Plasma Cutting Shade Chart

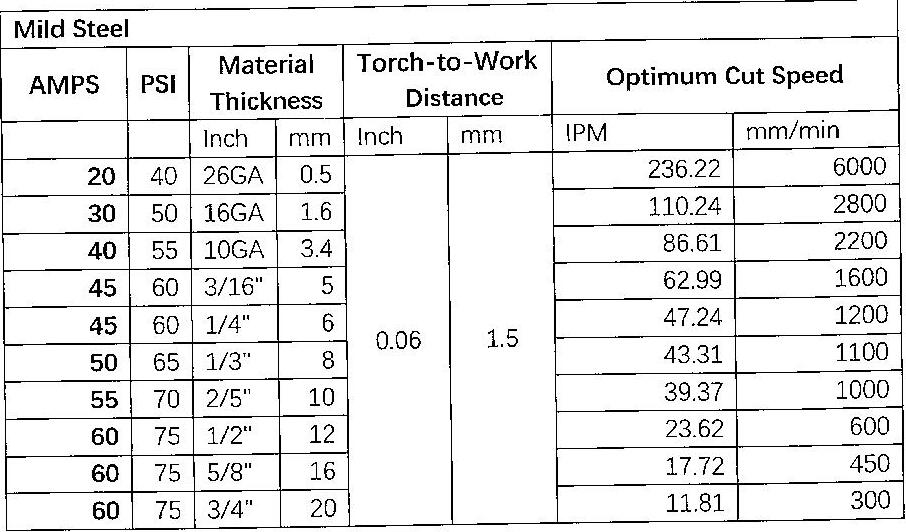

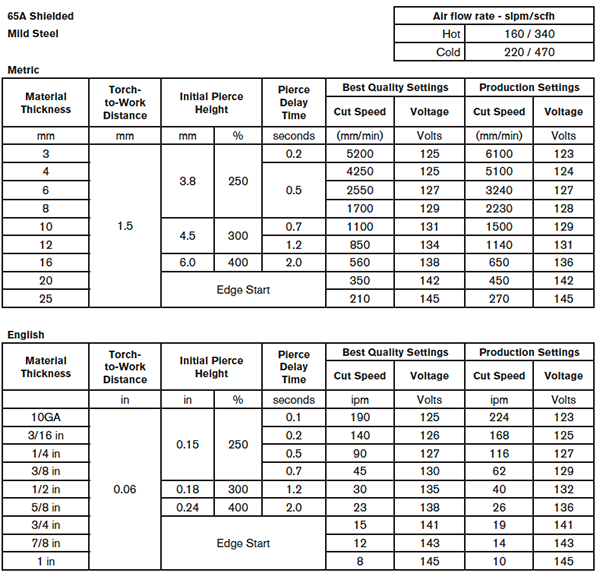

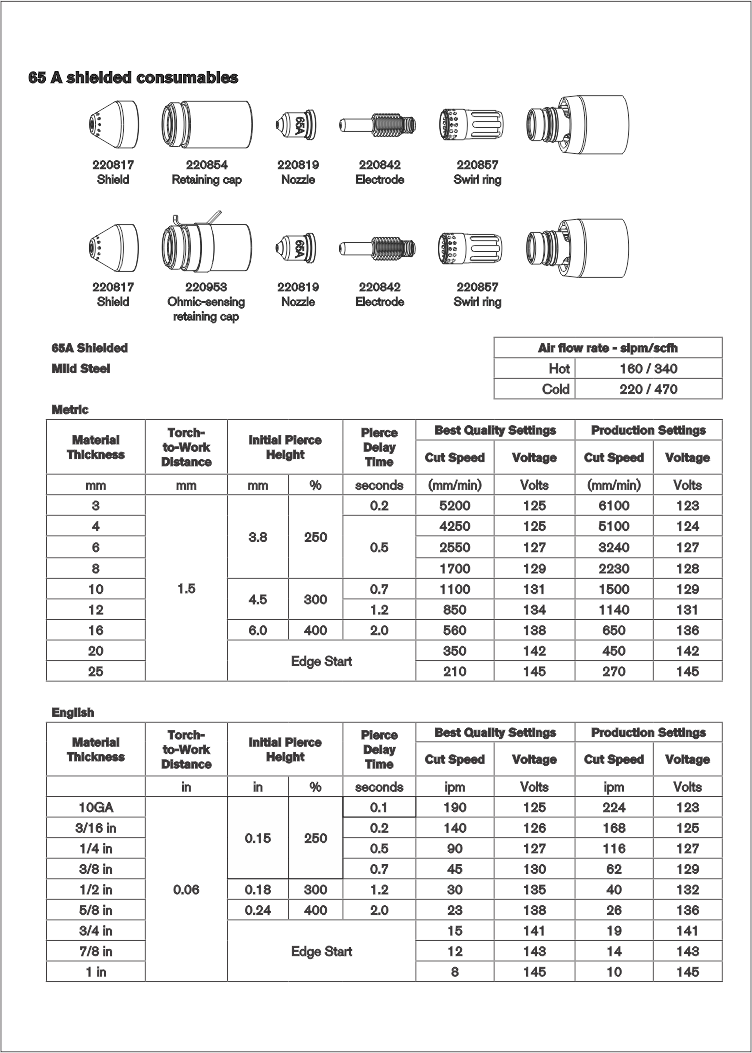

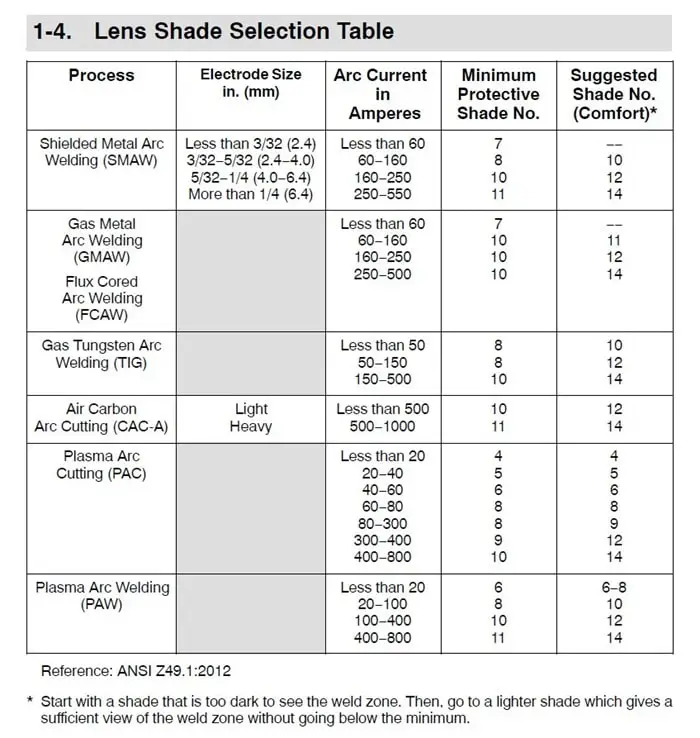

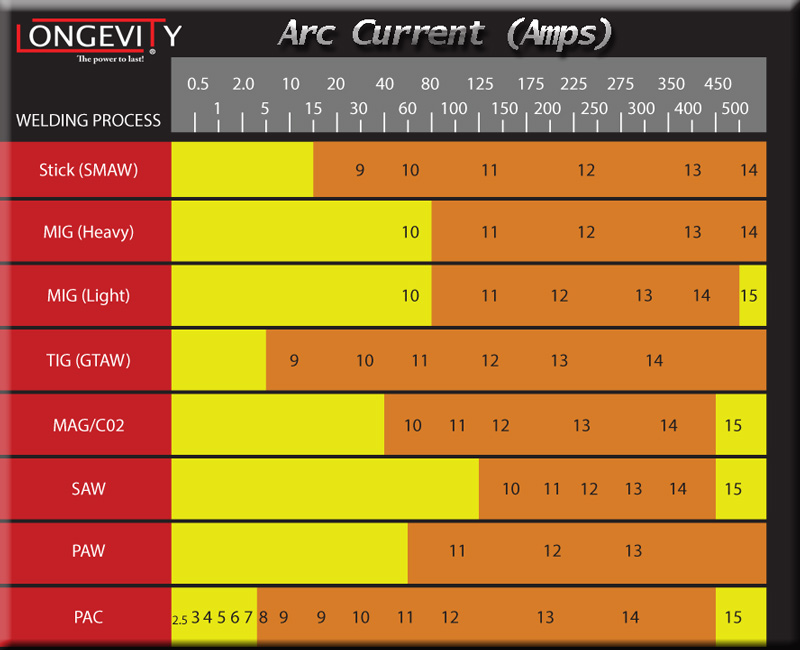

Plasma Cutting Shade Chart - If you use only torch goggles or safety glasses, you’ll get a nice sunburn on your face and neck in as little as 10 minutes of cutting. Web this is what i have found to work with most plasma cutter nozzles/tips that most people have in their shops or garages. Mechanic416 september 19, 2020, 4:59pm 5. Web you have lights on the front panel that will tell you when you have the correct air pressure. Choosing an appropriate shade lens is essential to ensure that you’re protected from harmful rays and intense light during plasma cutting operations. If the light from the machine is too intense even with a #10 shade lens, then it may be necessary to go up to a. This operating manual provides the basic knowledge required for plasma cutting, as well as highlighting important areas of how to operate the boc smoothcut plasma cutting machine. Cutting speed is the most critical aspect of plasma metal cutting. Web we’ll also include handy charts to help you adjust settings based on material type and thickness. The higher the number the darker the glass. Then go to a lighter shade which gives sufficient view of the weld zone without going below the minimum. Web the protective shade numbers refer to the darkness shade of safety glasses or welding shields. Web you have lights on the front panel that will tell you when you have the correct air pressure. For those working with a plasma. For those working with a plasma cutter operating at 40 amps, ansi recommends using shade 5 glasses. Mechanic416 september 19, 2020, 4:59pm 5. These are only starting points. When a worker wears eyewear equipped with filter lenses under a welding helmet, the shade number of the lens in the helmet may be reduced. Web chart for lens tint for protection. Mechanic416 september 19, 2020, 4:59pm 5. The higher the number the darker the glass. It is not a replacement for the detailed information found in the operator’s manual for your plasma system. This operating manual provides the basic knowledge required for plasma cutting, as well as highlighting important areas of how to operate the boc smoothcut plasma cutting machine. In. Web the protective shade numbers refer to the darkness shade of safety glasses or welding shields. Here is a summary of the recommended parameters for different thicknesses of materials and the corresponding amperage and air pressure settings: Web the tables below list the minimum protective lens shade numbers for commonly used welding and cutting processes. Web this chart provides minimum. Web most people find that a #10 shade or higher is sufficient for protecting their eyes during plasma cutting. Web generally speaking, low amperage cutters require at least a #6 shade lens while higher amperage ones may need something as high as #12 or beyond. You could use these cut charts to help up to 60 amps! I have some. Web chart for lens tint for protection against radiant energy. Choosing an appropriate shade lens is essential to ensure that you’re protected from harmful rays and intense light during plasma cutting operations. Web most people find that a #10 shade or higher is sufficient for protecting their eyes during plasma cutting. Web lens shade for plasma cutting? Web cut50 plasma. I have a 375 miller plasma. Web chart for lens tint for protection against radiant energy. Web the chart below outlines their recommendations for eye protection when plasma cutting: Web this chart provides minimum suggested protective lens shades and suggested comfort lens shades for a variety of commonly used welding and cutting processes. In other words, it uses the basic. The higher the number the darker the glass. Ansi and the american welding society (aws) publish a slightly more detailed chart in “ansi z49.1:2005 safety in welding, cutting, and allied processes.” This operating manual provides the basic knowledge required for plasma cutting, as well as highlighting important areas of how to operate the boc smoothcut plasma cutting machine. As a. Web how to plasma cut. Web shield your eyes with the proper shade lens for the plasma cutter you plan to use. 1.0mm/50 amp, 1.1mm/60 amp, 1.2mm/70 amp and 1.3mm/80 amp. In this blog post, we will explore what shade lens is best for plasma cutting and why. Cutting speed is the most critical aspect of plasma metal cutting. Web lens shade for plasma cutting? Web cut50 plasma cutter suggested amperage & air setting cutter chart. Orifice hole size 1mm =.03937. Web most people find that a #10 shade or higher is sufficient for protecting their eyes during plasma cutting. It’s not just your eyes you need to be concerned about. Web most people find that a #10 shade or higher is sufficient for protecting their eyes during plasma cutting. Web plasma cutters range in power level from 10 amps to 1000 amps, just like with welding, more amps equals a more intense arc. These settings provide a guideline for achieving optimal welding results based on the thickness of the materials. This operating manual provides the basic knowledge required for plasma cutting, as well as highlighting important areas of how to operate the boc smoothcut plasma cutting machine. Then go to a lighter shade which gives sufficient view of the weld zone without going below the minimum. For those working with a plasma cutter operating at 40 amps, ansi recommends using shade 5 glasses. Web cut50 plasma cutter suggested amperage & air setting cutter chart. The decision comes down to how flexible your welding needs are going to be. These are only starting points. Web if you are looking to purchase a lens for plasma cutting, it is important to know what shade is required. You could use these cut charts to help up to 60 amps! Web for plasma cutting steel, the recommended shade number varies depending on the amperage: Web from welding helmets to cutting lens and shade 5 glasses to face shields to torch goggles to otg safety glasses, here are the safest plasma cutting eye protection options! The higher the number the darker the glass. Web plasma cutting is the process that cuts through electrically conductive materials by using a strong jet of hot plasma. The owner’s manual will state the necessary shade for the amperage.

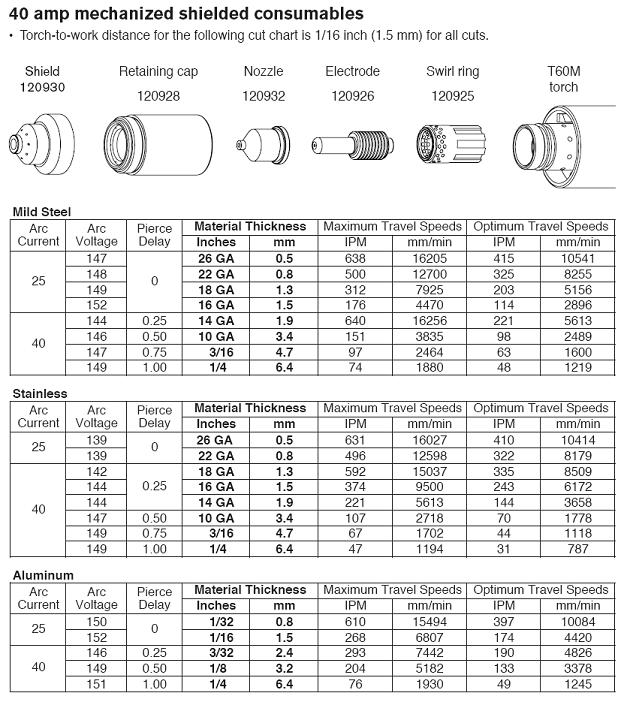

Cut charts for everlast plasma 9 by hunterthehobbyist Plasma

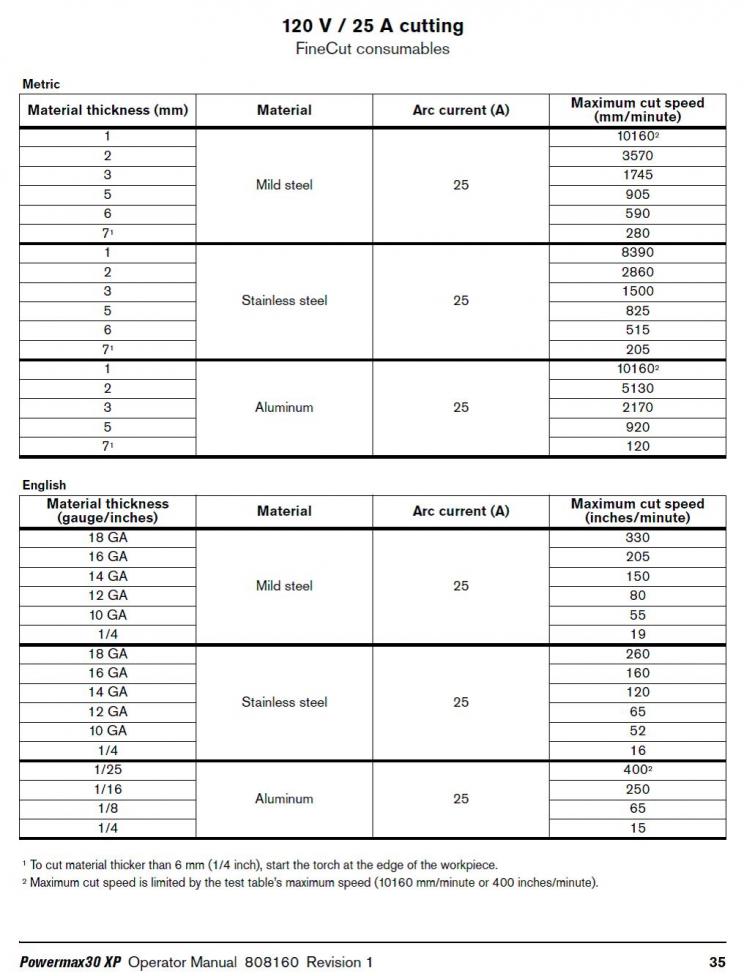

Plasma Cutting Thickness Chart

Plasma Cutting Shade Chart

Improve cut quality with these CNC steel and metal cutting tips

Plasma Cutter Thickness Chart

hypertherm 45xp cut chart Bamil

What shade lens is used for welding & welding lens shade chart

CNC Plasma

A check list for a plasma cutting table retrofit The Fabricator

Welding Helmets, Welding Masks, AutoDarkening Hoods Longevity

Ansi And The American Welding Society (Aws) Publish A Slightly More Detailed Chart In “Ansi Z49.1:2005 Safety In Welding, Cutting, And Allied Processes.”

1.0Mm/50 Amp, 1.1Mm/60 Amp, 1.2Mm/70 Amp And 1.3Mm/80 Amp.

But Getting The Speed Right Requires Some Trial And Error.

Here Is A Summary Of The Recommended Parameters For Different Thicknesses Of Materials And The Corresponding Amperage And Air Pressure Settings:

Related Post: