Stainless Steel Corrosion Resistance Chart

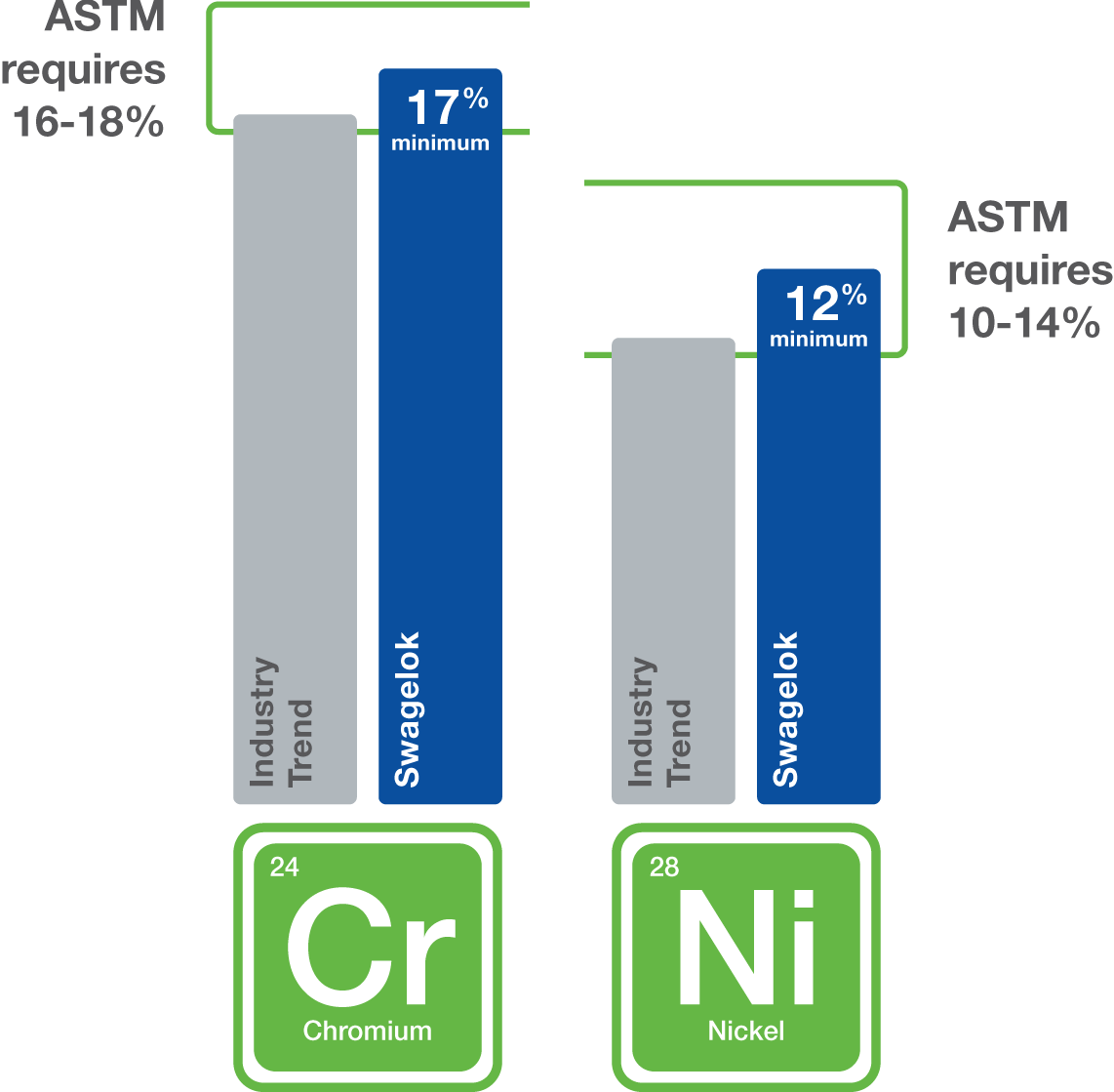

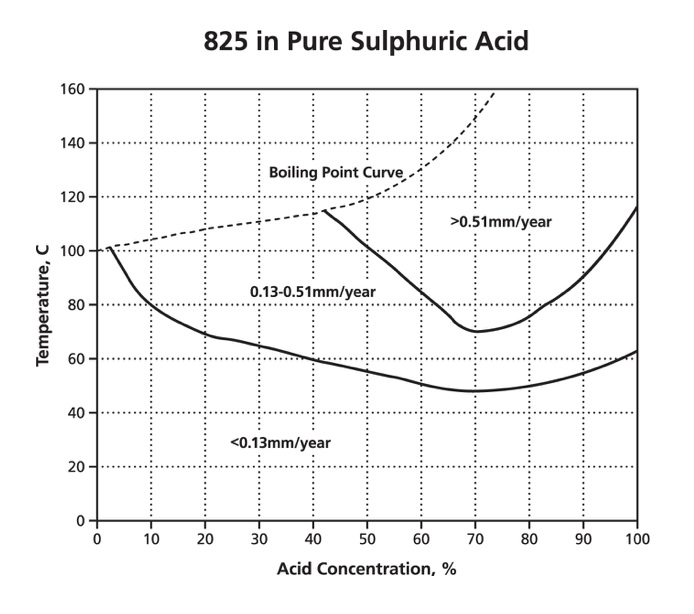

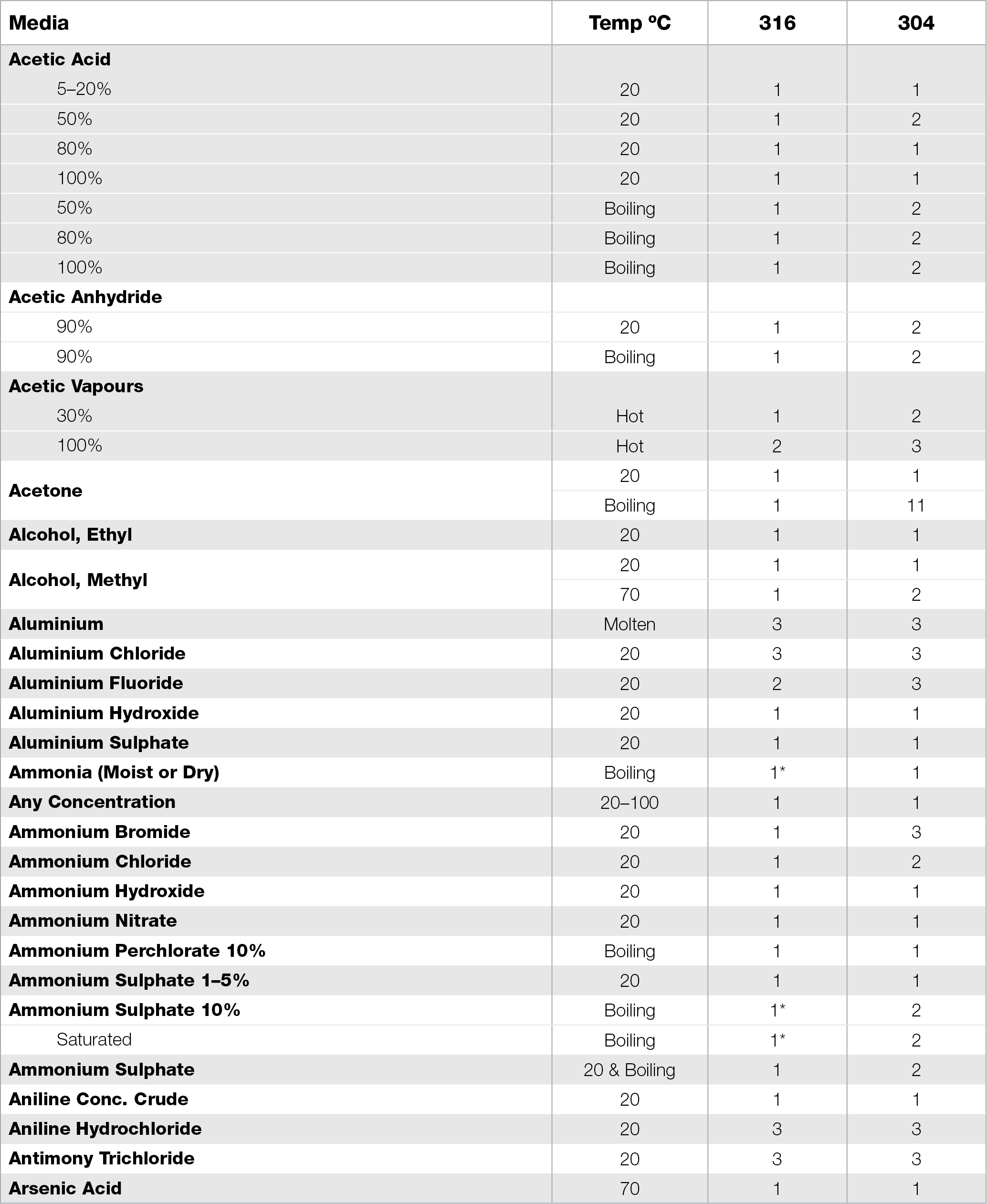

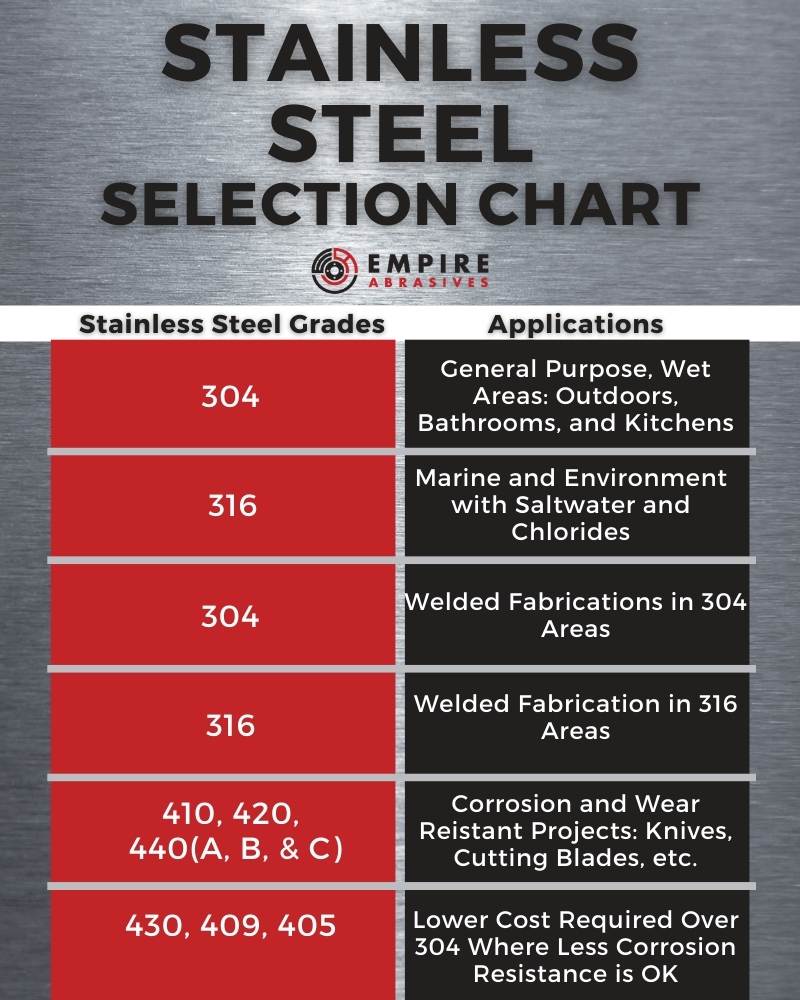

Stainless Steel Corrosion Resistance Chart - Web the table below indicates the approximate corrosion resistance of selected corrosion resistant metals to a range of common chemicals. Web in practice, most stainless steels contain 18% chromium to improve corrosion resistance. Bsen 10088:1 defines that a stainless steel must have a minimum of 10.5% (by weight) chromium & a maximum of 1.2% carbon to be classified as stainless. This is collated information from various sources but is of limited quality. Most stainless steels also contain nickel, to increase corrosion resistance still further. Web for stainless steel corrugated tubes, compensators and couplings. The chart on the left shows the corrosion rate in mpy (millimeters per year) as a function of the chromium content. Web corrosion resistance of aisi stainless steels in typical environments: For all metals this entity corresponds with approximately mm/per year (1 g/m2h = 1,1 mm/year) because the specifi c gravity (7.7 to 8.1) for all metal is similar. And intends merely to provide the consumer with a guide value. The chart on the left shows the corrosion rate in mpy (millimeters per year) as a function of the chromium content. However, not all stainless steel is created equal, so understanding corrosion resistance is crucial when. Acceptable combinations of more or less aggressive fluids and commonly used materials are. Web identification of stainless steel. The chemical can be selected from. However, not all stainless steel is created equal, so understanding corrosion resistance is crucial when. Web corrosion tables and diagrams (corrosion handbook) the corrosion tables show the anticipated resistance of a range of stainless steel grades to a wide range of chemicals, (including most common acids). A higher chromium content increases the alloy’s corrosion resistance. Basis of laboratory tests with. F1 rates the risk of exposure to chlorides from salt water or deicing salts. This is collated information from various sources but is of limited quality. F2 rates the risk of exposure to sulphur dioxide. And intends merely to provide the consumer with a guide value. Web for stainless steel corrugated tubes, compensators and couplings. The chemical can be selected from an alphabetical index or by entering the chemical formula. Web corrosion resistance of aisi stainless steels in typical environments: Web the corrosion tables provide an initial guide to the selection of materials and are intended to facilitate understanding of the different types of corrosion damage that can arise due to poor material selection. Web. Web january 13, 2024 | 11:21 pm. However, not all stainless steel is created equal, so understanding corrosion resistance is crucial when. Web corrosion resistance of aisi stainless steels in typical environments: And intends merely to provide the consumer with a guide value. The following resistance table has been put together on the. Basis of laboratory tests with chemically pure corrosive agents. Web january 13, 2024 | 11:21 pm. A major problem in process industry is corrosion of metals in pipes, valves and other parts of the constructions. Web corrosion criteria based on laboratory tests are commonly expressed in grams per square meter per hour. F2 rates the risk of exposure to sulphur. There are over 200 different types of stainless steel, each with a. Web the main factor in the selection process for stainless steels is corrosion resistance. However, not all stainless steel is created equal, so understanding corrosion resistance is crucial when. Web the inherent corrosion resistance of stainless steels is derived from alloying the base iron with chromium. For all. F3 rates the cleaning regime or exposure to washing by rain. Bsen 10088:1 defines that a stainless steel must have a minimum of 10.5% (by weight) chromium & a maximum of 1.2% carbon to be classified as stainless. Web in practice, most stainless steels contain 18% chromium to improve corrosion resistance. Web corrosion criteria based on laboratory tests are commonly. Web chromium effect on corrosion resistance of stainless steel. Web outokumpu stainless steel corrosion tables provide a guide to the selection of materials and are intended to facilitate understanding of the different types of corrosion damage that can arise due to poor materials selection. Web in practice, most stainless steels contain 18% chromium to improve corrosion resistance. A higher chromium. And intends merely to provide the consumer with a guide value. However, not all stainless steel is created equal, so understanding corrosion resistance is crucial when. A higher chromium content increases the alloy’s corrosion resistance. Basis of laboratory tests with chemically pure corrosive agents. Web the table below indicates the approximate corrosion resistance of selected corrosion resistant metals to a. The chart on the left shows the corrosion rate in mpy (millimeters per year) as a function of the chromium content. Most stainless steels also contain nickel, to increase corrosion resistance still further. The steel types are shown as outokumpu. Web identification of stainless steel. Basis of laboratory tests with chemically pure corrosive agents. The following resistance table has been put together on the. Web for stainless steel corrugated tubes, compensators and couplings. For all metals this entity corresponds with approximately mm/per year (1 g/m2h = 1,1 mm/year) because the specifi c gravity (7.7 to 8.1) for all metal is similar. The chemical can be selected from an alphabetical index or by entering the chemical formula. Alloy 6hn (uns n08367) contains 6 weight percent more nickel (ni) than alloy 254 (uns s31254). Web outokumpu stainless steel corrosion tables provide a guide to the selection of materials and are intended to facilitate understanding of the different types of corrosion damage that can arise due to poor materials selection. F3 rates the cleaning regime or exposure to washing by rain. Practical conditions usually also involve impurities, in particular. And intends merely to provide the consumer with a guide value. F2 rates the risk of exposure to sulphur dioxide. Web the main factor in the selection process for stainless steels is corrosion resistance.

Material Applications Corrosion Resistant Alloy Comparison Part 2

Corrosion Resistant Metals Materials Selection Guide Swagelok

Corrosion Resistance Stainless Steel Chart

Duplex Stainless Steel Chemical Resistance Chart Reviews Of Chart

Stainless Corrosion Resistance Anzor

Corrosion Resistance Anzor Fasteners

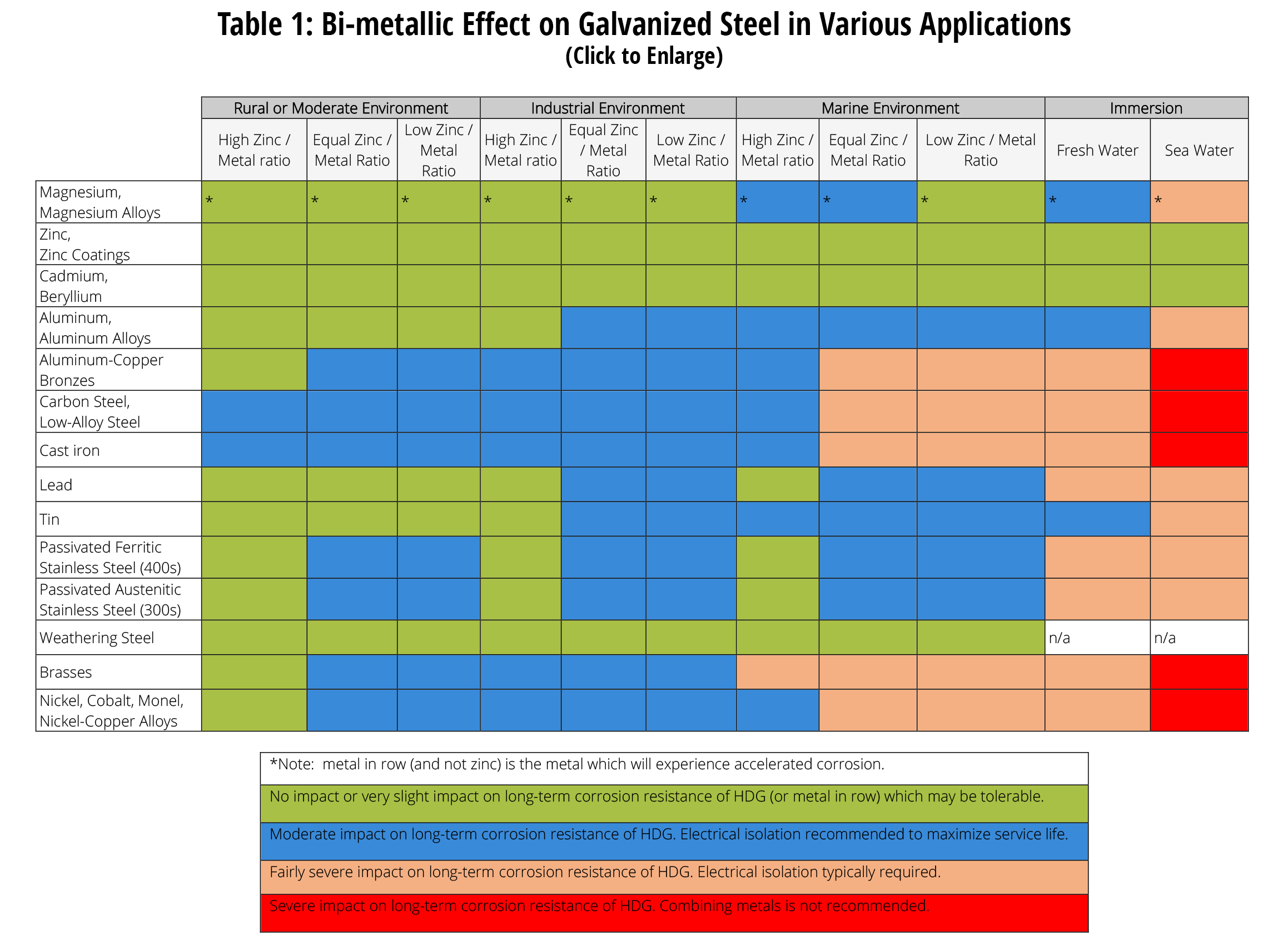

Stainless Steel Galvanic Corrosion Chart

Stainless Steel Galvanic Corrosion Chart

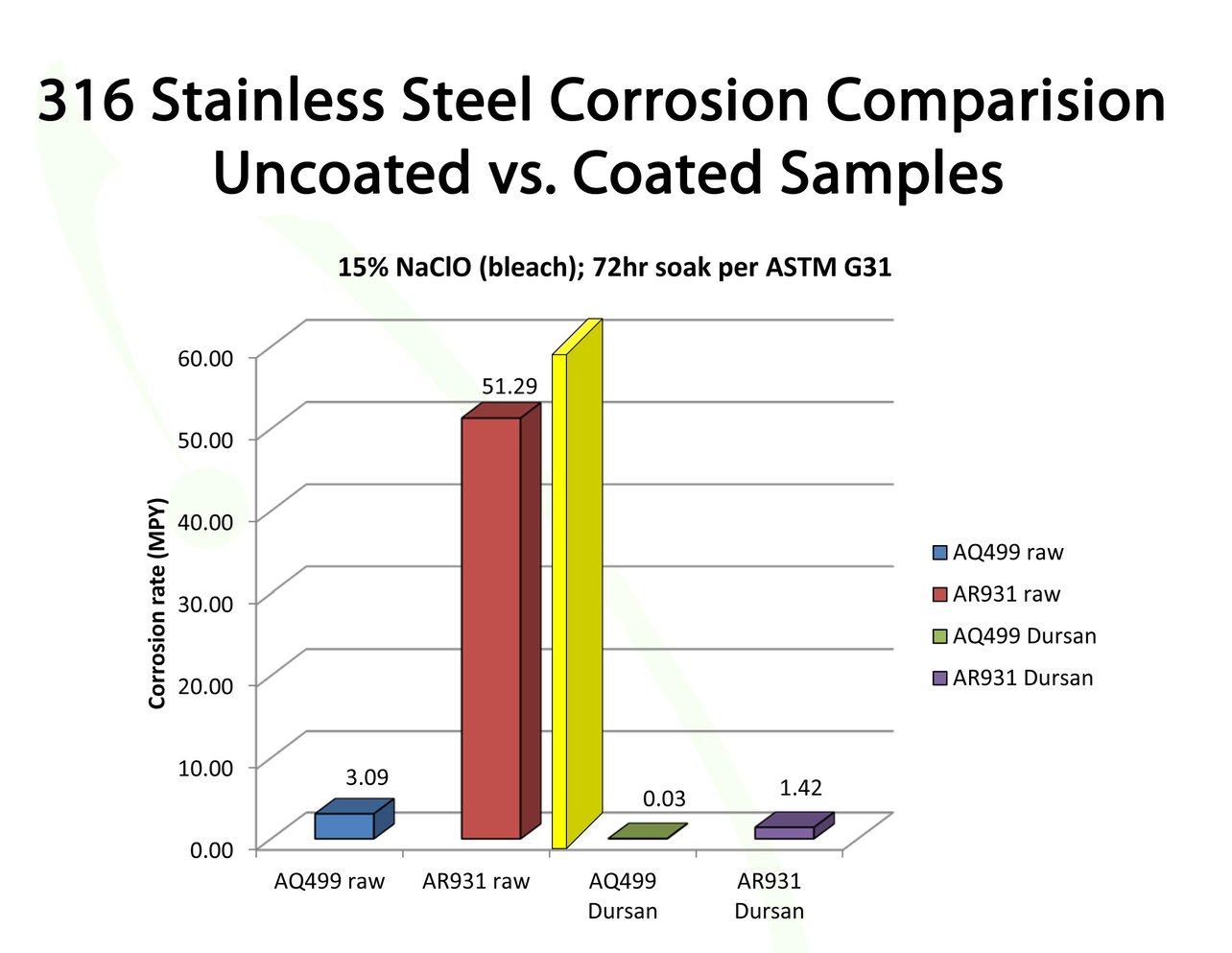

Comparing the Corrosion Resistance of 316 Stainless Steel

Stainless Steel Finish Chart

This Can Be Used In The Same Way As The Corrosion Handbook.

A Higher Chromium Content Increases The Alloy’s Corrosion Resistance.

Web The Corrosion Tables Provide An Initial Guide To The Selection Of Materials And Are Intended To Facilitate Understanding Of The Different Types Of Corrosion Damage That Can Arise Due To Poor Material Selection.

Acceptable Combinations Of More Or Less Aggressive Fluids And Commonly Used Materials Are.

Related Post: