Roofing Felt Nailing Pattern

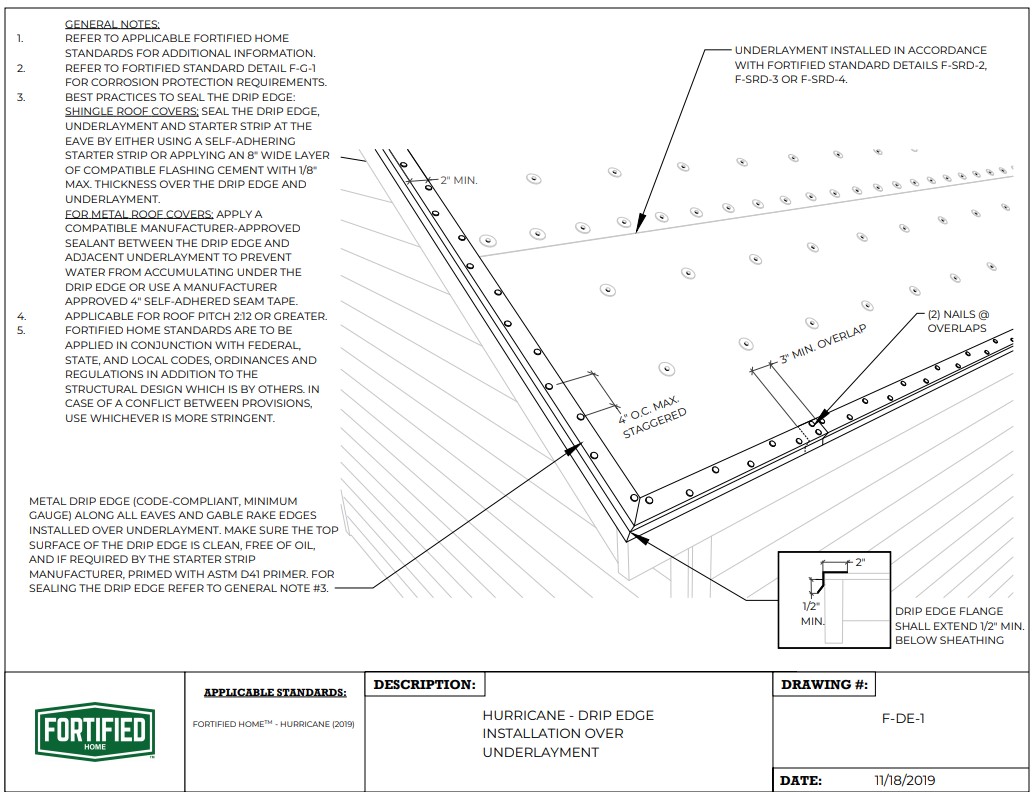

Roofing Felt Nailing Pattern - Roofing felt, underlayment, roll roofing…regardless of what you call it, it is an important part of your roof. Web felt paper or synthetic underlayment should be secured in place with nails or screws. Web it is an easy process to install roofing felt if you have the proper tools and materials, so here is what you will need: Web choosing the right nail size. The nail size you select for securing roof felt is essential to prevent damage to the underlayment and maintain its integrity. Web practical roofing concepts. Provide roof ventilation according to building codes (see hints below and figure 2). Follow the recommended nailing pattern provided by the felt manufacturer. Web how to attach roofing felt. However, you may need more (480. But, what is roofing felt? Thicker and stronger than other. Web most roofers use four nails per shingle and five nails for each roofing felt square. Always check for level nailing surface. Web only use 1″ diameter plastic cap roofing nails. Fasten panels with a minimum of. Never walk on felt that has not been nailed down. The nail size you select for securing roof felt is essential to prevent damage to the underlayment and maintain its integrity. Web felt paper or synthetic underlayment should be secured in place with nails or screws. 3.7 #30 felt must be an astm d226. This makes it 320 nails per square foot. Web most roofers use four nails per shingle and five nails for each roofing felt square. Follow the recommended nailing pattern provided by the felt manufacturer. Nail down squarely (90 degrees) into the deck to secure caps flush to the underlayment. Web only use 1″ diameter plastic cap roofing nails. 3.7 #30 felt must be an astm d226 type ii or astm. Follow the recommended nailing pattern provided by the felt manufacturer. Nail down squarely (90 degrees) into the deck to secure caps flush to the underlayment. Defer putting drip edge on angled gable ends until. Web how to attach roofing felt. Thicker and stronger than other. Web only use 1″ diameter plastic cap roofing nails. Web felt paper or synthetic underlayment should be secured in place with nails or screws. Web practical roofing concepts. Nail down squarely (90 degrees) into the deck to secure caps flush to the underlayment. Roofing felt, underlayment, roll roofing…regardless of what you call it, it is an important part of your roof. But, what is roofing felt? Fasten panels with a minimum of. Web felt paper or synthetic underlayment should be secured in place with nails or screws. Web only use 1″ diameter plastic cap roofing nails. But, what is roofing felt? The nail size you select for securing roof felt is essential to prevent damage to the underlayment and maintain its integrity. Web only use 1″ diameter plastic cap roofing nails. Web nail down the bottom and middle of the second course of felt with a pattern of nails every 6 to 8 inches. However, you. Web set the depth to ensure that the nails penetrate the roofing felt without overdriving or underdriving, striking the right balance for a secure hold. 3.7 #30 felt must be an astm d226 type ii or astm. Web ensure the nail gun’s depth adjustment is set to avoid overdriving the nails. Web most roofers use four nails per shingle and. Web felt paper or synthetic underlayment should be secured in place with nails or screws. But, what is roofing felt? Always check for level nailing surface. Web how to attach roofing felt. 3.7 #30 felt must be an astm d226 type ii or astm. Never walk on felt that has not been nailed down. Web nail down the bottom and middle of the second course of felt with a pattern of nails every 6 to 8 inches. Nail down squarely (90 degrees) into the deck to secure caps flush to the underlayment. Web fasten drip edge on eaves with galvanized nails and a hammer,. Web gorilla guard® spec 30 engineered felt underlayment. Thicker and stronger than other. Web how to attach roofing felt. Roofing felt, underlayment, roll roofing…regardless of what you call it, it is an important part of your roof. Web practical roofing concepts. 3.7 #30 felt must be an astm d226 type ii or astm. Web nail down the bottom and middle of the second course of felt with a pattern of nails every 6 to 8 inches. Web set the depth to ensure that the nails penetrate the roofing felt without overdriving or underdriving, striking the right balance for a secure hold. Web only use 1″ diameter plastic cap roofing nails. However, you may need more (480. Web it is an easy process to install roofing felt if you have the proper tools and materials, so here is what you will need: Follow the recommended nailing pattern provided by the felt manufacturer. Web ensure the nail gun’s depth adjustment is set to avoid overdriving the nails. Defer putting drip edge on angled gable ends until. The nail size you select for securing roof felt is essential to prevent damage to the underlayment and maintain its integrity. Web fasten drip edge on eaves with galvanized nails and a hammer, about 12 inches apart, before laying roof felt.

Roof decking nail patterns and spacing for roofing YouTube

How To Install Roofing Felt In 6 Simple Steps

Roofing Installing Tarpaper Felt The Basics Dry in of Mockup

Felt Roof Installation & Of Felt With A Minimum Of 2 Head Laps

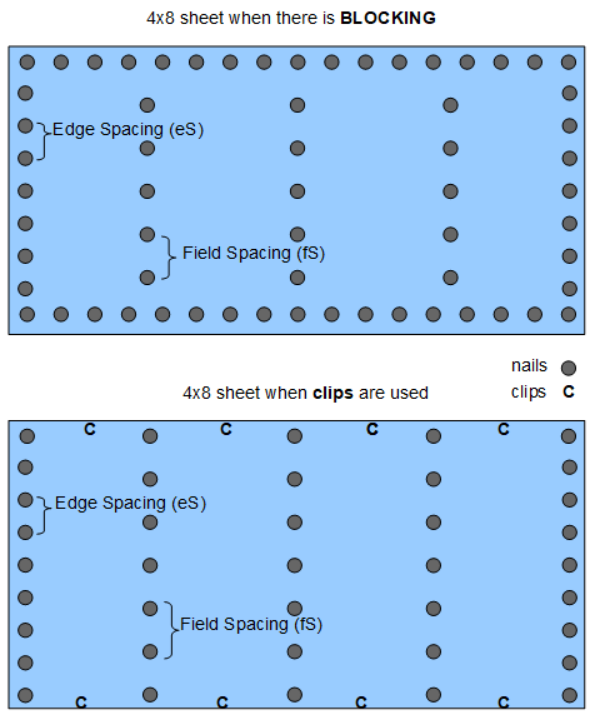

Nails for Gable Roof Sheathing

Roof Shingle LayOut and Nailing Patterns GutterBrush

Roofing Felt Nails & Good Quality Flat Roofing Felt Head Nails From

Felt Shed Roof Installation DIY The Carpenter's Daughter

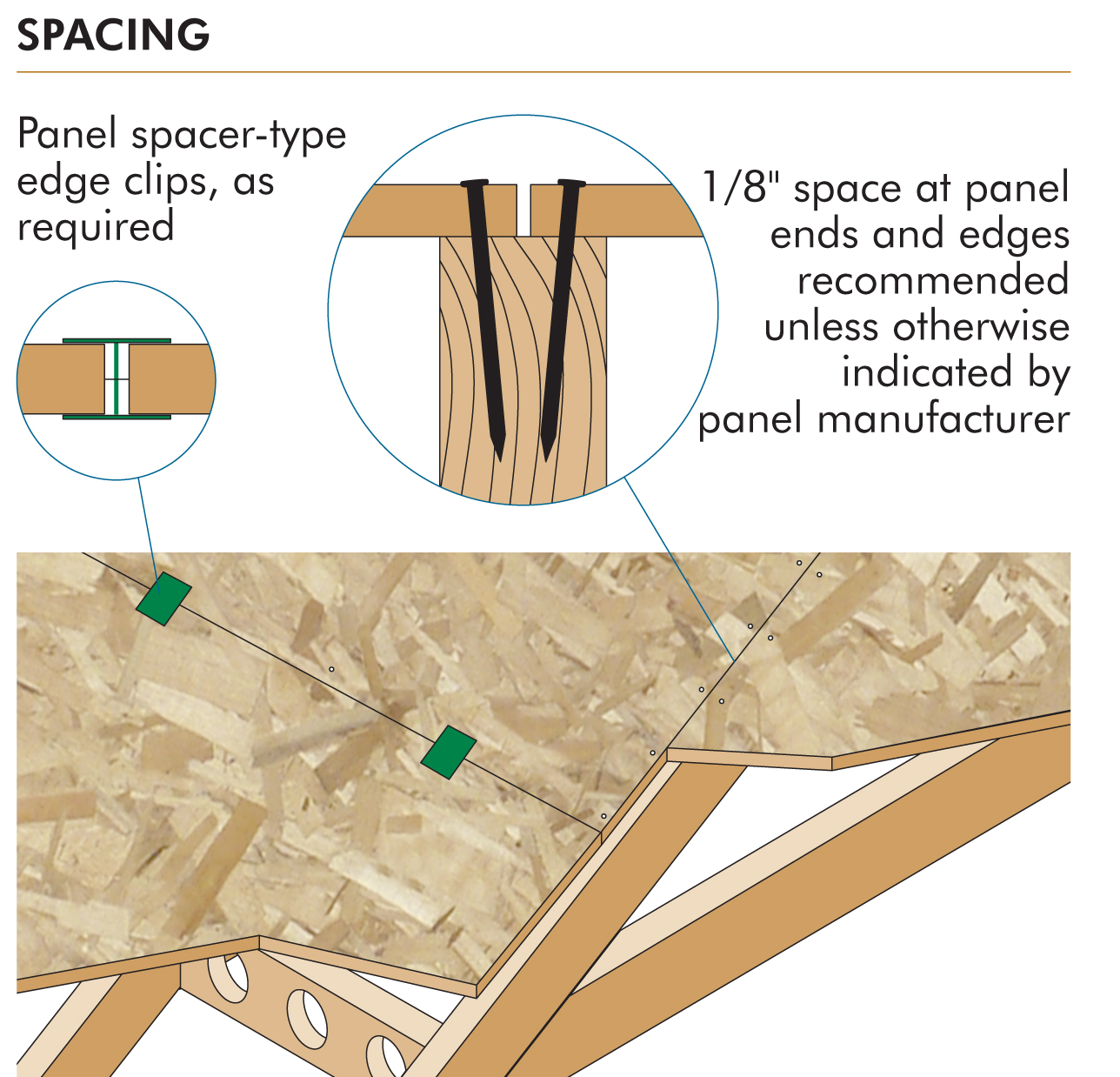

5 Steps to Proper Roof Sheathing Installation

Roof Sheathing Nail Pattern Nail Ftempo

This Makes It 320 Nails Per Square Foot.

Fasten Panels With A Minimum Of.

In Normal Wind Zones The Nails Should.

Nail Down Squarely (90 Degrees) Into The Deck To Secure Caps Flush To The Underlayment.

Related Post: