Types Of Welding Rod Chart

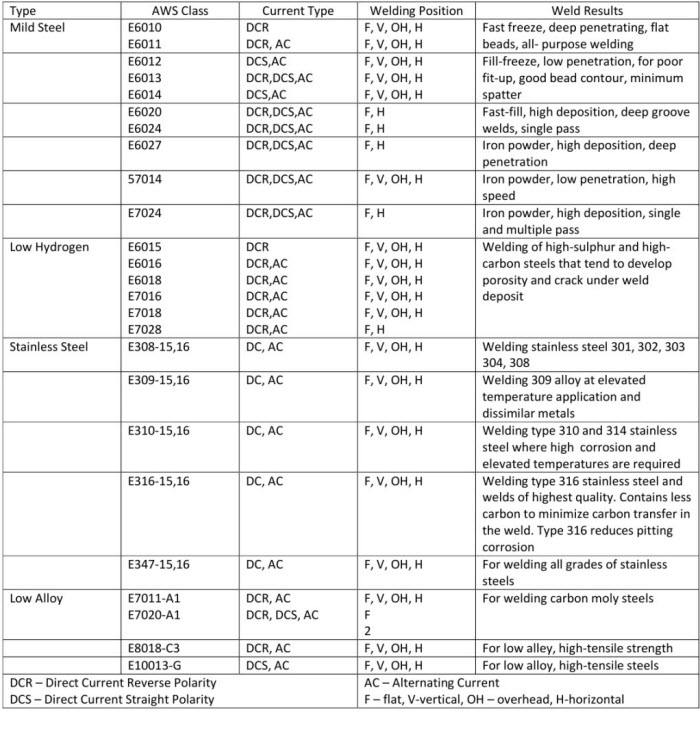

Types Of Welding Rod Chart - A welding rod is a welding. How to choose the correct stick welding rod size? These welding rods, also known as electrodes, are essential to the production of clean, solid, and finished welds. You need to pick the right diameter welding rod for. In other words, it’s a wire joining the welder with the materials you’re fusing together. It has a thin coating and produces less shielding gas which is used to reduce impurities such as oxide, sulphur, and phosphorus. Identifying and understanding these classifications will help you make informed decisions when choosing a. Web the most common types of welding electrodes for mild steel are e6010, e6011, e6013, e7018 and e7024. Plus you'll get the most complete welding rod chart on the internet in pdf! This page serves as a point of reference and a guide for selecting the right stick welding rod size and amperage to get the best results when stick welding. The size of the tig welding rod, also known as the filler metal, is determined by the thickness of the material being welded and the desired strength of. Web in this article, you will learn what are different types of welding rods in welding? Several of the different kinds of welding require the use of consumable welding rods. G:\pv products/welding. A welding rod is a piece of wire that joins a current from a wire to the welding machine itself. How and when to use them? The type of welding rods you are going to be using will depend upon the type of metal you are going to be working on. You need to pick the right diameter welding rod. Before you buy a box of electrodes, there’s still one more factor to consider. Mig vs tig vs stick vs flux core. There are many types of welding rods in different sizes, and as a welder, it’s kinda difficult to memorize everything. Choosing the correct type of stick electrode is vital to stick welding success. A welding rod is a. Bare electrodes simply mean they don’t have a flux coating that can shield the weld pool. This page serves as a point of reference and a guide for selecting the right stick welding rod size and amperage to get the best results when stick welding. Welding consumables are a factor to consider with welding. Versatile and easy to run. Learn. Several of the different kinds of welding require the use of consumable welding rods. Web our powerful calculator let's you easily determine which stick electrode you need. Web not sure what kind of welding rod you need? Web these six different types of welding rods are the most uses and quite popular in the welding industry. It improves the stability. These guidelines can vary between different manufacturers so always check the manufacturer’s guidelines if possible. The coating factor is 1.25. This page serves as a point of reference and a guide for selecting the right stick welding rod size and amperage to get the best results when stick welding. It has a thin coating and produces less shielding gas which. Web the most common types of welding electrodes for mild steel are e6010, e6011, e6013, e7018 and e7024. It has a thin coating and produces less shielding gas which is used to reduce impurities such as oxide, sulphur, and phosphorus. Explained with images & pdf. Web 4 types of welding explained: Mig vs tig vs stick vs flux core. Web the most common types of welding electrodes for mild steel are e6010, e6011, e6013, e7018 and e7024. At present, this naming system is arguably the most widely used system to identify a welding rod. Web stick welding rods are classified based on their tensile strength, welding position, coating type, and welding current. This page serves as a point of. Several of the different kinds of welding require the use of consumable welding rods. How and when to use them? Web what’s in the name? Versatile and easy to run. G:\pv products/welding rod\welding rod reference chart.indd. How to choose the correct stick welding rod size? Versatile and easy to run. Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Web but first, the basics. It improves the stability of the arc. Plasma arc welding electrode types. There are many types of welding rod types available on the market, each with their own specific purpose. You need to pick the right diameter welding rod for. These welding rods, also known as electrodes, are essential to the production of clean, solid, and finished welds. Which is best suited for welding mild steel, carbon steel and low alloy steel. At present, this naming system is arguably the most widely used system to identify a welding rod. Web stick welding rods are classified based on their tensile strength, welding position, coating type, and welding current. Web what’s in the name? This page serves as a point of reference and a guide for selecting the right stick welding rod size and amperage to get the best results when stick welding. It has a thin coating and produces less shielding gas which is used to reduce impurities such as oxide, sulphur, and phosphorus. Learn more about our process here. Popular welding rod (e6010) used for general purpose fabrication, construction, pipe welding, and shipbuilding. There are many types of welding rods in different sizes, and as a welder, it’s kinda difficult to memorize everything. It improves the stability of the arc. Bare electrodes simply mean they don’t have a flux coating that can shield the weld pool. Web in this article, you will learn what are different types of welding rods in welding?

The ultimate guide to welding rod sizes and classifications, including

Welding Rod Sizes Here's The Complete Guide

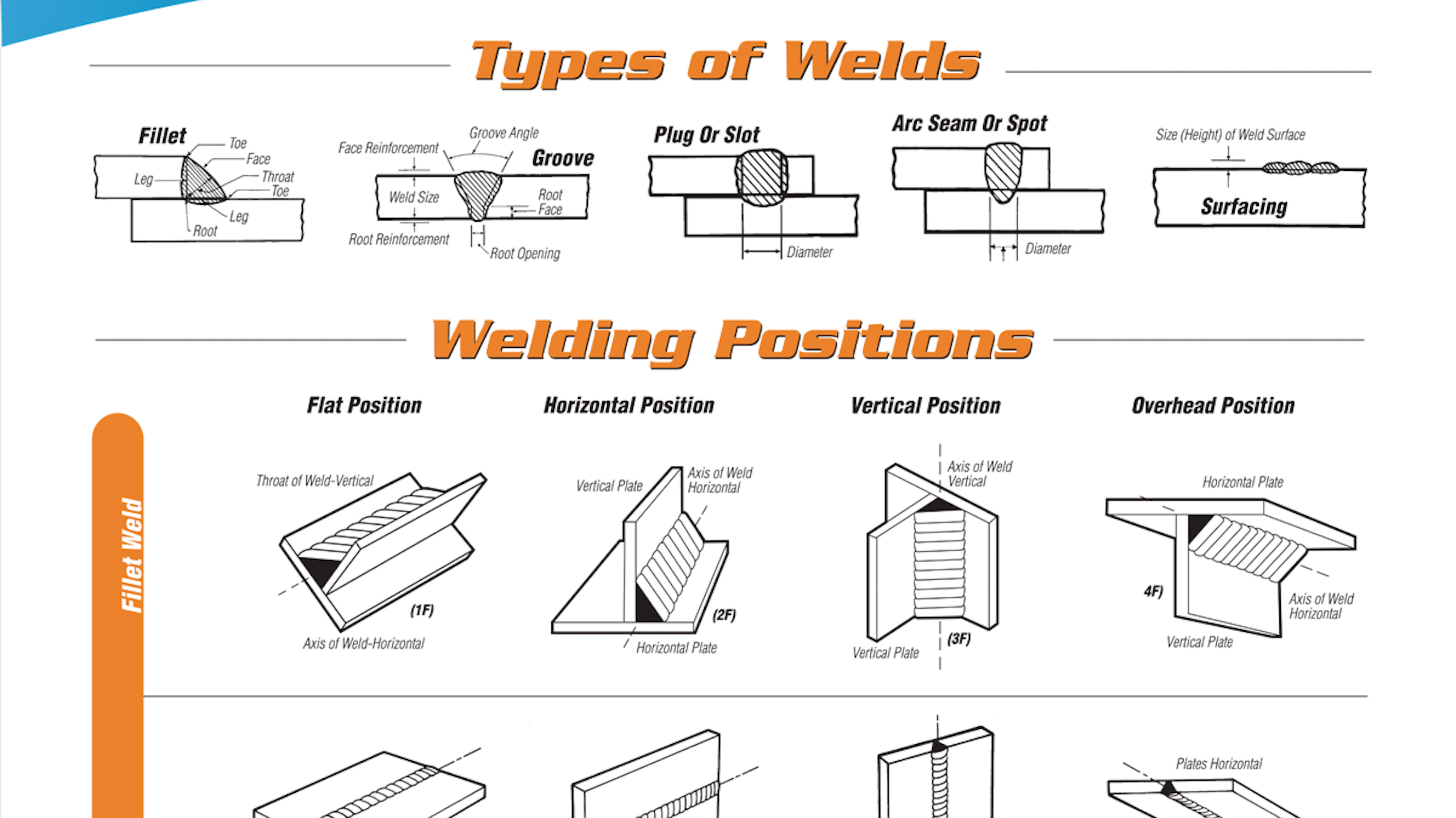

Welding Types and Positions poster Fleet Maintenance

Types of Welding Rods and Their Applications

Hobart Welding Rod Chart

Arc Welding Rods Guide

Welding Rod Types Pictures to Pin on Pinterest PinsDaddy

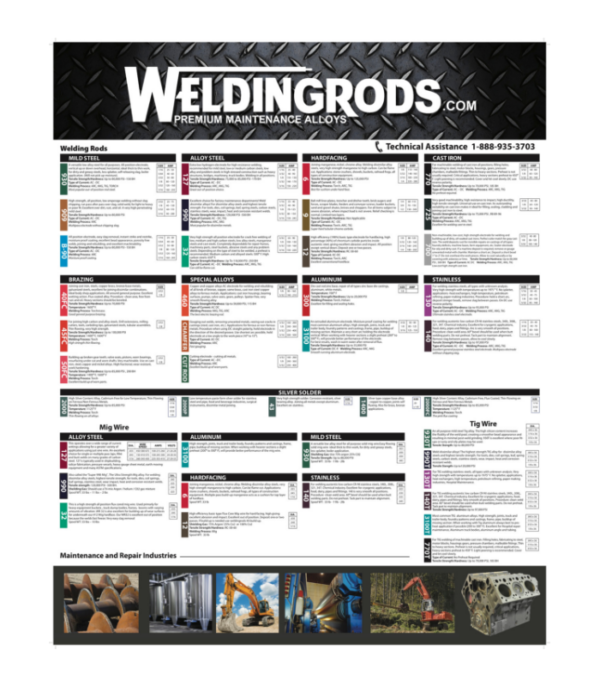

Welding rod chart, Welding rods, Welding and fabrication

Welding Rod Chart

![Different Types of Welding Rods & Their Uses [Explained] PDF](https://www.theengineerspost.com/wp-content/uploads/2022/07/Welding-Rods-1.jpg)

Different Types of Welding Rods & Their Uses [Explained] PDF

Web Home » Welders » Stick Welders.

Similar To 6010 But With Ac Capabilities.

Web These Six Different Types Of Welding Rods Are The Most Uses And Quite Popular In The Welding Industry.

Several Of The Different Kinds Of Welding Require The Use Of Consumable Welding Rods.

Related Post: