Tig Weld Amp Chart

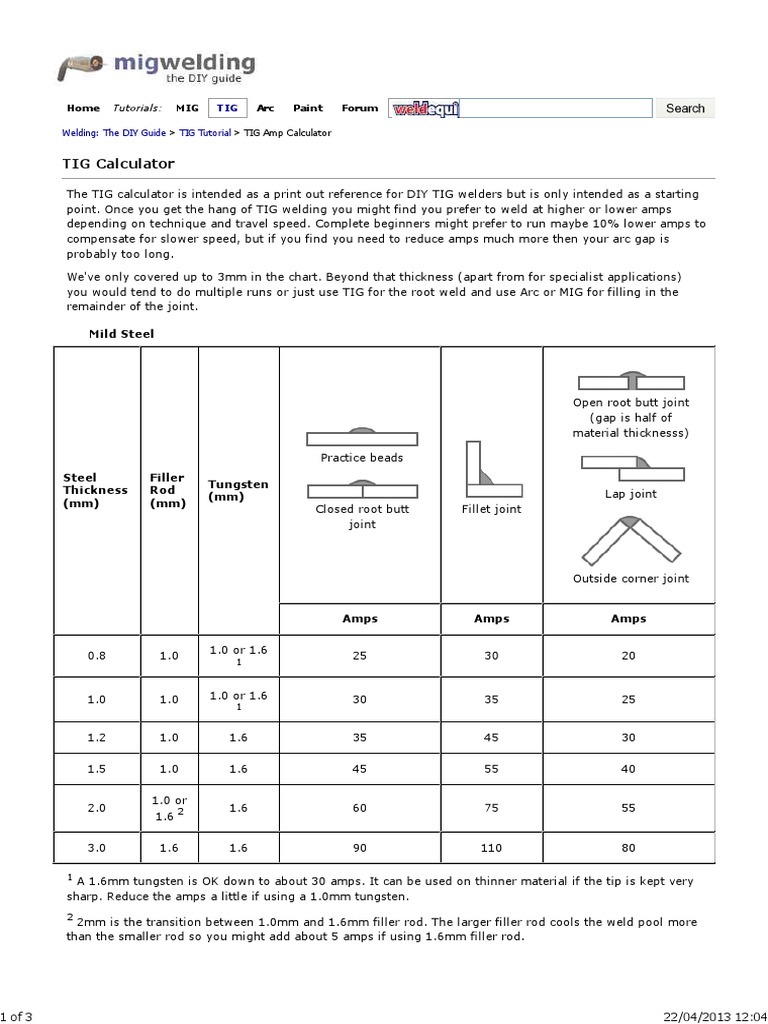

Tig Weld Amp Chart - Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. 8.4 is carbon dioxide on aluminum any good. Tig welding is a versatile welding technique that can be used to weld a wide range of metals and has tons of applications. It lists recommended amperages for. Web how many amps does a tig welder need?—ultimate guide. 12 (307.2 mm) 1/16 (1.6 mm) 1/16 (1.6 mm) 4, 5, 6. Web using a welding amperage chart is an effective way to determine the appropriate amperage range for different welding applications. What metal are you welding? Well, the answer is not a simple or straightforward one. Web the document provides a tig welding amp calculator chart for mild steel and stainless steel in thicknesses ranging from 0.8mm to 3mm. It caters to different material types and thicknesses for effective welding. Web mainly on the material thickness and the amperage needed to achieve a proper weld. Web empower your tig welding projects with our free online tig welding calculator. Web what is a tig welding chart. Stainless steel dissimilar welding chart; Web the document provides a tig welding amp calculator chart for mild steel and stainless steel in thicknesses ranging from 0.8mm to 3mm. Whether you’re working on steel, aluminum, or stainless steel, this tool provides you with tailored recommendations for electrode size, type, and amperage, ensuring that your welds meet the highest standards. The chart usually includes the current range,. Web 6 what amperage should you use for tig welding on aluminum. Web what is a tig welding chart. 12 (307.2 mm) 1/16 (1.6 mm) 1/16 (1.6 mm) 4, 5, 6. Web the document provides a tig welding amp calculator chart for mild steel and stainless steel in thicknesses ranging from 0.8mm to 3mm. This document provides a tig welding. The chart usually includes the current range, polarity, filler metal type, shielding gas type, and tungsten electrode size. For aluminum welding, switch your amperage setting on the front panel to ac. 8.2 is helium a good option. Stainless steel dissimilar welding chart; Other current values may be employed depending on the shielding gas, type of Web mainly on the material thickness and the amperage needed to achieve a proper weld. For mild steel, it recommends running 10% lower amps for complete beginners. Filler metal suggested for casting alloys; The chart usually includes the current range, polarity, filler metal type, shielding gas type, and tungsten electrode size. See the chart below for current ranges of all. Filler metal suggested for casting alloys; The tig calculator is intended as a. Well, the answer is not a simple or straightforward one. 9.1 steps for tig welds on aluminum. Web welders are often looking for a good reference detailing recommended amperage levels based on tungsten welding electrode size and type. Grind your tungsten to a point. Tig welding is a versatile welding technique that can be used to weld a wide range of metals and has tons of applications. Download the app version of the weld setting calculator for easy reference! Web 6 what amperage should you use for tig welding on aluminum. It lists recommended amperages for. For steel and steel alloy welding, switch your amperage setting to dc tig or dcen. Web 6 what amperage should you use for tig welding on aluminum. Tig welding is a versatile welding technique that can be used to weld a wide range of metals and has tons of applications. 12 (307.2 mm) 1/16 (1.6 mm) 1/16 (1.6 mm) 4,. It notes that the chart provides starting point amps that may need adjusting based on technique and travel speed. Well, the answer is not a simple or straightforward one. Download the app version of the weld setting calculator for easy reference! Web welders are often looking for a good reference detailing recommended amperage levels based on tungsten welding electrode size. What metal are you welding? Download the app version of the weld setting calculator for easy reference! For beginners it’s recommended to stick with a 3/32” diameter tungsten. One of the most common questions that beginners ask is how many amps a tig welder needs. Aluminium (achf) shield gas flow metal guage. A tig welding chart visually represents the welding parameters needed to achieve a specific weld. Filler metal suggested for wrought stainless steels; Web welders are often looking for a good reference detailing recommended amperage levels based on tungsten welding electrode size and type. Web the aluminum tig welding settings chart is a comprehensive guide comprising various critical parameters necessary for tig welding. One of the most common questions that beginners ask is how many amps a tig welder needs. Web see our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables. Tig welding is a versatile welding technique that can be used to weld a wide range of metals and has tons of applications. Web mainly on the material thickness and the amperage needed to achieve a proper weld. 9.1 steps for tig welds on aluminum. Aluminium (achf) shield gas flow metal guage. Although midwest tungsten service only provides 1/16, 3/32, and 1/8 electrodes, some projects call for a slightly bigger diameter, such as 5/32 or 3/16. Web what is a tig welding chart. Web using a welding amperage chart is an effective way to determine the appropriate amperage range for different welding applications. Web 6 what amperage should you use for tig welding on aluminum. Web the document provides a tig welding amp calculator chart for mild steel and stainless steel in thicknesses ranging from 0.8mm to 3mm. It caters to different material types and thicknesses for effective welding.Tig parameters chart MIG Welding Forum

Aluminum Tig Welding Settings Chart

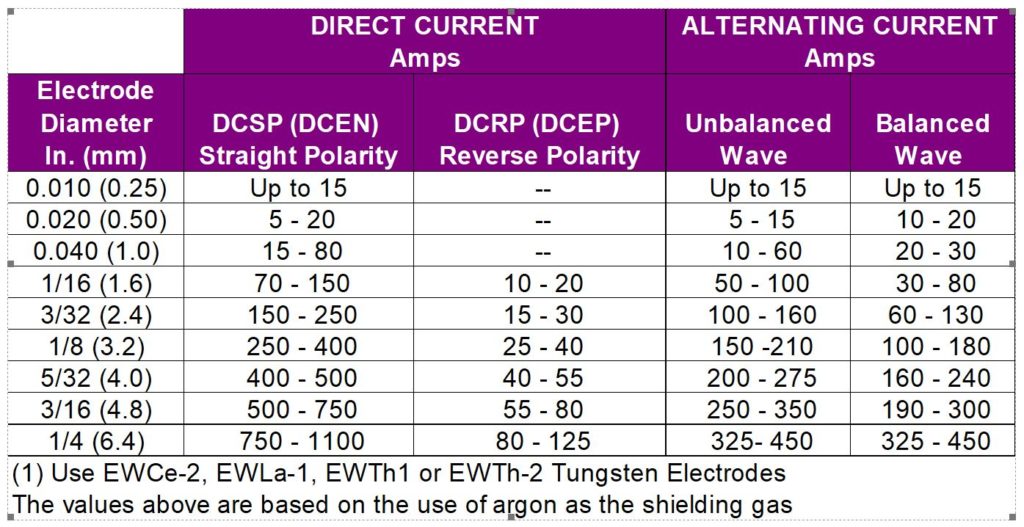

TIG Tungsten Electrodes Explained (with Color Chart)

TIG Welding Amp Charts Welding Building Materials

Tig Weld Amp Chart

TIG Welding Charts ILMO Products Company

Tig Welding Amperage Chart

Tig Welding Rods Chart

Tig Welding Settings Chart Pdf

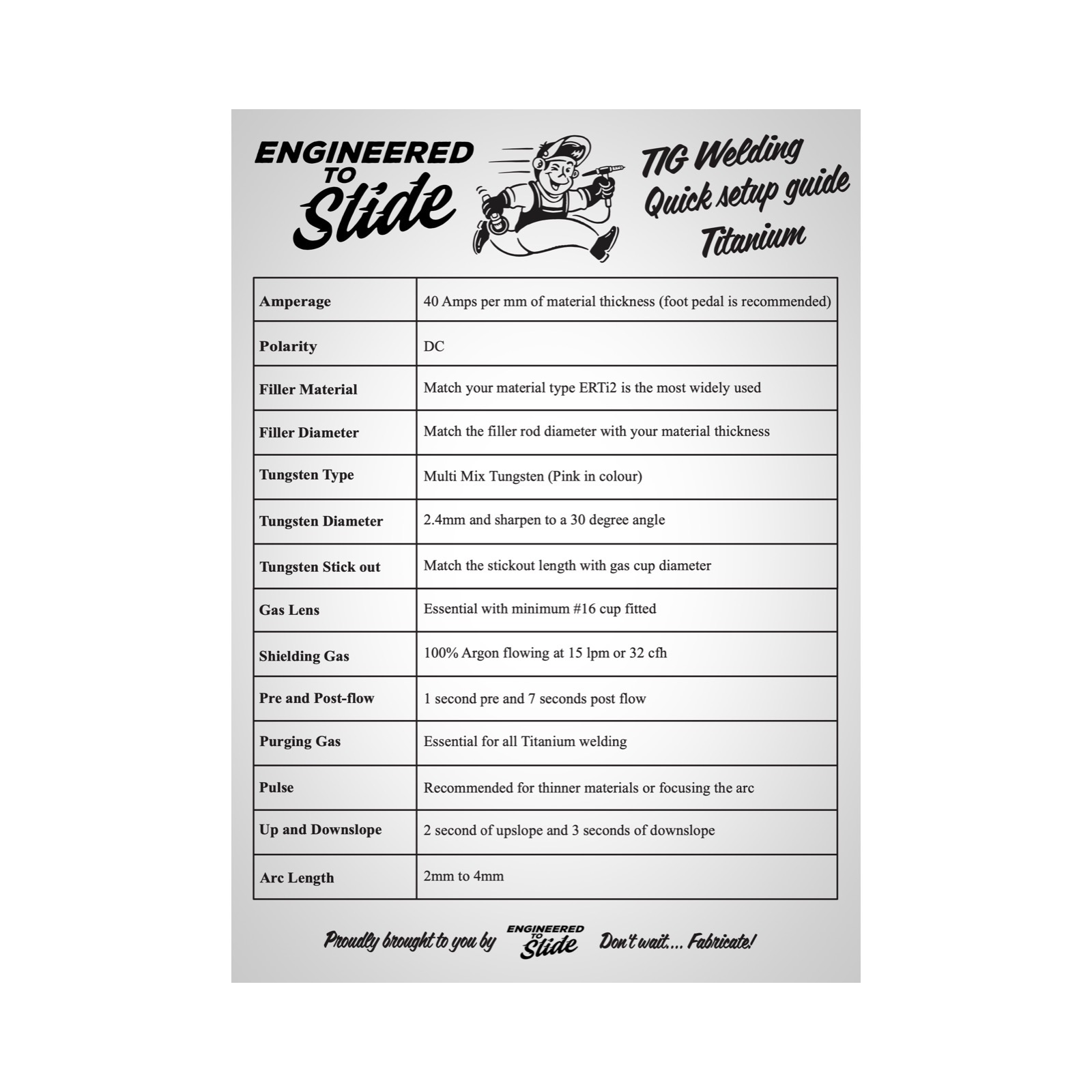

TIG Welding Charts Engineered to Slide

Additionally, You Might Have Your Own Preference.

For Mild Steel, It Recommends Running 10% Lower Amps For Complete Beginners.

Grind Your Tungsten To A Point.

What Metal Are You Welding?

Related Post: