Roof Sheathing Nailing Pattern

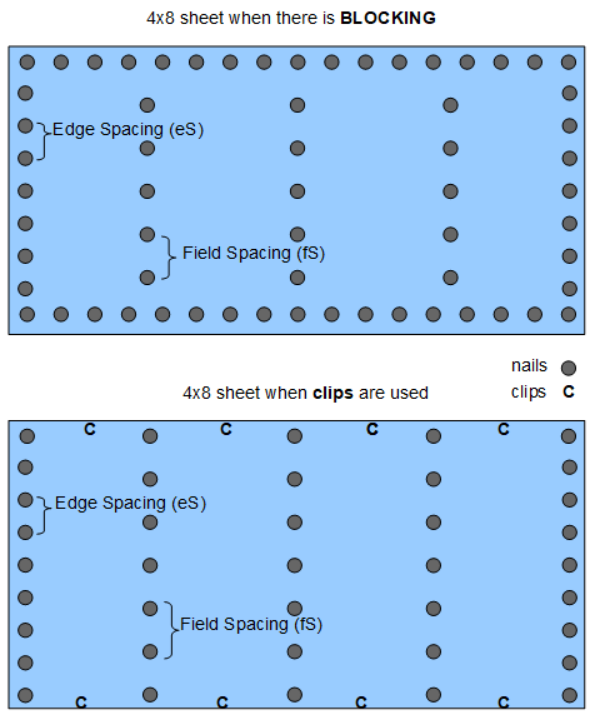

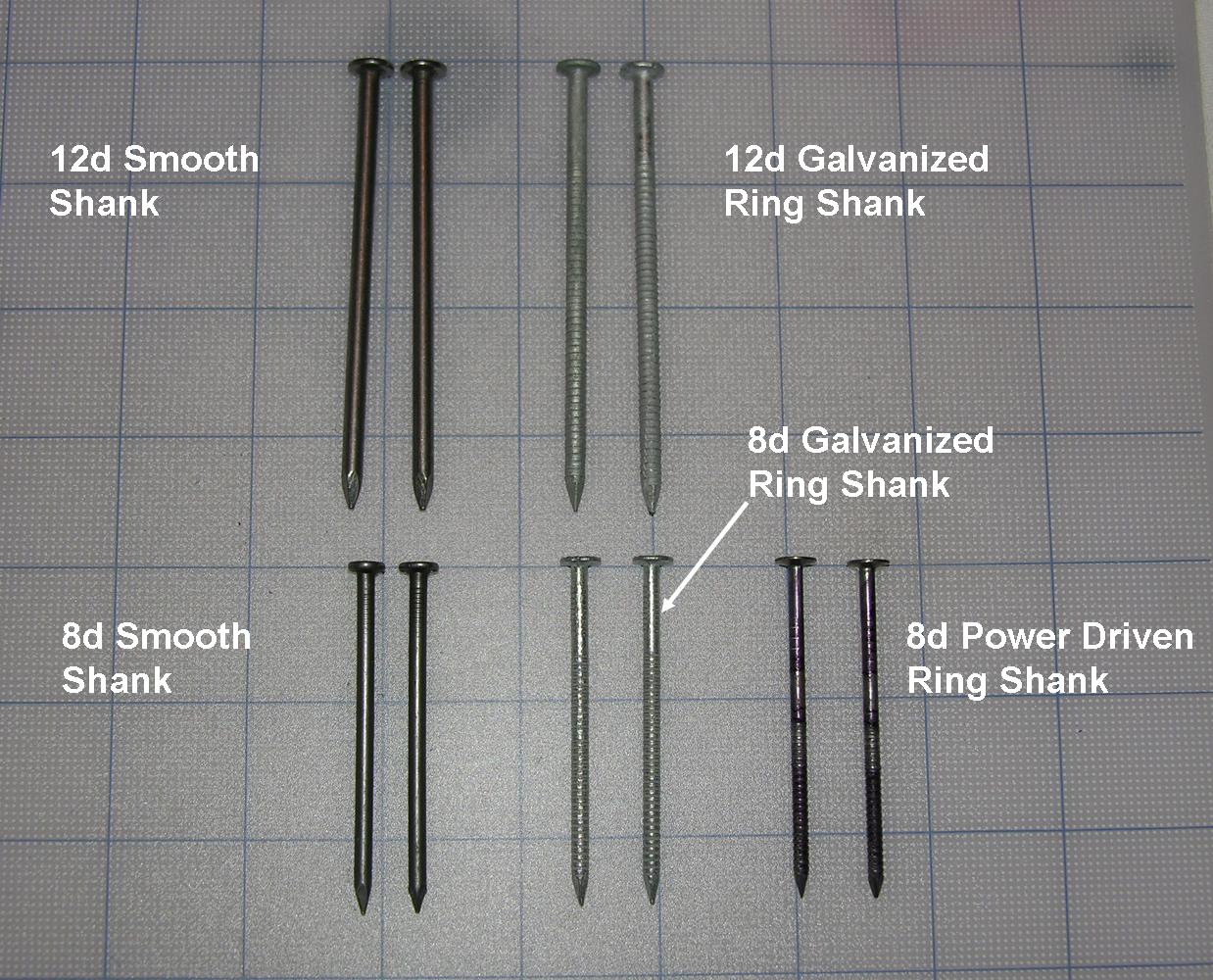

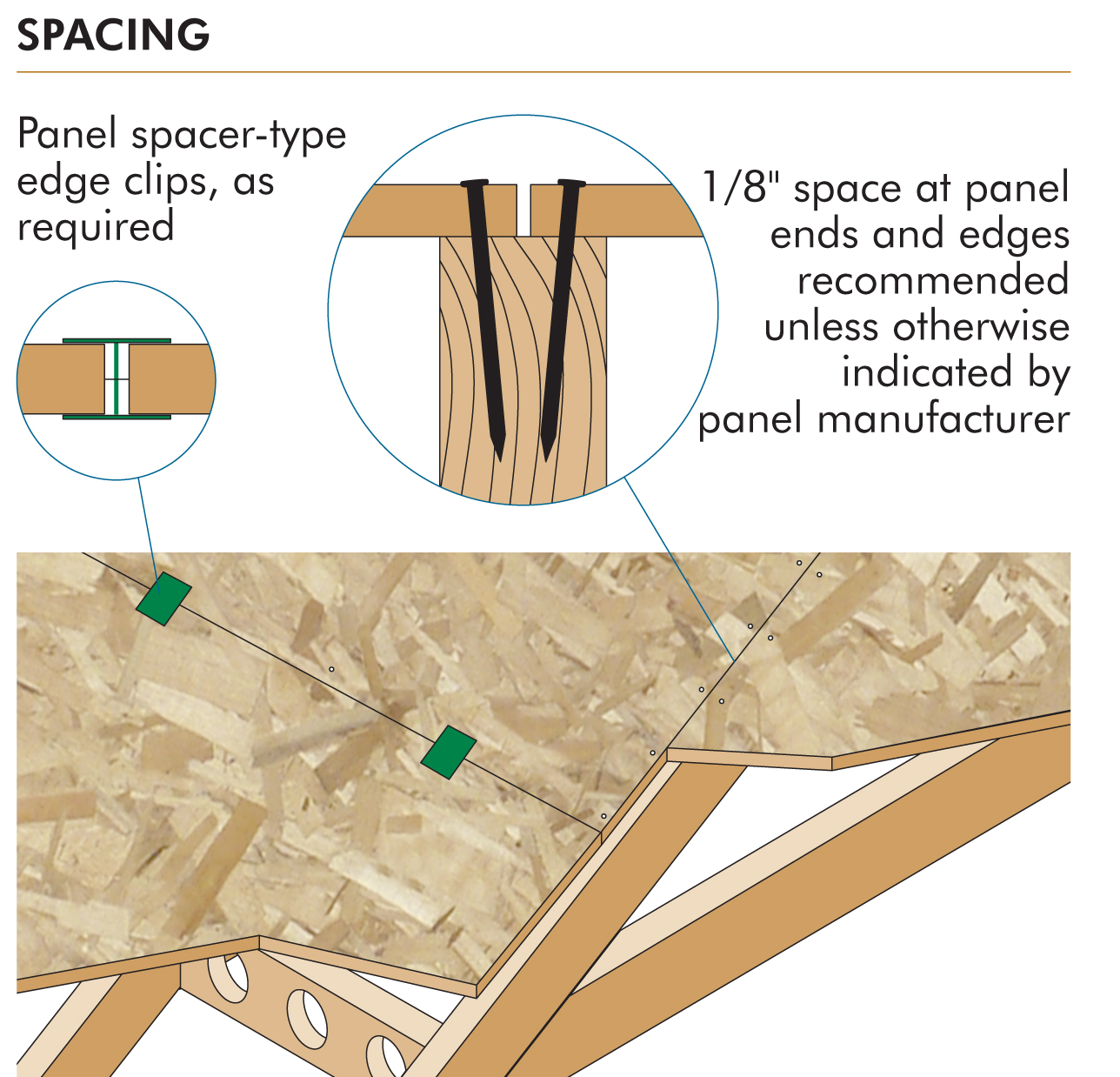

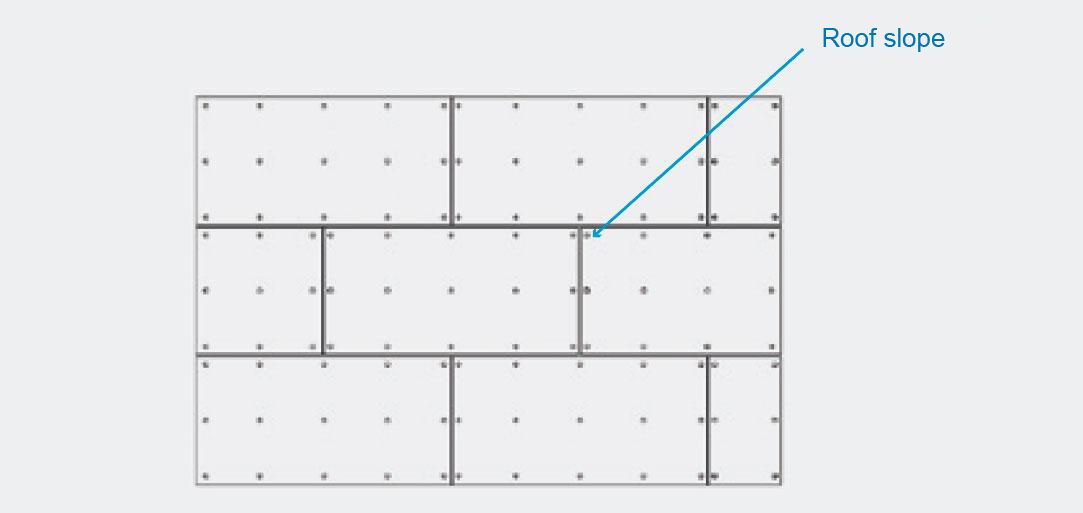

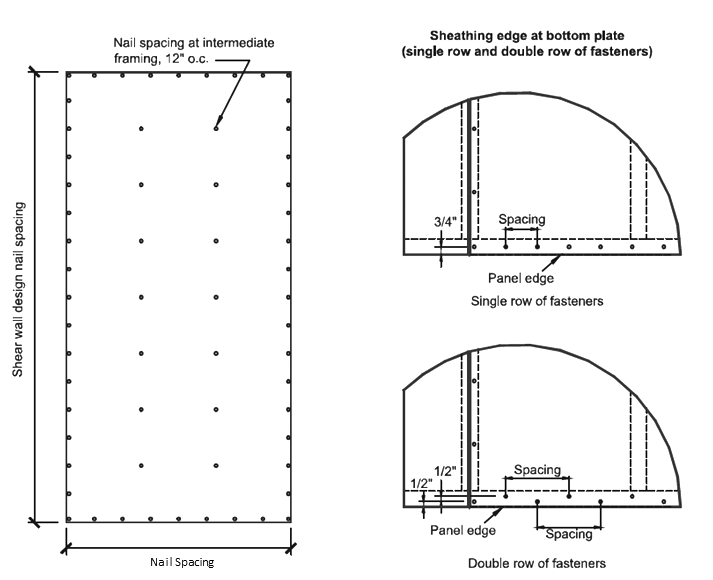

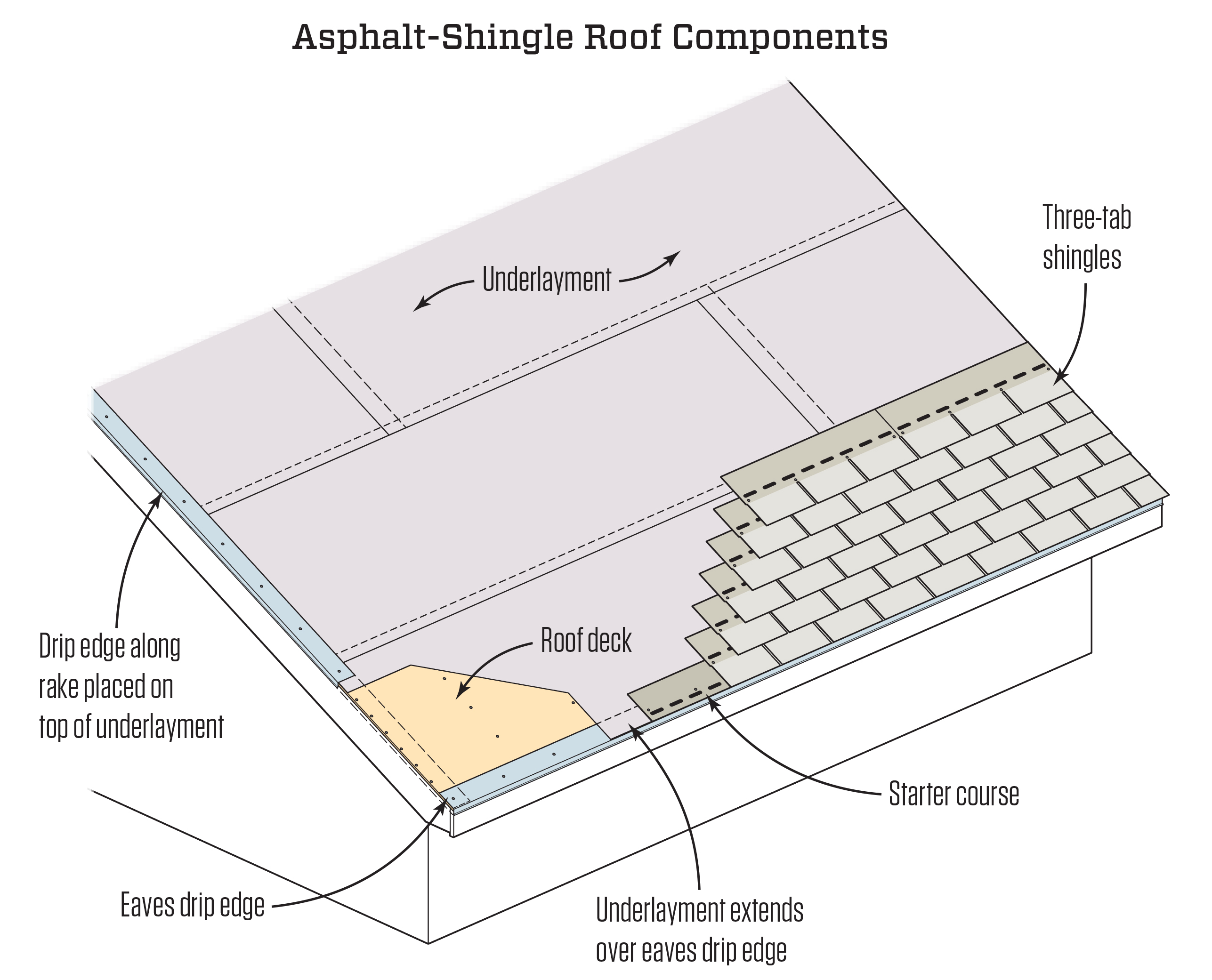

Roof Sheathing Nailing Pattern - Align shingles properly to avoid nail exposure. In preframed panels 8x8 feet or larger (figure 24), the panel strength axis may run either parallel or perpendicular to stiffeners spaced 16 or 24 inches on center. Benefits of using the right fasteners for roof sheathing. Position the nails appropriately according to the shingle installation instructions. Web before hurricane andrew devastated south florida in 1992, roof sheathing was generally attached using 6d nails spaced at 6 inches along the edges of the sheathing and at 12 inches along. Among other topics, the author, a custom home builder in massachusetts, discusses panel layout, explains how to nail off panels, and looks at the advantages of using roof staging. Proper nail patterns distribute the load evenly, preventing sagging, and ensuring a secure roof. Web roof sheathing, often synonymous with roof decking, is a structural layer that provides a solid base on which roofing materials like shingles, tiles, or metal panels are installed. Check the nailing surface is level. There are two common nail patterns used for roof sheathing: Web indicates the fastener is a ring shank roof sheathing nail. Cover sheathing as soon as possible with roofing felt for Tab shingles need two nails on each side of the tab. A variety of tips that will make it easier to sheathe a roof with plywood. Figure 21 apa panel roof sheathing notes: Benefits of using the right fasteners for roof sheathing. C&c wind loads at roof edges require tighter nailing schedules. In most cases, 4 nails are adequate. Web roof sheathing, often synonymous with roof decking, is a structural layer that provides a solid base on which roofing materials like shingles, tiles, or metal panels are installed. Roof sheathing fastening schedules for. When it comes to attaching roof sheathing, one common. Table r803.2.3.1 specifies the maximum fastener spacing based on framing specific gravity, exposure category, and wind speed. Recommended nail schedules for high wind zones are described in apa data file: Roof sheathing may not seem like a difficult job, but there is a lot to know about keeping sheets of plywood. Tab shingles need two nails on each side of the tab. The documentation requirements for roof sheathing attachment photos have changed, effective april 4, 2022. Web the nail pattern is the layout and spacing at which fasteners are applied to secure the sheathing. Increased nail schedules may be required in high wind zones. Web indicates the fastener is a ring. Web roof sheathing fastener schedule changes. When it comes to attaching roof sheathing, one common. Increased nail schedules may be required in high wind zones. Web roof sheathing, often synonymous with roof decking, is a structural layer that provides a solid base on which roofing materials like shingles, tiles, or metal panels are installed. Figure 21 apa panel roof sheathing. Web the nail pattern is the layout and spacing at which fasteners are applied to secure the sheathing. Roof sheathing is a critical component of any roofing system, providing structural support and stability. Cover sheathing as soon as possible with roofing felt for Web fortified hometm roof sheathing nail pattern documentation requirements. Web secure roof sheathing to rafters or trusses. Web roof sheathing, often synonymous with roof decking, is a structural layer that provides a solid base on which roofing materials like shingles, tiles, or metal panels are installed. The documentation requirements for roof sheathing attachment photos have changed, effective april 4, 2022. When it comes to attaching roof sheathing, one common. Web before hurricane andrew devastated south florida in. Among other topics, the author, a custom home builder in massachusetts, discusses panel layout, explains how to nail off panels, and looks at the advantages of using roof staging. Always check for level nailing surface. Web secure roof sheathing to rafters or trusses using dense screw patterns, clips, and straps to increase the uplift resistance. Minimum nailing requirements for preframed. In preframed panels 8x8 feet or larger (figure 24), the panel strength axis may run either parallel or perpendicular to stiffeners spaced 16 or 24 inches on center. Benefits of using the right fasteners for roof sheathing. Fastening the sheathing with nails that have a longer shank, larger diameter, and larger head will help to create a stronger roof. This. Web fortified hometm roof sheathing nail pattern documentation requirements. When it comes to attaching roof sheathing, one common. The documentation requirements for roof sheathing attachment photos have changed, effective april 4, 2022. Web in the 2021 ibc and 2021 irc, nailing patterns for wood structural panel roof systems have been updated. Benefits of using the right fasteners for roof sheathing. Web install the roof decking in accordance with ibhs fortified home sheathing nailing pattern recommendations. Ventilate the roof according to current building codes. Web secure roof sheathing to rafters or trusses using dense screw patterns, clips, and straps to increase the uplift resistance. Position the nails appropriately according to the shingle installation instructions. There are two common nail patterns used for roof sheathing: In preframed panels 8x8 feet or larger (figure 24), the panel strength axis may run either parallel or perpendicular to stiffeners spaced 16 or 24 inches on center. C&c wind loads at roof edges require tighter nailing schedules. After that point, a total of eight photos (four taken from above the roof sheathing and four taken from within the attic) are required. Table r803.2.3.1 specifies the maximum fastener spacing based on framing specific gravity, exposure category, and wind speed. Roof sheathing may not seem like a difficult job, but there is a lot to know about keeping sheets of plywood or osb on a consistent layout, with the right workflow, and proper nailing pattern. Excerpt of table r803.2.2 7th edition (2020) fbcr table r803.2.2 minimum roof sheathing thickness (excerpt). Figure 21 apa panel roof sheathing notes: Always check for level nailing surface. Longer nails are necessary for roofing projects involving thicker sheathing material to penetrate the osb material underneath fully. Web by robert weatherall issue 119. Proper nail patterns distribute the load evenly, preventing sagging, and ensuring a secure roof.

Nails for Gable Roof Sheathing

Roof Sheathing Nail Pattern Nail Ftempo

5 Steps to Proper Roof Sheathing Installation

Sheathing a Roof Fine Homebuilding

Roof Sheathing Nail Pattern Nail Ftempo

How To Select The Perfect Roofing Nails For Metal Sheathing On Stone

Roof Sheathing Nail Pattern Nail Ftempo

Roof Sheathing Nail Pattern Nail Ftempo

Roof Sheathing Pattern

Roof Sheathing Nail Pattern Nail Ftempo

Web In The 2021 Ibc And 2021 Irc, Nailing Patterns For Wood Structural Panel Roof Systems Have Been Updated.

Tab Shingles Need Two Nails On Each Side Of The Tab.

In Most Cases, 4 Nails Are Adequate.

Minimum Nailing Requirements For Preframed Panels Are The Same As For Roof Sheathing.

Related Post: