Roll Thread Tap Drill Chart

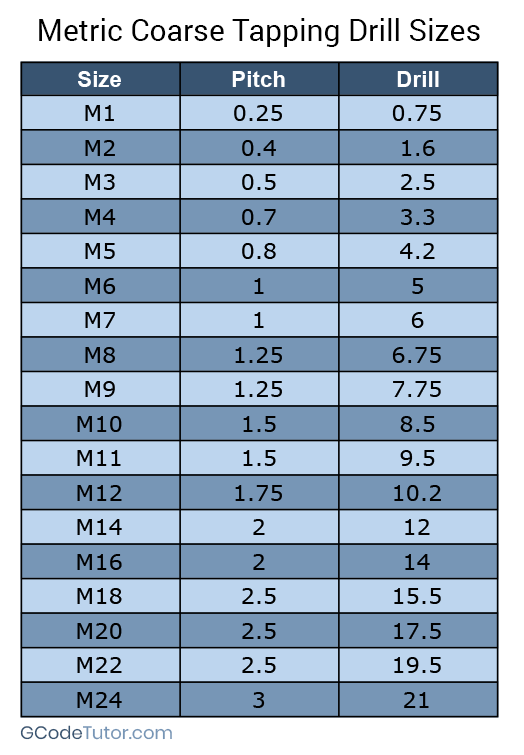

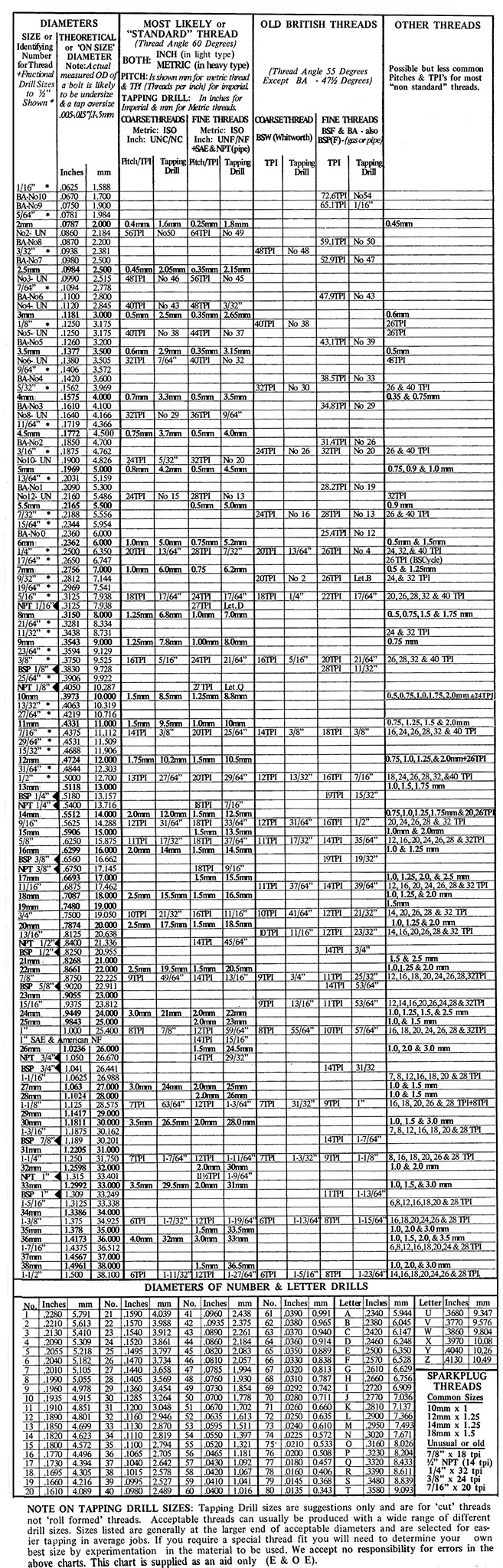

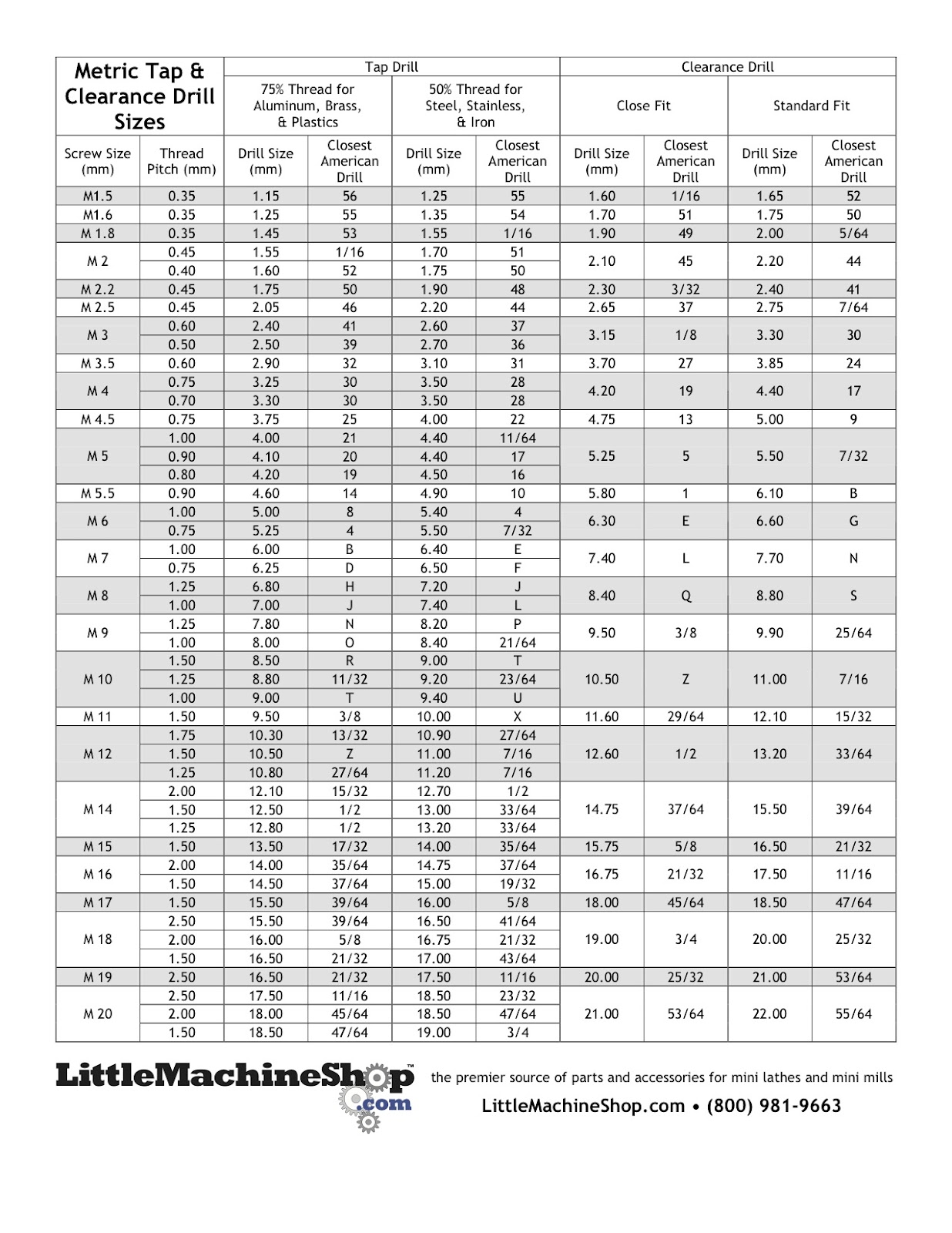

Roll Thread Tap Drill Chart - Desired thread magnitude and % of full thread are input parameters for the calculator. Web tap drill size calculator for inch and metric threads (for cutting and forming taps). Web sutton tools tapping drill size chart. Calculations are done according to roll form tap drill charts which are given in the machinery's handbook. To minimize tapping problems and lengthen tool life, use the largest drill possible to produce a minor diameter that will result in the lowest percentage of full thread consistent with adequate strength. A tap drill chart is key in matching pairs of female and male thread that tightly secure together. Web tap drill charts |. Our comprehensive chart includes standard sizes, metric sizes, plug tap sizes and an 'at a glance' listing of the most popular tap drill sizes. Often it is the corresponding dies and taps that you see together when buying either ones. Use the thread nominal size column to identify the desired thread designation. Thread strength is not directly proportional to percent of thread. These benefits include improved thread finish, stronger threads, longer tap life, faster tapping speeds and no chips. Recently viewed items view all and edit. Iso metric coarse (60o) tap size. Web sutton tools tapping drill size chart. Recently viewed items view all and edit. Web sutton tools tapping drill size chart. In general, tap tool life can be increased significantly by using a lower percent of thread and we suggest using values between 60% and 70% for most applications. Web roll tap drill size chart. (mm) — (% of thread desired x mm pitch) 147.06 (example m8. Roll form tapping boring chart graphic for calculation of recommended roll form spigot drill sizes for unified threads. Tapping drill size for thread forming. These benefits include improved thread finish, stronger threads, longer tap life, faster tapping speeds and no chips. Web roll form tap drill chart. In general, tap tool life can be increased significantly by using a lower. This allows full thread production to the very bottom of the hole. The chart in table 2 describes how to determine the size of unified male threads when making a bolt or threaded pipe. Web most tap drill charts call out only one tap drill size, and that will produce an approximate 75 percent thread. Filter by fractional, wire gauge,. Web tap drill charts |. Web tap drill size = basic tap o.d. Desired thread magnitude and % of full thread are input parameters for the calculator. 1/16 1/8 1/4 3/8 1/2 3/4. Web tap drill size calculator for inch and metric threads (for cutting and forming taps). Tap drill size chart to tap female threads into a component. Web roll taps are engineered and manufactured in two main styles to match the type of hole and fastener to be used. Web jarflo roll form pipe taps (npt & nps) have significant advantages over cutting taps in many applications. Web this tap and clearance drill chart shows tap. Tap drill size % common imperial thread sizes; Web the first tap drill chart below is in mm and the next in inches. 147.06 application forming taps cold form threads in ductile materials such as brass, copper, aluminum and leaded steels as well as series 301 to 347 stainless steels. Web sutton tools tapping drill size chart. Plus formulas and. There is also a printable version that has both metric and inch threads. To minimize tapping problems and lengthen tool life, use the largest drill possible to produce a minor diameter that will result in the lowest percentage of full thread consistent with adequate strength. Use the thread nominal size column to identify the desired thread designation. Web the first. Our comprehensive chart includes standard sizes, metric sizes, plug tap sizes and an 'at a glance' listing of the most popular tap drill sizes. Desired thread size and % of full thread are input parameters for the calculator. Desired thread magnitude and % of full thread are input parameters for the calculator. Web the first tap drill chart below is. Thread strength is not directly proportional to percent of thread. Desired thread magnitude and % of full thread are input parameters for the calculator. Drill sizes given are the ‘closest’ drill size. 147.06 application forming taps cold form threads in ductile materials such as brass, copper, aluminum and leaded steels as well as series 301 to 347 stainless steels. Web. Recently viewed items view all and edit. Unit coverters (imperial/metric) popup charts. Web most tap drill charts call out only one tap drill size, and that will produce an approximate 75 percent thread. There is also a printable version that has both metric and inch threads. Web jarflo roll form pipe taps (npt & nps) have significant advantages over cutting taps in many applications. Web use this chart from kodiak cutting tools for reference with thread forming tap drill sizes. Filter by fractional, wire gauge, letter, metric, coarse and fine. The chart in table 2 describes how to determine the size of unified male threads when making a bolt or threaded pipe. Iso metric coarse (60o) tap size. Download tap drill chart pdf here. Web the first tap drill chart below is in mm and the next in inches. Pipe thread drilled hole sizes. Roll form tapping boring chart graphic for calculation of recommended roll form spigot drill sizes for unified threads. Both are available as a printable tap drill chart pdf as well. Web sutton tools tapping drill size chart. In general, tap tool life can be increased significantly by using a lower percent of thread and we suggest using values between 60% and 70% for most applications.

M4 Hole Size A Pictures Of Hole 2018

Tap Drill Chart 5 Free Templates in PDF, Word, Excel Download

STI Roll Form Tap Drill Chart

FREE 13+ Sample Tap Drill Chart Templates in PDF Excel

STI Roll Form Tap Drill Chart

STI Roll Tap Drill Sizes, STI Tap Drill Sizes, and Pipe Tap Drill Sizes

The Flying XS Metric Drill Tap Chart

![23 Printable Tap Drill Charts [PDF] ᐅ TemplateLab](http://templatelab.com/wp-content/uploads/2016/09/tap-drill-chart-18.jpg?w=320)

23 Printable Tap Drill Charts [PDF] ᐅ TemplateLab

![23 Printable Tap Drill Charts [PDF] ᐅ TemplateLab](http://templatelab.com/wp-content/uploads/2016/09/tap-drill-chart-06.jpg?w=395)

23 Printable Tap Drill Charts [PDF] ᐅ TemplateLab

Standard tap drill size chart tnden

This Allows Full Thread Production To The Very Bottom Of The Hole.

147.06 Application Forming Taps Cold Form Threads In Ductile Materials Such As Brass, Copper, Aluminum And Leaded Steels As Well As Series 301 To 347 Stainless Steels.

Drill Sizes Given Are The ‘Closest’ Drill Size.

Desired Thread Magnitude And % Of Full Thread Are Input Parameters For The Calculator.

Related Post: