Wheel Stud Torque Chart

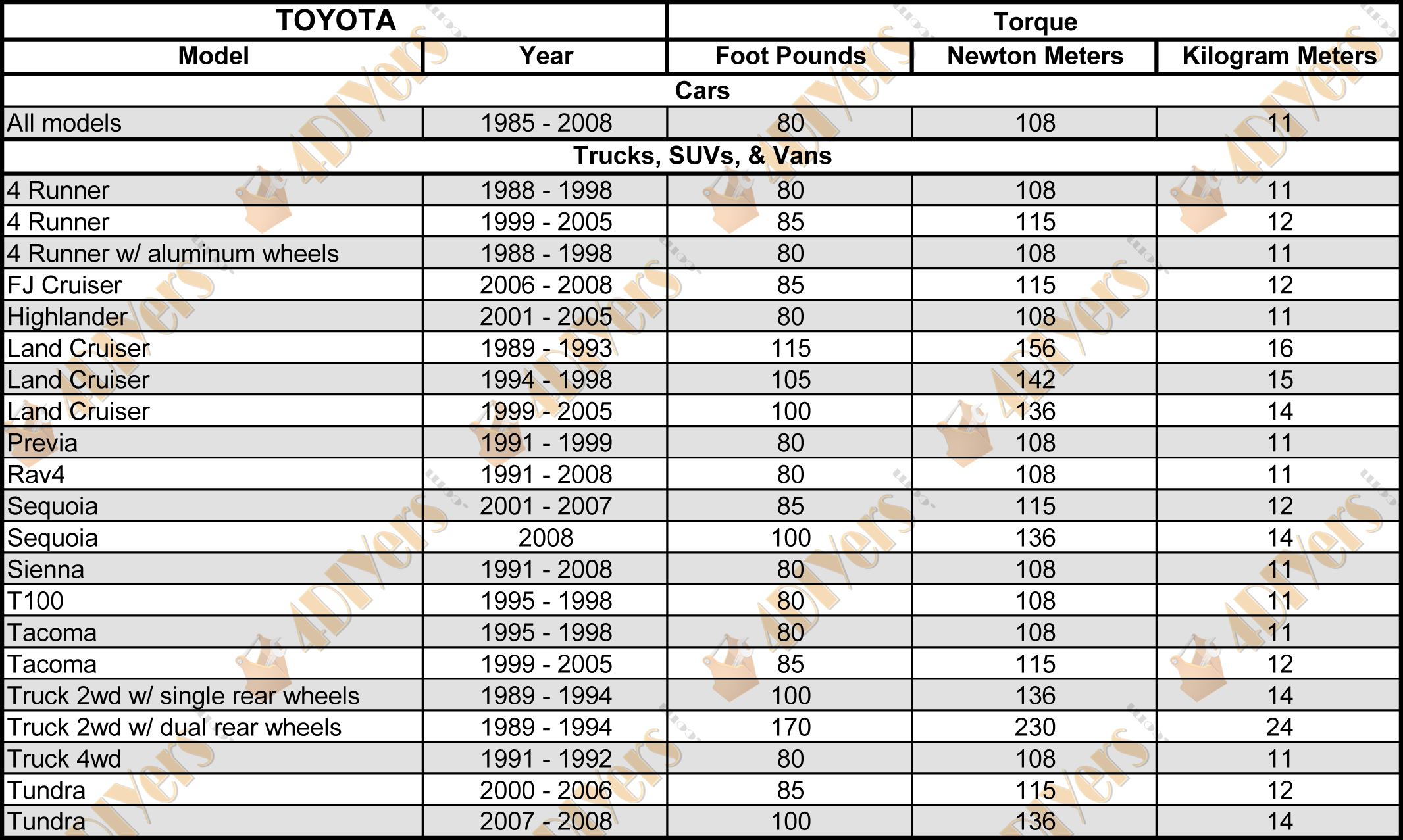

Wheel Stud Torque Chart - Web once secured hand tight, use the torque wrench set to the proper torque as indicated from a lug nut torque chart or the vehicle’s owner's manual, for the final tightening sequence based on the number of studs or bolts as shown below. For speciic mounting instructions, refer to the vehicle manufacturer’s service manual for that model. Using the manufacturer recommended torque also helps guarantee that there isn’t either too much or too little pressure on any of the assemblies to which the wheel attaches. Web torquing down the bolts or studs per specification ensures that the wheel is tight with the hub and there’s no movement. Need more help with your wheels? All sales are final on this item. Web using the proper torque helps ensure that the wheel assembly is securely installed. Web a chart such as this indicates the torque based on the size of the wheel stud. 1.3 identifying and preventing wheel hub damage. Web proper and accurate torque must be maintained to prevent wheels from loosening, studs from cracking and/or breaking or other possible hazardous breakage resulting in serious injury or death. Download the lug nut torque chart pdf. 2 applying the correct torque. Web this wheel lug torque chart is collected information from many different resources to get you as much up to date specs as possible. Web the general rule for steel wheel lug nut torque is usually around 80ft/lb, and for aluminum wheels it is around 100ft/lb, this being. Web their wheel nuts somewhere between the wheel manufacturers guide and the hub manufacturers torque setting @ 80% of max. Loss of wheel or broken wheel studs can occur if torque speciication is not correct. Size' bolt'circle' off'set'' recommended'torque'(ftlbs)' steel'' aluminum'' 12”! This is an optional step that can help both center the wheels and protect the studs. 1.3 identifying. Web improper torque can lead to wheel hub movement and allow potential damage to the wheel hub and surrounding components. Web once secured hand tight, use the torque wrench set to the proper torque as indicated from a lug nut torque chart or the vehicle’s owner's manual, for the final tightening sequence based on the number of studs or bolts. Hub type pcd stud size steel grade manufacturer. 1.2 proper installation and torque specifications. Web a comprehensive guide on how and why to torque wheel lug nuts or bolts for passenger and light commercial vehicles. 2 applying the correct torque. How tight should the lug nuts be on my vehicle? Pro race oval track & drag race center bolts: Web a chart such as this indicates the torque based on the size of the wheel stud. This product is expected to be ship early june 2024. Tightening the lug nuts and bolts correctly also reduces the chance of warping the brake. Web the chart gives you the recommended torque specs. Web their wheel nuts somewhere between the wheel manufacturers guide and the hub manufacturers torque setting @ 80% of max. 2.1 the importance of torque wrenches. Web using the proper torque helps ensure that the wheel assembly is securely installed. Click here to open torque chart. Web below you will find wheel lug nut torque specs for most us makes. Loss of wheel or broken wheel studs can occur if torque speciication is not correct. How to torque wheel bolts? Web once secured hand tight, use the torque wrench set to the proper torque as indicated from a lug nut torque chart or the vehicle’s owner's manual, for the final tightening sequence based on the number of studs or bolts. Web this wheel lug torque chart is collected information from many different resources to get you as much up to date specs as possible. Web below you will find wheel lug nut torque specs for most us makes and models with data from dorman products. 1.2 proper installation and torque specifications. Web wheels and lug torquing. Find a store near. Loss of wheel or broken wheel studs can occur if torque speciication is not correct. You should only use a torque wrench for torquing bolts. Web improper torque can lead to wheel hub movement and allow potential damage to the wheel hub and surrounding components. Web below you will find wheel lug nut torque specs for most us makes and. Web a comprehensive guide on how and why to torque wheel lug nuts or bolts for passenger and light commercial vehicles. Web proper and accurate torque must be maintained to prevent wheels from loosening, studs from cracking and/or breaking or other possible hazardous breakage resulting in serious injury or death. Using the manufacturer recommended torque also helps guarantee that there. 2.1 the importance of torque wrenches. Lbs.) make/model years torque acura all models except: Simply download the pdf and print it out to keep in your car. Click here to open torque chart. 2 applying the correct torque. 1.2 proper installation and torque specifications. Web torquing down the bolts or studs per specification ensures that the wheel is tight with the hub and there’s no movement. Web once secured hand tight, use the torque wrench set to the proper torque as indicated from a lug nut torque chart or the vehicle’s owner's manual, for the final tightening sequence based on the number of studs or bolts as shown below. The table can be filtered and is searchable. Need more help with your wheels? All sales are final on this item. Web wheel nut torque specifications (shown in ft. Web 424 rows use the appropriate crisscross sequence (shown above) for the number of wheel lugs on your vehicle until all have reached their proper torque value. How tight should the lug nuts be on my vehicle? This also means that the wheel and bolts will withstand the forces and you won’t have any issues. Tightening the lug nuts and bolts correctly also reduces the chance of warping the brake.

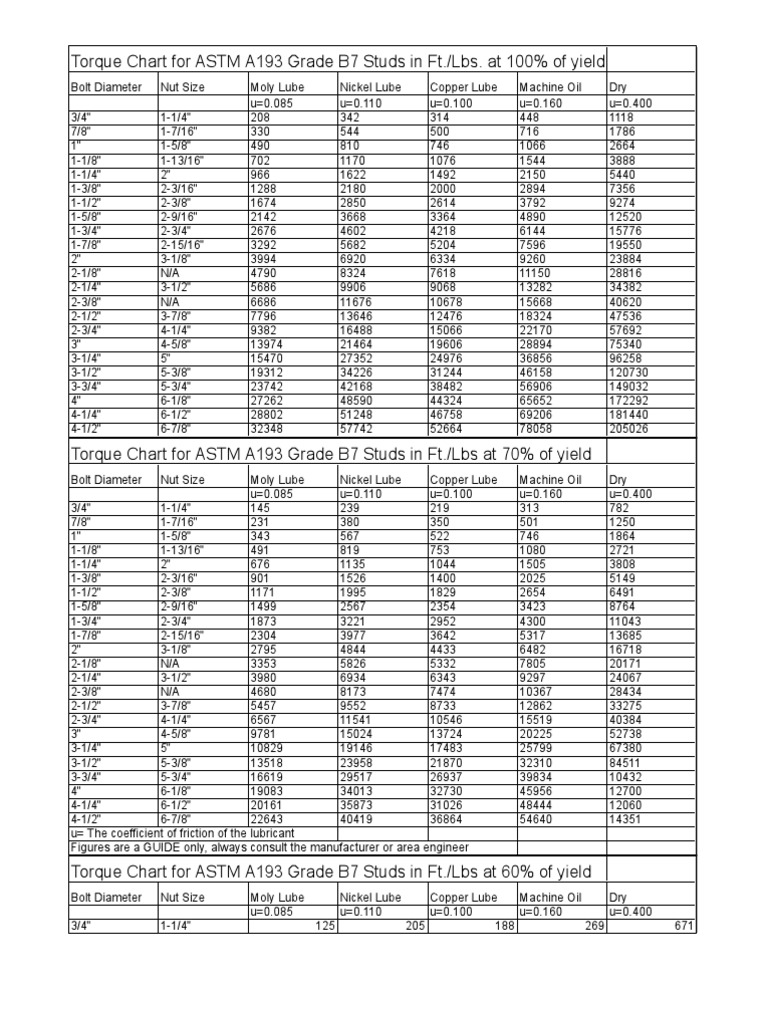

Bolt Torque Chart 7 Free PDF Download

Torque Chart for ASTM A193 Grade B7 Studs Motor Oil Nut (Hardware)

4DIYers Wheel Stud Torque Specifications

KTool International KTI30103A K Tool Wheel Nut Torque Charts Summit

4DIYers Wheel Stud Torque Specifications

4DIYers Wheel Stud Torque Specifications

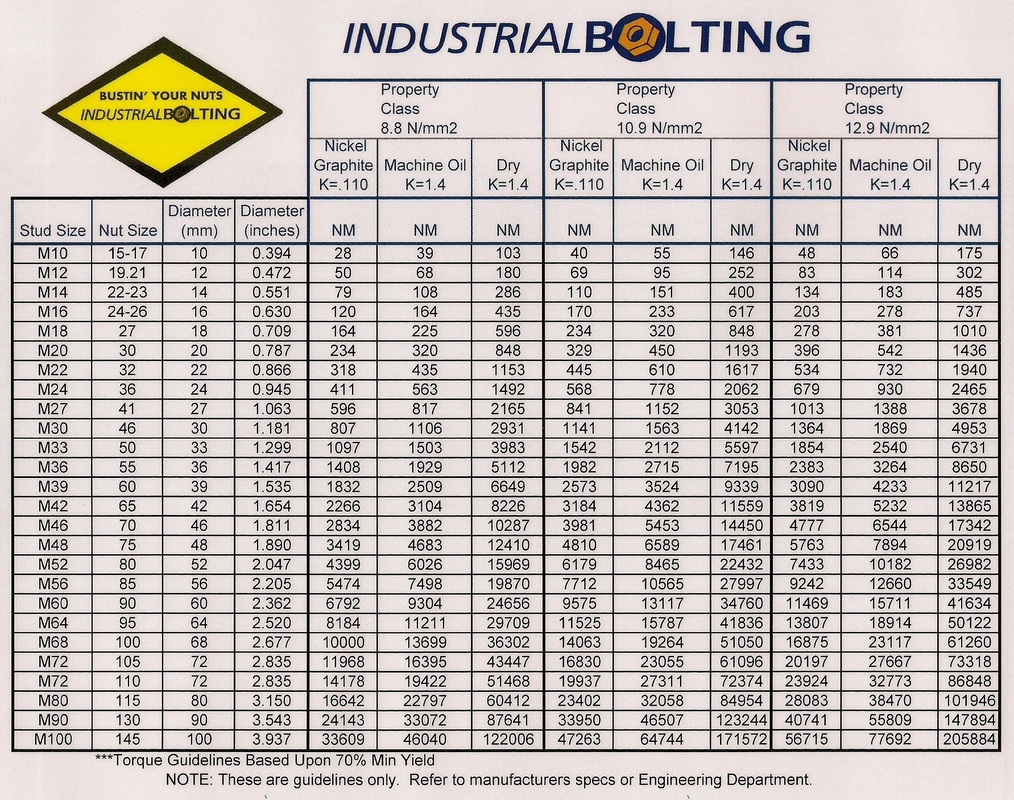

Torque Charts Industrial Torque Tools

Torque Spec For Ford F150 Lug Nuts

2019 Subaru Wrx Lug Nut Torque Spec

4DIYers Wheel Stud Torque Specifications

Download The Lug Nut Torque Chart Pdf.

You Should Only Use A Torque Wrench For Torquing Bolts.

Web Wheels And Lug Torquing.

Web Improper Torque Can Lead To Wheel Hub Movement And Allow Potential Damage To The Wheel Hub And Surrounding Components.

Related Post: