Run Chart Vs Control Chart

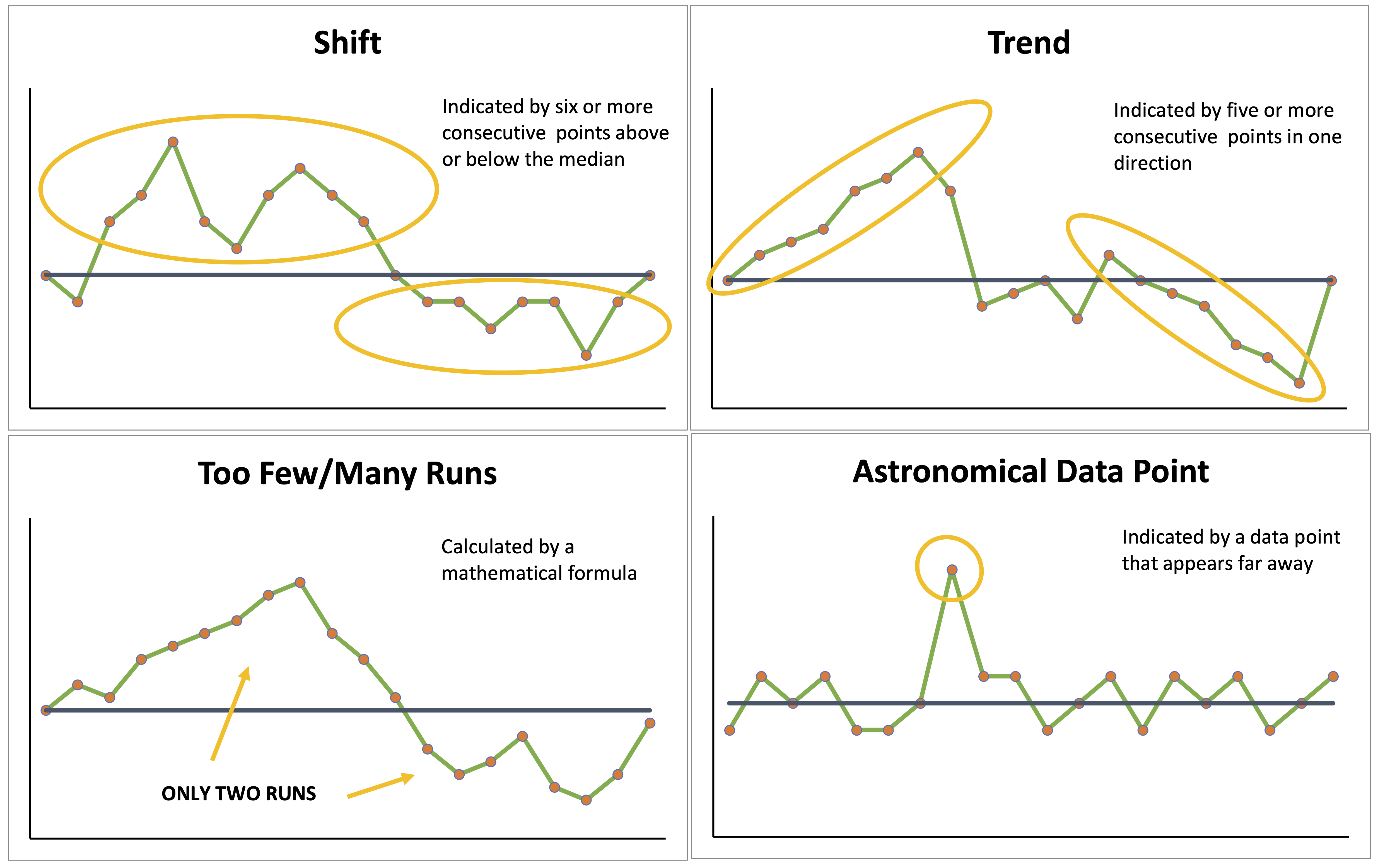

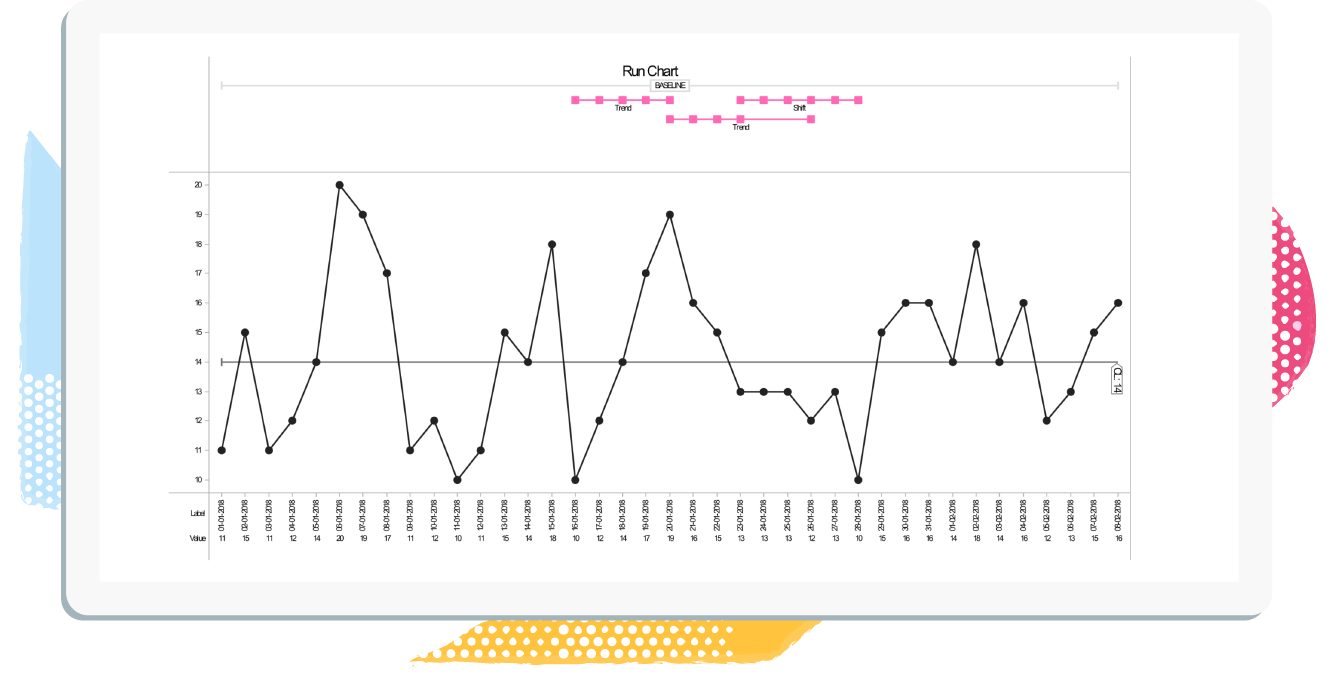

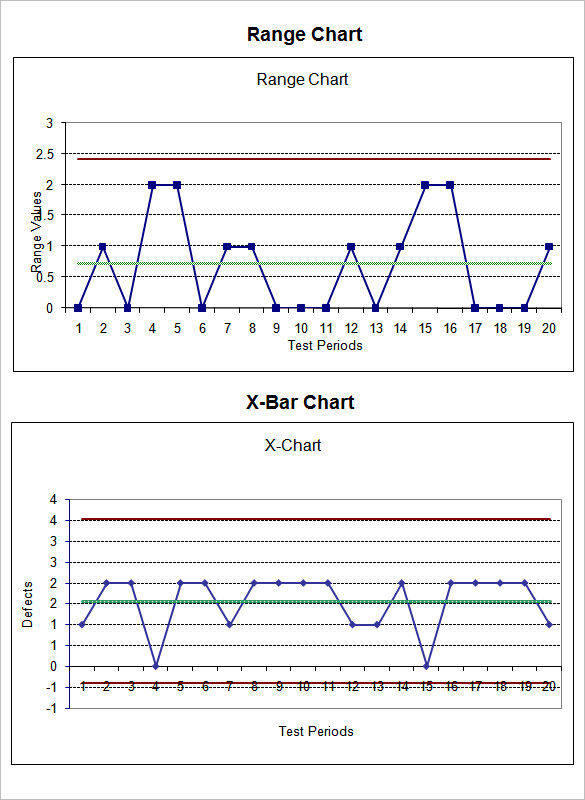

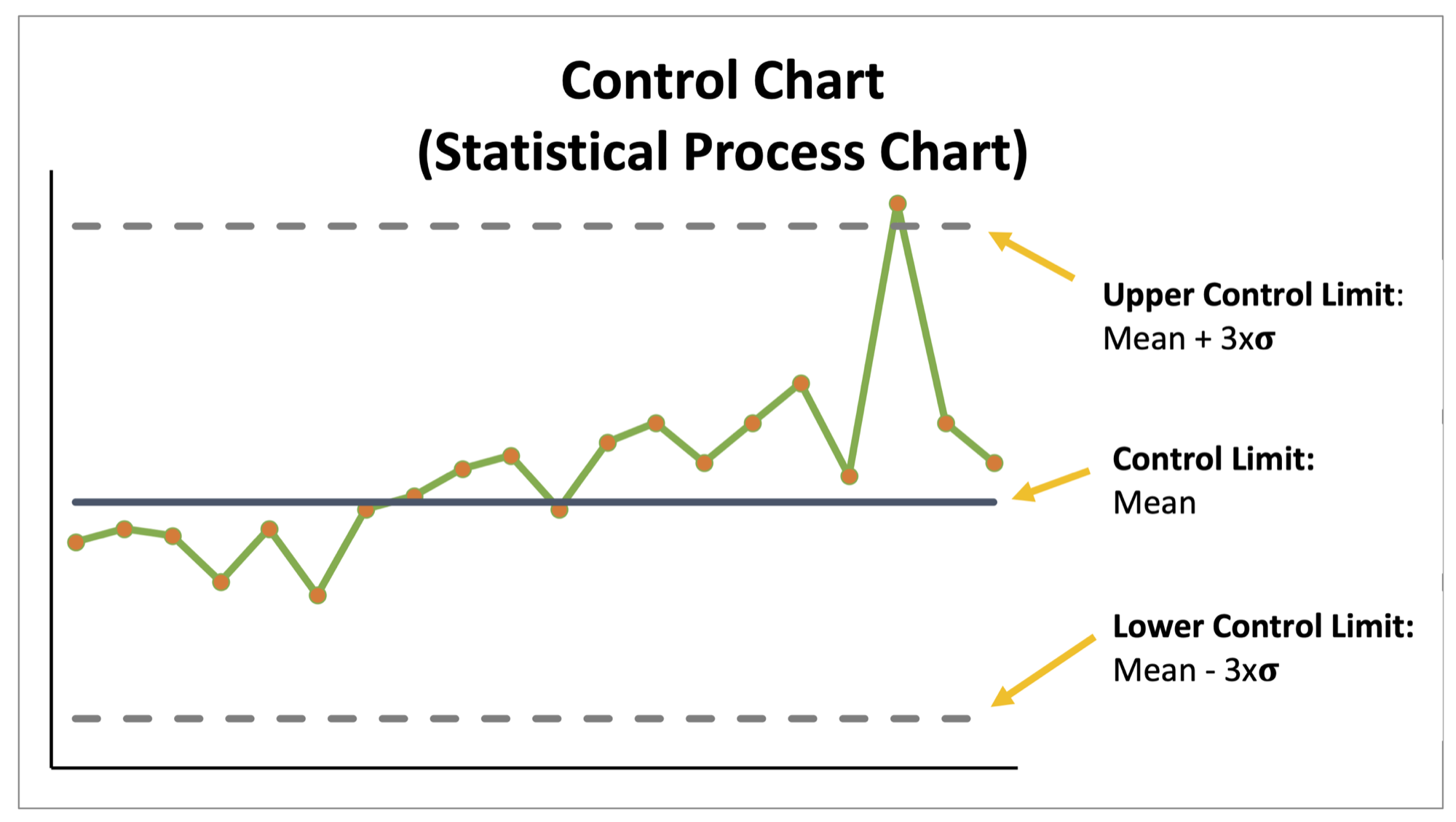

Run Chart Vs Control Chart - Typically it is a two dimensional graph in which one axis shows time and the other axis shows the value. When determining whether a process is stable (in statistical control) A process is in control when based on past experience it can be predicted how the process will vary (within limits) in. Web but they also have key differences. Web what’s the difference between a run chart and a control chart? What is a run chart? A stable process operates within an ordinary, expected range of variation. Web control chart vs run chart vs histogram. • the central line on a control chart is the mean of the Web control charts are simple but very powerful tools that can help you determine whether a process is in control (meaning it has only random, normal variation) or out of control (meaning it shows unusual variation, probably due to a special cause). Through analysis of a run chart, the following can be derived: Web understanding when to employ control charts can significantly boost your process management capabilities. Winred, the payment processor for republican campaign donations, crashed after former president. Run charts and control charts are both important and valid qi tools, but have very different analytical and reporting abilities. When a process. Web elements of a control chart a control chart is similar to a run chart in so far as it plots a measurement over time. However, it will graphically depict how. Web while run charts provide intuitive visuals to show trends and patterns, control charts add statistical control limits to determine stability and make the analysis more rigorous. Web but. Web run chart : Typically it is a two dimensional graph in which one axis shows time and the other axis shows the value. Web control charts help prevent overreactions to normal process variability while prompting quick responses to unusual variation. A run chart simply plots the data of a variable over time. Web a run chart is a simple. Web run charts are used to track the progress of a project over time. Changes / trends of the process over time. Once i got used to these new (and super useful!) tools, there was something i noticed… Web supporters of donald trump after the guilty verdict on thursday. Changes are inevitable, but you have to be swift in responding. When predicting the expected range of outcomes from a process. Any pattern / cycle of the process. Web variable control charts contribute to quality improvement in healthcare by enabling visualization and monitoring of variations and changes in healthcare processes. Chartexpo’s control charts allow you to respond to these changes proactively. Web control charts incorporate statistical calculations, control limits, and help. Run charts are similar in some regards to the control charts used in statistical process control, but do not show the control limits of the process. Changes are inevitable, but you have to be swift in responding to fluctuations in performance and quality. A run chart is a simple graph. Any pattern / cycle of the process. Examples of a. Web elements of a control chart a control chart is similar to a run chart in so far as it plots a measurement over time. Web variable control charts contribute to quality improvement in healthcare by enabling visualization and monitoring of variations and changes in healthcare processes. You have the chance to act before issues occur! Web by opex learning. A run chart simply plots the data of a variable over time. Web control charts and run charts have a few things in common, namely monitoring process performance. The displayed data in a run chart mostly show trends, the performance of manufacturing, etc. When predicting the expected range of outcomes from a process. Winred, the payment processor for republican campaign. They can be used to identify special causes of variation in a process. Web in may, south africa’s constitutional court barred zuma from running for parliament following his 2021 contempt of court conviction; A run chart is a simple graph. Web both charts are handy; You have the chance to act before issues occur! Both charts have their unique attributes and applications. Web control charts incorporate statistical calculations, control limits, and help in identifying systematic variations, while run charts offer a basic representation of data points plotted against time. When predicting the expected range of outcomes from a process. Web control charts help prevent overreactions to normal process variability while prompting quick responses to. You may well have come across both run charts and control charts in your qi journey so far. A stable process operates within an ordinary, expected range of variation. However, he remains the face of the party and is expected to. Let’s explore these charts and see how they work. The differences are as follows: Web supporters of donald trump after the guilty verdict on thursday. The displayed data in a run chart mostly show trends, the performance of manufacturing, etc. With the proper use of the former, you can eliminate errors in products and processes and focus on improving the process. You have the chance to act before issues occur! Web it didn’t take long for me to realize that pareto charts are essentially just compound column and line charts, a run chart is just a line chart with a median line, and control charts are line charts that also show mean and special standard deviations. Each task or activity is represented by a bar on the gantt chart, and the length of the bar. They can be used to identify trends and patterns in project data. Web both charts are handy; However, it will graphically depict how. They can be used to identify special causes of variation in a process. Examples of a run chart:Run Chart Template

Example Of A Run Chart

Control Chart versus Run Chart in Quality Control projectcubicle

Run Chart vs Control Chart

Control Chart Versus Run Chart PM Study Circle

13+ Free Run Chart Template Sample Excel Templates

Control Chart Healthcare

Understanding Run Chart Vs Control Chart PMP

![Run Chart vs Control Chart Comprehensive Comparison [2024]](https://deeprojectmanager.com/wp-content/uploads/2023/11/Run-Chart-vs-Control-Chart.png)

Run Chart vs Control Chart Comprehensive Comparison [2024]

Run Charts Improvement

Web Control Charts Are Simple But Very Powerful Tools That Can Help You Determine Whether A Process Is In Control (Meaning It Has Only Random, Normal Variation) Or Out Of Control (Meaning It Shows Unusual Variation, Probably Due To A Special Cause).

Changes / Trends Of The Process Over Time.

A Run Chart Simply Plots The Data Of A Variable Over Time.

Web Control Charts Incorporate Statistical Calculations, Control Limits, And Help In Identifying Systematic Variations, While Run Charts Offer A Basic Representation Of Data Points Plotted Against Time.

Related Post: