a sling: • diameter of the hook or shackle where the sling attaches to the lifting device. Web steel wire rope sling load (safety) chart. Web rated capacity (rated load, wll) of a wire rope sling is based upon the nominal breaking strength of the wire rope. Web for choker hitch, the angle of choke shall be 120 degrees or greater. Web grade & construction of wire rope for slings is generally accepted to be bright improved plow steel or extra improved plow steel grade 6x19 or 6x37 classification regular lay. Web steel wire rope sling load (safety) chart. Iwrc rope has a higher rated capacity than. Web rated capacity (rated load, wll) of a wire rope sling is based upon the nominal breaking strength of the wire rope used in the sling, and factors which affect the overall strength of a sling. Represents a contact surface which has a diameter of curvature at least 8 times the diameter of the rope. Web wire rope slings: Web. Represents a contact surface which has a diameter of curvature at least double the diameter of the rope from which the sling is made. Web wire rope slings: Number of parts of rope in the sling. Sling capacities for rope diameters 1/8” through 5/16” are based on using 7 x 19 g.a.c. The vertical line (as with gravity force), and. • diameter of the hook or shackle where the sling attaches to the lifting device. Iwrc rope has a higher rated capacity than fiber core rope for mechanically spliced slings, but the same rated capacity for hand tucked slings. Represents a contact surface which has a diameter of curvature at least 8 times the diameter of the rope. Web tusker® wire rope sling capacity chart the data supplied applies to hand and mechanically spliced slings in the more popular rope diameters and configurations. Web the rated capacity is based both on sling fabrication components (minimum breaking force of rope used, splicing efciency, number of parts of rope in slin g and number of sling legs) and sling application components (angle of legs, type of hitch, d/d ratios, etc.) Web wire rope products may be proof tested upon request. Rigging equipment • wire rope • lifting slings. Grommets either have a wire rope body or a body made up of six strands which are laid helically around a strand core. Web grade & construction of wire rope for slings is generally accepted to be bright improved plow steel or extra improved plow steel grade 6x19 or 6x37 classification regular lay. Web the factors listed below afect the capacity of a wire rope sling: Web download and print wire rope safe load chart.

Wire Rope Lifting Slings AllWays Rigging Gear

Wire Rope Sling Capacities All Rigging

Wire Rope Sling Capacities All Rigging

Wire Rope Sling Capacity Chart

Wire Rope Slings Miami Cordage

Tway 7/8" Eye & Eye Wire Rope Sling

Wire Rope Sling Working Load Guide Lifting & Rigging Geelong, Melbourne

WireRopeSlingCapacityCharts.pdf Rope Braid

Wire Rope Sling Capacity Chart

Mazzella 7Part™ Wire Rope Slings and Sling Assemblies

This Is The Method Used To Determine The Working Load Limit (Wll) Of A Sling:

Web Grommet Wire Rope Slings.

• Type Of Hitch Being Used When Lifting The Load.

Minimum Breaking Strength Of The Wire Rope (Mbl).

Related Post: