Printable Socket Size Chart

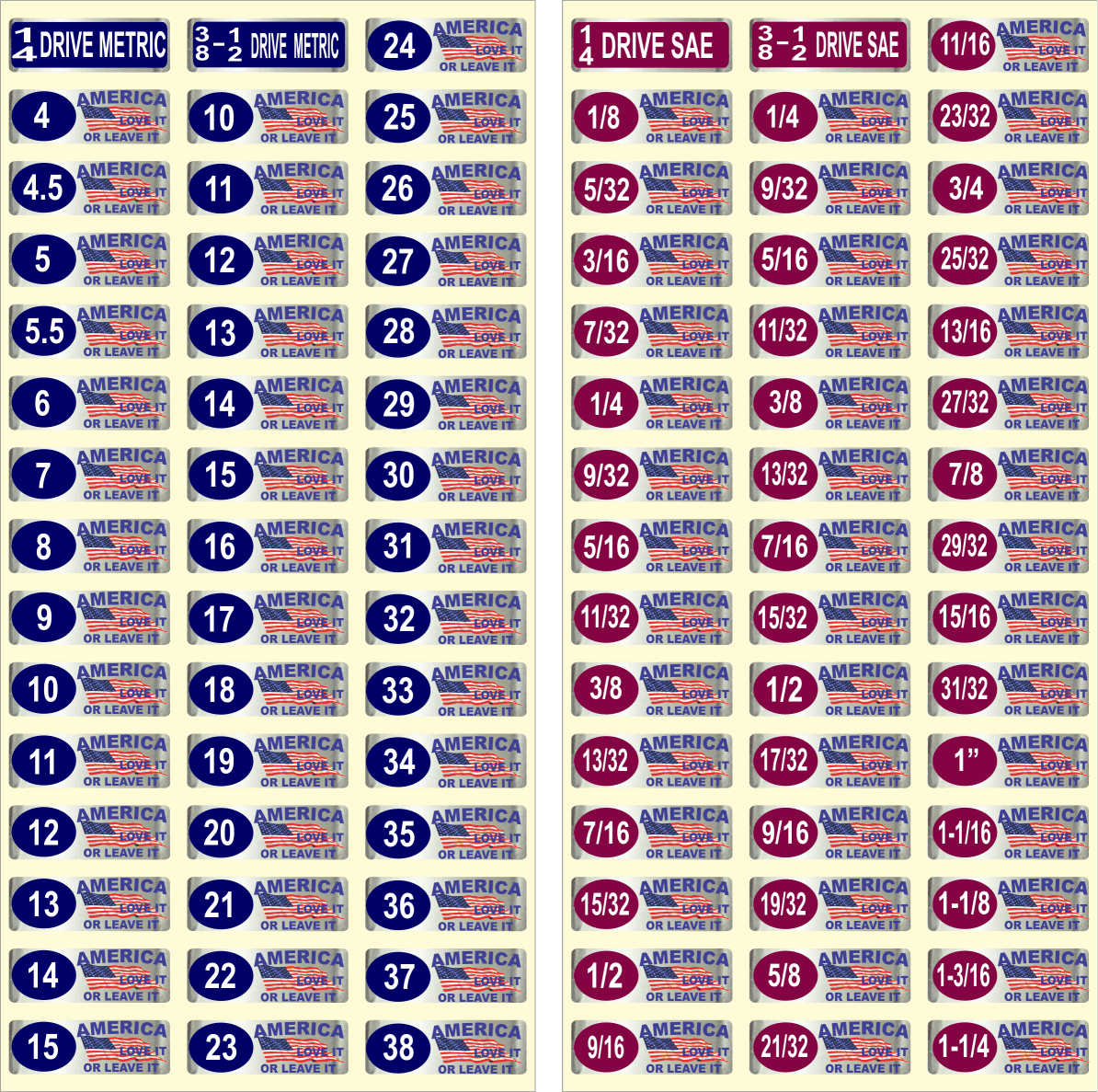

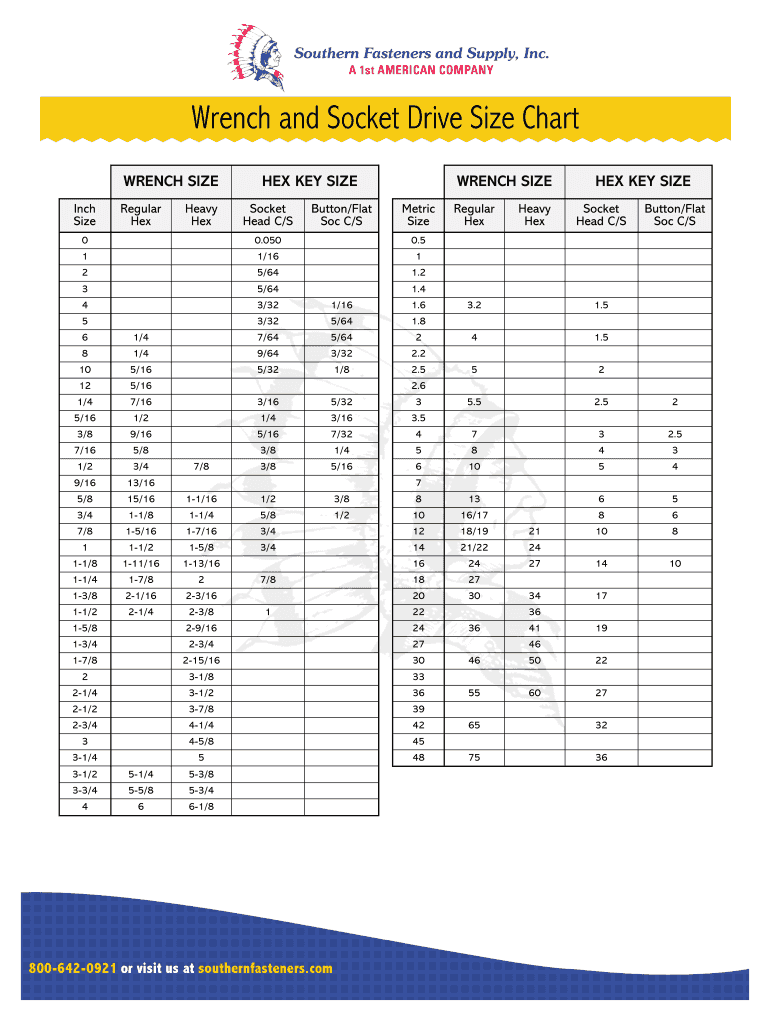

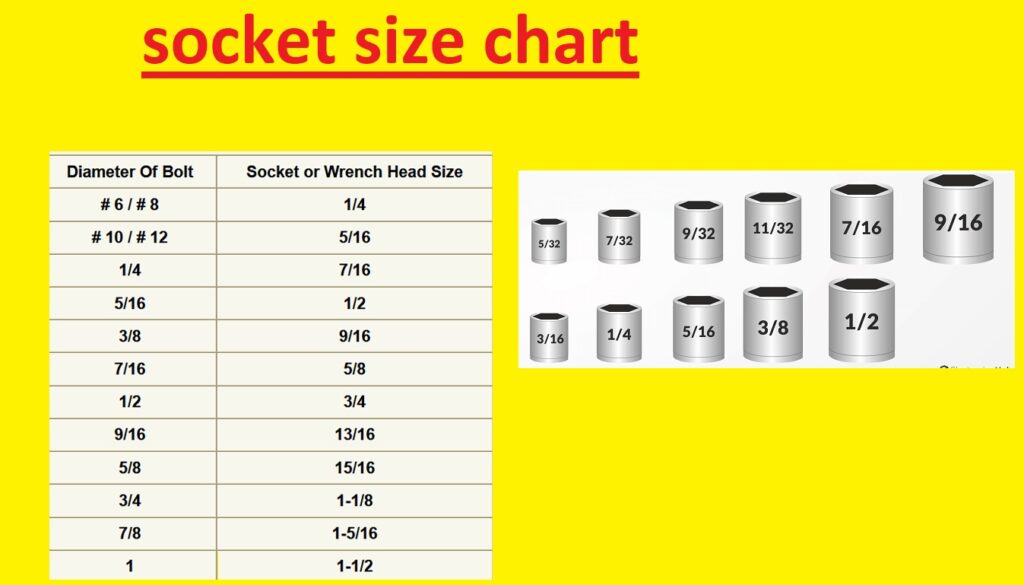

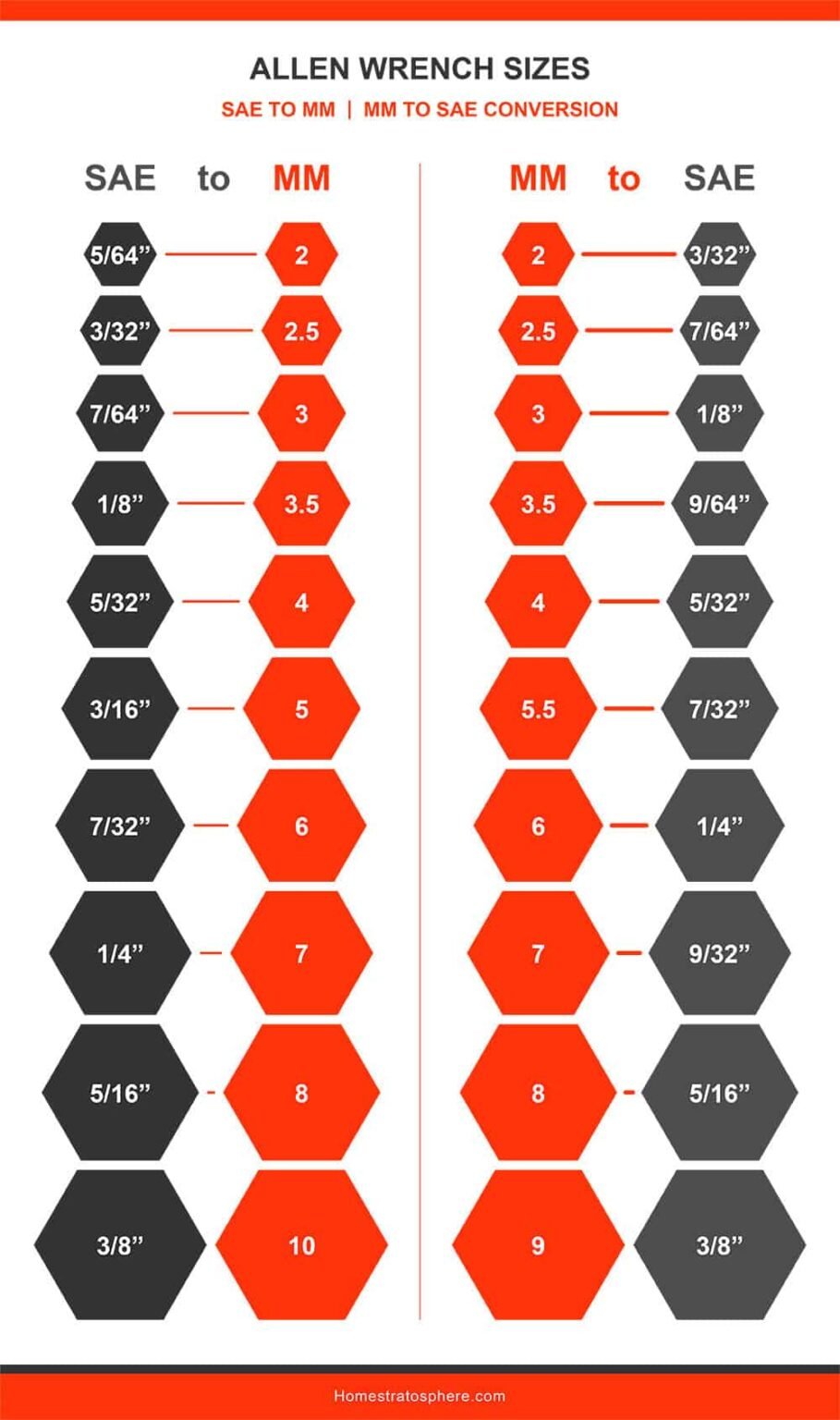

Printable Socket Size Chart - In our daily life, we commonly find 3 standard drives sizes for our jobs. Allowance/deviations (es/el) tolerances (t d /t d) normal length of engagement. Let’s take a closer look at two common socket types. Web here you can find all the craftsman socket sizes in order using the socket sizes chart 1, which covers sae conventional sockets rather than metric. And here are the two main quantifying standards: Most common craftsman drive sizes. Web here you can find the socket sizes in order from the smallest to the largest you are most likely to use in the home or on your vehicle (and a complete socket set). They are ideal for precision or interior jobs that require a lighter touch. Below is a list of commonly used sae (imperial) standard and metric wrench and socket sizes in ascending order up to 2 inches. Web here are the most common standard wrench sizes and socket sizes in order, along with one size smaller, larger, and their metric conversion. Web socket size chart: They are ideal for precision or interior jobs that require a lighter touch. You can learn more about drive types here. Web to properly organize your sockets, understand the three common drive sizes: The commonly used socket types are 1/4″, 3/8″,. Web here you can find the socket sizes in order from the smallest to the largest you are most likely to use in the home or on your vehicle (and a complete socket set). 1/4″ drives are suitable for low torque jobs and small sockets with a maximum size of 14mm. Used for low torque, precision, or interior work. Web. The three most common drive size types are 1/4″, 3/8″, and 1/2″. Most of the time you can find one of them fit for a wrench or a ratchet. In our daily life, we commonly find 3 standard drives sizes for our jobs. There are many different types of nuts or bolts out in the market. And here are the. If you’re looking for an easily reference socket size chart, you’re in the right place! 2 charts to easily find the size or conversion you need. Web whether you just got your first socket set, want to know which sizes you’re missing in your socket organizer, or simply need a quick reference to see if a metric size converts to. Web to properly organize your sockets, understand the three common drive sizes: Web common metric socket sizes 1/4 drive 3/8 drive 1/2 drive 3/4 drive 1 drive 4mm 5.5mm 8mm 19mm 36mm 4.5mm 6mm 9mm 20mm 38mm 5mm 7mm 10mm 21mm 41mm 5.5mm 8mm 11mm 22mm 46mm 6mm 9mm 12mm 23mm 50mm 7mm 10mm 13mm 24mm 54mm 8mm 11mm 14mm. Different socket types are suitable for different jobs. Mm to inch and inch to mm socket conversion charts vary slightly because the converted socket should be larger than the fastener. If it's not slightly larger it won't fit. Each is suited for different torque levels and applications. In contrast, metric socket sizes are measured in millimeters and are used more. Additionally, trial and error can be used to confirm the correct fit before applying torque. Here is the metric socket size chart for 1”, 1/2″, and 1/4″ drive: They streamline tool selection, enhancing efficiency and accuracy. Each is suited for different torque levels and applications. Web this socket size chart will help you whether you just got your first socket. Here is the metric socket size chart for 1”, 1/2″, and 1/4″ drive: The commonly used socket types are 1/4″, 3/8″,. Different socket types are suitable for different jobs. Due to various sizes of nuts and bolts, different socket drive sizes are required. In our daily life, we commonly find 3 standard drives sizes for our jobs. Different socket types are suitable for different jobs. 1/4″ drives are suitable for low torque jobs and small sockets with a maximum size of 14mm. Web to properly organize your sockets, understand the three common drive sizes: Web in this post, you will find a socket size chart for both metric and standard (sae), in their respective order of size.. If it's not slightly larger it won't fit. Used for low torque, precision, or interior work. Let’s take a closer look at two common socket types. By adam williams june 9, 2023. 2 charts to easily find the size or conversion you need. Additionally, trial and error can be used to confirm the correct fit before applying torque. Web here you can find all the craftsman socket sizes in order using the socket sizes chart 1, which covers sae conventional sockets rather than metric. Web this page will help you discover the precise order of metric and standard socket sizes, for each set and type, and ensure your sockets are organized and ready to work. The three most common drive size types are 1/4″, 3/8″, and 1/2″. 2 charts to easily find the size or conversion you need. Web use this chart to simplify your socket conversions and streamline your tool selection. They are ideal for precision or interior jobs that require a lighter touch. Most common craftsman drive sizes. They streamline tool selection, enhancing efficiency and accuracy. Below is a list of commonly used sae (imperial) standard and metric wrench and socket sizes in ascending order up to 2 inches. By adam williams june 9, 2023. Each is suited for different torque levels and applications. The commonly used socket types are 1/4″, 3/8″,. Web this socket size chart will help you whether you just got your first socket set, or you want to know which sizes you’re missing in your toolset, like maybe a 10mm? Web to properly organize your sockets, understand the three common drive sizes: Check out the table of contents below to quickly find the chart you need.

Printable Socket Size Chart

Socket Size Chart Metric and Standard Form Fill Out and Sign

Printable Socket Size Chart

Printable Socket Size Chart lupon.gov.ph

Socket Size Chart Socket Sizes in Order from Smallest to Largest

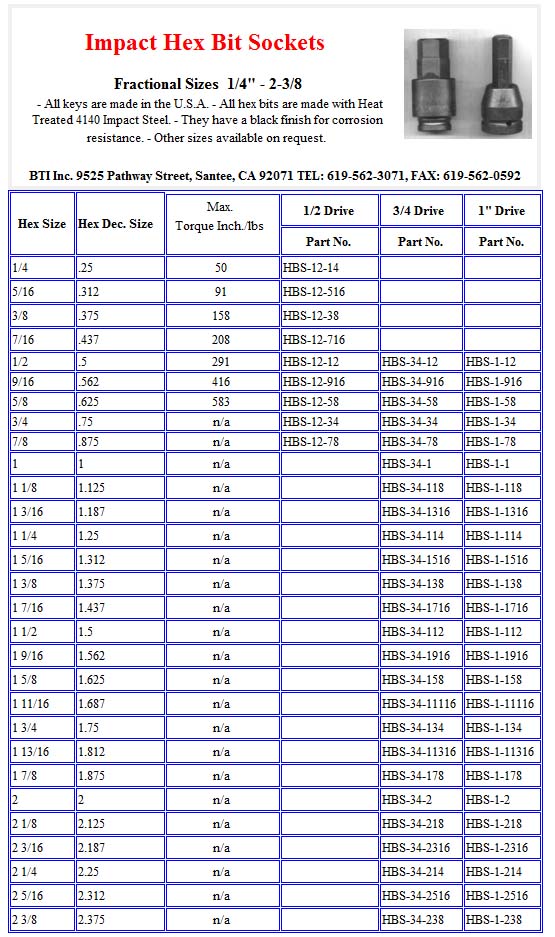

Products Hand Tools Hex Bit Sockets Fractional Sizes 12in

Printable Socket Size Chart Metric And Standard Download Your

![[View 19+] Socket Wrench Metric Sizes](https://i1.wp.com/handtoolessentials.com/wp-content/uploads/2019/06/Wrench-Conversion-Chart-SAE-Metric-Sizes.jpg?resize=800%2C2391&ssl=1)

[View 19+] Socket Wrench Metric Sizes

Printable Socket Size Chart Free Printable Templates

Printable Socket Size Chart Metric And Standard

If It's Not Slightly Larger It Won't Fit.

Common Socket Conversions And Downloadable Chart (Pdf) Are Below The Chart.

How To Make Bubble Flare With A Double Flare Tool.

Learn More About The Different Socket Sets, Their Benefits, And Their Uses, Too.

Related Post: