Tubing Bend Radius Chart

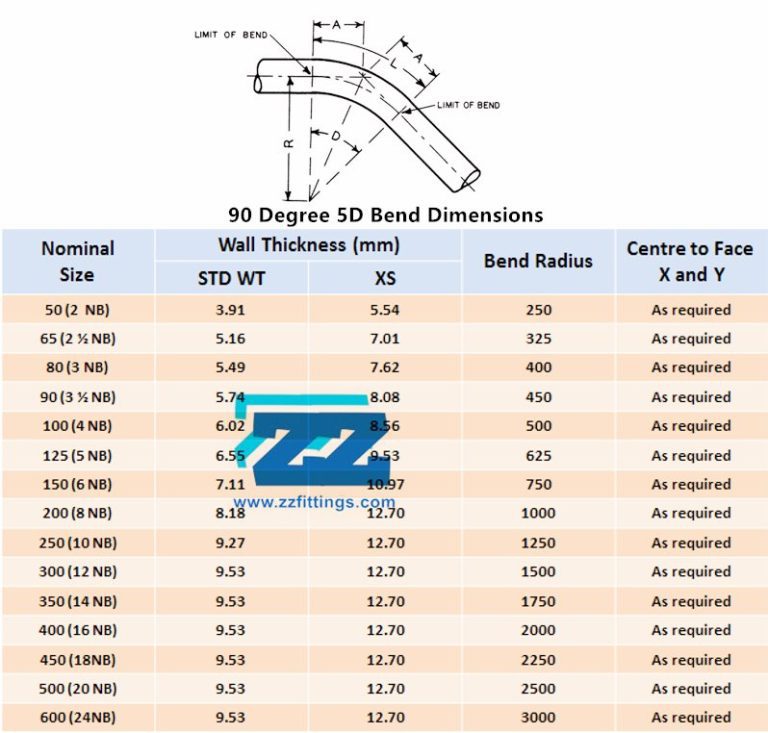

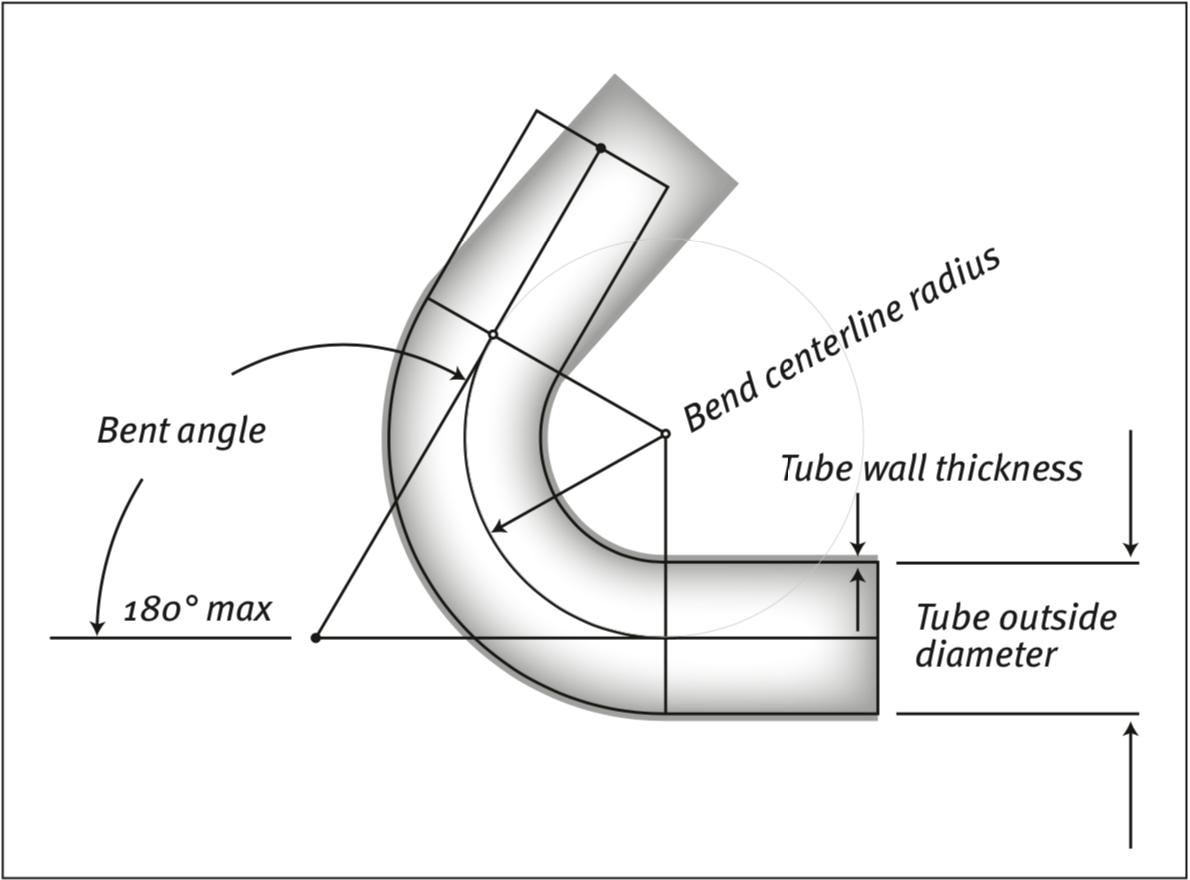

Tubing Bend Radius Chart - Web mandrel tube bending dominates the stainless steel tubing bending landscape, especially applications with tight radii. Nose distance ahead of tangent. Pipe, usually used to transport fluid or air, is specified by its nominal pipe size (see figure 1 ). Learn the key principles to maximize efficiency and precision in your bending projects. When choosing a die, factors that will affect the clr you choose include the material type and grade to be bent, wall thickness, the od, the application or design of the end product, and overall appearance required. Web the radius of a bend is expressed in relation to the diameter of the tube or pipe. 1d bend will have a radius equal to the diameter of the material, so a 1d bend in a 2” od tube will have a centerline radius (clr) of 2” (1 x 2”od). Web tubing to be free of scratches, suitable for bending and flaring. But when you’re specifying a bending machine, the centerline radius, the outside diameter, and wall thickness are critical. Web this chart provides the available piping bend radiuses with wall thickness and the size of the bending. This calculator will generate optimal mandrel nose placement. There are different specifications to cover different application requirements and the piping bending can be made from any different material grade. Tubing, with a bending radius from 1d to 4d. Input tube and bend specifications into the boxes shown below. But when you’re specifying a bending machine, the centerline radius, the outside. Web the radius of a bend is expressed in relation to the diameter of the tube or pipe. Web tubing to be free of scratches, suitable for bending and flaring. Hydro tube's cnc and manual benders are capable of bending 1/16 to 6 o.d. Bending guide for copper tube This uniformity is crucial in maintaining fluid flow and structural integrity. Order to outside diameter and wall thickness only, not to inside diameter, average wall specification. Minimum tube length, bend radius, and wall thickness limits required to make a 90° bend in annealed tubing are listed below. Some applications require specific bend radii; Download and keep or continue reading below. Pipe, usually used to transport fluid or air, is specified by. When you think of how to bend stainless steel tubing to a radius, you should choose mandrel bending. 1d bend will have a radius equal to the diameter of the material, so a 1d bend in a 2” od tube will have a centerline radius (clr) of 2” (1 x 2”od). Web explore our detailed guide on pipe bending radius. Web learn how to determine the minimum bend radius for different sizes and materials of tubing. A 3d bend in a 2” od tube will have a clr of 6” (3 x 2” od). Long radius pipe bends & return dimensions. Tubing should be free of scratches and suitable for bending. Nose distance ahead of tangent. When you think of how to bend stainless steel tubing to a radius, you should choose mandrel bending. Web mandrel tube bending dominates the stainless steel tubing bending landscape, especially applications with tight radii. 1d bend will have a radius equal to the diameter of the material, so a 1d bend in a 2” od tube will have a centerline. Web tubing to be free of scratches, suitable for bending and flaring. Download and keep or continue reading below. Hydro tube's cnc and manual benders are capable of bending 1/16 to 6 o.d. Pipe, usually used to transport fluid or air, is specified by its nominal pipe size (see figure 1 ). A 3d bend in a 2” od tube. 1d bend will have a radius equal to the diameter of the material, so a 1d bend in a 2” od tube will have a centerline radius (clr) of 2” (1 x 2”od). Available tooling, tube size, material thickness and composition are all components that can add into what the minimum bend radius is for a piece of metal. This. When choosing a die, factors that will affect the clr you choose include the material type and grade to be bent, wall thickness, the od, the application or design of the end product, and overall appearance required. Web mandrel tube bending dominates the stainless steel tubing bending landscape, especially applications with tight radii. Web tubing to be free of scratches,. Minimum tube length, bend radius, and wall thickness limits required to make a 90° bend in annealed tubing are listed below. This calculator will generate optimal mandrel nose placement. This hand tool offers the advantage of consistent bending radius and angle, ensuring that each bend meets the required specifications. When choosing a die, factors that will affect the clr you. Learn the key principles to maximize efficiency and precision in your bending projects. Input tube and bend specifications into the boxes shown below. On a daily basis we receive quotation requests where meeting the design requirements of the tube component is extremely complex, and may limit it to certain bending machines, involve special. This calculator will generate optimal mandrel nose placement. Web tube bending fundamental terms. When you think of how to bend stainless steel tubing to a radius, you should choose mandrel bending. For 25, 30, q255, the minimum bending radius is 0.6t. Some applications require specific bend radii; Tubing should be free of scratches and suitable for bending. This hand tool offers the advantage of consistent bending radius and angle, ensuring that each bend meets the required specifications. See a table of bend radius values for ptfe industrial wall tubing with various inside diameters. The swagelok hand tube bender bends 1/8, 1/4, 5/16, 3/8, and 1/2 in., and 3, 6, 8, 10, and 12 mm outside diameter tubing in a variety of wall thicknesses. Order to outside diameter and wall thickness only, not to inside diameter, average wall specification. Hydro tube's cnc and manual benders are capable of bending 1/16 to 6 o.d. Minimum tube length, bend radius, and wall thickness limits required to make a 90° bend in annealed tubing are listed below. Long radius pipe bends & return dimensions.

Stainless steel tube bend radius chart mazincredible

jametp Blog

Standard Pipe Bend Radius Chart

Bending Stainless Steel Tubing Effective Processes and Considerations

Minimum tube bend radius chart vsamad

Standard Pipe Bends Dimensions appliedalloysinternational

Steel Pipe Bend Radius Chart

Tube Bending Radius Chart

Electrical Conduit Math Math Encounters Blog

How To Bend Conduit change comin

Web Often, Even The Most Competent Of Designers Are Not Fully Aware Of Exactly How Tube Bending Machines Work And Hence Their Capabilities And Limitations.

Web Using The Image Below, You Can See How The Radius Of A Bend Has A Significant Impact On The Resulting Part.

Bending Guide For Copper Tube

Web For 15, 20, Q235, Q235A, 15F, The Minimum Bending Radius Is 0.5T.

Related Post: