Welding Amp Chart

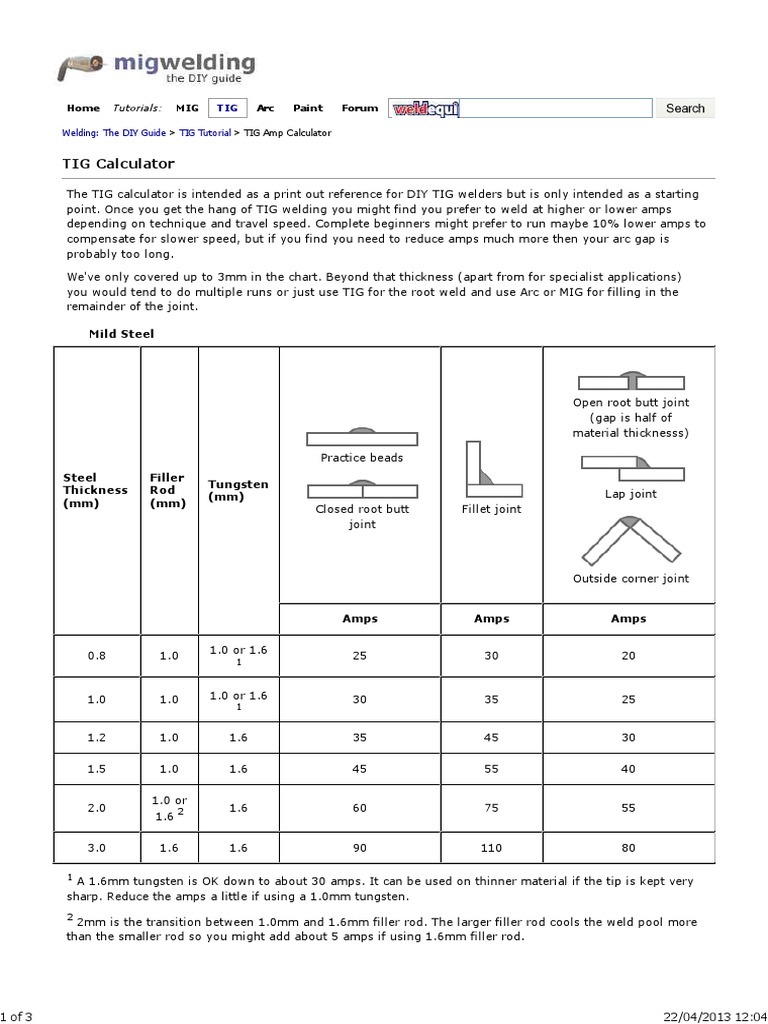

Welding Amp Chart - Before tackling any mig welding application, look at the charts and tips below. Web there are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. Web as a guideline, each.001 inch of material thickness requires 1 amp of output: Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its thickness. Tig welding electrodes and amperage. For mig welding mild steel, a good rule of thumb is to adjust the welder amperage level using one amp for every thousandth of an inch of thickness. Browse suggested weld parameter settings for stick welding. Stainless steel and aluminium amps chart. Wire feed speed (wfs), another of the welding variables, controls amperage and the amount of weld penetration. Simply because thicker material requires more heat to penetrate with a smooth and efficient weld. Web to tig weld mild steel that is 2mm thick, you will need 60 amps for a closed root butt joint, 75 amps for a fillet joint, and only 55 amps for a lap joint or an outside corner. Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its. It is important to use the chart as a guide when setting your welding parameters. Web as you can see in this chart, the thicker the material, the stronger the material, and the higher the amperage and voltage, the lower the welding speed. Gas metal arc welding (gmaw or mig): Web setting the amperage on a welding machine, whether stick. Web the general rule, also known as the thumb rule, states you should use 1 amp for.001 inch of material thickness. 6013 welding rod amperage chart. Web welder amperage chart. Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its thickness. Web here is a chart that summarizes the. Flux cored arc welding ( fcaw ): Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. 7014 welding rod amperage chart. 6013 welding rod amperage chart. Web welder amperage chart. So, how many amps does it take to weld 3/8 steel? Web as a guideline, each.001 inch of material thickness requires 1 amp of output: Browse suggested weld parameter settings for stick welding. Since you don't want to change wire, select one for your most commonly used thicknesses. 1) what is voltage in welding? Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Stainless steel and aluminium amps chart. Web this chart provides an overview of the most common stick welding rod sizes and their corresponding classifications. Web to tig weld mild steel that is 2mm thick, you. Gas metal arc welding (gmaw or mig): Web this chart provides an overview of the most common stick welding rod sizes and their corresponding classifications. 7014 welding rod amperage chart. Remember to adjust the parameters as necessary based on the type of weld you are trying to achieve. Shielded metal arc welding ( smaw ): Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its thickness. Web as a guideline, each.001 inch of material thickness. Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its thickness. Web the chart provides a visual representation of the required settings, making it easy for welders to select the right amperage, depending on the material, joint type, electrode size, and welding position being used. Simply because thicker material. 7014 welding rod amperage chart. Web if you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes and amps to how much welding rod you need Once you determine these three main variables, you can set your welding machine and start. Web a mig welding amperage chart is a useful tool for ensuring. Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Electrode amperage chart | types and thicknesses. Web a general rule of thumb is you need 1 amp of power for every 0.001 inches of steel. Remember to adjust the parameters as necessary based on the type of weld you are trying to achieve. However, you should also consider some other factors for your welder. .125 inch = 125 amps. Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Web as a guideline, each.001 inch of material thickness requires 1 amp of output: Below shows the approximate amperage range for various welding processes: You might also find our welding calculators useful. Browse suggested weld parameter settings for stick welding. Web setting the amperage on a welding machine, whether stick (smaw), mig (gmaw) (*typically uses voltage setting), or tig (gtaw), depends on some key variables such as application and base material, welding process, and electrode. There might be variations with the settings depending on the manufacturer. Web if you are looking for welding rod charts, we created the ultimate resource, listing everything from electrode sizes and amps to how much welding rod you need Web to tig weld mild steel that is 2mm thick, you will need 60 amps for a closed root butt joint, 75 amps for a fillet joint, and only 55 amps for a lap joint or an outside corner. Web this chart provides an overview of the most common stick welding rod sizes and their corresponding classifications.

Welding Rod Amp Chart

Welding Amperage Selection Beginner Welding Guide

How To MIG Weld Aluminum Beginners Guide (with Chart)

Welding Rod Amp Chart

Welding

TIG Welding Amp Charts Welding Building Materials

Welding Rod Amp Chart

Welding Amps Metal Thickness Chart

Important MIG Welder Settings You Need to Know (with Chart)

7018 1/8 Welding Rod Amperage Chart

Web The Chart Provides A Visual Representation Of The Required Settings, Making It Easy For Welders To Select The Right Amperage, Depending On The Material, Joint Type, Electrode Size, And Welding Position Being Used.

Before Tackling Any Mig Welding Application, Look At The Charts And Tips Below.

Diameter (Inches) Diameter (Mm) 6010/6011.

Since You Don't Want To Change Wire, Select One For Your Most Commonly Used Thicknesses.

Related Post: