Plastic Surface Finish Chart

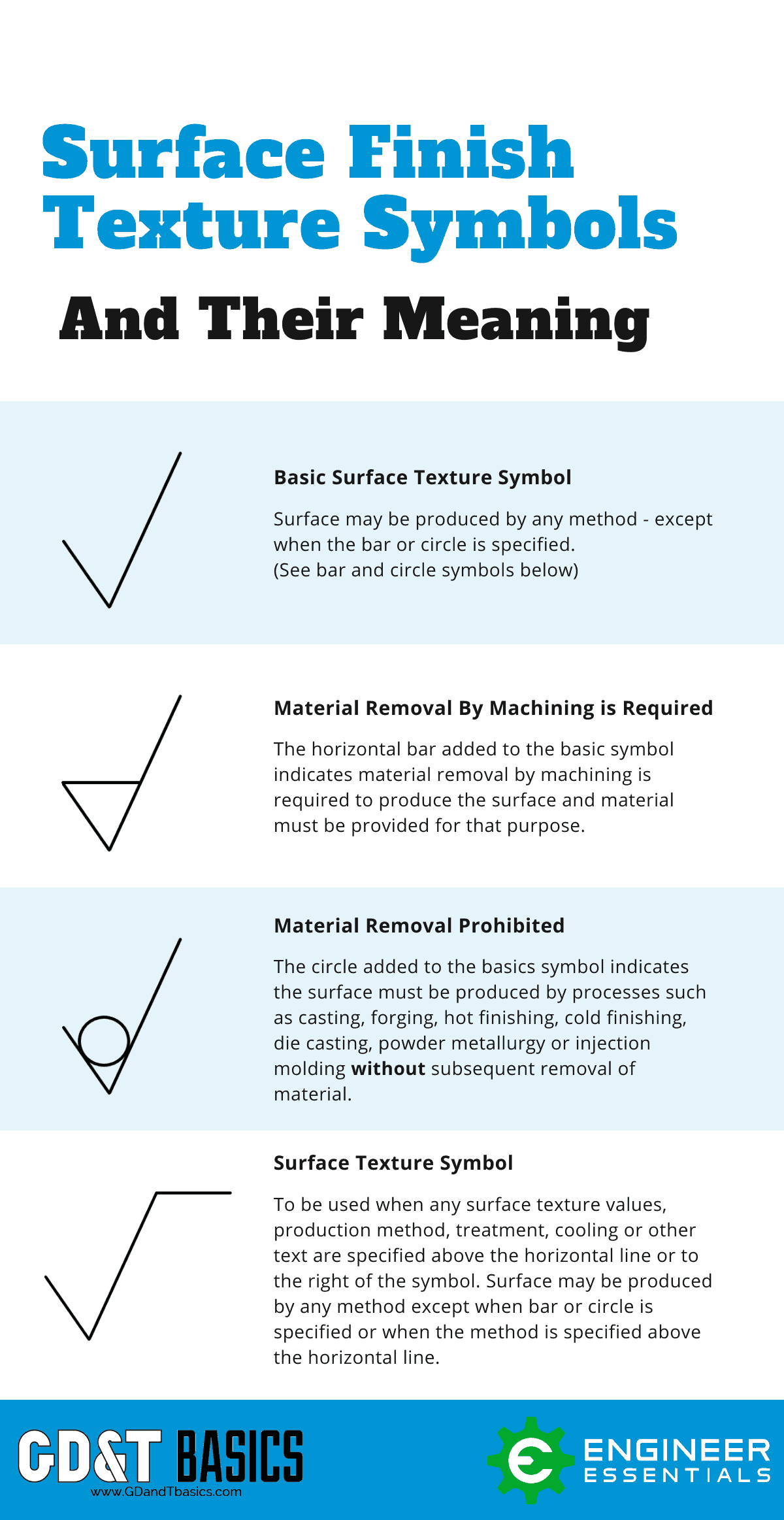

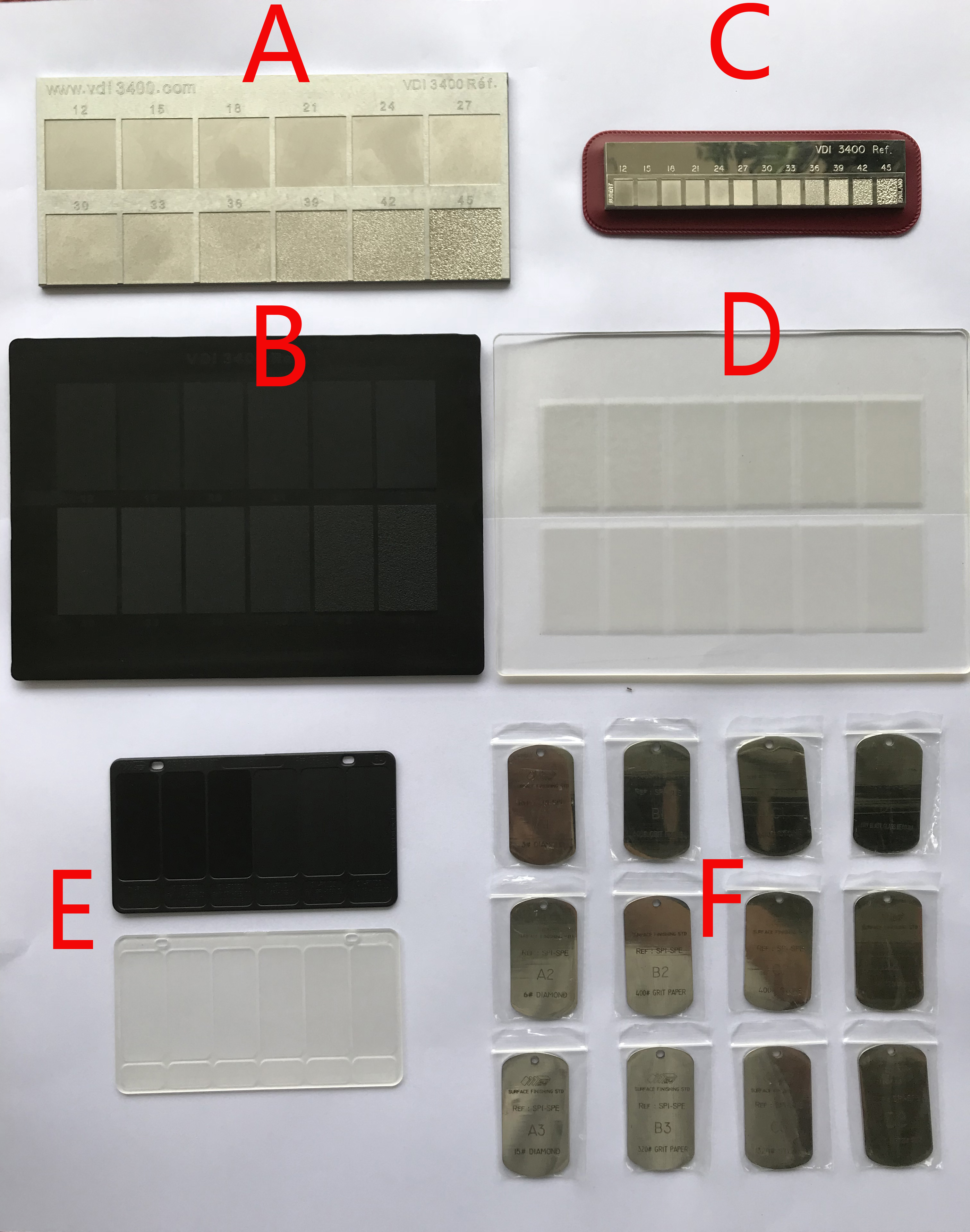

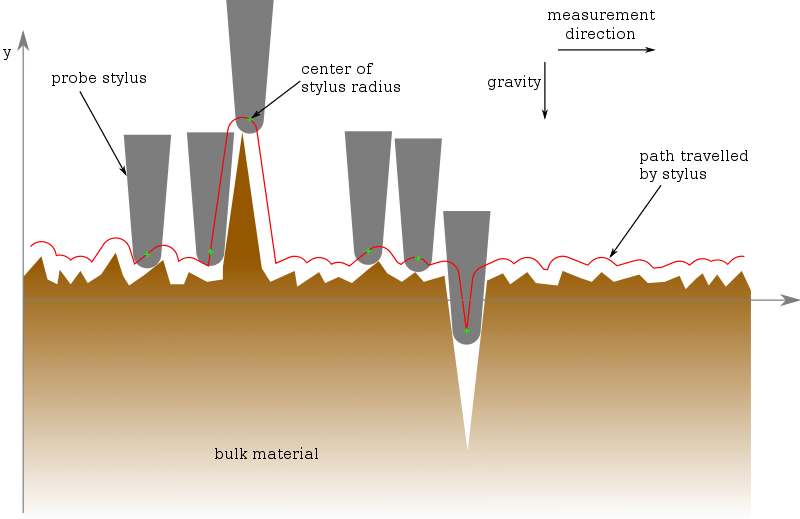

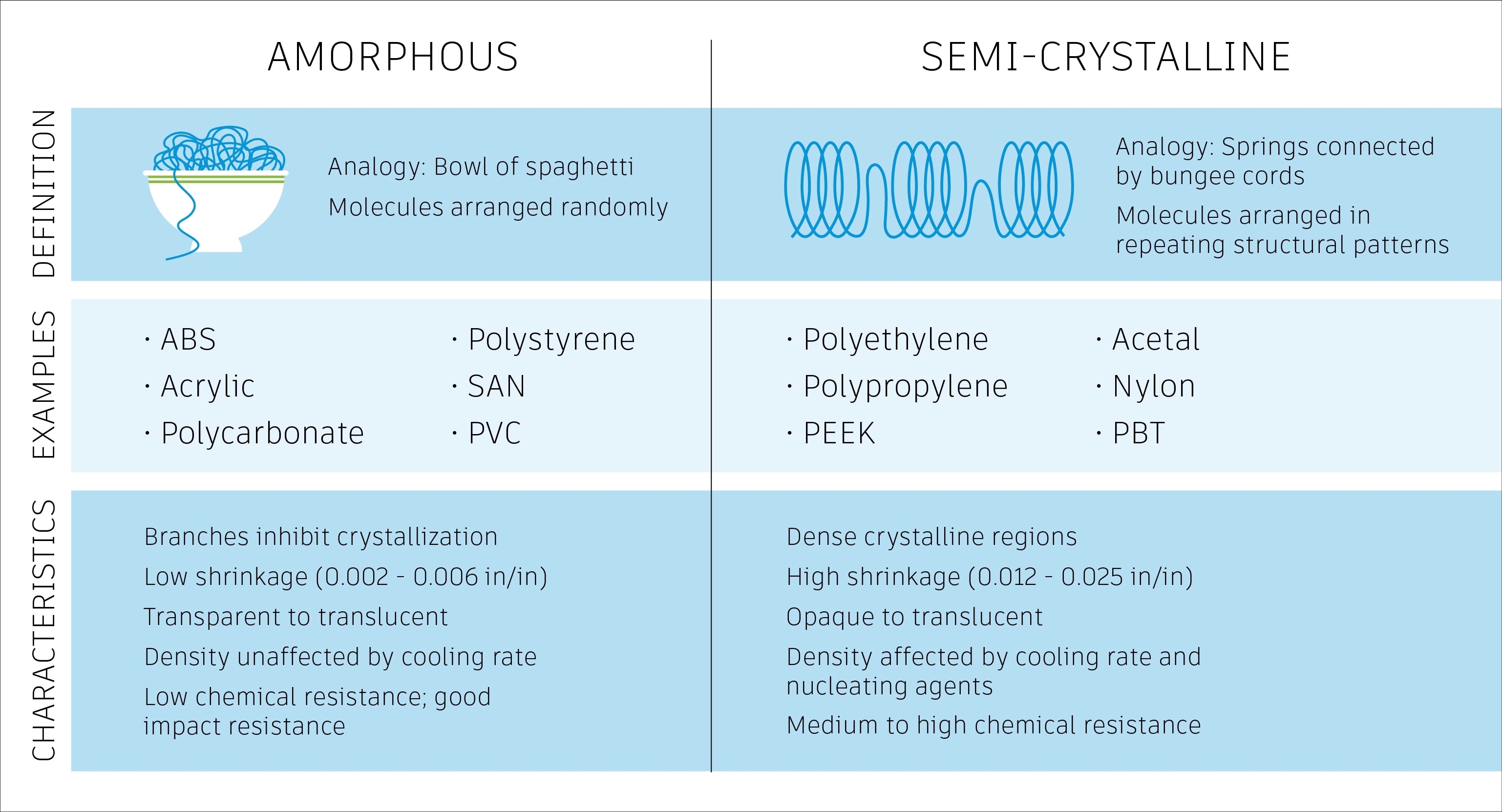

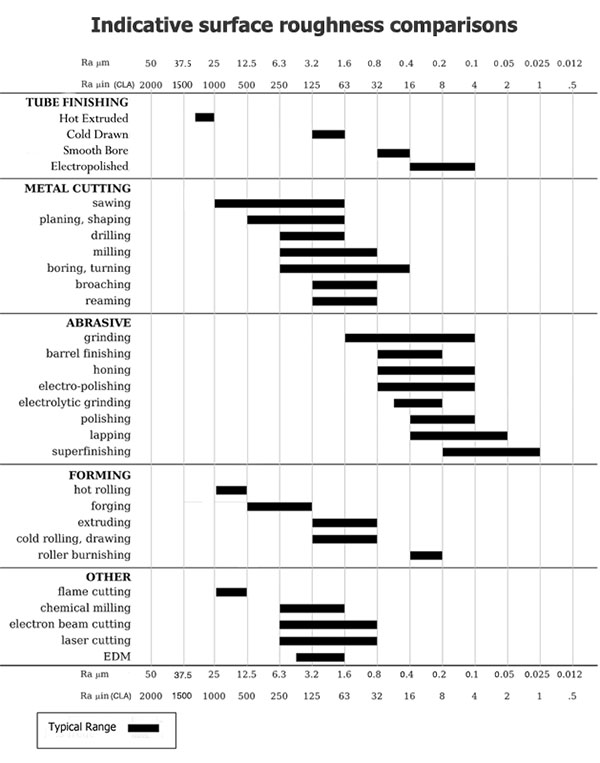

Plastic Surface Finish Chart - Web below are images depicting each surface finish option for injection molding. That is why plastic finishes can make or break a product. Web surface finish charts are used to depict the average roughness profile of a certain material after different processing techniques i.e., grinding, polishing and buffing. Texture is characterized by three qualities: By looking at these charts we can choose material and process wisely for. Spi mold finish look, feel, and quality depends on the thermoplastic material’s mechanical properties and part color. Web surface roughness chart. How do i choose a surface finish? The chart lists the name of the finish, the roughness (in microns), and the finishing method and spi standard. Web spi surface finish chart for roughness technology. That is why plastic finishes can make or break a product. Plastic surface finish is a critical part of the design process. Web spi surface finish standards the spi is that society of the plastics industry sets standard for plastics industry in the united states that identifies the cosmetic quality of plastics, upmold uses the spi standard to define finish. Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of the surface. Web the tables below detail how to select the right mold finish and materials for your specific application. How do i choose a surface finish? Web spi surface finishes are the most common set of. Web below are images depicting each surface finish option for injection molding. Spi mold finish look, feel, and quality depends on the thermoplastic material’s mechanical properties and part color. How to measure surface roughness. Web we provide you ultimate guide on explantion of spi surface finish standard, process how to make spi finish, references of spi finish cards/plaques and conversion. Tips for improving surface finish. By looking at these charts we can choose material and process wisely for. Surface finish is a measure of the overall texture of a surface that is characterized by the lay, surface roughness, and waviness of the surface. Web surface finish charts are used to depict the average roughness profile of a certain material after. Plastic surface finish is a critical part of the design process. Web we provide you ultimate guide on explantion of spi surface finish standard, process how to make spi finish, references of spi finish cards/plaques and conversion to vdi 3400 textures. The standard covers 12 spi surface finish grades and features at: Web spi mold finish guide, spi mold finish. Web the society of plastics industry (spi) has set several standard finishing procedures that result in different part surface finishes. Web the below chart shows the spi finish along with the finish method and surface roughness values. Web spi surface finishes are the most common set of injection molding finishing standards around the world with over 12 different grades. Web. Web spi surface finishes are the most common set of injection molding finishing standards around the world with over 12 different grades. Web aside from dimensions and tolerances, another important callout is surface finish. Need more advice on injection molding custom parts? Cnc machining is one of the many manufacturing processes that can produce a surface texture. Web spi surface. By looking at these charts we can choose material and process wisely for. Lay (the general direction of the surface pattern), roughness (the average of vertical deviations), and waviness (surface irregularities). They are explained in the below table. Web there are twelve grades of finishes specified by the spi in four categories that range from shiny to dull. Web the. How do i choose a surface finish? The mold can be textured with machines or polished manually. Web the spi finish standards refer to the surface finish standard set by american spi (society of the plastics industry ). Texture is characterized by three qualities: Manufacturers always use it as a reference material to ensure quality in the manufacturing process. Spi mold finish look, feel, and quality depends on the thermoplastic material’s mechanical properties and part color. Manufacturers always use it as a reference material to ensure quality in the manufacturing process. Web spi surface finishes are the most common set of injection molding finishing standards around the world with over 12 different grades. Web the plastic surface roughness chart. Manufacturers always use it as a reference material to ensure quality in the manufacturing process. Plastic surface finish is a critical part of the design process. Web the society of plastics industry (spi) has set several standard finishing procedures that result in different part surface finishes. Web spi surface finish standards the spi is that society of the plastics industry sets standard for plastics industry in the united states that identifies the cosmetic quality of plastics, upmold uses the spi standard to define finish of plastic injection molded parts. Surface finish is a term describing the texture of the surface of a printed object. What does a 32 surface finish mean? Lay (the general direction of the surface pattern), roughness (the average of vertical deviations), and waviness (surface irregularities). By jeremy losek, jul 5th, 2023. Need more advice on injection molding custom parts? From spi a1 to spi d3 ( ra 0.012 μm to ra 18.00μm). That is why plastic finishes can make or break a product. Spi surface finish recommendations for plastic part. Cnc machining is one of the many manufacturing processes that can produce a surface texture. How do i choose a surface finish? In other words, texture is a subset or type of surface finish. Get the latest manufacturing news delivered to your mailbox.

SPI surface finish standard of metal, plastics scale

The Basics of Surface Finish GD&T Basics

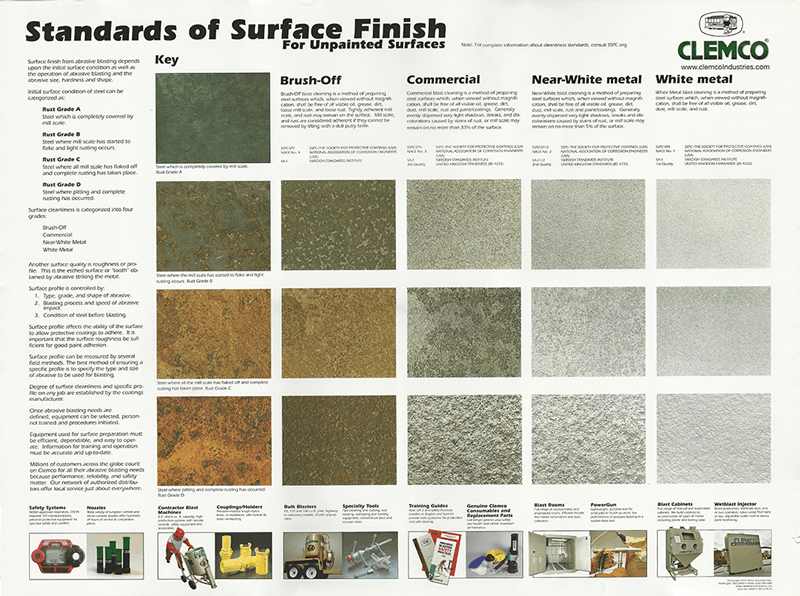

Standards of Surface Finish Chart Hodge Clemco

EDM plastic surface finishes

Surface roughness chart

Surface Finishes Chart For CNC Machining The Ultimate Guide Xin Tian

What is Surface Finish? Units, Symbols & Chart

Plastic Surface Finish Chart Labb by AG

Surface_Finish_Charts.pdf

Complete Guide to Surface Finish Charts, RA, RZ, Measurements, Callouts

Web Spi Surface Finishes Are The Most Common Set Of Injection Molding Finishing Standards Around The World With Over 12 Different Grades.

Web Below Are Images Depicting Each Surface Finish Option For Injection Molding.

The Chart Lists The Name Of The Finish, The Roughness (In Microns), And The Finishing Method And Spi Standard.

Web There Are Twelve Grades Of Finishes Specified By The Spi In Four Categories That Range From Shiny To Dull.

Related Post: