Propane Temperature Correction Chart

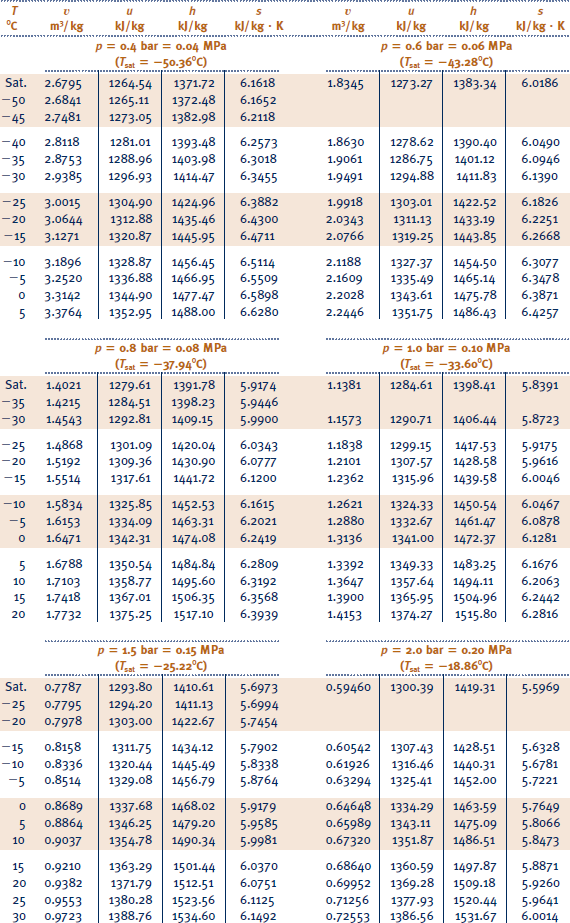

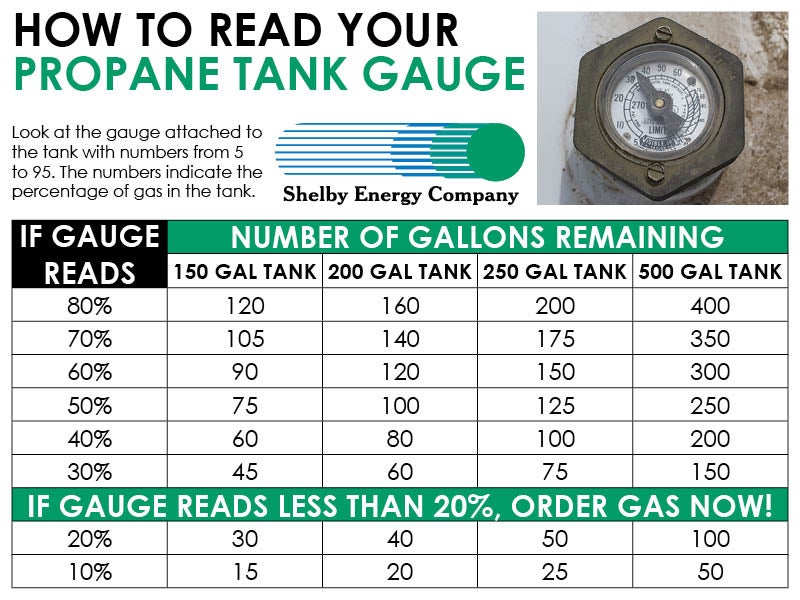

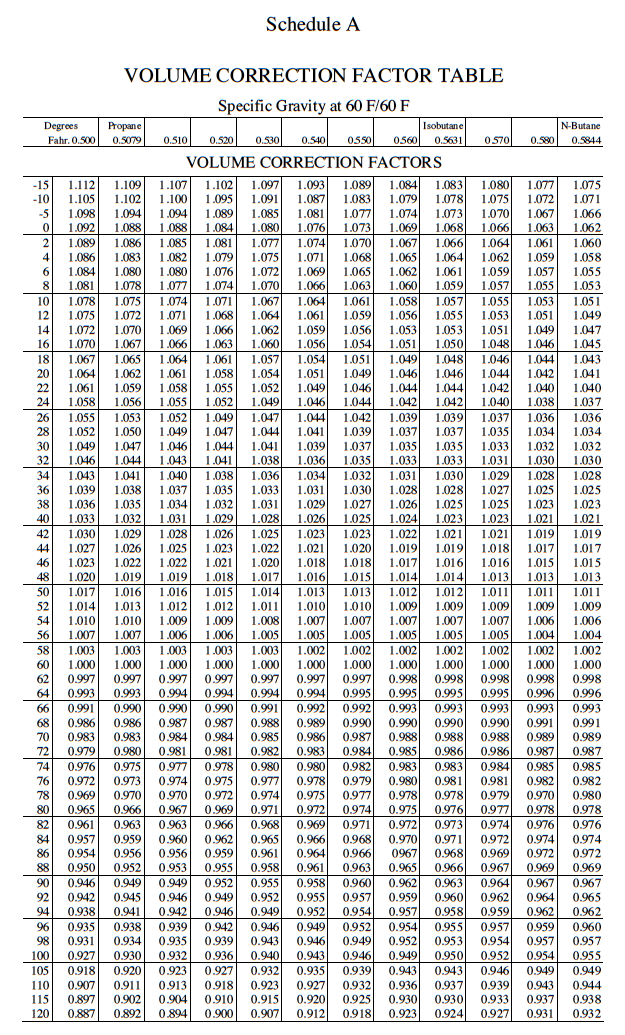

Propane Temperature Correction Chart - Volume correction factors for use with liquefied petroleum gas or propane at various densities. 1.0000 the liquid density at 60°f to the density of water at 60°f. To determine the corrected correction factor: Web this table shows the correction for the effects of temperature on the liquid. That is, observed temperatures above 60 °f (or the base temperature used) typically correlate with a correction factor below 1, while temperatures below 60 °f correlate with a factor above 1. Web propane volume correction takes into account the temperature of liquid propane and adjusts accordingly to ensure the amount propane bought equals the amount of propane delivered. In general, vcf / ctl values have an inverse relationship with observed temperature relative to the base temperature. However, the compensated meter will read something less than 200. The correction factors in the table on the next page apply to new sensors. This correction is normally referred to as ctl. The correction factors in the table on the next page apply to new sensors. Web petroleum and related products — temperature and pressure volume correction factors (petroleum measurement tables) and standard reference conditions. If it is 80°, you still fill it to the same 80% level and there will be 200 actual gallons in it and that’s what an uncompensated. Web the table below lists the most commonly used gases and their approximate conversion factors. Given dot regulations, we can only load to 80,000 pounds. Volume correction factors for use with liquefied petroleum gas or propane at various densities. Web propane volume correction takes into account the temperature of liquid propane and adjusts accordingly to ensure the amount propane bought. Imperial gauge pressure can be calculated as. 0.7000/1000 = 0.0007 specific gravity, divide the correction factor by 1000 and add it to the measured value. In addition, the following are also true: A properly functioning float gauge will read 40% 100 gallons of. F p = line pressure (psig) + atmospheric pressure (psia) contract base pressure (psia) f t =. Web the formulae for calculating the factors for pressure and temperature are given below: A properly functioning float gauge will read 40% 100 gallons of. In general, vcf / ctl values have an inverse relationship with observed temperature relative to the base temperature. 0.7000/1000 = 0.0007 specific gravity, divide the correction factor by 1000 and add it to the measured. F p = line pressure (psig) + atmospheric pressure (psia) contract base pressure (psia) f t = 460 + base temperature (°f) 460 + line temperature (°f) note: Web these tables corrected to standard temperatures of 15 °c and 60 °f only, and were based on data for crude petroleum and petroleum fractions published in 1916 by the (united states). It will be more like 193.4, a difference of nearly 7 gallons. The base pressure and base temperature values can normally be found in your contract with your gas Web these tables corrected to standard temperatures of 15 °c and 60 °f only, and were based on data for crude petroleum and petroleum fractions published in 1916 by the (united. Volume correction factors to 15 °c for use with liquefied petroleum gas or propane at 505 kg/m3. In addition, the following are also true: Web these tables corrected to standard temperatures of 15 °c and 60 °f only, and were based on data for crude petroleum and petroleum fractions published in 1916 by the (united states) national bureau of standards. Web the table below lists the most commonly used gases and their approximate conversion factors. Sales in the bulk market are measured and priced in net gallons. Pétrole et produits connexes — facteurs de correction de volume par rapport à la température et à la pression (tables de mesure du pétrole) et conditions de référence standard. If it is 80°,. Per gallon) if there is a significant temperature drop (over 20°f) the gauge will indicate that there is less propane in the tank. Web increasing temperature decreases the response by less than 4% between 0° and 40° c. In general, vcf / ctl values have an inverse relationship with observed temperature relative to the base temperature. Web natural gas liquids. *see appendix a for combined formula and application. Web factors apply to hydrometers calibrated at 60°/60°f specific gravity, the ratio of measured specific gravity at 20°c: To determine the corrected correction factor: Per gallon) if there is a significant temperature drop (over 20°f) the gauge will indicate that there is less propane in the tank. Web petroleum and related products. Web propane volume correction takes into account the temperature of liquid propane and adjusts accordingly to ensure the amount propane bought equals the amount of propane delivered. The correction factors in the table on the next page apply to new sensors. If it is 80°, you still fill it to the same 80% level and there will be 200 actual gallons in it and that’s what an uncompensated meter will read. *see appendix a for combined formula and application. It will be more like 193.4, a difference of nearly 7 gallons. A properly functioning float gauge will read 40% 100 gallons of. Web this table shows the correction for the effects of temperature on the liquid. To determine the corrected correction factor: Temperature fluctuation & the billing process. Web these tables corrected to standard temperatures of 15 °c and 60 °f only, and were based on data for crude petroleum and petroleum fractions published in 1916 by the (united states) national bureau of standards (nbs) and some later data on natural gasoline reported in 1942. Web the table below lists the most commonly used gases and their approximate conversion factors. This correction is normally referred to as ctl. The imperial chart indicates absolute pressure. Sales in the bulk market are measured and priced in net gallons. That is, observed temperatures above 60 °f (or the base temperature used) typically correlate with a correction factor below 1, while temperatures below 60 °f correlate with a factor above 1. Per gallon) if there is a significant temperature drop (over 20°f) the gauge will indicate that there is less propane in the tank.

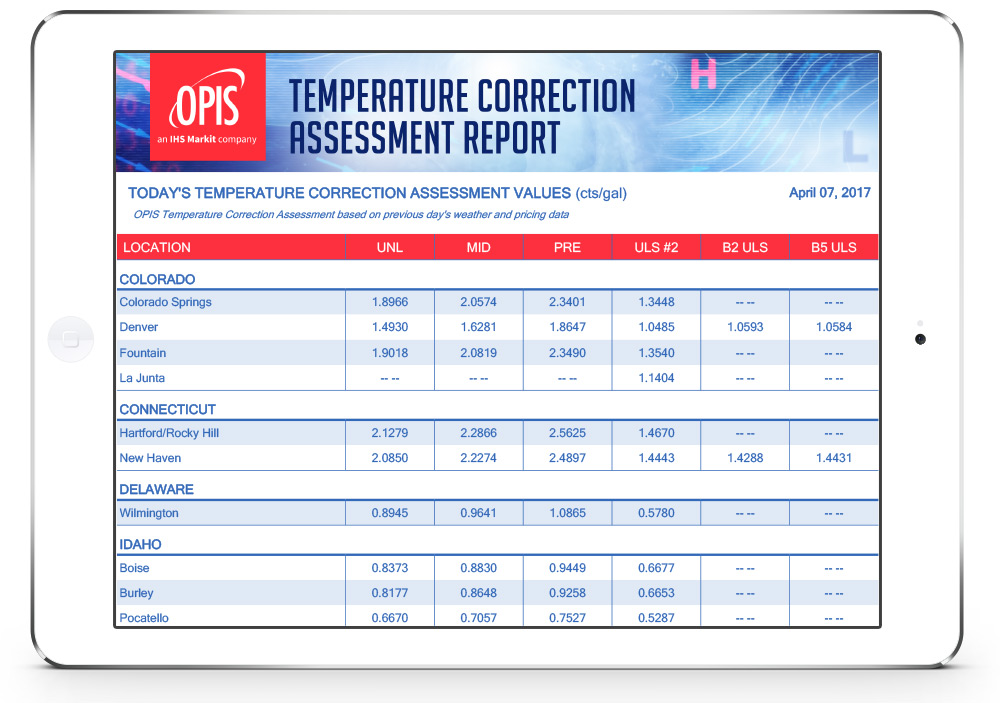

Propane Volume Temperature Correction Chart Online Shopping

Propane Volume Temperature Correction Chart Online Shopping

Propane Natural Gas Conversion Chart

propane volume temperature correction chart Focus

How to Read a Propane Gauge Shelby Energy Company

Propane Temperature Correction Chart

Propane Volume Temperature Correction Chart Best Picture Of Chart

Propane Temperature Correction Chart

Volume Correction Factor for Propane

Nebraska Legislature

A Properly Functioning Float Gauge Will Read 40% 100 Gallons Of Propane Weighs 424 Pounds (4.24 Lbs.

Given Dot Regulations, We Can Only Load To 80,000 Pounds.

F P = Line Pressure (Psig) + Atmospheric Pressure (Psia) Contract Base Pressure (Psia) F T = 460 + Base Temperature (°F) 460 + Line Temperature (°F) Note:

Web Natural Gas Liquids Can Take The Form Of Higher Vapor Pressure Hydrocarbon Liquids (E.g., Condensates, Ethane, Propane, Butane Mixes) In Which The Liquid Volumes Can Be Measured In Spherical Tanks, Or In Horizontal Cylindrical Tanks With High Pressure End Caps.

Related Post: