Propress Fitting Take Off Chart

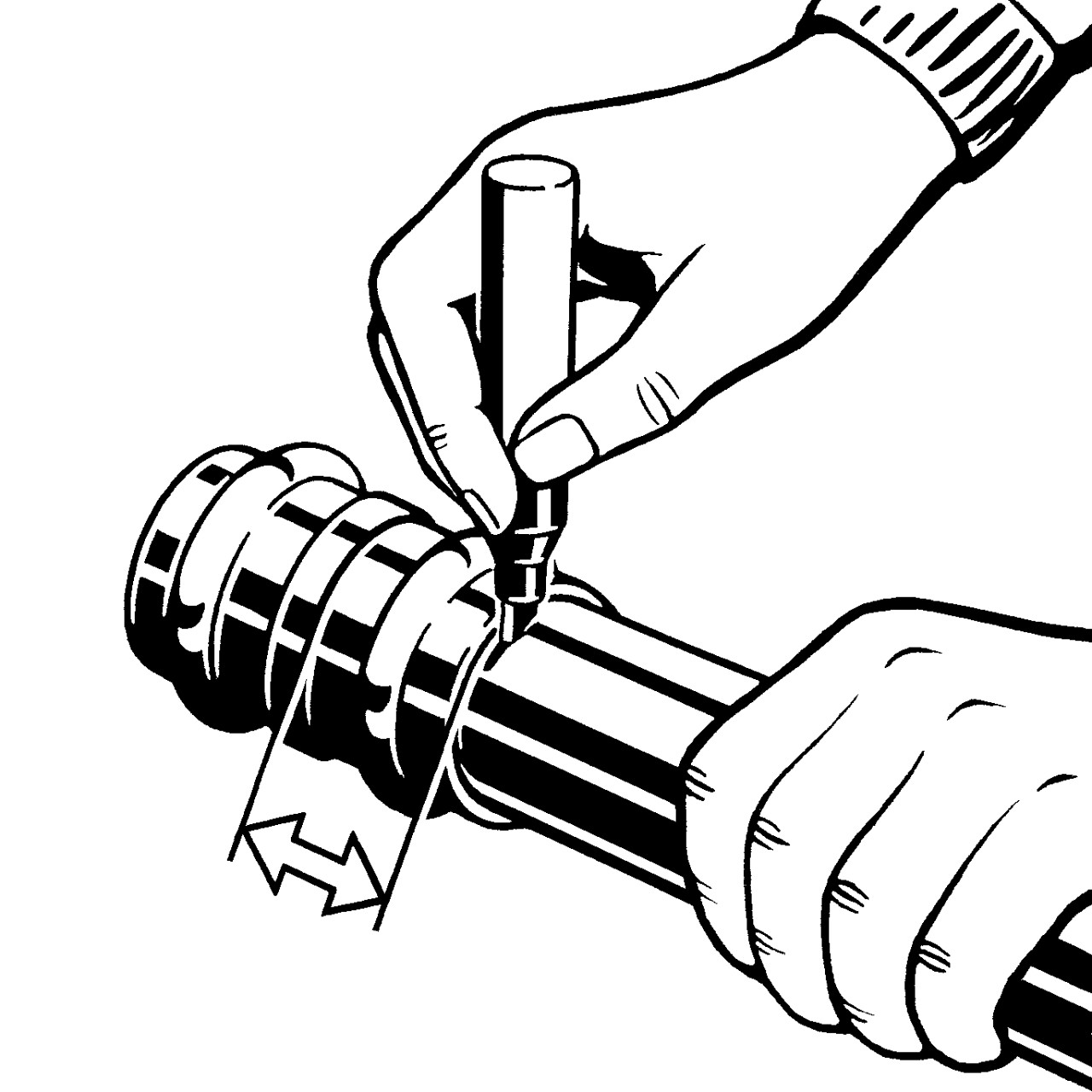

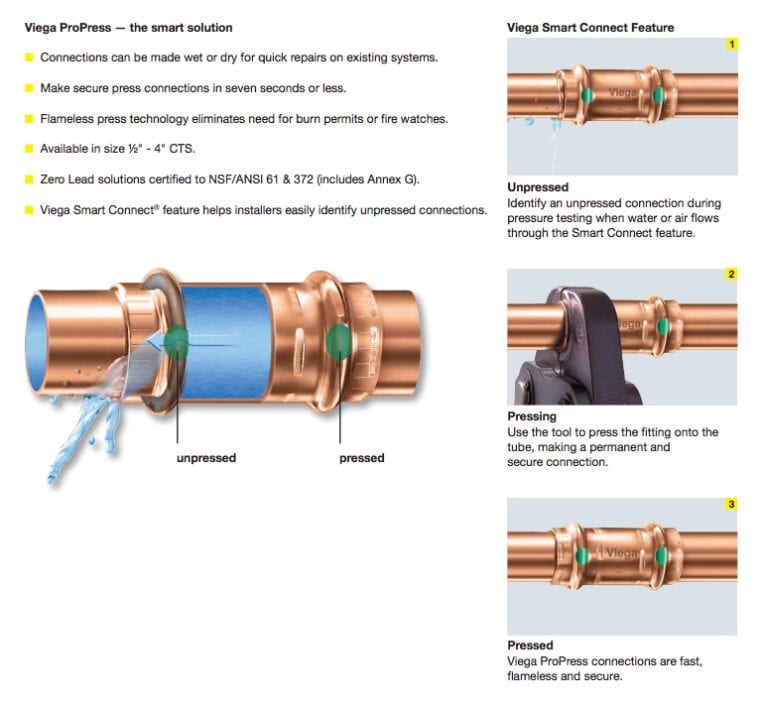

Propress Fitting Take Off Chart - Please see the below charts for a quick reference for megapress pressure rating and propress fittings pressure ratings organized by media. In all propress ½ to 2 fittings, viega’s unique, patented smart connect technology helps installers ensure that they have pressed all connections. Web table 32 minimum distance between soldered fitting and propress fitting_____42 table 33 minimum insertion depths for propress stainless ½ to 2 ____44 table 34 minimum insertion depths propress stainless 2½ to 4_____47. Web propress fitting systems propress fittings are available in elbows, couplings, reducers, tees, reducing tees, threaded adapters, unions, caps, and flanges. Viega propress and viega propress xl (copper) fittings conform to nsf 61 annex g. Web 5.1 limited warranty for viega propress fittings and valves _____38 5.2 limited warranty for viega metal systems for industrial applications_____39 5.3 limited warranty for viega marine applications _____41 table of contents, continued. ¾ ⅞ ⅞ 1 1 7/16 1 9/16 copper tubing must be free of surface imperfections, including metal stamped print lines, before a propress fitting is installed. Pros choose propress because there are more pipe fitting configurations approved for more applications than any other brand. While turning slightly, slide press fitting onto tubing to the marked depth. Web propressg (gas) fittings and propress (water) fittings. The #1 press fitting in the industry. Web table 32 minimum distance between soldered fitting and propress fitting_____42 table 33 minimum insertion depths for propress stainless ½ to 2 ____44 table 34 minimum insertion depths propress stainless 2½ to 4_____47. Use of propress xl rings and/or actuator (for bronze fittings) will result in an improper connection. ¾ ⅞ ⅞ 1. Failure to follow all instructions may result in extensive property damage, serious injury or death. Viega also offers 316 stainless steel tubing in ½ to 4 sizes to complement the viega propress stainless fittings and offer a complete system solution. Web viega provides us with pressure ratings in their approved applications chart, which also includes temperature ratings for each product. Web propress g™ fittings also incorporate the viega patented smart connect™ feature. In all propress ½ to 2 fittings, viega’s unique, patented smart connect technology helps installers ensure that they have pressed all connections. Pros choose propress because there are more pipe fitting configurations approved for more applications than any other brand. Web table 32 minimum distance between soldered fitting. Please see the below charts for a quick reference for megapress pressure rating and propress fittings pressure ratings organized by media. In all propress ½ to 2 fittings, viega’s unique, patented smart connect technology helps installers ensure that they have pressed all connections. Keep extremities and foreign objects away from press tool during pressing operation to prevent injury or incomplete. Viega propress and viega propress xl (copper) are safe, reliable, and economical copper pipe installation systems that use modern cold press connection technology for a wide assortment of more than 600 fittings in dimensions ranging from ½ to 4. Web table 32 minimum distance between soldered fitting and propress fitting_____42 table 33 minimum insertion depths for propress stainless ½ to. After pressing, open the jaws. Test results have shown that this sealing element can maintain a gas tight seal at temperatures up to 427°c. Available in sizes sizes ½ to 4. The propressg fittings also incorporate the viega Web propress insertions depth chart. Web references to zero lead throughout this publication mean products meet the requirements of both nsf/ ansi 372 (≤0.25% maximum weighted average lead content) and nsf/ ansi/can 61. Smart connect feature the smart connect feature is a special indentation in the inside surface of the fitting near the sealing element. Connections can be made wet or dry in 7 seconds. Available in sizes sizes ½ to 4. While turning slightly, slide press fitting onto tubing to the marked depth. Traditional propress fittings use a shiny black, high performance epdm seal. ¾ ⅞ ⅞ 1 1 7/16 1 9/16 copper tubing must be free of surface imperfections, including metal stamped print lines, before a propress fitting is installed. Failure to follow. Viega propress and viega propress xl (copper) fittings conform to nsf 61 annex g. Test results have shown that this sealing element can maintain a gas tight seal at temperatures up to 427°c. Size (in) a (in) l (in) l1 (in) 1 2 dec frac dec frac dec frac 77637 ½ x ½ 0.31 5/16 1.06 11/16 1.10 11/8 77053. Web fittings are offered with different sealing elements that meet a broad range of piping applications. Web table 32 minimum distance between soldered fitting and propress fitting_____42 table 33 minimum insertion depths for propress stainless ½ to 2 ____44 table 34 minimum insertion depths propress stainless 2½ to 4_____47. ¾ ⅞ ⅞ 1 1 7/16 1 9/16 copper tubing must. Web propress g™ fittings also incorporate the viega patented smart connect™ feature. Traditional propress fittings use a shiny black, high performance epdm seal. Web safe, certain, and secure, viega fittings are designed for peace of mind. Web 5.1 limited warranty for viega propress fittings and valves _____38 5.2 limited warranty for viega metal systems for industrial applications_____39 5.3 limited warranty for viega marine applications _____41 table of contents, continued. Available in sizes sizes ½ to 4. Connections can be made wet or dry in 7 seconds or less on both copper and stainless steel pipe in sizes ranging from ½ to 4. Keep extremities and foreign objects away from press tool during pressing operation to prevent injury or incomplete press. Web unions, caps and flanges. Viega propress and viega propress xl (copper) are safe, reliable, and economical copper pipe installation systems that use modern cold press connection technology for a wide assortment of more than 600 fittings in dimensions ranging from ½ to 4. Propressg fittings use a yellow. Web propressg (gas) fittings and propress (water) fittings. After pressing, open the jaws. While turning slightly, slide press fitting onto tubing to the marked depth. A green dot on a viega propress fitting indicates smart connect technology with an epdm sealing element. Pros choose propress because there are more pipe fitting configurations approved for more applications than any other brand. The epdm sealing element is suitable for many applications.

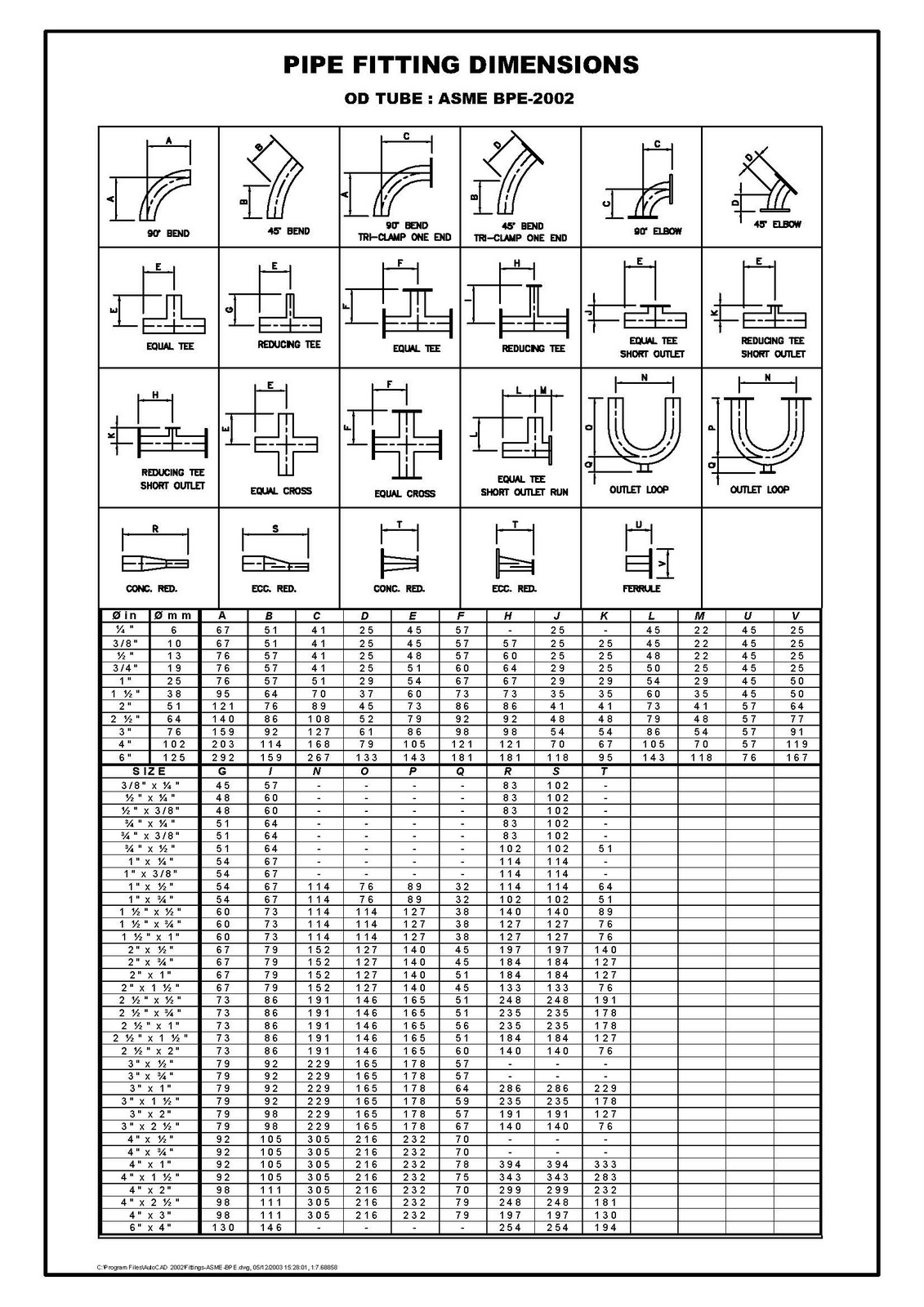

Pipe Fitting Take Off Chart

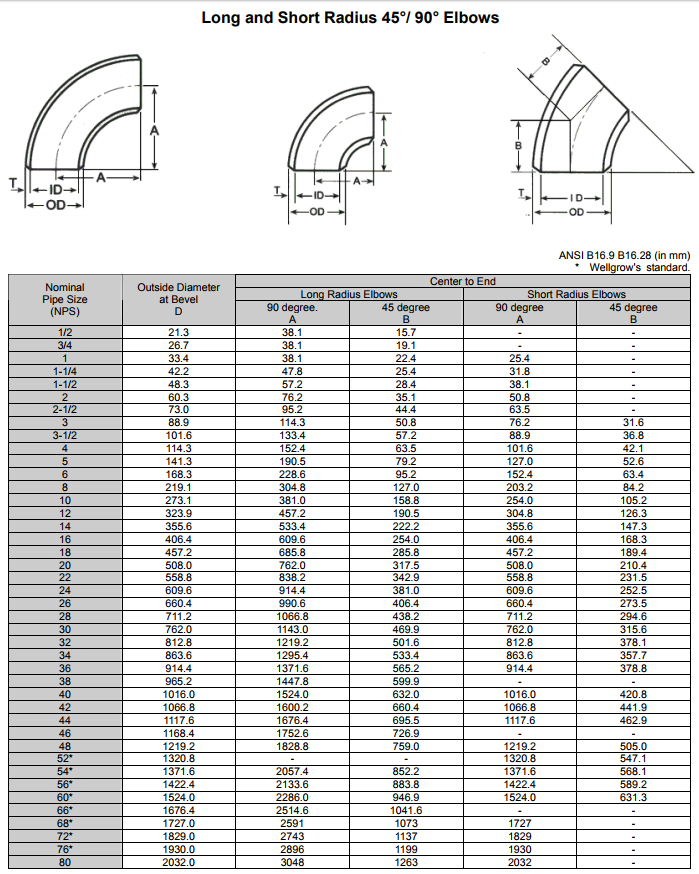

Weld Fitting Take Off Chart

Socket Weld Fitting Take Off Chart

Weld Fitting Take Off Chart

Take Off Chart For Pipe Fittings

Takeoff Chart Take Off For Threaded Pipe Fittings

Viega ProPress 1/2" to 2" Fittings Product Instructions viega.us

Copper Press Fittings, Copper Press Fittings For Air

Copper ProPress Technology San Diego PIC Plumbing Services

DMNI Propress Fitting Copper Coupling Pack of 10 1” Zero Lead

Available In Sizes Sizes ½ To 4.

Web Table 32 Minimum Distance Between Soldered Fitting And Propress Fitting_____42 Table 33 Minimum Insertion Depths For Propress Stainless ½ To 2 ____44 Table 34 Minimum Insertion Depths Propress Stainless 2½ To 4_____47.

Web Propress Insertions Depth Chart.

The Propressg Fittings Also Incorporate The Viega

Related Post: