Torque Wrench Size Chart

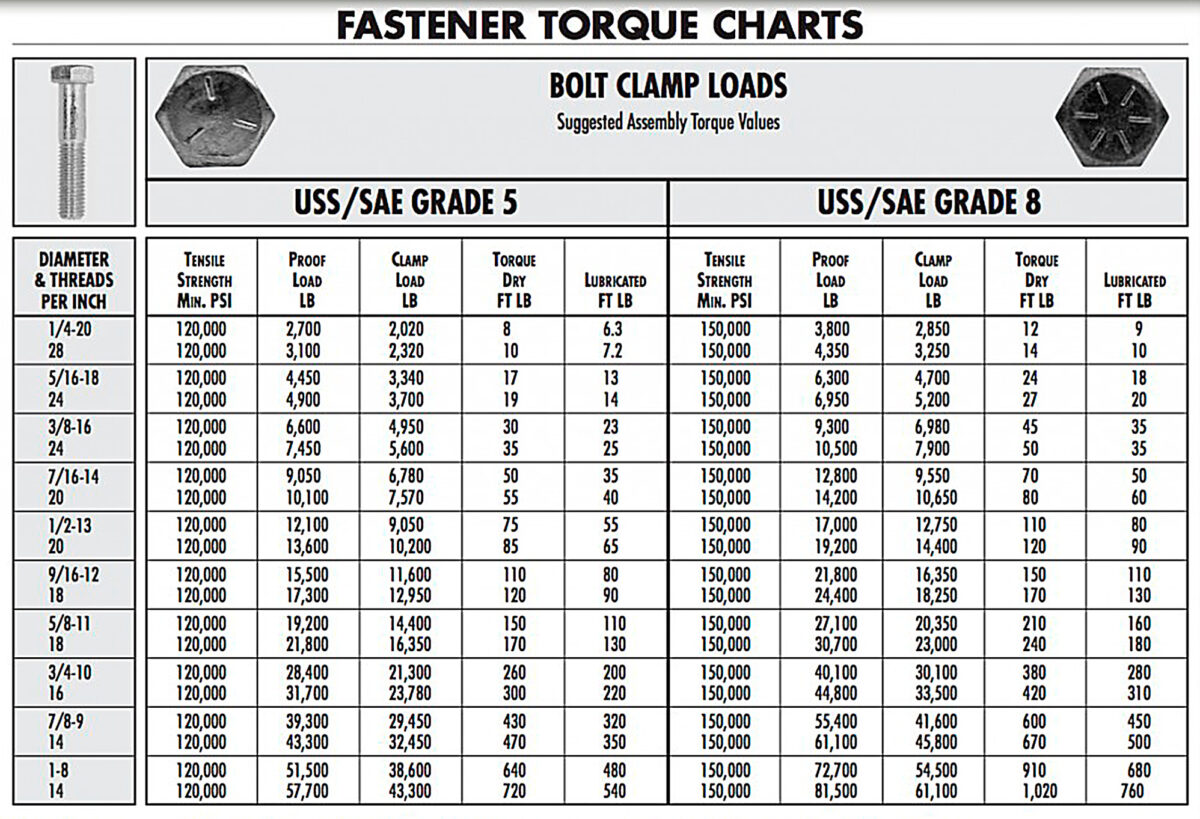

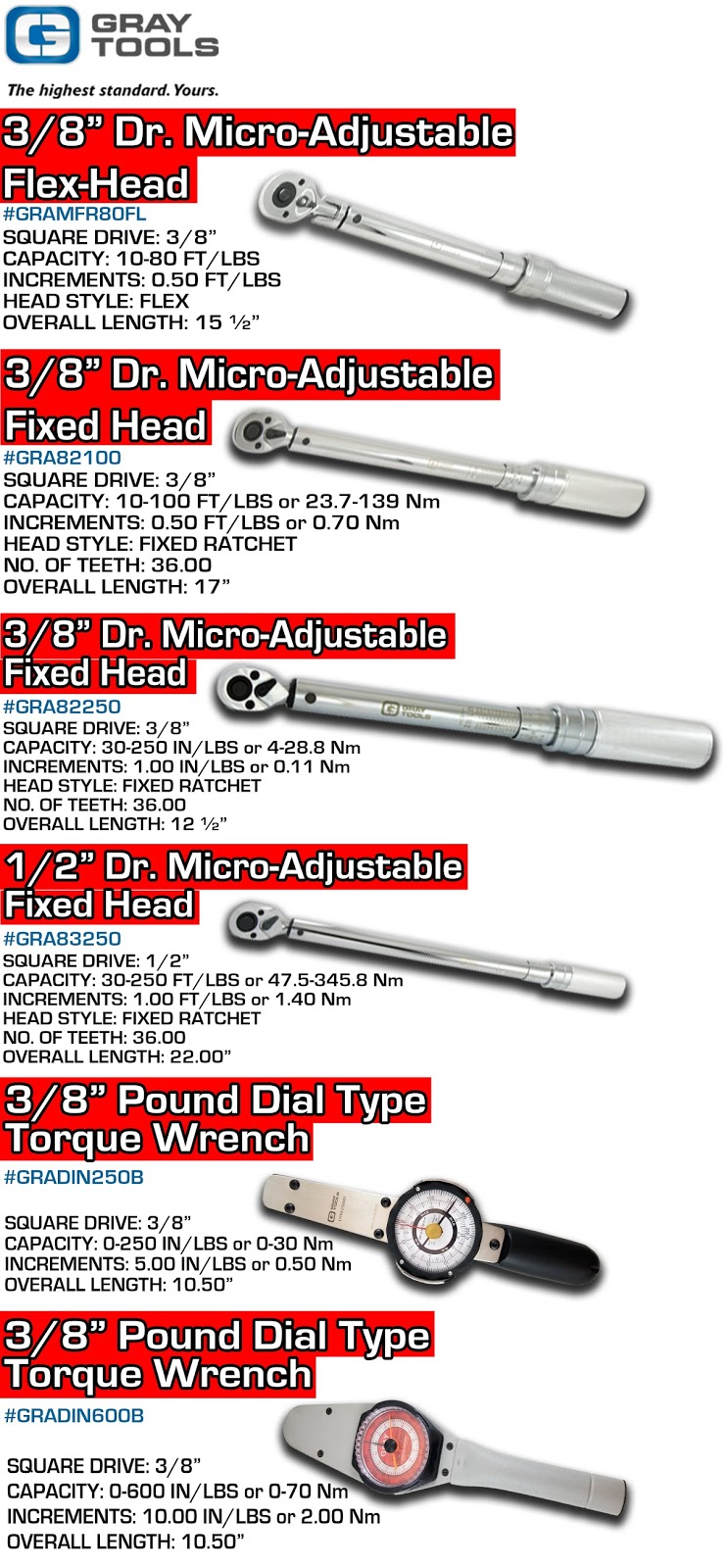

Torque Wrench Size Chart - Web some of the most common sizes include 1/4″, 3/8″, 1/2″, and 3/4″. Web for torque wrenches, ¼, ⅜, ½, ¾ and 1 drives are the most common drive size offerings. You’ll know this if you’ve ever needed to change a tire. Web this article provides the information for choosing the correct bolt tightening torque for standard bolt sizes. Web here are the four common torque wrench sizes and when you need each one. Last updated april 10th, 2023. While in itself it’s a type of wrench, there are actually six main types of torque wrenches available, each of which has its own pros and cons. All the drive size comes with different torque ranges. Matching the right size to the task is crucial for efficient work. The below estimated torque calculations are only offered as a guide. Understanding the numbers and scales of your torque wrench is key to applying the correct torque to your bolts and nuts. Understanding the different drive sizes for torque wrenches. Use of its content by anyone is the sole responsibility of that person and they assume all risk. The amount of torque that is applied depends on the mount of force. To figure out the torque, the torque formula is: Web some of the most common sizes include 1/4″, 3/8″, 1/2″, and 3/4″. Web determine the length of the torque wrench from the center of the grip to the center of the square drive (remember that this changes as you adjust the torque wrench setting). While in itself it’s a type. Any decent automobile technician must know about different types of fasteners (nuts and bolts), tightening procedures, what size torque wrench to use, etc. The click type torque wrench. Web the wide range of 'ndustr'al tools are broadly categorised as below : Speaking of tightening fasteners, we should not over tighten or under tighten it as it can damage or break. Unlock the potential of your toolbox by understanding wrench sizes. The below estimated torque calculations are only offered as a guide. Life is so much easier when you have the right tool for a job. ½ inch, ⅜ inch, ¼ inch and ¾ or 1 inch. It’s the standard type of torque wrench available in the market. Beam torque wrenches consist of a lever arm and a calibrated scale. Life is so much easier when you have the right tool for a job. To figure out the torque, the torque formula is: Secure and rapid torque setting adjustment. The selection of optimal drive size is largely dependent on the sockets the user owns, the most common fastener. Cdi comfort grip micrometer adjustable torque wrench. Web there are mainly four torque wrench sizes to choose from: Unlock the potential of your toolbox by understanding wrench sizes. When you place the arm in the desired position, you will tighten the wrench until the lever arm is in line with the force that is being applied, which will then be. This type of wrench can be used in a variety of industries such. Web there are mainly four torque wrench sizes to choose from: The click type torque wrench. All the drive size comes with different torque ranges. And now you’re tool shopping but wondering what. And now you’re tool shopping but wondering what. Web there are mainly four torque wrench sizes to choose from: Web a torque wrench is a calibrated tool that is going to apply a certain amount of load to a nut or a bolt. The below estimated torque calculations are only offered as a guide. Several types of screwdriver have been. Beam torque wrenches consist of a lever arm and a calibrated scale. Life is so much easier when you have the right tool for a job. They are best for tightening large size fasteners like lug nuts as well as for fixing general mechanical issues like changing tires. This torque wrench derives its names from the audible click it produces. Force x length = torque. Multiply the amount of torque you are trying to apply (1) by. Web march 29, 2023 by dan miller. You’ll know this if you’ve ever needed to change a tire. The click type torque wrench. Web the torque wrench is designed to measure the torque being applied to the fastener and to give an audible or visual indication when the correct torque has been reached. Web there are three types of torque wrenches: It is important to note that the chart is merely a guide and you should also consider factors like the material being used, the size of the bolt head, and the intended torque specification. Web this article provides the information for choosing the correct bolt tightening torque for standard bolt sizes. Web typically, there are five types of torque wrenches with having each its own merits and demerits. Web there are mainly four torque wrench sizes to choose from: You’ll know this if you’ve ever needed to change a tire. Use of its content by anyone is the sole responsibility of that person and they assume all risk. Discover the impact of metric vs. Understanding the different drive sizes for torque wrenches. This type of wrench can be used in a variety of industries such. While in itself it’s a type of wrench, there are actually six main types of torque wrenches available, each of which has its own pros and cons. This torque wrench derives its names from the audible click it produces once the user attains the ideal amount of torque, making them relatively easy to use. Understanding the numbers and scales of your torque wrench is key to applying the correct torque to your bolts and nuts. Web the chart provides a reference table for common bolt sizes and the corresponding torque wrench size required. And now you’re tool shopping but wondering what.

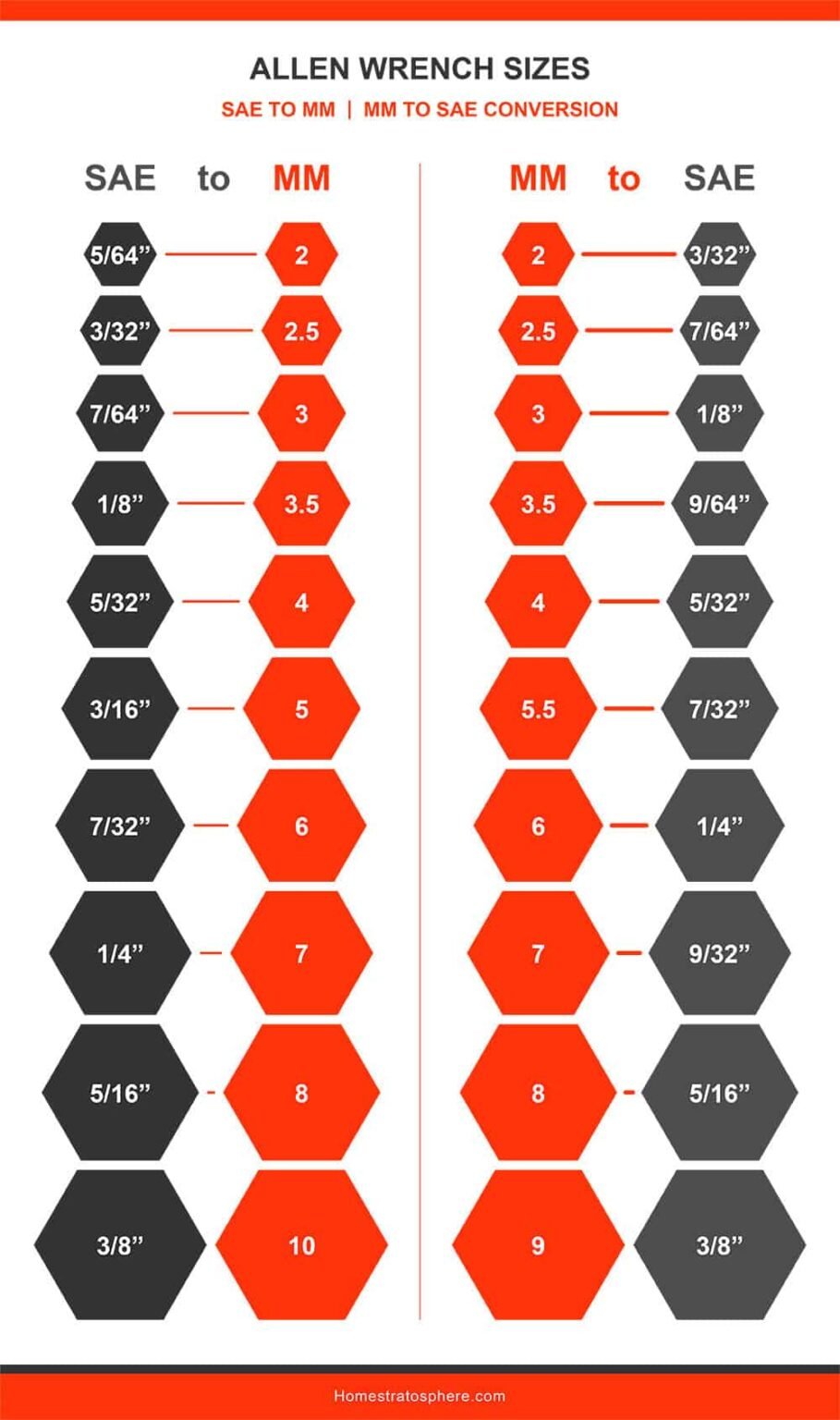

Printable Wrench Size Chart

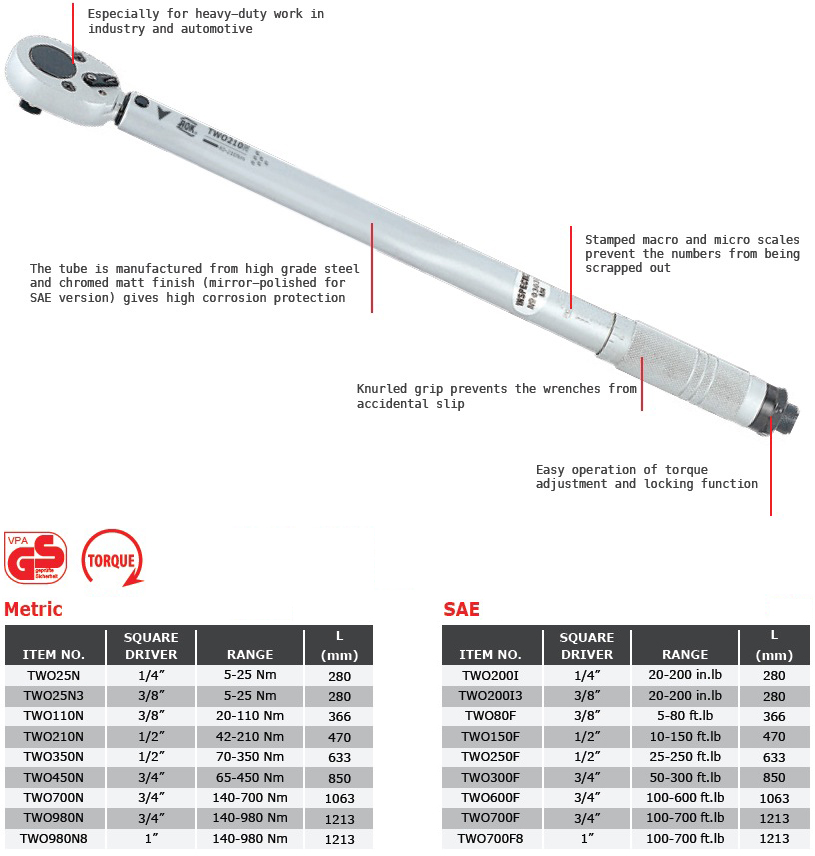

Adjustable Torque Wrenches, TWO A.O.K. INDUSTRIAL CO.

Printable Wrench Size Chart Customize and Print

Top 5 Digital Torque Wrenches for Precision Tightening Our InDepth

Torque wrench settings chart

6 Main Torque Wrench Types and Sizes Which One Do You Need?

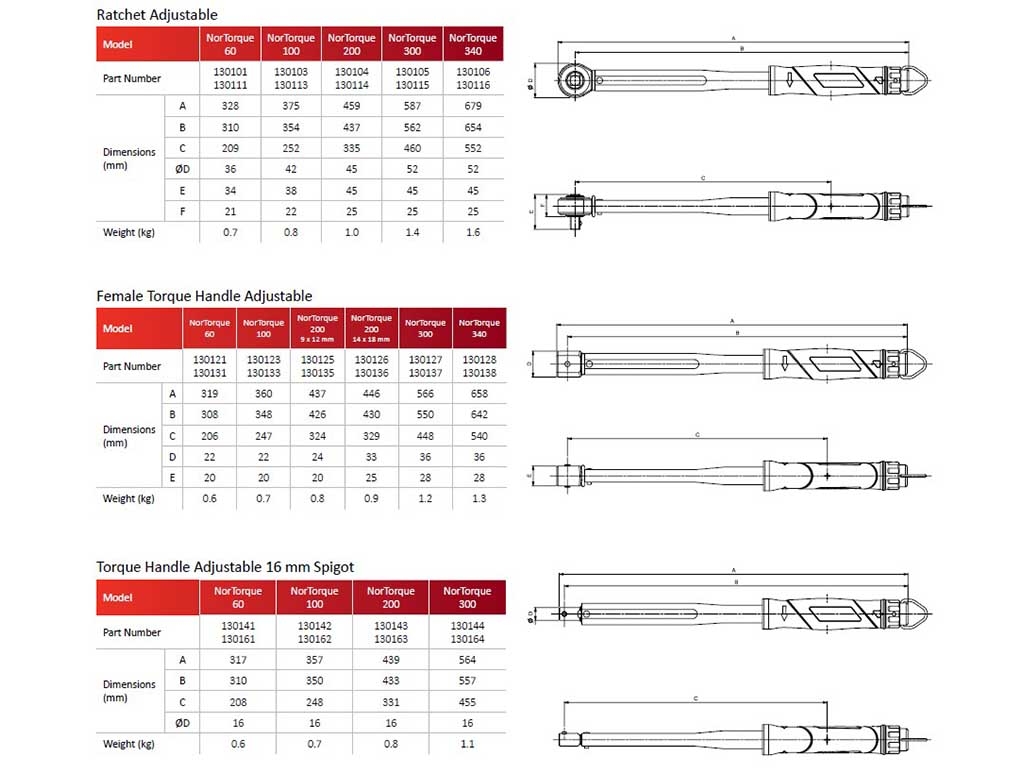

Norbar 130101 Torque Wrench Surkon International

Buyer's Guide Selecting the Proper Torque Wrench Edmonton Fasteners

Torque Wrench Size Chart

Printable Wrench Size Chart

Web A Torque Wrench Is A Calibrated Tool That Is Going To Apply A Certain Amount Of Load To A Nut Or A Bolt.

As Someone Who Has Delved Into The World Of Mechanical Tools And Machines, I Understand That The Concept Of Torque Wrench Measurement Can Be A Bit Intimidating For Beginners.

Web For Torque Wrenches, ¼, ⅜, ½, ¾ And 1 Drives Are The Most Common Drive Size Offerings.

A Smaller Torque Wrench Is Suitable For Delicate And Precise Work, While A Larger One Can.

Related Post: