Plasma Cutter Amperage Chart

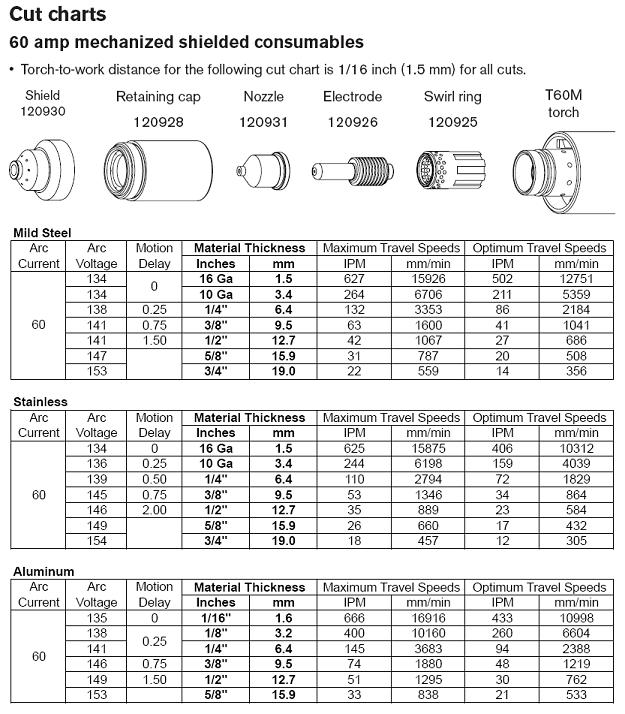

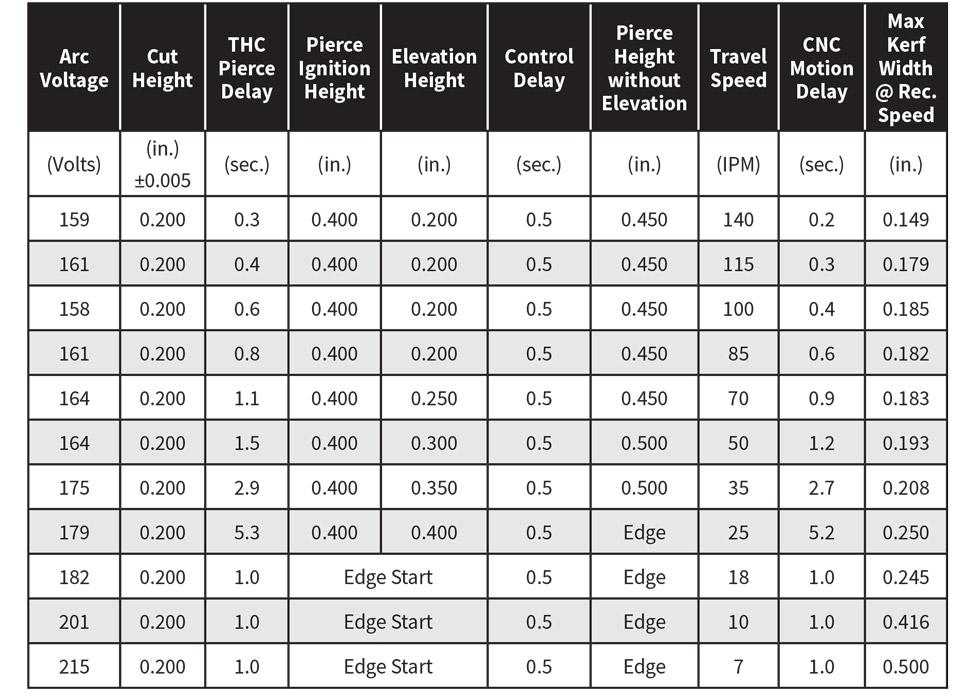

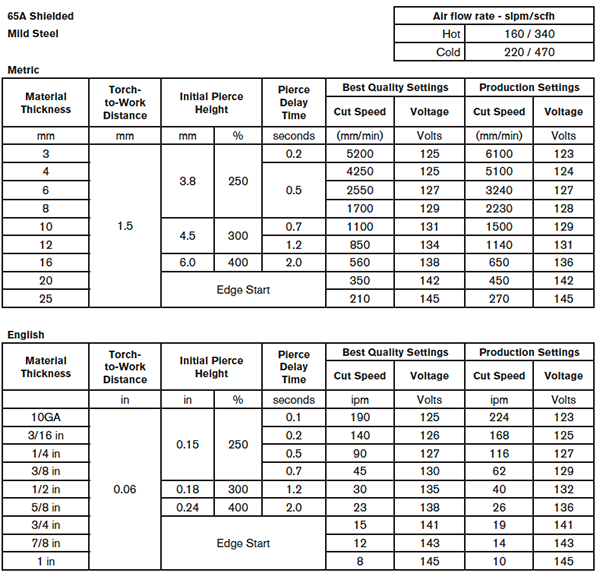

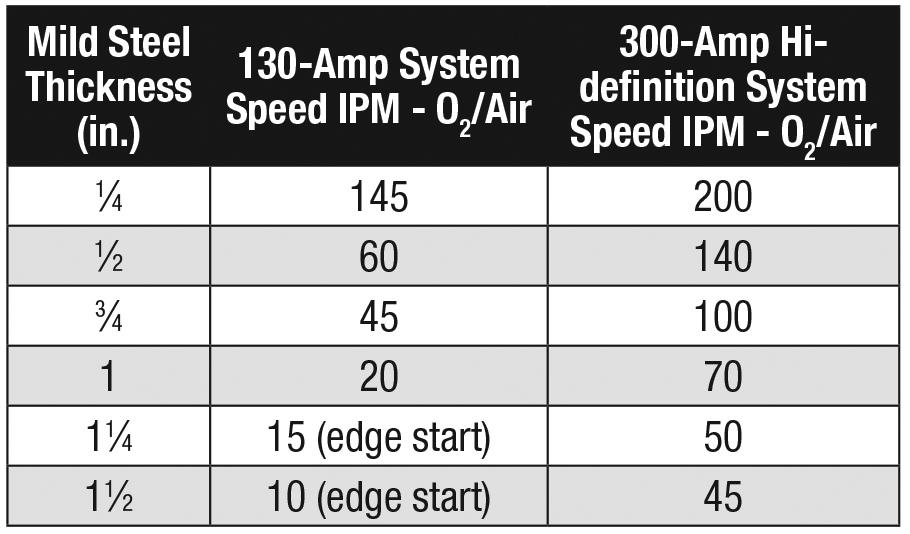

Plasma Cutter Amperage Chart - Web amperage usually isn’t included in cut charts because the amperage you choose should be based on the amperage of your nozzle. Web to determine the optimal amperage and air setting for your plasma cutter, consider the following steps: People in welding and cutting industries often talk about machine output in terms of amperage and purchasing decisions are regularly based on amperage numbers. Is the plasma arc cutting in the appropriate direction? Web what you need to begin. By matching the correct air pressure settings with the correct amperage settings for. Web you can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come in the door for your plasma table. Typically, all you need is: Web the following cut charts provide the necessary information in order for the operator using the max200 machine torch system to be successful in plasma arc cutting. Web all of our manuals contain very detailed cut charts, including plasma cut charts for aluminum. Every cutting system requires “fine tuning” for each cutting application to obtain the desired cut quality. Web to determine the optimal amperage and air setting for your plasma cutter, consider the following steps: Always start with the settings found in those charts. Web cut charts are intended to provide a good starting point for each different cut assignment. People in. •in finecut charts, the amperage for each thickness is included in the cut chart. Is the plasma arc cutting in the appropriate direction? Web what you need to begin. The following recommended settings are for mechanized cutting at 50 amps. Web the plasma cutter settings chart is a reference guide that provides recommendations for amperage, gas pressure, cutting speed, and. The higher the amps, the faster you can cut. Web cut charts are intended to provide a good starting point for each different cut assignment. Web in finecut charts, the amperage setting for each thickness is included in the cut chart. One of the great things about air plasma cutters is their ease of use and versatility. The following recommended. Web you can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come in the door for your plasma table. Adjust the cutting direction by changing your plasma cutting settings, if needed. It provides concise, accurate information about the thickness of different metals which can be cut using a particular. Orifice hole size 1mm =.03937. Power supply, whether electricity from your wall or an appropriately sized generator. •in finecut charts, the amperage for each thickness is included in the cut chart. The thickness of metal you will routinely cut and maximum metal thickness are important in selecting the right plasma cutter. Is the plasma arc cutting in the appropriate direction? Like a welding power source, a plasma cutter's amperage and voltage capacities determine its size. Web you can develop your own charts and reference those in the future to save yourself time and frustration when different jobs come in the door for your plasma table. If two cutters made by different manufacturers have the same amperage, then the assumption is. Refer to the plasma cutter's user manual: Always start with the settings found in those charts. Typically, all you need is: Low amperage cuts will require less air pressure for more stable operation, sometimes down to 45 psi or so, or the arc will be blown out. You can always make slight adjustments later if needed. Web the amperage applies to all the settings on that page. 7.9k views 2 years ago #plasmacutter #millerwelders. The user manual should contain a chart or table specifying the suggested amperage and air settings for various metal thicknesses. Can you plasma cut aluminum with a water table? Web the plasma cutter settings chart is a reference guide that provides recommendations. 7.9k views 2 years ago #plasmacutter #millerwelders. Keep in mind this isn’t the maximum thickness of cut that a plasma cutter is capable of cutting but rather, it is a good rule to follow for decent cutting speed and quality. Web cut charts are intended to provide a good starting point for each different cut assignment. Web the following cut. Web the following cut charts show the consumable parts, cutting speeds and the gas and torch settings required for each process. Web plasma cutting amperage gives the arc power to slice metal. Power supply, whether electricity from your wall or an appropriately sized generator. Web in finecut charts, the amperage setting for each thickness is included in the cut chart.. Web for 3/8” cut, 40 amps works out well for most brands of plasma cutters. Typically, all you need is: The user manual should contain a chart or table specifying the suggested amperage and air settings for various metal thicknesses. Web in finecut charts, the amperage setting for each thickness is included in the cut chart. Web all of our manuals contain very detailed cut charts, including plasma cut charts for aluminum. Orifice hole size 1mm =.03937. Power supply, whether electricity from your wall or an appropriately sized generator. Always start with the settings found in those charts. One of the great things about air plasma cutters is their ease of use and versatility. Is the plasma arc cutting in the appropriate direction? Web the plasma cutter settings chart is a reference guide that provides recommendations for amperage, gas pressure, cutting speed, and standoff distance based on different material thicknesses and desired cut qualities. Like a welding power source, a plasma cutter's amperage and voltage capacities determine its size. 7.9k views 2 years ago #plasmacutter #millerwelders. People in welding and cutting industries often talk about machine output in terms of amperage and purchasing decisions are regularly based on amperage numbers. When it comes to plasma cutter setup and technique, setting the correct amperage and using the right. Web cut charts are intended to provide a good starting point for each different cut assignment.

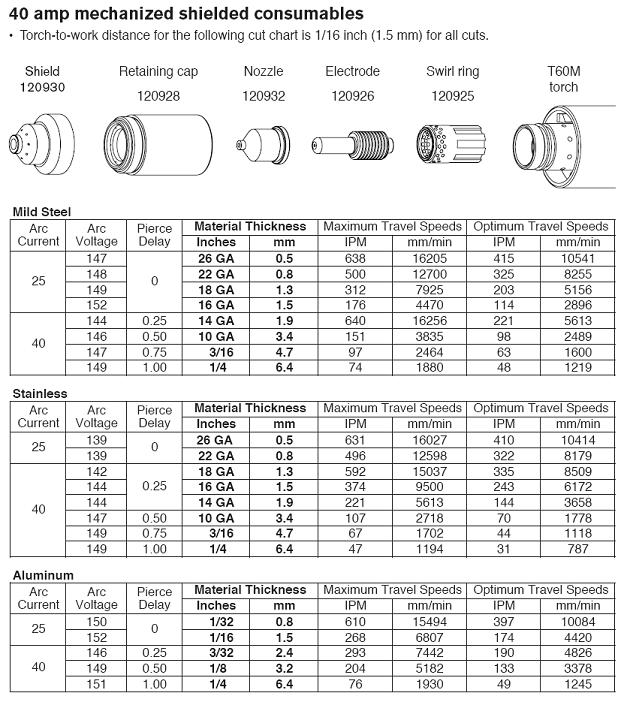

hypertherm 45xp cut chart Bamil

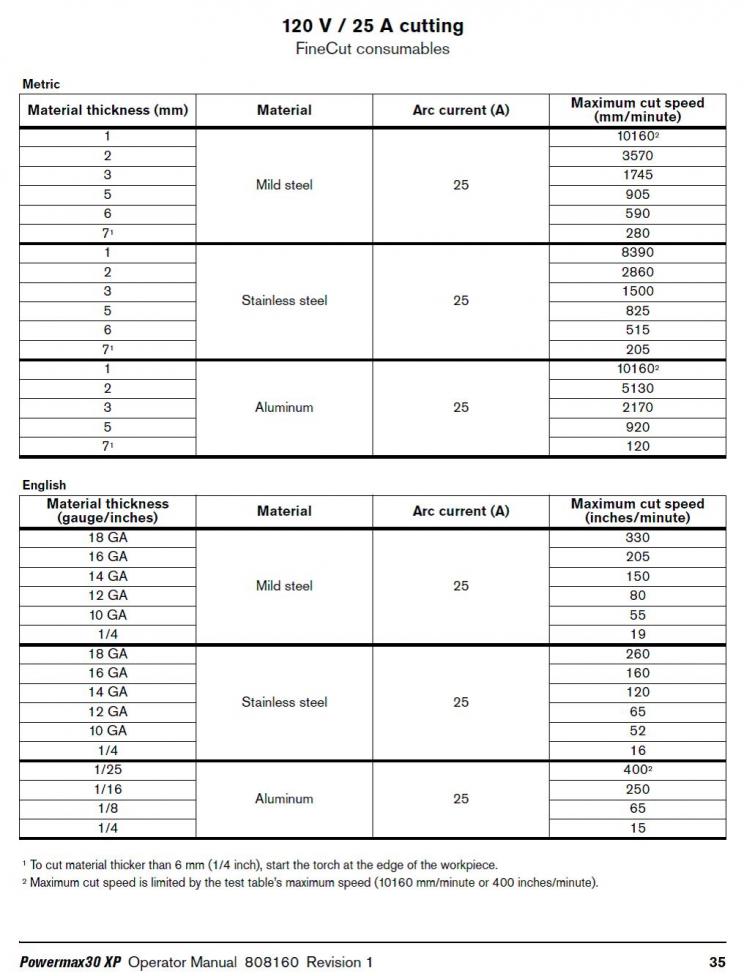

Plasma Cutter Amps Thickness Chart Online Shopping

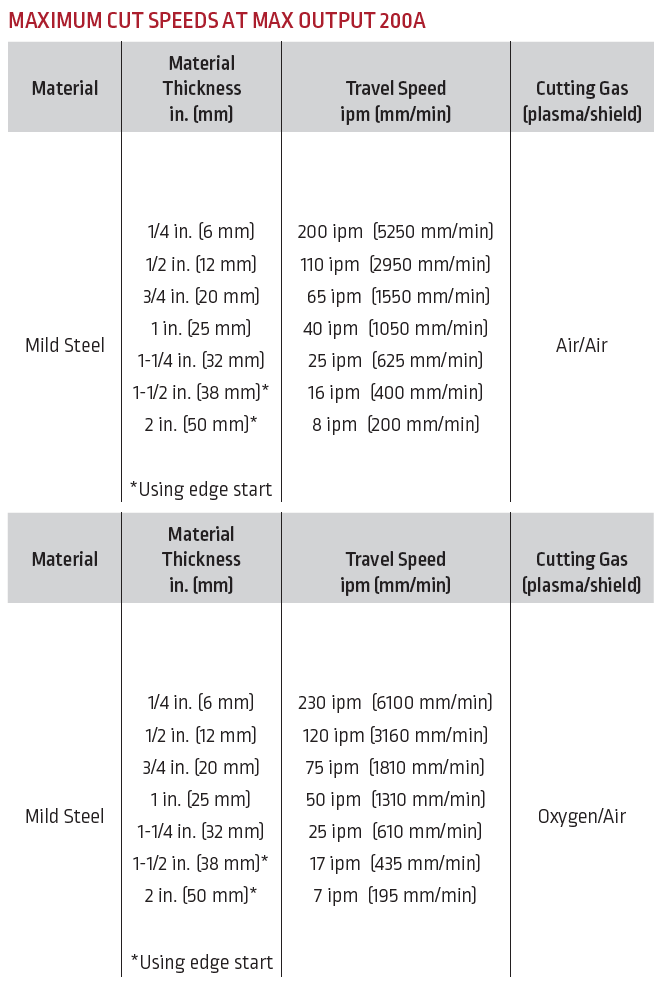

Cut charts for everlast plasma 9 by hunterthehobbyist Plasma

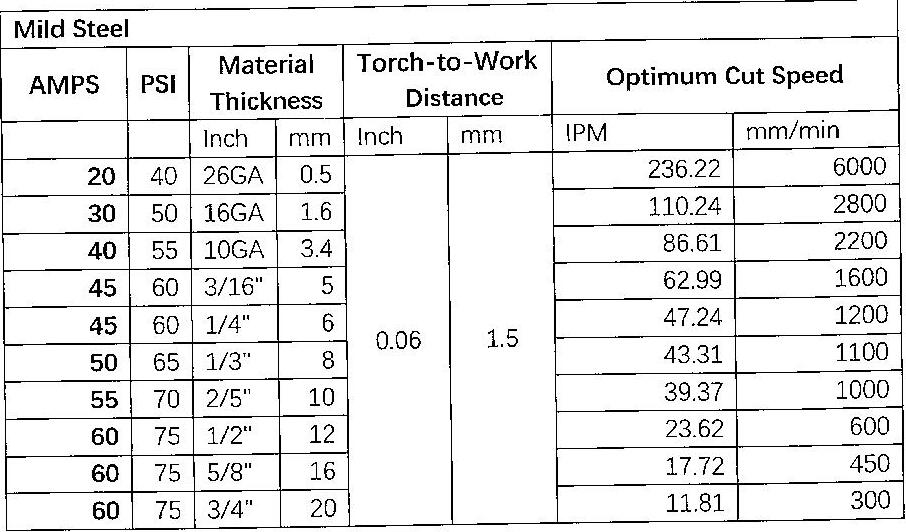

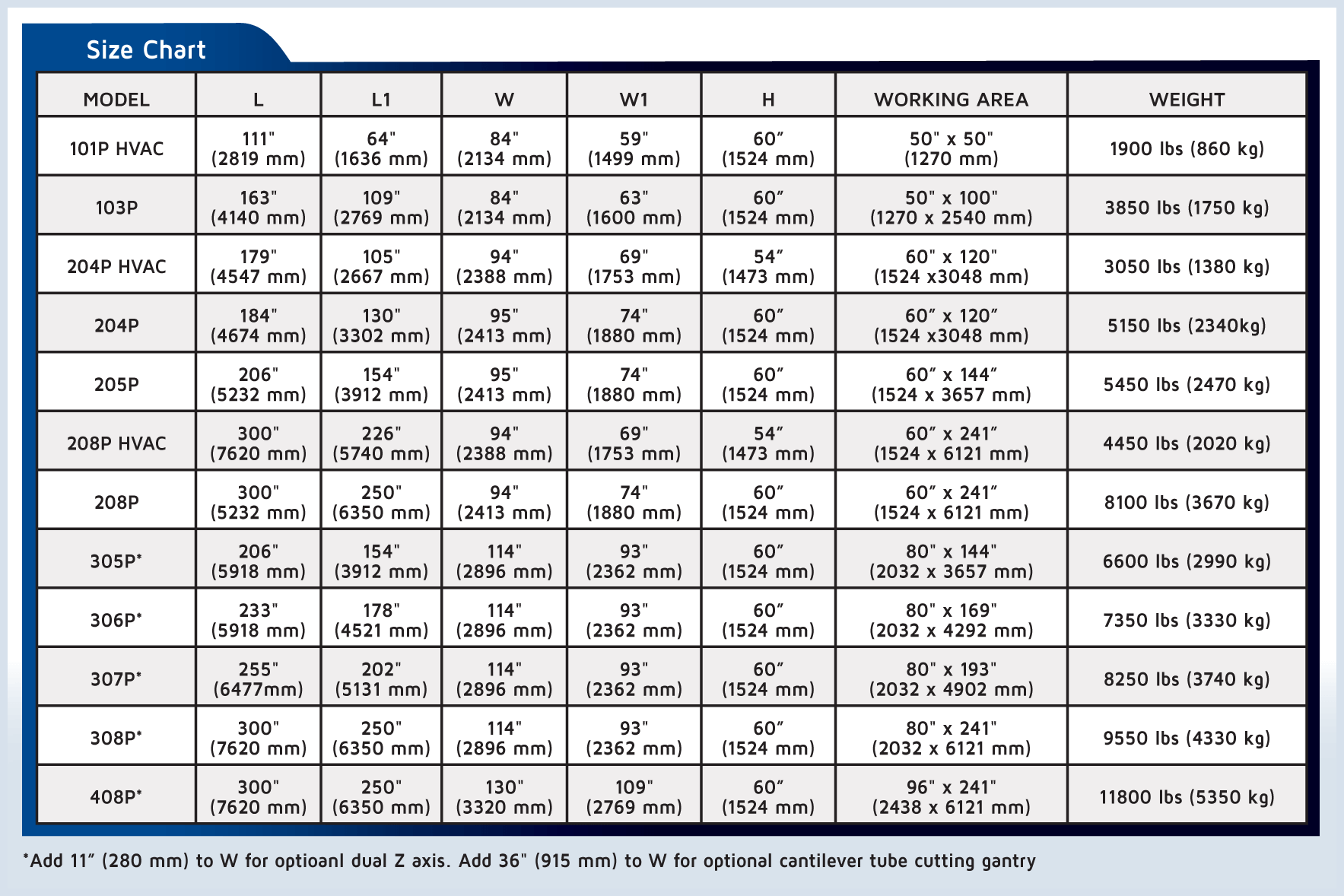

CNC Plasma

CNC Plasma

A check list for a plasma cutting table retrofit The Fabricator

Hypertherm Powermax 65 Plasma Cutter E and M Motor Factors

Improve cut quality with these CNC steel and metal cutting tips

Plasma Cutter Amps Thickness Chart Online Shopping

Plasma Cutting Machine 3000 Series MultiCam East, Shrewsbury PA

For ½” Cut, 50 Amps Works Out Well, Etc.

When Cnc Steel Cutting, The Squarest Cut Angles Are Always To The Right Side, With Respect To The Forward Motion Of The Torch.

You Can Always Make Slight Adjustments Later If Needed.

The Higher The Amps, The Faster You Can Cut.

Related Post: