Ring Pinion Pattern

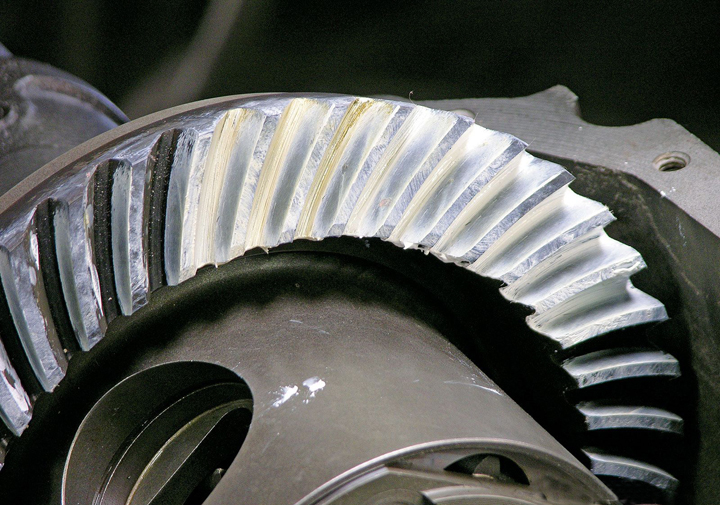

Ring Pinion Pattern - When setting the pinion position, many of the service manuals required a final pinion position check by using gauges that verified the dimension from the center line of the differential carrier (center line of ring gear) to the face of the pinion (button). The toe of the gear is the portion of the tooth surface at the end towards the center. Web this is a demonstration of the proper setup of a ring and pinion gear set in the rear. Ideally, the contact pattern should be seen in the Web rotate by grabbing and turning the ring gear, not the pinion. Web ring and pinion gear teeth are cut with the drive faces positioned closer to vertical and the coast faces at a steeper angle. If the pattern is heavy on the “heel” (outboard area of the ring gear teeth), add shims. Move the ring gear away from the pinion (increase backlash) while maintaining minimum backlash. Web ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Web the pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. This chart illustrates different patterns and adjustments. Ensuring peak performance and longevity. Web the pattern should be centered on the tooth from face to flank. Web rotate by grabbing and turning the ring gear, not the pinion. Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe (ring gear inside diameter). Web in general, pattern movements can be summarized this way: This chart illustrates different patterns and adjustments. The toe of the gear is the portion of the tooth surface at the end towards the center. Pinion bearing preload usually provides enough resistance for a good pattern, but additional resistance can be added by wrapping a shop towel around the yoke. Web here's how to achieve the best ring & pinion contact pattern , every time, in just 3 simple steps!reading contact patterns can be daunting when looking at th. The mating ring gear is bolted to the differential carrier and spins on a set of. The procedure involves changing the pinion position via shims in the carrier and repositioning the. The final pinion position will be verified by using the gear contact pattern method described as follows: Web rotate by grabbing and turning the ring gear, not the pinion. This video was created to give people a. These symptoms can be signs of a fairly serious problem with your ring and pinion gears,. See manufacturer or the gearset for exact. Web the pattern should be centered on the tooth from face to flank. Reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. Or an ominous clunking sound? The pattern refers to how the ring gear and pinion gears mesh. Ensuring peak performance and longevity. Web the pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. The mating ring gear is bolted to the differential carrier and spins on a set of. Rotate the ring gear several times by hand and inspect the ring gear teeth. 32k views 9 months ago. Ideally, the contact pattern should be seen in the Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe (ring gear inside diameter). If the pattern is heavy on the “heel” (outboard area of the ring gear teeth), add shims. Pinion is too far away. These symptoms can be signs of a fairly serious problem with your ring and pinion gears,. Web the pattern should. Ensuring peak performance and longevity. There is a process used when reassembling a differential that optimizes ring gear and pinion tooth contact. Web in general, pattern movements can be summarized this way: Web proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. Shows how varying pinion depth and back lash a. The mating ring gear is bolted to the differential carrier and spins on a set of. Move the pinion away from the ring gear centerline. Web proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. When setting the pinion position, many of the service manuals required a final pinion position check. When setting the pinion position, many of the service manuals required a final pinion position check by using guages that verified the dimension from the center line of the different carrier (center line of ring gear) to the face of the pinion (button). 32k views 9 months ago. When setting the pinion position, many of the service manuals required a. This chart illustrates different patterns and adjustments. Reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. Move the ring gear away from the pinion (increase backlash) while maintaining minimum backlash. The drive faces are also typically convex, curving outward while coast sides are concave, curving inward. Web ring and pinion gear teeth are cut with the drive faces positioned closer to vertical and the coast faces at a steeper angle. If the pattern is heavy on the “heel” (outboard area of the ring gear teeth), add shims. Ensuring peak performance and longevity. Web the pattern’s position to the tooth face (ridge/top land) and flank (valley/root) indicates pinion depth. Is it prematurely worn or chipped teeth? Rotate the ring gear several times by hand and inspect the ring gear teeth. These symptoms can be signs of a fairly serious problem with your ring and pinion gears,. When setting the pinion position, many of the service manuals required a final pinion position check by using gauges that verified the dimension from the center line of the differential carrier (center line of ring gear) to the face of the pinion (button). Disregard the pattern’s position to the tooth’s heel (ring gear outside diameter) or toe (ring gear inside diameter). Begin by setting proper pinion. The pattern refers to how the ring gear and pinion gears mesh. Bearing preload, total turning preload, and ring gear backlash.Weber_Ring_Gear_Contact_Pattern_Interpretation.pdf Gear Tooth

How to Set up Your Rear Gear Correctly RacingJunk News

Ring Pinion Pattern Patterns Gallery

Dana 44 Ring & Pinion Setup, Pattern / Ring Problems? YouTube

Ring Gear And Pinion Pattern

Ring Gear And Pinion Pattern

How To Create & Read Ring Gear Patterns

The Easiest Way to Read Ring & Pinion Contact Patterns YouTube

Any differential experts care to comment on my ring and pinion pattern

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

Web Ring And Pinion Gear Pattern Is One Of The Most Valuable Tools For Determining If A Differential Is Properly Set Up.

Web Here's How To Achieve The Best Ring & Pinion Contact Pattern , Every Time, In Just 3 Simple Steps!Reading Contact Patterns Can Be Daunting When Looking At Th.

Ring Gear And Run A Full Contact Pattern Check.

Web Rotate By Grabbing And Turning The Ring Gear, Not The Pinion.

Related Post: