Tig Welding Rod Chart

Tig Welding Rod Chart - E6010 and e6011 size and amperage chart. Web this article will teach you the basics of tig filler rods and help you establish your filler rod collection because 99% of the jobs are done with the rods we will discuss soon. Web tig welding chart based on material and shielding gas. Select a topic below to get started. Free stick welding electrodes pdf chart. Ron covell explains the different tig tungsten options, the tungsten color code and how to sharpen and store these electrodes. Welding rod sizes and base metal thickness chart. 2 2mm is the transition between 1.0mm and 1.6mm filler rod. 6010 and 6011 are virtually the same rod. The larger filler rod cools the weld pool more than the smaller rod so you might add about 5 amps if using 1.6mm filler rod. Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. What metal are you welding? Web characteristics of current types for tig welding. The current polarity, power source, thickness of the material, and metal type play a role in tungsten selection. 6010 and 6011 are virtually the same rod. 6010 and 6011 are virtually the same rod. Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. Free stick welding electrodes pdf chart. It caters to different material types and thicknesses for effective welding. The larger filler rod cools the. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. Web this article will teach you the basics of tig filler rods and help you establish your filler rod collection because 99% of the jobs are done with the rods we will discuss soon. Web there is a really good chart for selecting. Here you can find articles, videos, webinars and all things tig. Select a topic below to get started. Web selecting the right tungsten electrode is an essential part of tig welding. Reduce the amps a little if using a 1.0mm tungsten. Additionally, we will give you tig filler rod charts for all standard and less often used rods, including titanium. Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. The larger filler rod cools the weld pool more than the smaller rod so you might add about 5 amps if using 1.6mm filler rod. Select a topic below to get started. Web tig welding chart based on material and shielding gas. Welding rod sizes. Web once you’ve chosen your welding rod diameter, use the stick welding rod chart at the top of the page to find the amperage range for that specific electrode. Web learn how to select the right tig welding filler rod size and composition with helpful guidelines and charts. Web 1 a 1.6mm tungsten is ok down to about 30 amps.. However, only bare uncoated rods should be used. It can be used on thinner material if the tip is kept very sharp. Select a topic below to get started. Web characteristics of current types for tig welding. Whether you're new to tig welding or want to hone your skills, you're in the right place. Welding rod sizes and base metal thickness chart. The chart contains detailed descriptions of the different types of rods available for use in tig welding processes, as well as their respective. Web selecting the right tungsten electrode is an essential part of tig welding. Web tig welding chart based on material and shielding gas. Web a tig welding settings chart. Whether you're new to tig welding or want to hone your skills, you're in the right place. And do yourself a favor and get some 4047 aluminum filler rod for castings where porosity rares its ugly head. Tig welding can be used to weld aluminium, copper, titanium etc. The larger filler rod cools the weld pool more than the smaller. Reduce the amps a little if using a 1.0mm tungsten. The current polarity, power source, thickness of the material, and metal type play a role in tungsten selection. Web characteristics of current types for tig welding. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. The three main types of metals typically. Web this article will teach you the basics of tig filler rods and help you establish your filler rod collection because 99% of the jobs are done with the rods we will discuss soon. Browse suggested weld parameter settings for tig welding. The amperage that you choose from the range will come down to a few different factors, but you should use a high amperage on thicker metal and low amperage on thinner metal. Free stick welding electrodes pdf chart. Correctly matching the tungsten electrode with a weld’s requirements saves time and money. 4047 aluminum filler rod contains 12% silicon. The three main types of metals typically worked on with a tig welder include steel, stainless steel, and aluminum. 6010 and 6011 are virtually the same rod. And do yourself a favor and get some 4047 aluminum filler rod for castings where porosity rares its ugly head. Web a look at each type and its uses will help the operator select the best current type for the job. The type of current used will have a great effect on the penetration pattern as well as the bead configuration. Tig welding can be used to weld aluminium, copper, titanium etc. Web a tig welding chart visually represents the welding parameters needed to achieve a specific weld. Web welding rod sizes sizes & material thickness chart (mild steel) contents. However, only bare uncoated rods should be used. Web learn how to select the right tig welding filler rod size and composition with helpful guidelines and charts.

Tig Welding Rods Chart

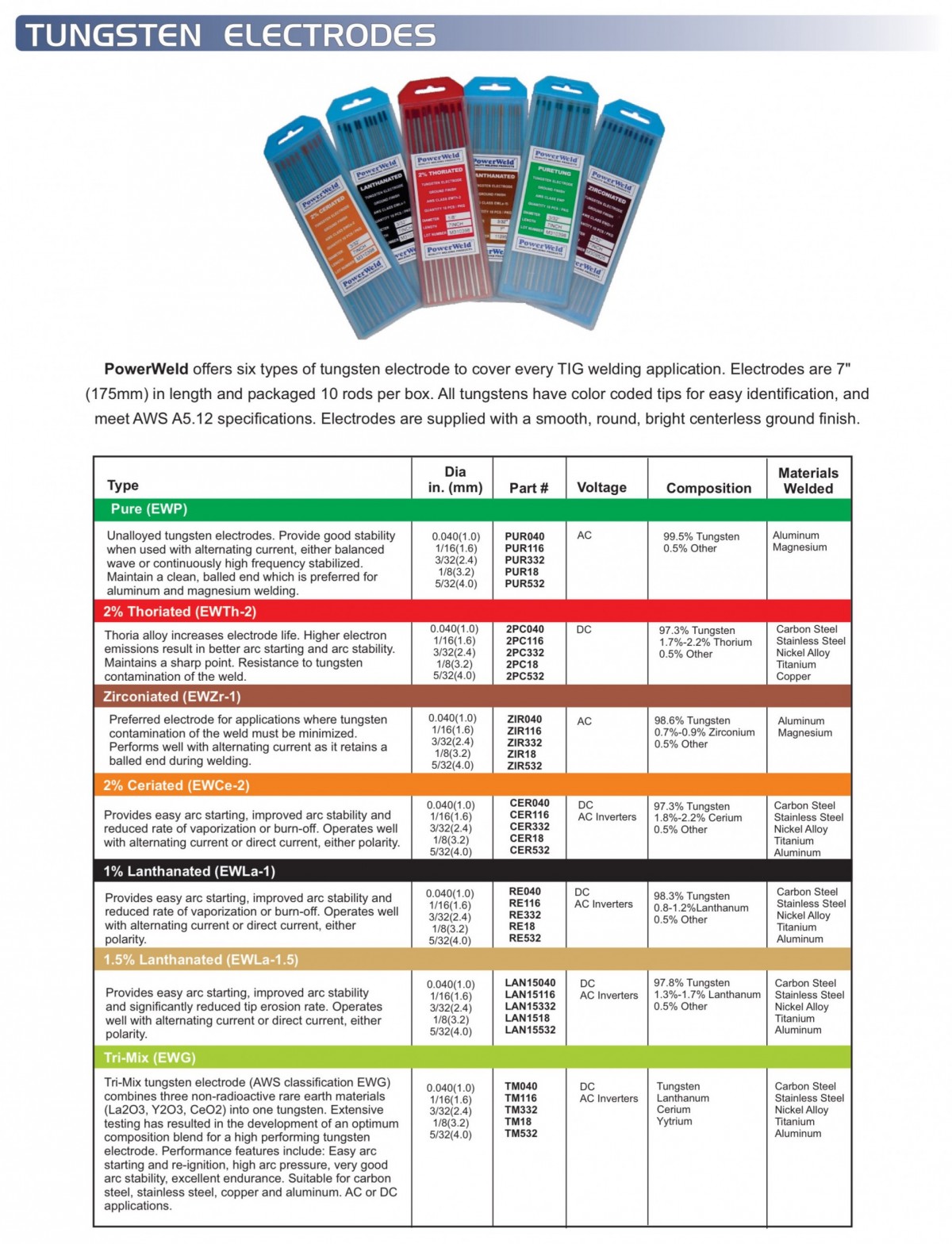

TIG Tungsten Electrodes Explained (with Color Chart)

How Do I Calculate How Much Welding Rod I Need

Tig Welding Tungsten Chart

Tig Welding Filler Rod Selection Chart Reviews Of Chart

TIG Welding Charts ILMO Products Company

Tig Welding Rod Chart

TIG Welding Charts ILMO Products Company

Types Of Welding Rods Chart vlr.eng.br

Tig Welding Settings Chart Pdf

The Larger Filler Rod Cools The Weld Pool More Than The Smaller Rod So You Might Add About 5 Amps If Using 1.6Mm Filler Rod.

2 2Mm Is The Transition Between 1.0Mm And 1.6Mm Filler Rod.

The Chart Usually Includes The Current Range, Polarity, Filler Metal Type, Shielding Gas Type, And Tungsten Electrode Size.

The Chart Contains Detailed Descriptions Of The Different Types Of Rods Available For Use In Tig Welding Processes, As Well As Their Respective.

Related Post: