Slump Chart For Concrete

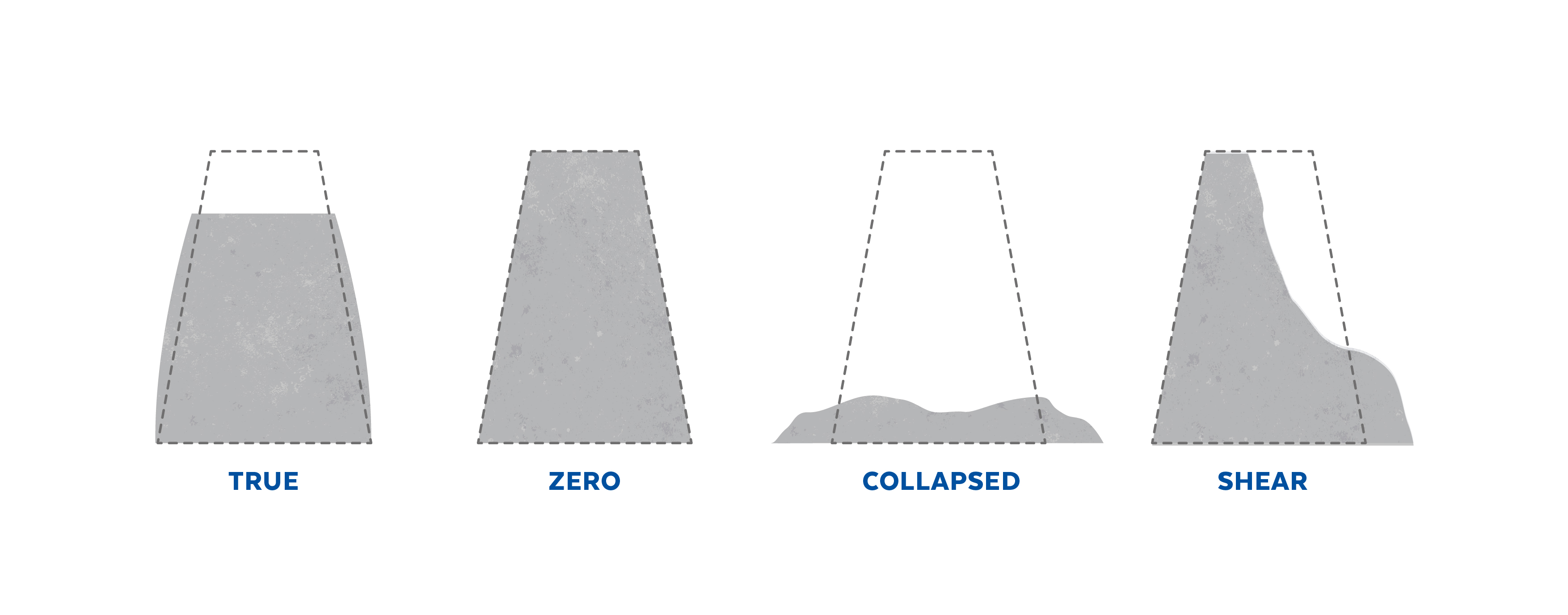

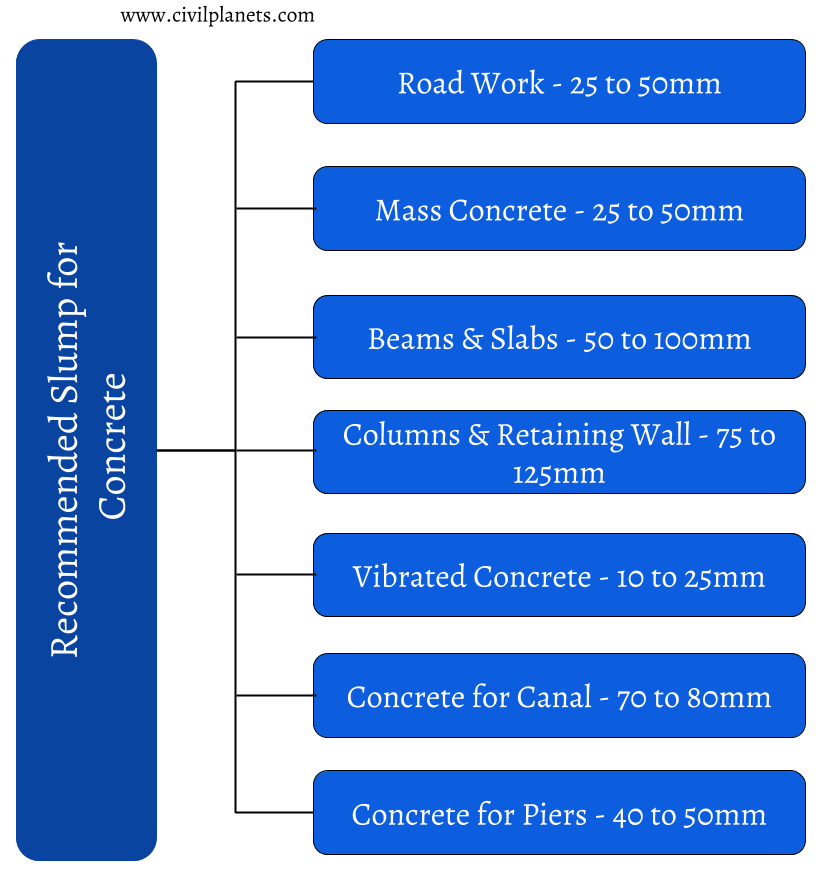

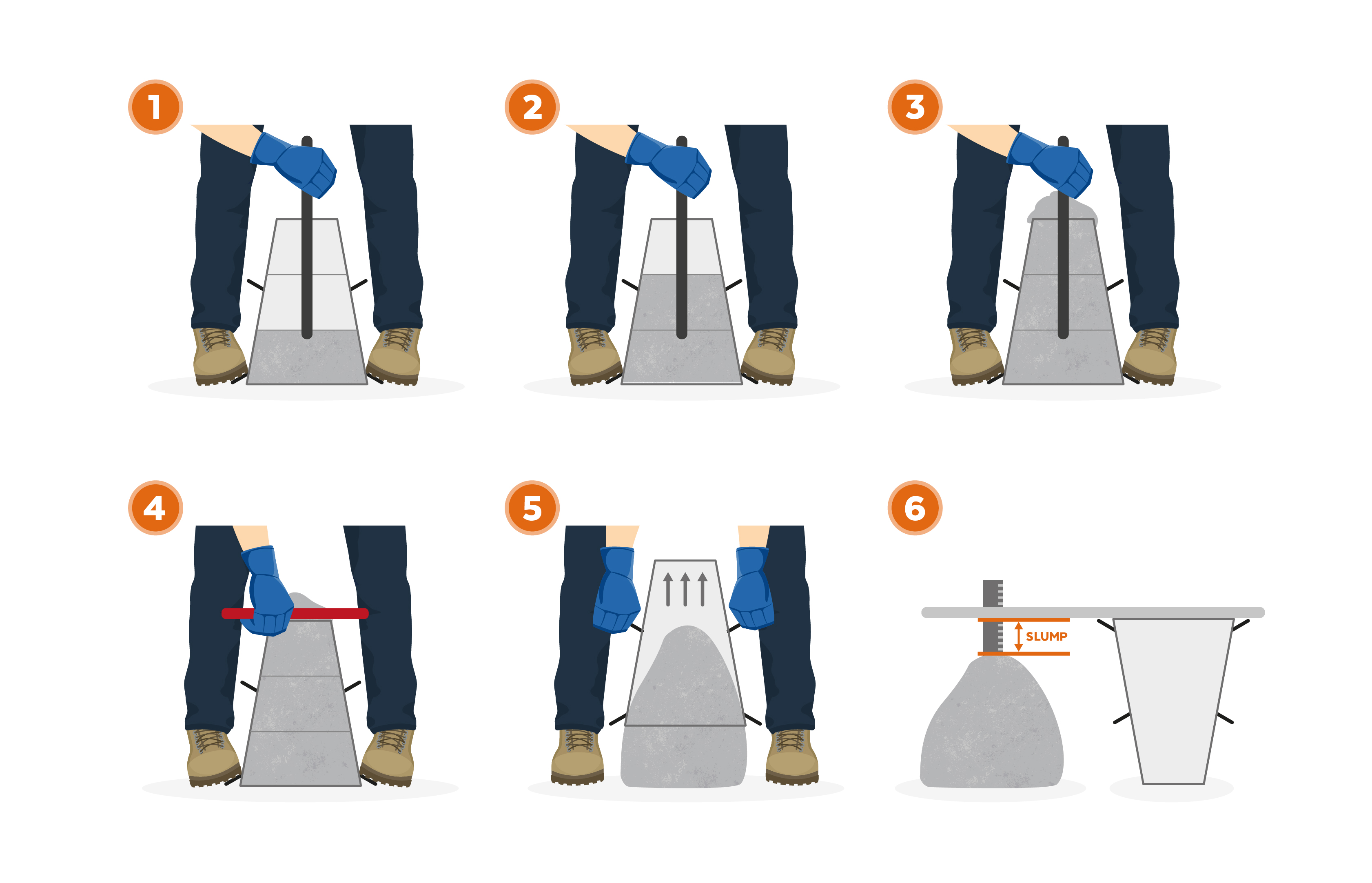

Slump Chart For Concrete - Obtaining the right slump is key to building a stable. In normal reinforced concrete structures, the ideal. Concrete slump testing procedure & equipment | concrete slump chart ranges. The slump test is the most simple workability test for. Slump test values that deviate from project. Although a supplier will endeavour to provide the required value or range,. Once ready to begin the test, ensure that the slump cone is clean and secured to the base plate. Normal manually placed reinforced concrete / heavily reinforced. It emphasizes such aspects of construction as site. Web a concrete slump chart can aid in interpreting the slump values, indicating whether the concrete mix is too dry or too wet. It is performed to check the workability of freshly made concrete, and therefore the ease with. Normal manually placed reinforced concrete / heavily reinforced. Web concrete slump test is carried out from batch to batch to check the uniform quality of concrete during construction. Web for most exterior decorative concrete, a slump ranging from 4 to 5 inches is ideal.. Web the concrete slump test measures the workability of hydraulic cement concrete, verifying the consistency of various concrete loads under field conditions. Slump, in (mm) degree of workability. Web concrete slump is the measure that tells us about the consistency and workability of fresh concrete before it sets — essentially, it’s the flow factor. The slump test is the most. Web the concrete slump test measures the workability of hydraulic cement concrete, verifying the consistency of various concrete loads under field conditions. If the slump for the mix is not specified, determine the appropriate maximum slump from the table below, the minimum slump of 1 in (25 mm) is already. Web the concrete slump test assesses the consistency and workability. Web the acceptable tolerances of the concrete slump are specified in the project specifications or as part of the concrete mix design. Normal manually placed reinforced concrete / heavily reinforced. Web slump cone is placed over a 200 mm diameter circle on the base plate and filled with scc mix in such a way that concrete is not leaked from. Web slump cone is placed over a 200 mm diameter circle on the base plate and filled with scc mix in such a way that concrete is not leaked from the bottom of the cone without any. Normal manually placed reinforced concrete / heavily reinforced. The slump test is the most simple workability test for. The purchaser of the concrete. Slump, in (mm) degree of workability. You want the mix to be similar in consistency to thick oatmeal, without being watery. It emphasizes such aspects of construction as site. Web slump cone is placed over a 200 mm diameter circle on the base plate and filled with scc mix in such a way that concrete is not leaked from the. You want the mix to be similar in consistency to thick oatmeal, without being watery. It emphasizes such aspects of construction as site. Normal manually placed reinforced concrete / heavily reinforced. Web updated april 1, 2024. Once ready to begin the test, ensure that the slump cone is clean and secured to the base plate. Concrete slump testing procedure |. Obtaining the right slump is key to building a stable. Concrete slump testing procedure & equipment | concrete slump chart ranges. You want the mix to be similar in consistency to thick oatmeal, without being watery. Web a concrete slump chart can aid in interpreting the slump values, indicating whether the concrete mix is too. Web updated april 1, 2024. Concrete slump indicates the workability and moisture levels of a concrete mixture. There are 5 consistency classes, ranging from s1 to s5. Web the concrete slump test results are interpreted using table b.1 of bs 8500 as shown below. In normal reinforced concrete structures, the ideal. Web the concrete slump test measures the workability of hydraulic cement concrete, verifying the consistency of various concrete loads under field conditions. Web a concrete slump chart can aid in interpreting the slump values, indicating whether the concrete mix is too dry or too wet. Once ready to begin the test, ensure that the slump cone is clean and secured. It emphasizes such aspects of construction as site. Web workability of concrete by slump test. You want the mix to be similar in consistency to thick oatmeal, without being watery. If the slump for the mix is not specified, determine the appropriate maximum slump from the table below, the minimum slump of 1 in (25 mm) is already. Web step1, choice of slump: Web concrete slump test is carried out from batch to batch to check the uniform quality of concrete during construction. The purchaser of the concrete is responsible. Web the concrete slump test measures the consistency of fresh concrete before it sets. There are 5 consistency classes, ranging from s1 to s5. Slump, in (mm) degree of workability. Web the concrete slump test assesses the consistency and workability of concrete before it sets, with the slump cone being a vital instrument for measuring the mixture’s fluidity,. In normal reinforced concrete structures, the ideal. Concrete slump testing procedure |. Web a concrete slump chart can aid in interpreting the slump values, indicating whether the concrete mix is too dry or too wet. Web the concrete slump test results are interpreted using table b.1 of bs 8500 as shown below. Concrete in class s1 is a.

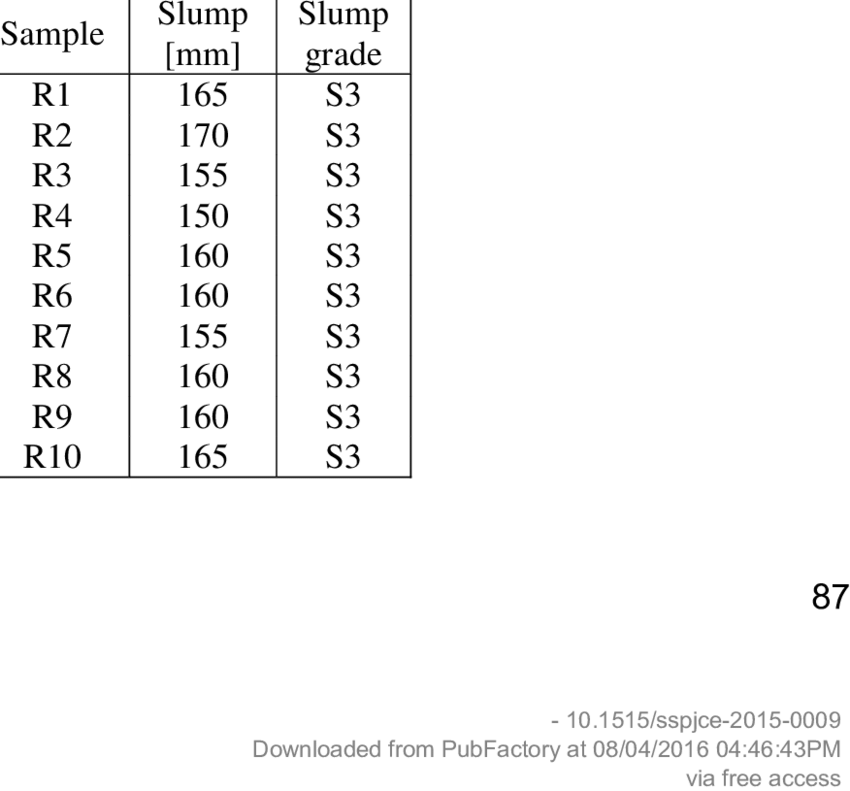

Slump Test Results

Slump For Beams And Slabs The Best Picture Of Beam

CE Blog ACI METHOD OF CONCRETE MIX DESIGN

What Is Meant By ‘Concrete Slump’ & Why Does It Matter? Total Concrete

The Slump value of normal and high strength concrete Download High

Building Guidelines Concrete Testing and Mixes

Table 4 from THE USE AND ABUSE OF THE SLUMP TEST FOR MEASURING THE

Slump Test of Concrete

Concrete Slump Tests Measuring the Workability of Concrete Total

Table 4 from THE USE AND ABUSE OF THE SLUMP TEST FOR MEASURING THE

Web The Concrete Slump Test Measures The Workability Of Hydraulic Cement Concrete, Verifying The Consistency Of Various Concrete Loads Under Field Conditions.

Obtaining The Right Slump Is Key To Building A Stable.

Once Ready To Begin The Test, Ensure That The Slump Cone Is Clean And Secured To The Base Plate.

Web The Acceptable Tolerances Of The Concrete Slump Are Specified In The Project Specifications Or As Part Of The Concrete Mix Design.

Related Post: