Welding Amps To Metal Thickness Chart

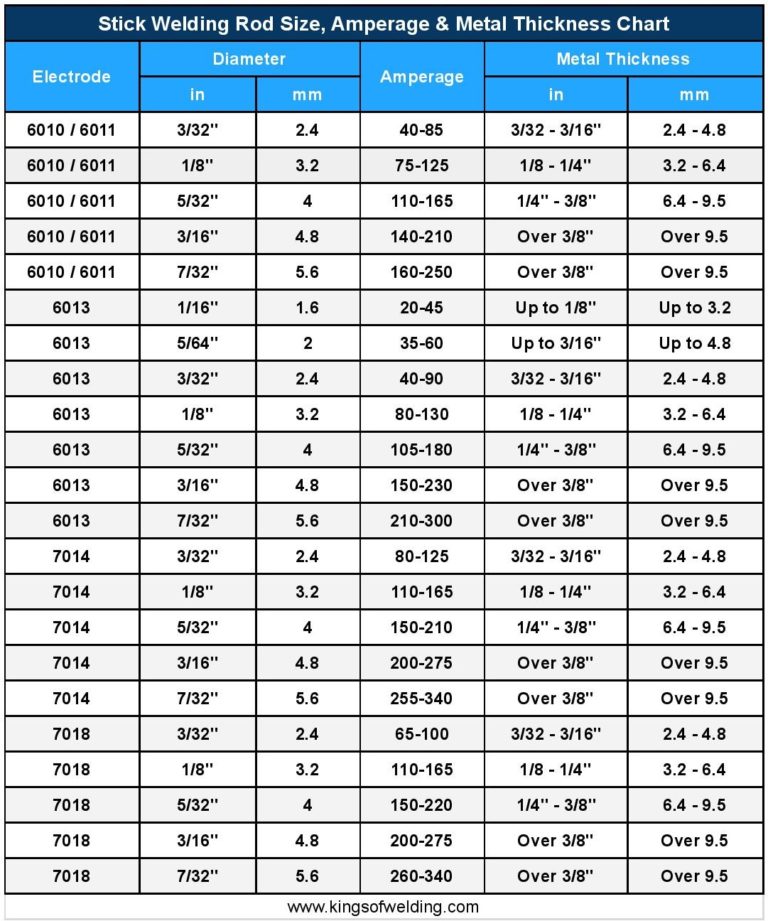

Welding Amps To Metal Thickness Chart - It lists recommended amperages for different weld joint types and thicknesses. I had the setting to 125 amps, lowered to 115 and made a difference. Web estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. For mild steel, it recommends running 10% lower amps for complete beginners. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: E6012 sizes and amperage range. Sheet metal is a thin and lightweight material used in many products, including car bodies, appliances, and aircraft. .125 inch = 125 amps. Also, similar to other welding styles, tig welding relies on essential variables to determine what settings are appropriate for each application. Additionally, we made the most complete stick welding rod chart pdf on the internet with over 220 electrodes. It lists recommended amperages for different weld joint types and thicknesses. Before tackling any mig welding application, look at the charts and tips below. Browse suggested weld parameter settings for stick welding. Web estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. The document provides guidelines for selecting the proper amperage and. This controls the amount of electricity flowing per second and determines the level of penetration and the quality of. Web to tig weld mild steel that is 2mm thick, you will need 60 amps for a closed root butt joint, 75 amps for a fillet joint, and only 55 amps for a lap joint or an outside corner. Browse suggested. Web mig welding sheet metal settings with charts. Web to tig weld mild steel that is 2mm thick, you will need 60 amps for a closed root butt joint, 75 amps for a fillet joint, and only 55 amps for a lap joint or an outside corner. There might be variations with the settings depending on the manufacturer. Download the. Sheet metal is a thin and lightweight material used in many products, including car bodies, appliances, and aircraft. .125 inch = 125 amps. Web to tig weld mild steel that is 2mm thick, you will need 60 amps for a closed root butt joint, 75 amps for a fillet joint, and only 55 amps for a lap joint or an. Web the document provides a tig welding amp calculator chart for mild steel and stainless steel in thicknesses ranging from 0.8mm to 3mm. Is there a chart the specifies how much amps to use on which metals with different thickness? .125 inch = 125 amps. Web a general rule of thumb is you need 1 amp of power for every. Any one got a easy amp setting guide for different thickness of metal or what to search to find one most ones i come up with are for america’s and are a bit complicated looking. Browse suggested weld parameter settings for stick welding. For mig welding mild steel, a good rule of thumb is to adjust the welder amperage level. It notes that the chart provides starting point amps that may need adjusting based on technique and travel speed. The document provides guidelines for selecting the proper amperage and electrode size for stick welding based on the thickness of the metal workpiece. Before tackling any mig welding application, look at the charts and tips below. For mig welding mild steel,. Web the mig welding amperage chart works by providing you with the maximum amperage, voltage and wire feed speed that should be used when welding a specific material and thickness. Similarly to 6013, it does not penetrate deep, while producing beautiful uniform beads, which makes it suitable for sheet metal as well as welding art. Web this document provides a. Web estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. For mig welding mild steel, a good rule of thumb is to adjust the welder amperage level using one amp for every thousandth of an inch of thickness. E6013 size and amperage chart. Before tackling any mig welding application, look at the. Similarly to 6013, it does not penetrate deep, while producing beautiful uniform beads, which makes it suitable for sheet metal as well as welding art. Web there are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. Download the app version of the weld setting calculator for easy reference!. You can get it for free below. Any one got a easy amp setting guide for different thickness of metal or what to search to find one most ones i come up with are for america’s and are a bit complicated looking. Web estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. Stainless steel and aluminium amps chart. Web i'm still new to stick welding and have been looking around for a chart for quite a while that would recommend what size rod to use at what amps for a certain base metal thickness. Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. The chart is intended as a starting point, as experienced welders may prefer higher or lower amperages depending on technique and travel speed. I'd like to print this out and. Browse suggested weld parameter settings for stick welding. So, how many amps does it take to weld 3/8 steel? However, welding sheet metal can be challenging due to its low thickness and high heat conductivity. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Additionally, we made the most complete stick welding rod chart pdf on the internet with over 220 electrodes. Also, similar to other welding styles, tig welding relies on essential variables to determine what settings are appropriate for each application. The document provides guidelines for selecting the proper amperage and electrode size for stick welding based on the thickness of the metal workpiece. Web the calculator below pinpoints exactly which electrode you need for the metal you are welding.

Welding Amps Metal Thickness Chart

Welding Amps Metal Thickness Chart

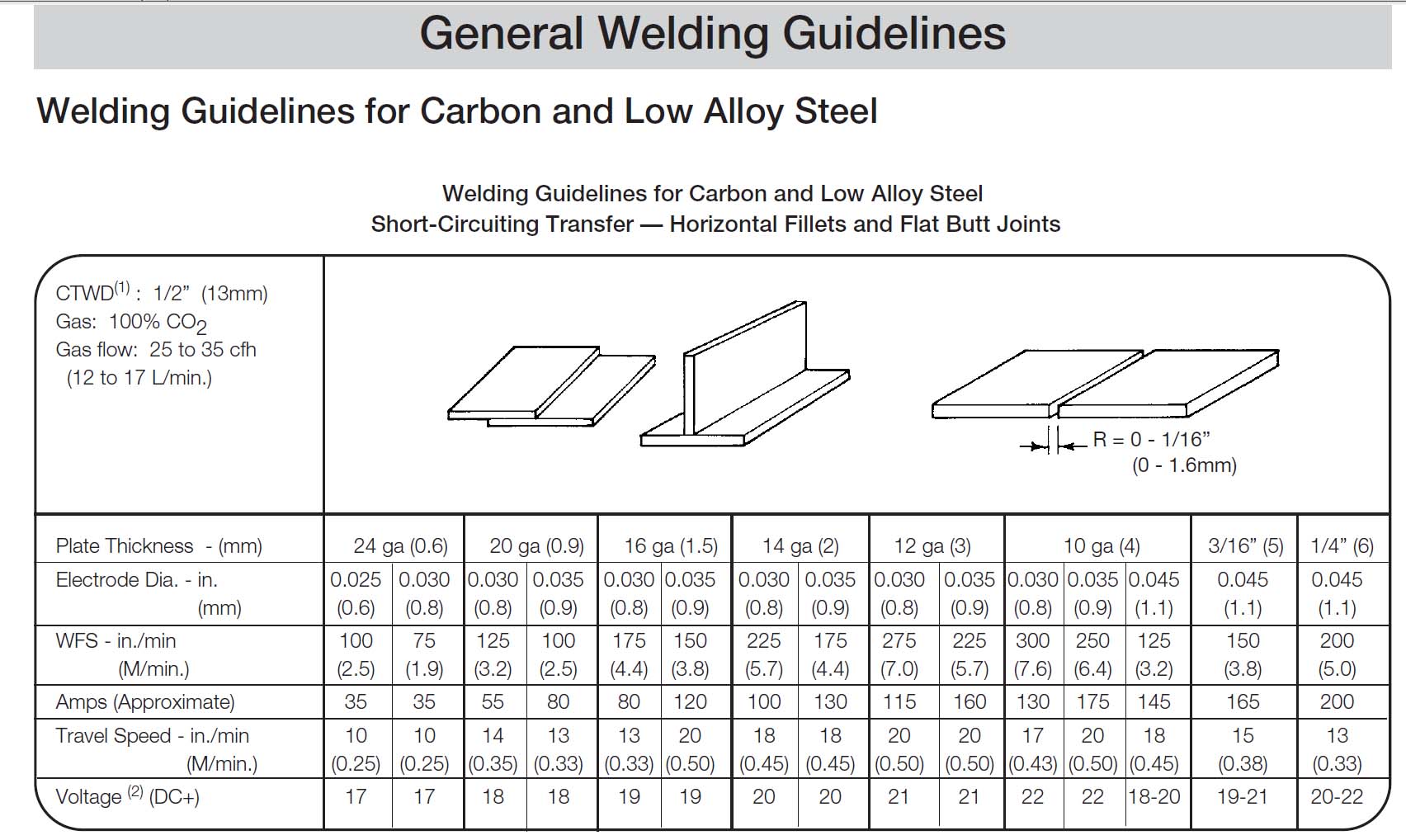

MIG settings for welding different thickness mild steel

MIG welder settings explained Amperage & Wire Speed

Tig Welding Amps To Metal Thickness Chart

Metal Thickness Stick Welding Amperage Chart

What are a reasonable rods to use ? Welding Site

Welding Rod Sizes, Amperage & Metal Thickness Chart Kings of Welding

Welding Rod Amp Chart

Tig Welding Amperage Chart

For Mild Steel, It Recommends Running 10% Lower Amps For Complete Beginners.

E6012 Sizes And Amperage Range.

Web What Material Are You Welding?

This Controls The Amount Of Electricity Flowing Per Second And Determines The Level Of Penetration And The Quality Of.

Related Post: