Steel Heat Treat Chart

Steel Heat Treat Chart - Hold times depend on the size of the heat treat load and furnace size. Web as indicated in the title, volume 4a focuses on the fundamental aspects of steel heat treating and the many processes of steel heat treating. The heat treating of s7 tool steel is listed below. The austenitizing of 1095 steel is commonly used on parts where. Web heat treater’s guide online contains recommended practices for heat treating in a broad array of ferrous and nonferrous alloys. Web find the optimal temperatures and quenching media for hardening, tempering, annealing, and normalizing various steels. Access to this subset of the asm materials. Other procedures and hardnesses may be available. Web alloy steel heat treating normalizing, annealing temperature table chart. Standard practices and procedures for steel is largely a tribute to its editors who came up with a unique, easy. Web is required, tool steels with higher alloy contents, such as a2 or d2 should be considered. Web the following chart may be used as a guideline for predicting final hardness. Annealing heat treat a2 steel annealing heat treat temperature:. Heat treatment hardness vs temperature. Web find the optimal temperatures and quenching media for hardening, tempering, annealing, and normalizing various. Aisi 4130 steel hardening heat treatment. Aisi 4130 steel tempering heat treatment. Web the following chart may be used as a guideline for predicting final hardness. Web heat treating overview heat treating, as the name implies, is a series of treatments in which heat is used to alter the properties of a metal or alloy. Web heat treater’s guide online. Aisi 4130 steel annealing heat treatment. Access to this subset of the asm materials. Web alloy steel 4340 heat treatment including: Web find the optimal temperatures and quenching media for hardening, tempering, annealing, and normalizing various steels. Heat treating instructions hardening critical temperature: Web find the optimal heat treating temperatures and atmospheres for various types of tool steels, such as a2, d2, o1, w1, s7, h13, m2, t2, 4130 and 4140. Heat treatment hardness vs temperature. Remove from the furnace and air cool. Normalizing, annealing, hardening, tempering, spheroidization, stress relief, etc. Web heat treating stainless steels table chart. Web heat treatment hardness vs temperature table chart. Compare the properties and applications of different. Web find the optimal temperatures and quenching media for hardening, tempering, annealing, and normalizing various steels. Case hardening processes harden only the exterior of. The volume 4b, planned for. Case hardening processes harden only the exterior of. Insert your workpiece and allow it to equalize at temperature. Aisi 4130 steel tempering heat treatment. The austenitizing of 1095 steel is commonly used on parts where. A guideline is to hold 2x the. Standard practices and procedures for steel is largely a tribute to its editors who came up with a unique, easy. * for certain applications, low temperature draw may apply. Web the following table shows 1095 steel heat treat and rockwell hardness. Web heat treating stainless steels table chart. Web dc53 heat treat chart. * for certain applications, low temperature draw may apply. Web heat treating stainless steels table chart. Web the heat treating information shown represents typical procedures and hardnesses for many applications. Aisi 4130 steel annealing heat treatment. Web heat treating overview heat treating, as the name implies, is a series of treatments in which heat is used to alter the properties. Web heat treating overview heat treating, as the name implies, is a series of treatments in which heat is used to alter the properties of a metal or alloy. Insert your workpiece and allow it to equalize at temperature. The effect of carbon content on. Web dc53 heat treat chart. The following are hardenable grades of alloy steel. Web dc53 heat treat chart. Web heat treater’s guide online contains recommended practices for heat treating in a broad array of ferrous and nonferrous alloys. Web the success ofthe 1982 edition of the heat treater's guide: Please contact international mold steel. Case hardening processes harden only the exterior of. Web the following chart may be used as a guideline for predicting final hardness. Heat to 845 to 900 °c. The volume 4b, planned for. Web find the optimal heat treating temperatures and atmospheres for various types of tool steels, such as a2, d2, o1, w1, s7, h13, m2, t2, 4130 and 4140. The austenitizing of 1095 steel is commonly used on parts where. Web heat treatment hardness vs temperature table chart. Web find the optimal temperatures and quenching media for hardening, tempering, annealing, and normalizing various steels. Normalizing, annealing, hardening, tempering, spheroidization, stress relief, etc. Web alloy steel 4340 heat treatment including: Aisi 4130 steel tempering heat treatment. Heat treatment hardness vs temperature. Aisi 4130 steel annealing heat treatment. Web carbon steel typical heat treatments case hardening grade table chart. Hold times depend on the size of the heat treat load and furnace size. Compare the properties and applications of different. Web dc53 heat treat chart.

TemperatureGuidetoHeatTreatingSteel Metal working, Blacksmithing

Steel Heat Treat Temperature Color Chart

The chart of heattreated colors for steel according to the temperature

Parameters used for heat treatment of SS 304L Download Table

Heat Treat Colors Of Steel Chart

A2 Heat Treat Chart

A2 Tool Steel Heat Treat Chart chartdevelopment

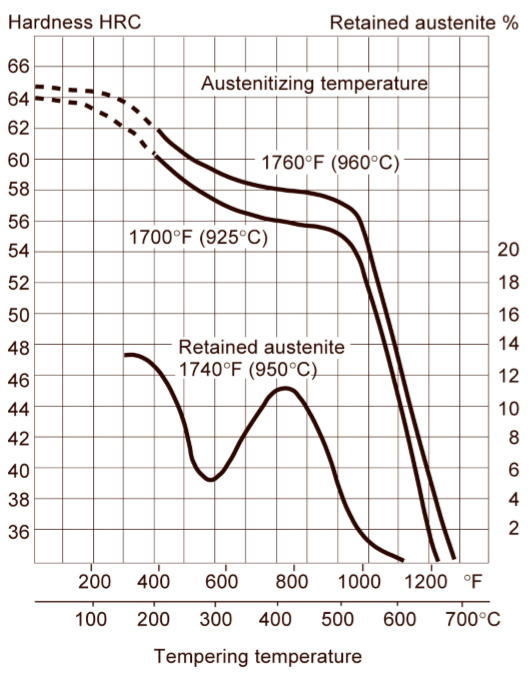

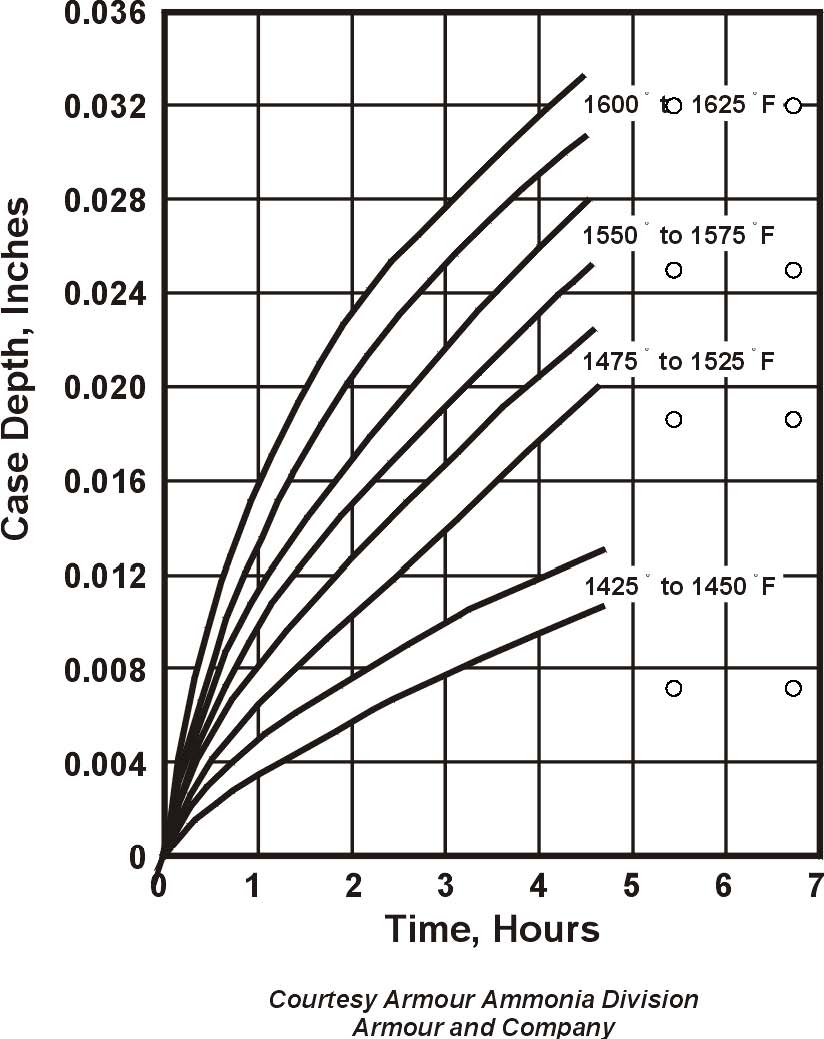

Heat Treating Steel Time vs Temperature and Case Harden Thickness

aisi 4340 heat treatment

Heat Treat Chart For Steel

Web Alloy Steel Heat Treating Normalizing, Annealing Temperature Table Chart.

Web The Following Table Shows 1095 Steel Heat Treat And Rockwell Hardness.

Web Heat Treating Overview Heat Treating, As The Name Implies, Is A Series Of Treatments In Which Heat Is Used To Alter The Properties Of A Metal Or Alloy.

Please Contact International Mold Steel.

Related Post: