Screen Printing Size Chart

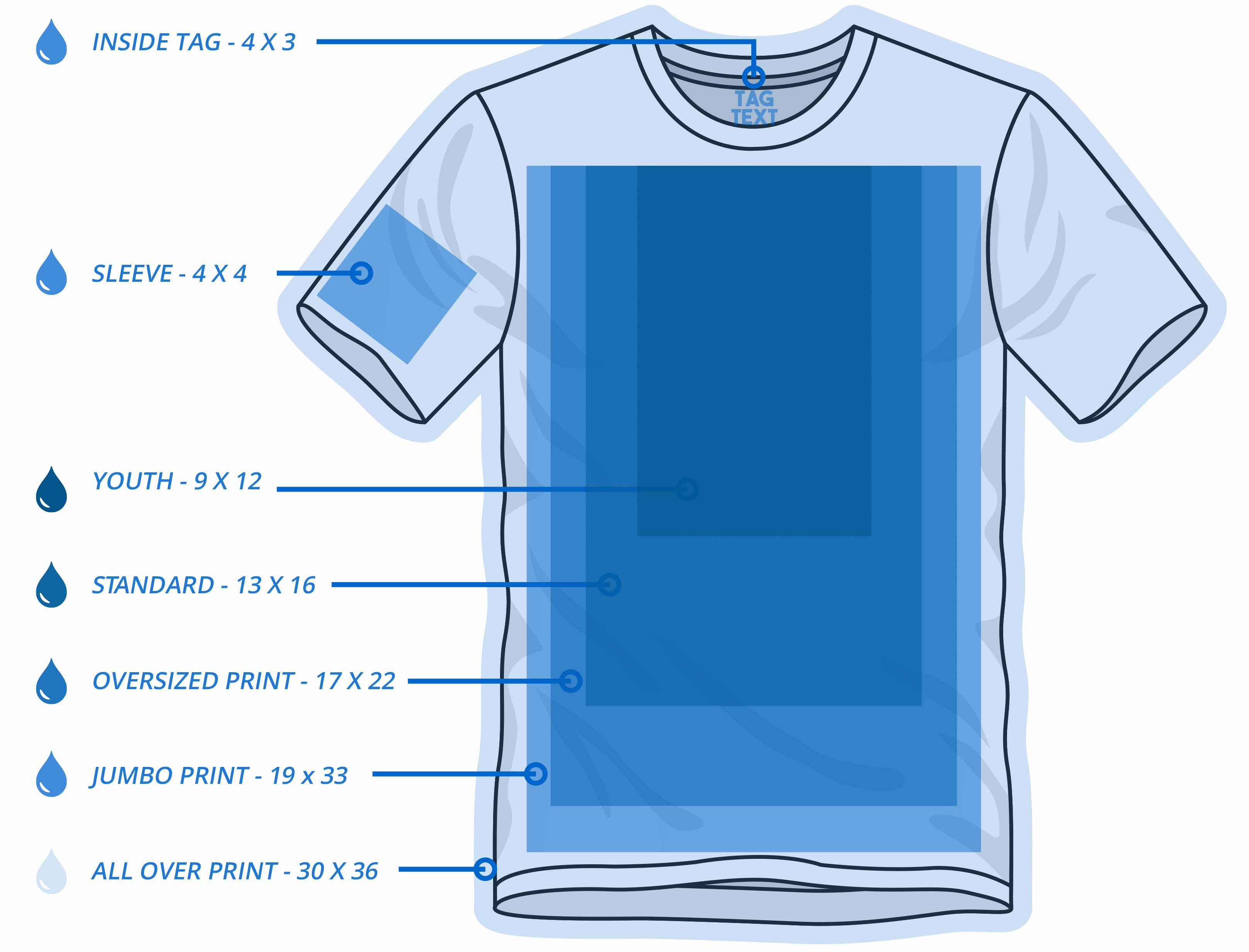

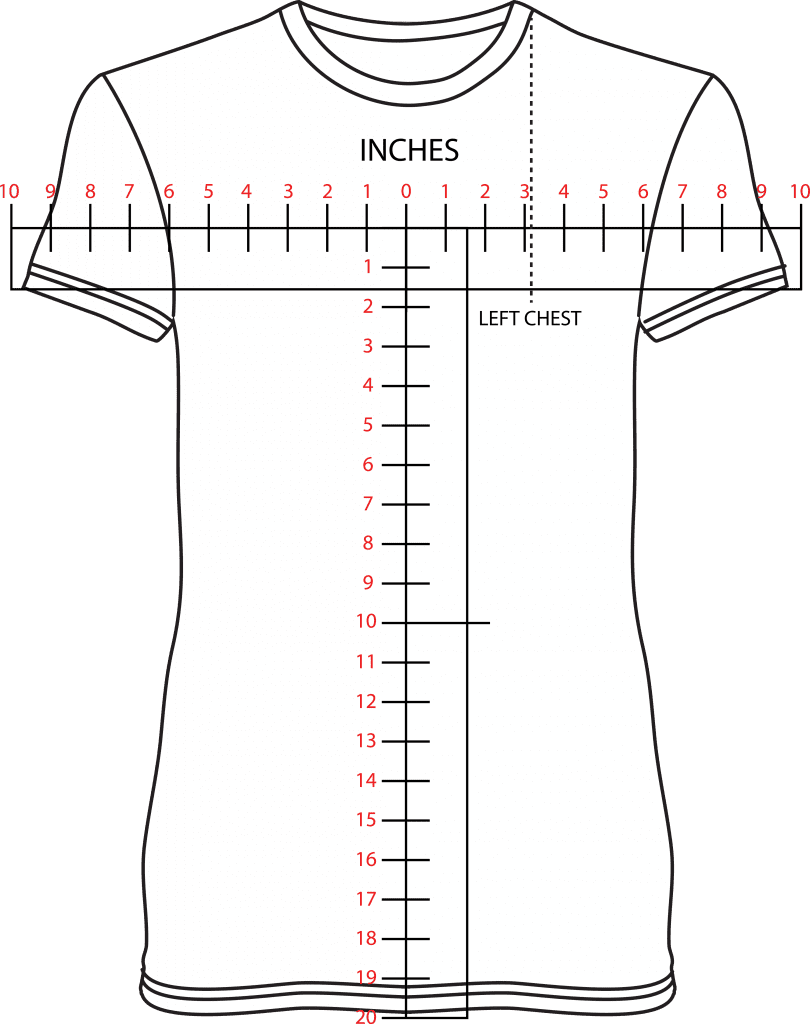

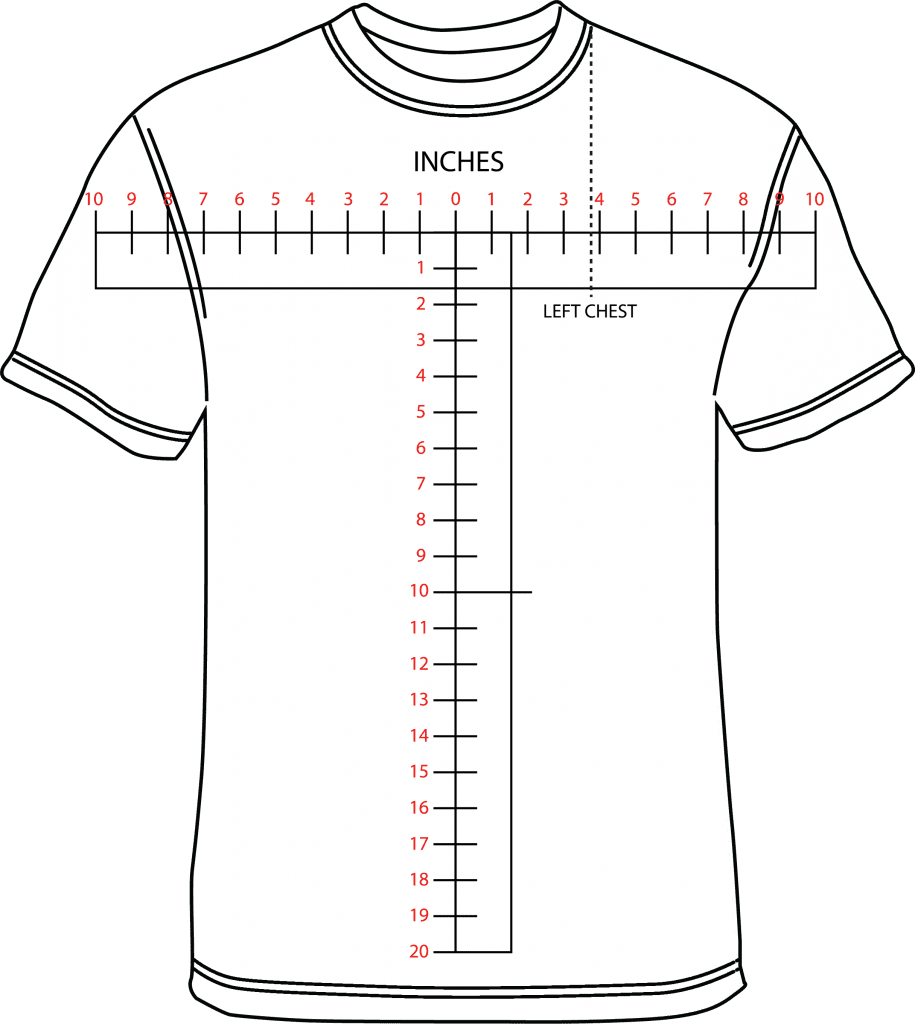

Screen Printing Size Chart - Web the screen printing mesh count chart is a crucial reference for those in the screen printing industry, aimed at delivering optimal print outcomes. Screen printing size & placement. Proper print placement can be difficult even for experienced screen printers. The first thing you’ll want to determine is the placement of the design. Web screen printing at home? What ink is being used? Web to decide which mesh count you need to use, you should consider the details of the print: Mesh count in screen printing refers to the number of polyester threads crossing each other per square inch on a screen; We hope you find the guide super helpful. Measure the height and width of the artwork to ensure it fits comfortably within the chosen. What ink is being used? 110 mesh lays a fairly thick layer of ink down. Method provides mockups in a final quote to provide a visual reference of your designs scale and placement. Web in this post, we’ll cover various design sizes, and how to determine the best size for what you are printing. What material (substrate) is being printed. Where should it be placed? What material (substrate) is being printed on? Before choosing a screen size, determine the dimensions of your design. Sizing shown is approximate and will vary in appearance depending on size, style and brand of garment. Screen printing size and placement reference. Web 110 to 160 mesh count screens are the most versatile and the most commonly used in screen printing. Web quick reference guide. What ink is being used? Web what is a mesh count? How much detail does the image have? The max print area of a location may alter depending on the garment style, manufacturing and smallest size chosen for print. Where should it be placed? What material (substrate) is being printed on? Screen mesh size refers to the number of threads per inch in the mesh fabric, and it can affect factors such as ink coverage, detail, and opacity.. Screen printing size and placement reference. The most standard mesh counts in screen printing are 110 and 156. Web what is a mesh count? Web the 2 most common sizes used for screen printing are 20x24 inches od (outside dimension) and 23x31 inches od. Supplies | equipment | classes. The higher the mesh count, the finer the threads and holes are in the screen. As one of the most frequently asked questions in the promotional products biz, we created a guide to put the answers at your fingertips. With higher counts providing finer detail and lower counts accommodating thicker inks or. In this system, there are eight standard photo. Web regarding screen printing, common screen sizes can range from 13″ x 15″ to 30″ x 40″. Measure the height and width of the artwork to ensure it fits comfortably within the chosen. Screen printing size & placement. Tune in for free print advice at norcal screen print supply. Web there’s a lot to consider when talking about print placement. Measure the height and width of the artwork to ensure it fits comfortably within the chosen. Before choosing a screen size, determine the dimensions of your design. Learn how to choose the right screen size, placement, and. The higher the mesh count, the finer the threads and holes are in the screen. Mesh count is determined by how many threads. Where should it be placed? Proper print placement can be difficult even for experienced screen printers. Web screen printing at home? The most standard mesh sizes are 110 & 156. The most standard mesh counts in screen printing are 110 and 156. Screen mesh size refers to the number of threads per inch in the mesh fabric, and it can affect factors such as ink coverage, detail, and opacity. Screens on the lower end of the mesh count spectrum put down heavier ink deposits and are ideal for printing underbases or printing bold colors on dark fabrics. The second system of photo. Here’s one swift product guide for measuring the sizes of publications: Web the dimensions for the printing sizes vary greatly, starting from 2.91″ x 4.13″ and going all the way up to 33.11″ x 46.81″. 110 mesh lays a fairly thick layer of ink down. 156 mesh also lays down a thick layer of ink but offers higher detail. The first thing you’ll want to determine is the placement of the design. The most standard mesh sizes are 110 & 156. Screen printing size and placement reference. The second system of photo printing is more common and is used by most photo printing labs around the world. Proper print placement can be difficult even for experienced screen printers. As one of the most frequently asked questions in the promotional products biz, we created a guide to put the answers at your fingertips. Tune in for free print advice at norcal screen print supply. Supplies | equipment | classes. Web regarding screen printing, common screen sizes can range from 13″ x 15″ to 30″ x 40″. Don’t worry about having all the answers. Screens on the lower end of the mesh count spectrum put down heavier ink deposits and are ideal for printing underbases or printing bold colors on dark fabrics. Here’s a guide to lining up and sizing popular design placements on garments.

Get quality screen printing services from the best company

Screen Printing Sizing And Placement Guides Kick Print

ESP Custom Screen Printing Print Size Guide — ESP

Screen Printing Imprint Sizing Chart Custom Design Placement Chart

Screen Printing Placement Chart Reviews Of Chart

Window Screen Mesh Size Chart

Screen Printing Placement Chart Reviews Of Chart

Screen Print Size Chart

Screenprint sizing & placement guide ecoprintlab Screen printing

screen print size chart Google Search sprintsize Pinterest Heat

One Of The Most Important Parts Of Successful Screen Printing Is Understanding How Mesh Count Relate To Print Quality.

Here Are Some Popular Placements.

The Higher The Mesh Count, The Finer The Threads And Holes Are In The Screen.

If You Have Any Questions, Don't Hesitate To Get In Touch!

Related Post: