Used Ring And Pinion Pattern

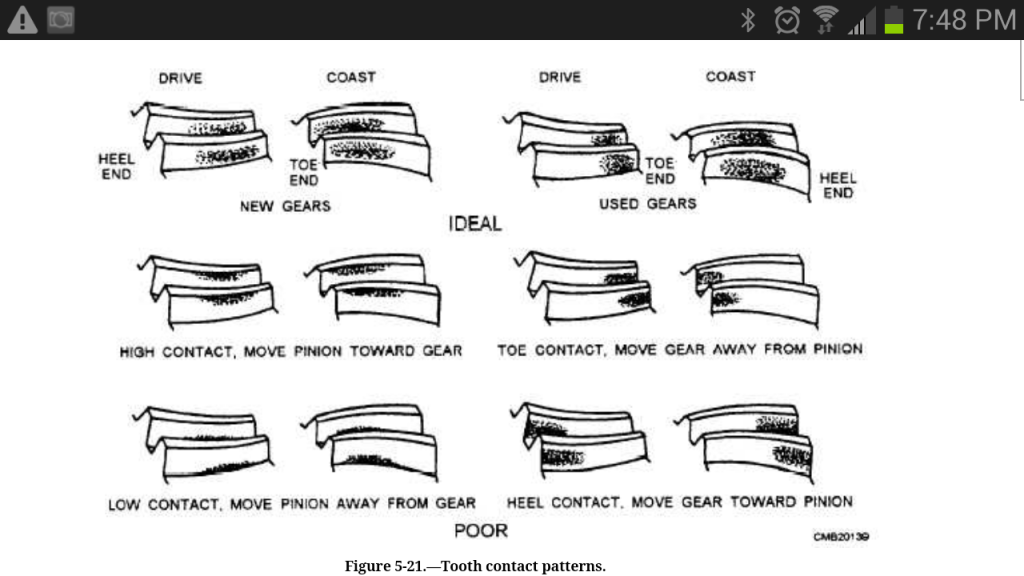

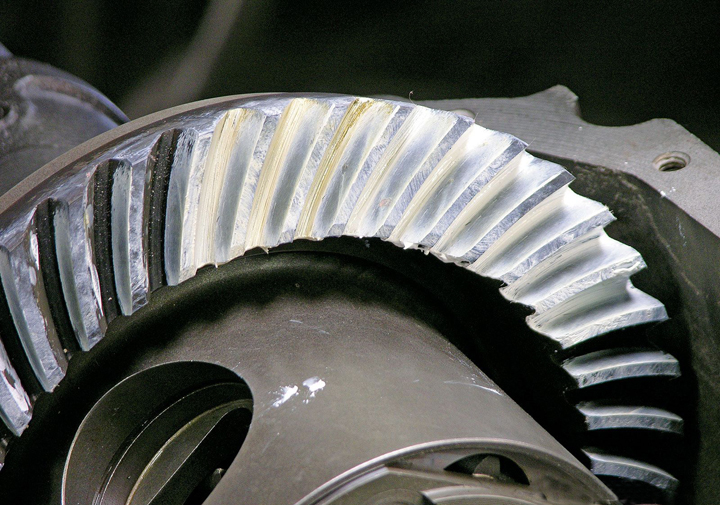

Used Ring And Pinion Pattern - The pattern refers to how the ring gear and pinion gears mesh. Begin by setting proper pinion. I have a 3.73 (richmond gear) and not. Web #1 · mar 28, 2009. Web remember the gears are used and will not normally run in the spec of a new gear set.all depends on the mileage and how sloppy the gear got over that. The prospect of installing and adjusting driveline ring & pinion gears can be intimidating for shops that don’t routinely perform this task. When checking the pattern i like to drag my hand on the outside edge of the ring gear while turning the pinion to give it some resistance. Even if you farm this work. Web we can determine how gears mesh by changing how close the pinion gear is to the ring gear centerline. When setting the pinion position, many of the service manuals required a final pinion position check by using guages that. Web ring and pinion gear tooth pattern. Web #1 · mar 28, 2009. Vehicle is new to me, po was mud happy and the rear was full of sandy muddy sludge which worn the pinion. I have a 3.73 (richmond gear) and not. I know these questions have been seen here before, but we do it one. Web ring and pinion. The final pinion position will be verified by using the gear contact pattern method described as. Automotive ring and pinion gears must be installed and set up in a very specific way to ensure that they will run smoothly and reliably. The differential bearings should be shimmed tight enough that you can't pull the. Bearing preload,. Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly toward the. Bearing preload, total turning preload, and. When checking the pattern i like to drag my hand on the outside edge of the ring gear while turning the pinion to give it some resistance. Web the coast side does. While we can’t physically see how the gears actually relate to. As you can see, the. Web i always try to get the pattern looking about right by adjusting the pinion to center distance (the mesh) before finally worrying to get the backlash in spec. I know these questions have been seen here before, but we do it one. 32k. Bearing preload, total turning preload, and. Automotive ring and pinion gears must be installed and set up in a very specific way to ensure that they will run smoothly and reliably. Web #1 · mar 28, 2009. Web pinion bearing preload with used bearings should be around 5 inch pounds. The pattern refers to how the ring gear and pinion. When setting the pinion position, many of the service manuals required a final pinion position check by using guages that. Web below is a photo of the above ring and pinion gear contact patterns after i had used them for many years (prior to removing this gear set). Web ring and pinion gear tooth pattern. Even if you farm this. Web ring and pinion. The pattern refers to how the ring gear and pinion gears mesh. Web i always try to get the pattern looking about right by adjusting the pinion to center distance (the mesh) before finally worrying to get the backlash in spec. I have a 3.73 (richmond gear) and not. Bearing preload, total turning preload, and. 32k views 9 months ago. Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly toward the. The final pinion position will be verified by using the gear contact pattern method described as. Web ring & pinion tooth pattern interpretation. As you can see, the. Dana 60, dodge, 4.10 dana, rear axle, m/t. I have a 3.73 (richmond gear) and not. Web pinion bearing preload with used bearings should be around 5 inch pounds. 1 2 next > rogga. The differential bearings should be shimmed tight enough that you can't pull the. 1 2 next > rogga. Web the coast side does look like you need to bring the pinion in a little deeper. I have a 3.73 (richmond gear) and not. Web below is a photo of the above ring and pinion gear contact patterns after i had used them for many years (prior to removing this gear set). Reading and. Web we can determine how gears mesh by changing how close the pinion gear is to the ring gear centerline. There is a process used when reassembling a differential that optimizes ring gear and. I have a 3.73 (richmond gear) and not. The pattern refers to how the ring gear and pinion gears mesh. Web ring gear and pinion tooth pattern interpretation. Web the coast side does look like you need to bring the pinion in a little deeper. 32k views 9 months ago. Web ring and pinion. Web remember the gears are used and will not normally run in the spec of a new gear set.all depends on the mileage and how sloppy the gear got over that. Moving the pinion gear closer to the carrier will move the drive side pattern closer to the flank and slightly toward the. Web proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. Web #1 · mar 28, 2009. Web i always try to get the pattern looking about right by adjusting the pinion to center distance (the mesh) before finally worrying to get the backlash in spec. The final pinion position will be verified by using the gear contact pattern method described as. Even if you farm this work. The differential bearings should be shimmed tight enough that you can't pull the.

73 Corvette ring and pinion pattern on a used 355 gear. YouTube

used ring and pinion pattern check Pirate 4x4

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

Ring Gear And Pinion Pattern

used ring and pinion pattern check Pirate 4x4

How to Set up Your Rear Gear Correctly RacingJunk News

The Easiest Way to Read Ring & Pinion Contact Patterns YouTube

RING AND PINION TOOTH CONTACT PATTERN...mine with pic MGB & GT Forum

Used Ring and Pinion Mesh Pattern Pirate 4x4

How To Create & Read Ring Gear Patterns

Web Below Is A Photo Of The Above Ring And Pinion Gear Contact Patterns After I Had Used Them For Many Years (Prior To Removing This Gear Set).

Web Ring And Pinion Gear Tooth Pattern.

I Know These Questions Have Been Seen Here Before, But We Do It One.

Vehicle Is New To Me, Po Was Mud Happy And The Rear Was Full Of Sandy Muddy Sludge Which Worn The Pinion.

Related Post: