Polishing Wheel Color Chart

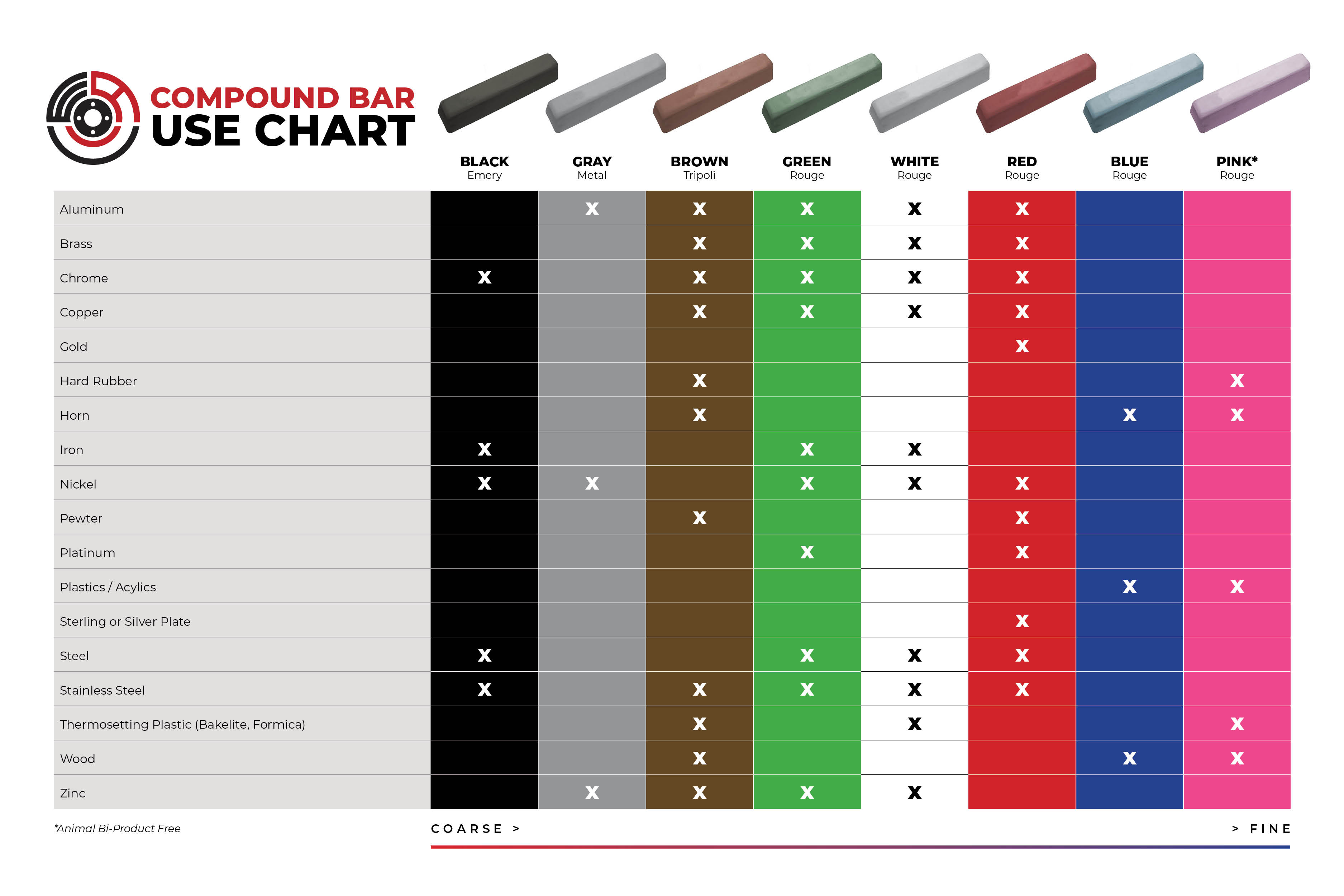

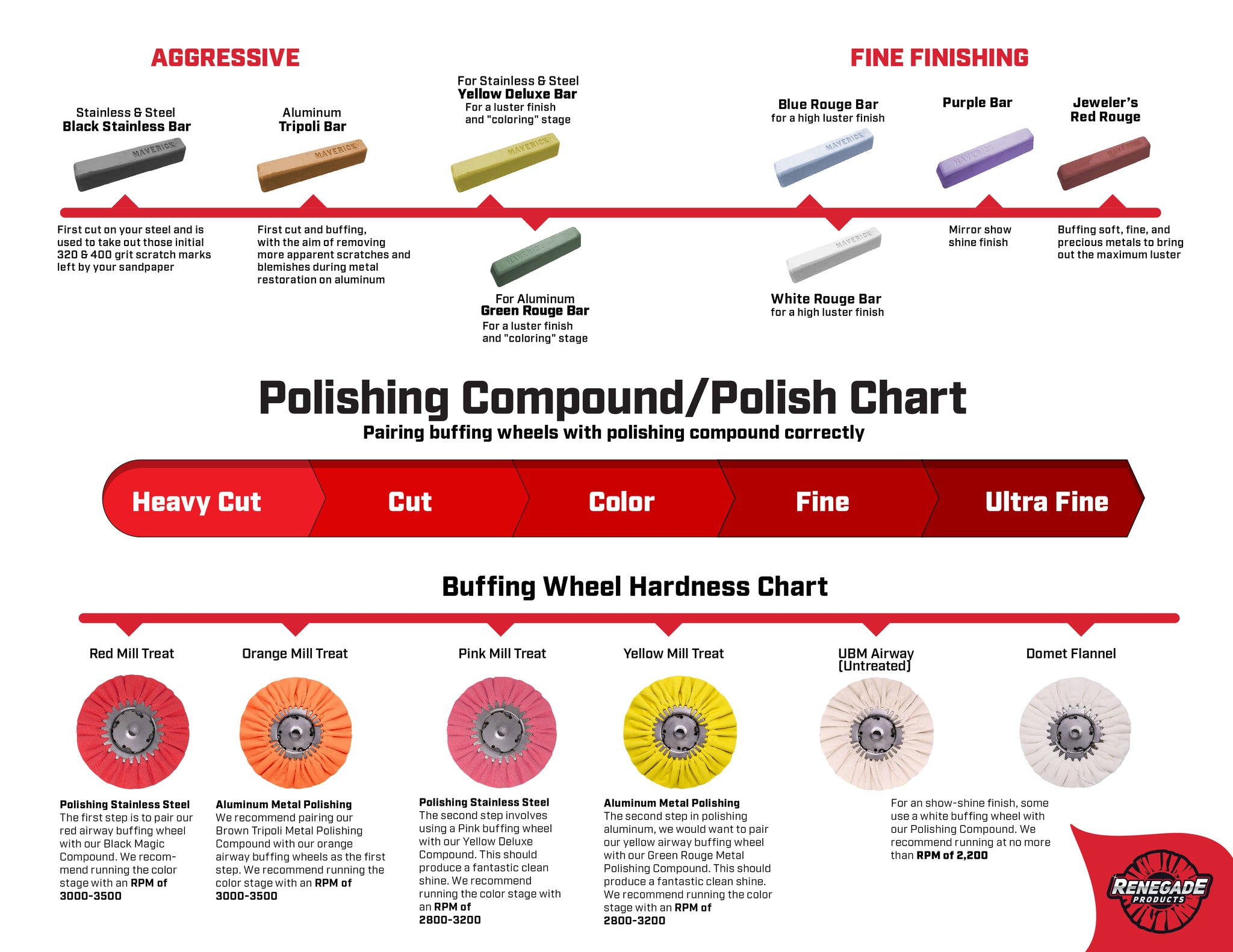

Polishing Wheel Color Chart - It also covers what colors are. Cut buffing with coarse polishing. For best results your wheel should maintain a surface speed of between 3600 & 7500 surface feet per minute. Web buffing wheel & compound reference chart for polishing stainless steel, aluminum, chrome, brass & other metals. It is also a good idea to change the wheel for each compound to avoid a. While the cut phase will leave a nice shine, this will really. Use appropriate buffing wheels matched with compounds when changing from cutting to coloring to prevent. Web in this post we will show you a color chart that displays the different buffing wheels and buffing compounds that we manufacture. Sisal buffs are often the first buffing wheel used for cutting processes, especially for harder. Web buffing compound has different colors and sizes. Covers emery, tripoli, white & jewelers rouge. For best results your wheel should maintain a surface speed of between 3600 & 7500 surface feet per minute. We have put a list together of the different buffing and. Web the different colors of airway buffs are not there to let you work with your favorite color. Web buffing compound has different. Use appropriate buffing wheels matched with compounds when changing from cutting to coloring to prevent. Next, you will find the buffing compounds color chart along. It also covers what colors are. The higher your speed, the. Web in this post we will show you a color chart that displays the different buffing wheels and buffing compounds that we manufacture. Web this chart will help you assess which jewellery polishing compound you need when you’re working with different types of metal. Covers emery, tripoli, white & jewelers rouge. Web in contrast, tripoli compounds are used for cutting and buffing to remove scratches from the metal. Web the best advice for applying the compound bars to your polishing wheel is to. It also covers what colors are. Web buffing compound has different colors and sizes. For best results your wheel should maintain a surface speed of between 3600 & 7500 surface feet per minute. It is also a good idea to change the wheel for each compound to avoid a. Web using this guide to help you determine which buffing wheels. The higher your speed, the. Cut buffing with coarse polishing. While the cut phase will leave a nice shine, this will really. Web the best advice for applying the compound bars to your polishing wheel is to apply little and often. Use appropriate buffing wheels matched with compounds when changing from cutting to coloring to prevent. Web the different colors of airway buffs are not there to let you work with your favorite color. Let the compound and the wheel do the work. Web in contrast, tripoli compounds are used for cutting and buffing to remove scratches from the metal. While the cut phase will leave a nice shine, this will really. Web buffing compounds are. Web using this guide to help you determine which buffing wheels and buffing compounds would serve you best for the various stages of buffing and polishing,. While the cut phase will leave a nice shine, this will really. Web the different colors of airway buffs are not there to let you work with your favorite color. Web these buffing wheels. Web there are many different types of buffing wheels, each designed to accomplish different tasks. Sisal buffs are often the first buffing wheel used for cutting processes, especially for harder. Web using this guide to help you determine which buffing wheels and buffing compounds would serve you best for the various stages of buffing and polishing,. It generally be used. For best results your wheel should maintain a surface speed of between 3600 & 7500 surface feet per minute. While the cut phase will leave a nice shine, this will really. It generally be used with a buffing wheel together to polish different materials for getting a fine surface or mirror surface. Web this chart will help you assess which. Next, you will find the buffing compounds color chart along. Web in contrast, tripoli compounds are used for cutting and buffing to remove scratches from the metal. Web this chart will help you assess which jewellery polishing compound you need when you’re working with different types of metal. It generally be used with a buffing wheel together to polish different. It is also a good idea to change the wheel for each compound to avoid a. We have put a list together of the different buffing and. Web in this post we will show you a color chart that displays the different buffing wheels and buffing compounds that we manufacture. Let the compound and the wheel do the work. Web this chart will help you assess which jewellery polishing compound you need when you’re working with different types of metal. Next, you will find the buffing compounds color chart along. Covers emery, tripoli, white & jewelers rouge. Below you will find our buffing wheel and buffing compound chart that displays from stiffness to hardness (buffing wheels) and from coarseness to finest finishing (compound bars). It generally be used with a buffing wheel together to polish different materials for getting a fine surface or mirror surface. It also covers what colors are. Web these buffing wheels will provide both polishing and cutting action. Web the different colors of airway buffs are not there to let you work with your favorite color. The higher your speed, the. Each of these colors has a different firmness/softness of the cloth pieces. Web the best advice for applying the compound bars to your polishing wheel is to apply little and often. While the cut phase will leave a nice shine, this will really.

Polishing Compound Color Chart

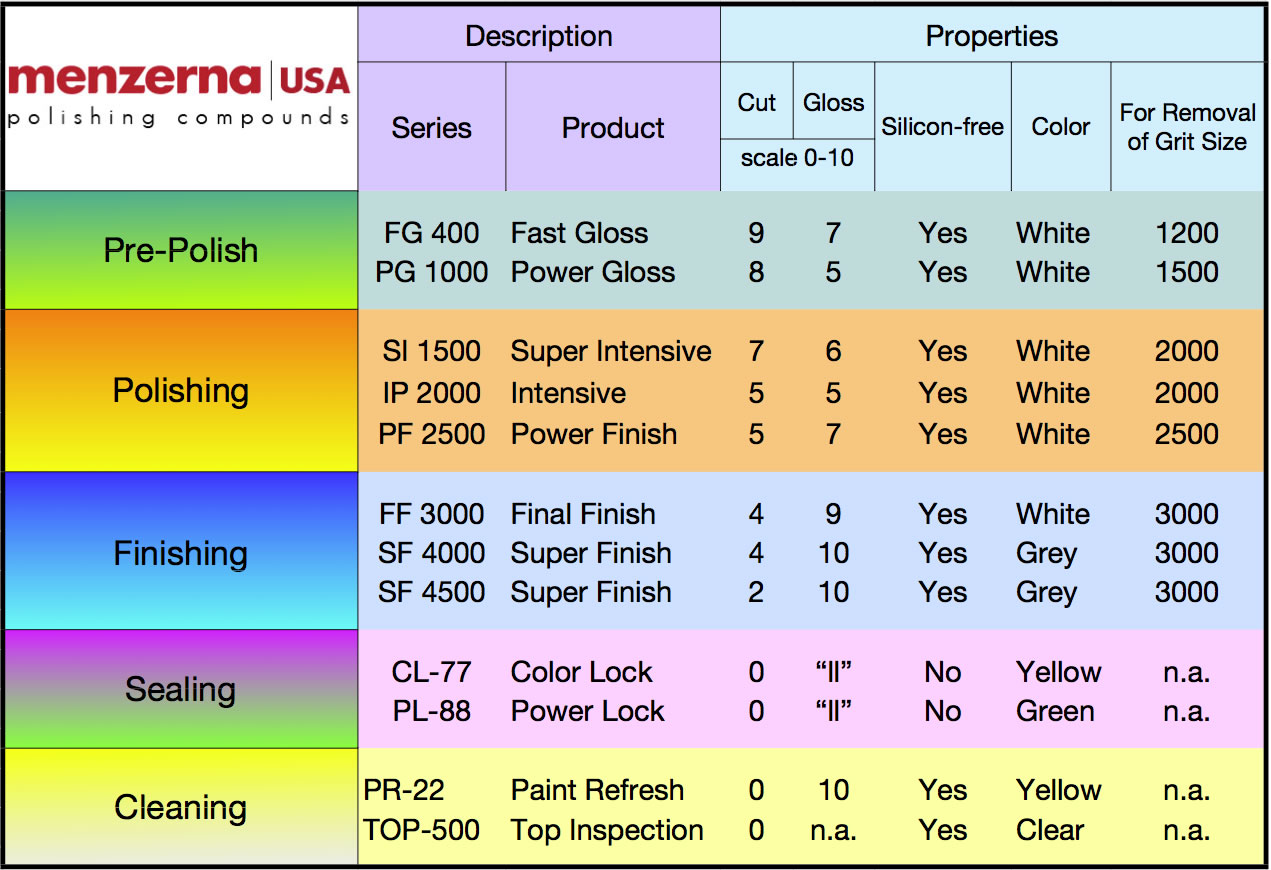

Menzerna Polishing Chart Detailed Image

Polishing Compound Color Chart Printable

Colors of airway polish buffing wheel Guangzhou Chuanglian Industrial

Polishing Buffs & Wax Victory Hardware Co

Pink OPI Nail Polish Pinks Colour Wheel Chart Opi pink, Pink nails

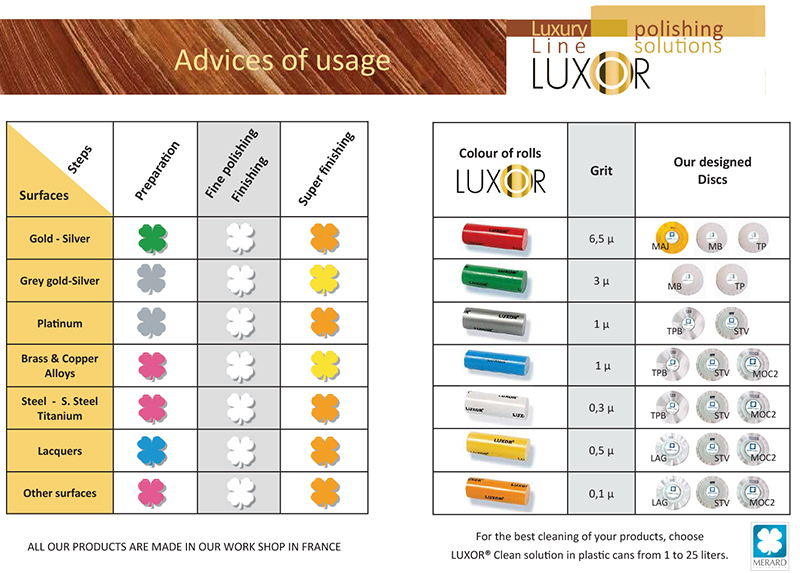

Luxor Polishing Compound Grey

A Jeweler’s Guide to Using Polishing Compounds

Nail Display Color Wheel Color Chart Nail Polish

15 Polishing Compound Color Chart Polishing chart menzerna pads polish

For Best Results Your Wheel Should Maintain A Surface Speed Of Between 3600 & 7500 Surface Feet Per Minute.

Web Buffing Compounds Are Used With Buffing And Polishing Wheels To Increase The Effectiveness Of The Wheel And To Help You Accomplish Your Tasks More Quickly.

(Color Phase) Pair Your Yellow Airway Buffing Wheel With Your Green Rouge Compound Bar.

Web Using This Guide To Help You Determine Which Buffing Wheels And Buffing Compounds Would Serve You Best For The Various Stages Of Buffing And Polishing,.

Related Post: