Shaft Torque Chart

Shaft Torque Chart - = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75% of the proof loads specified by the standard. Where r is the length and direction of the lever arm. Web if your swing speed is around 90 mph, you are right on the line between a regular shaft and a stiff shaft. If you read the first shafts 101, you know that there are virtually no industry standards in shafts. Web as you try different shafts, the fitter should solicit feedback about feel (flex, weight, impact) and performance, and evaluate how each shaft affects ball flight. Web the basic rules when choosing a shaft with the right torque are as follows: It is measured in degrees and indicates the resistance of the shaft to twisting forces. T = τ × \frac {j} {r} t = τ × rj. Web torque is the rotational resistance of a golf shaft, measured in degrees, indicating how much the shaft will twist during a swing. Web torque is really pretty simple: Web when a shaft is subjected to a torque or twisting a shearing stress is produced in the shaft. Project x shafts are known for their premium materials and craftsmanship. The torque speciication for this center axle nut is critical to performance and function of the wheel hub. Web if your swing speed is around 90 mph, you are right. A shaft with 3 degrees of torque will twist less than a shaft with 5 degrees of torque, and so on. Web to the average golfer, a shaft with a low torque number such as 2.1 degrees would feel like you're swinging a pipe. A club fitter will measure your swing and then match you up with an optimal shaft. Web as you try different shafts, the fitter should solicit feedback about feel (flex, weight, impact) and performance, and evaluate how each shaft affects ball flight. T = τ × \frac {j} {r} t = τ × rj. Somewhere along the line, you might have heard that lower torque shafts are more accurate. Web shaft torque refers to the amount. Higher torque shaft has a big impact on performance. I feel one of the best ways to look at a range of shaft offerings is to plot the trajectory effect of a shaft against the flex. Putting the proper torque on the center axle nut sets the preload for the bearing and keeps the bearing from separating while in operation.. Web torque is a property of golf shafts that describes how much the shaft is prone to twisting during the golf swing. The technical aspects of torque. Where r is the length and direction of the lever arm. Putting the proper torque on the center axle nut sets the preload for the bearing and keeps the bearing from separating while. Web torque is the rotational resistance of a golf shaft, measured in degrees, indicating how much the shaft will twist during a swing. Web if your swing speed is around 90 mph, you are right on the line between a regular shaft and a stiff shaft. If you read the first shafts 101, you know that there are virtually no. Web not every shaft has the torque number emblazoned on the shaft, but if you happen to play a project x hzrdus or aldila rogue — these are just a few examples — you might notice a number with a. Web as you try different shafts, the fitter should solicit feedback about feel (flex, weight, impact) and performance, and evaluate. Web weight and torque options: = clamp load for j429 grade 5 and 8, fnl grade 9, a574, class 4.6, 8.8, 10.9 and 12.9, the clamp loads are listed at 75% of the proof loads specified by the standard. A new shaft that matches your ball speed and club head speed can do wonders to your game. Web shaft torque. Web torque is a property of golf shafts that describes how much the shaft is prone to twisting during the golf swing. Web torque is the measurement of a shaft’s resistance to rotational twisting. As such, a low torque shaft will twist less than a high torque shaft, and vice versa. What does it really mean? T = τ ×. Project x shafts come in various weights and torque ratings. The shear stress varies from zero in the axis to a maximum at the outside surface of the shaft. Web to the average golfer, a shaft with a low torque number such as 2.1 degrees would feel like you're swinging a pipe. Web weight and torque options: Web shaft torque. Torque is a vital component to how a shaft feels as you swing the club. Web the torque of a golf shaft refers to how prone the shaft is to twisting when you swing the club. A low torque rating means the shaft has less twisting, while a high torque rating indicates more twisting. Web be torqued down onto the axle shaft to a speciic torque value. All shafts, steel and graphite, exhibit torque, which is measured in degrees. Every shaft, regardless of material or flex, exhibits torque, which is measured in degrees. The torque speciication for this center axle nut is critical to performance and function of the wheel hub. It is measured in degrees and indicates the resistance of the shaft to twisting forces. Web what does shaft torque actually do? If you read the first shafts 101, you know that there are virtually no industry standards in shafts. The shaft will have a boardy feeling and stout. How many degrees will the shaft twist under a certain amount of force), and you’ll typically see measurements as low as 2°. Assume the allowable shear stress of mild steel τ = 42 mpa. Web torque is the measurement of a shaft’s resistance to rotational twisting. Somewhere along the line, you might have heard that lower torque shafts are more accurate. Measuring torque is no exception.Torque Chart Av1 PDF Electrical Connector Pump

Driver Shaft Length Fitting Chart

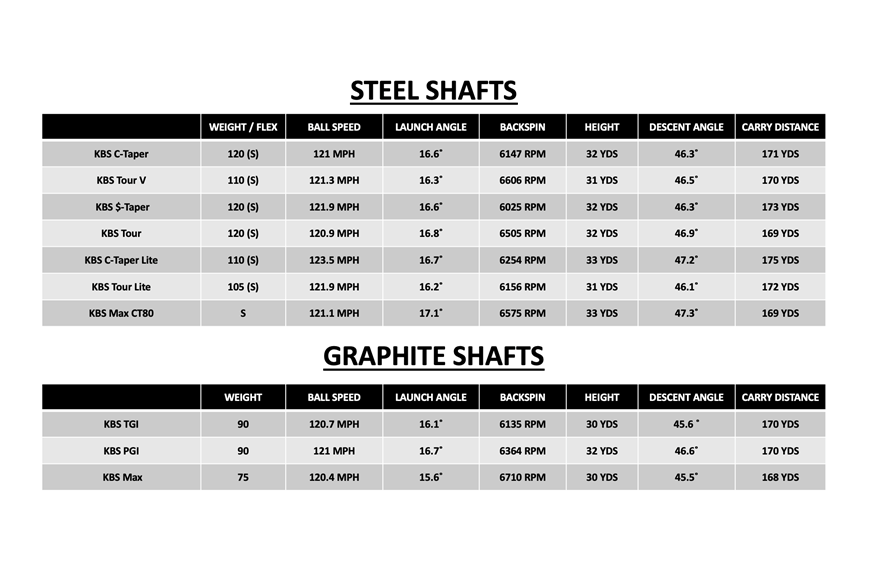

Which 2023 KBS iron shaft is best for you? Today's Golfer

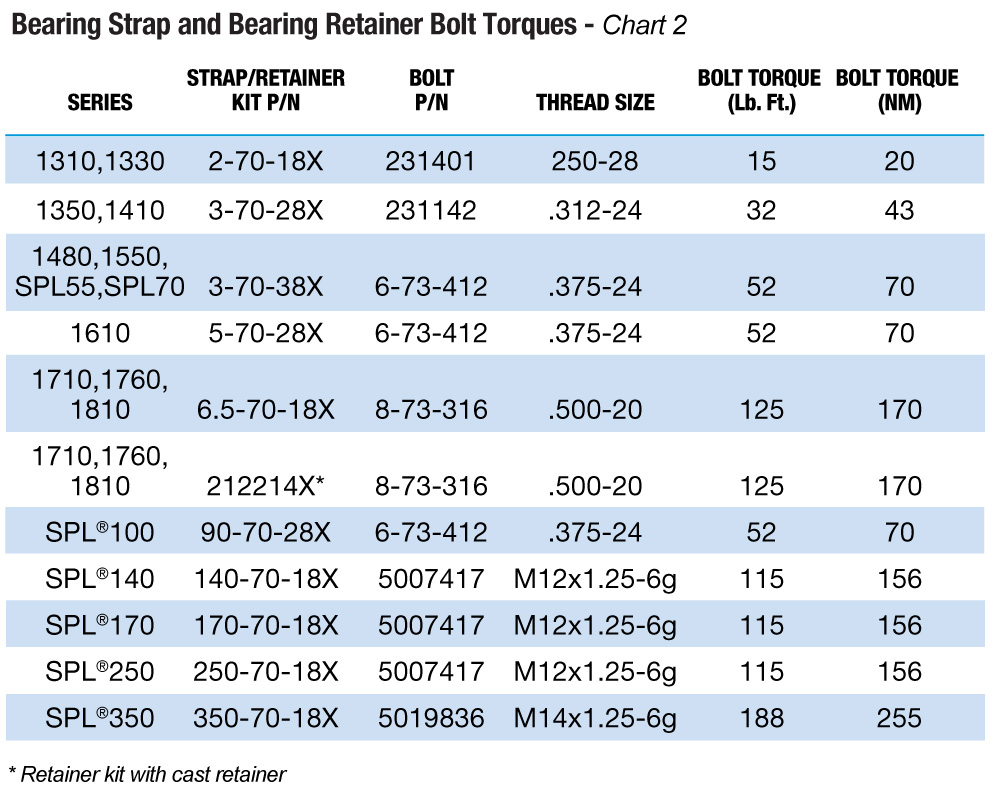

Spicer® Driveshaft Lube & Torque Specification Spicer Parts

Kbs Iron Shafts Chart

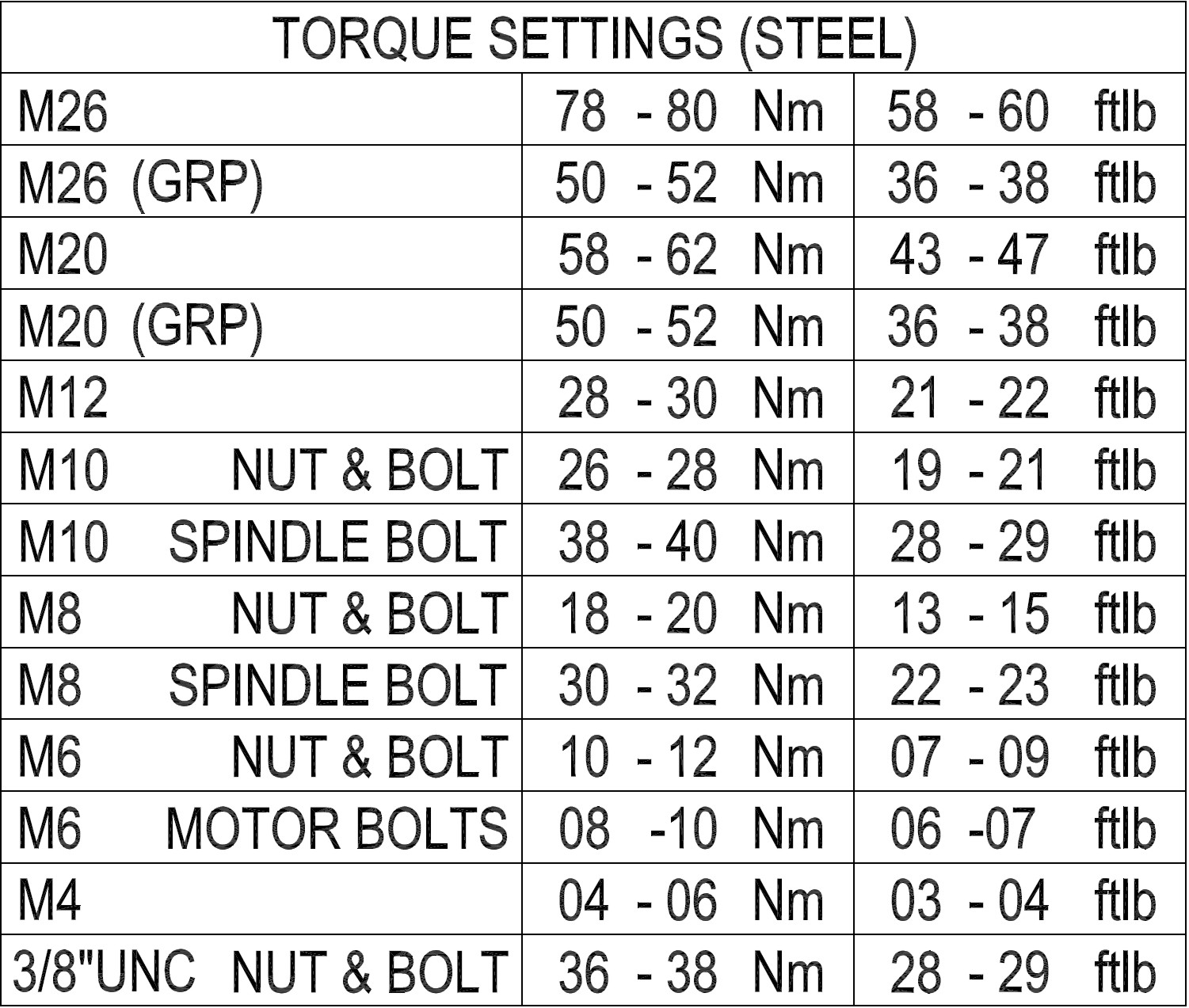

Torque Charts Industrial Torque Tools

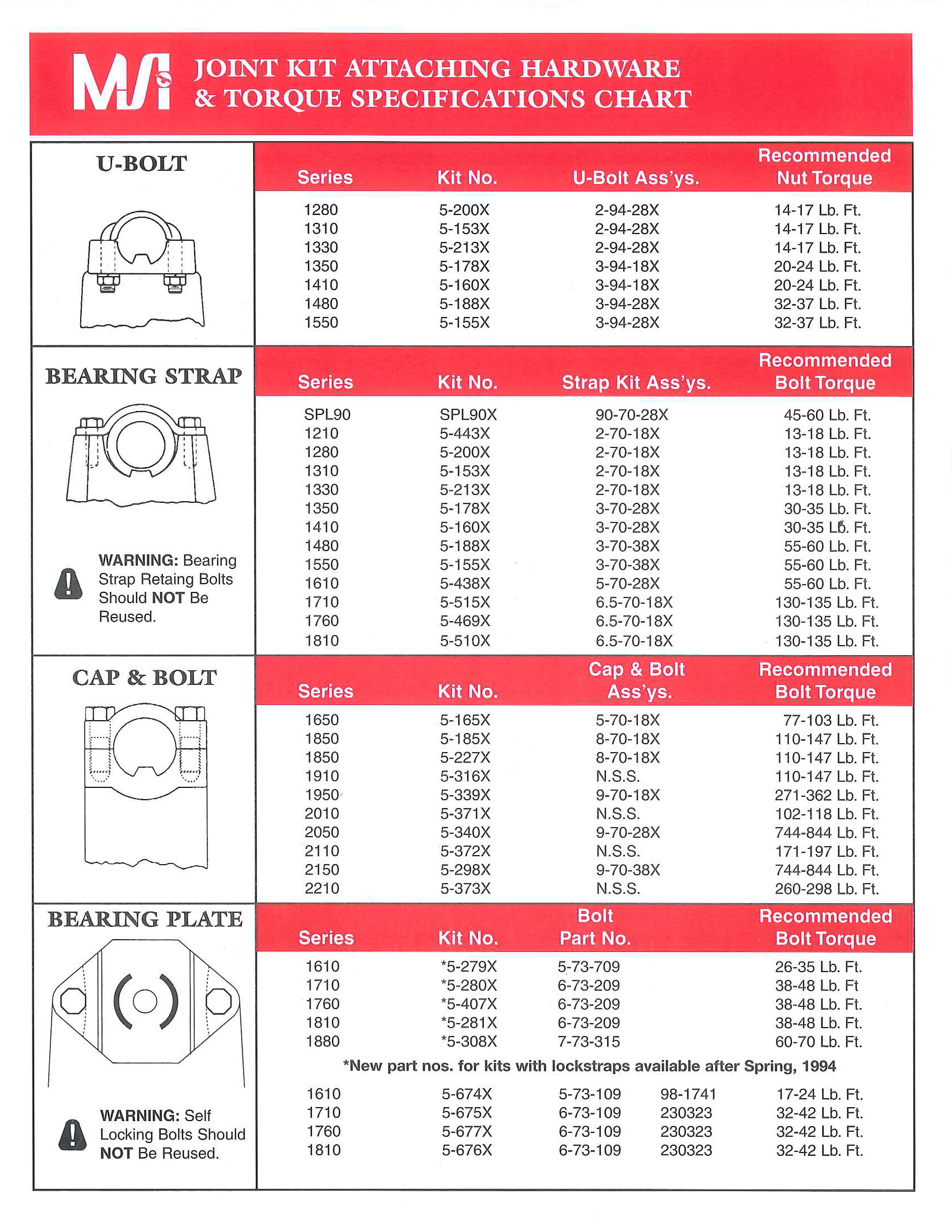

Torque Specifications Machine Service, Inc.

shaftprofilechart2021nav Fujikura Golf

Q&A How Often to ReTorque Toyota Sienna XLE Drive Shaft Bolt?

Support Hepworth WWT

Testing Two Near Identical Shafts With Two Different Torque Ratings To Determine What Effect On Ball Flight Can Occur By Isolating That Variable.

For A307 Grade A, 75% Of 36,000 Psi Is Utilized.

Torque Is Measured In Degrees (Meaning:

Project X Shafts Come In Various Weights And Torque Ratings.

Related Post: