Pipe Fitting Takeoff Chart

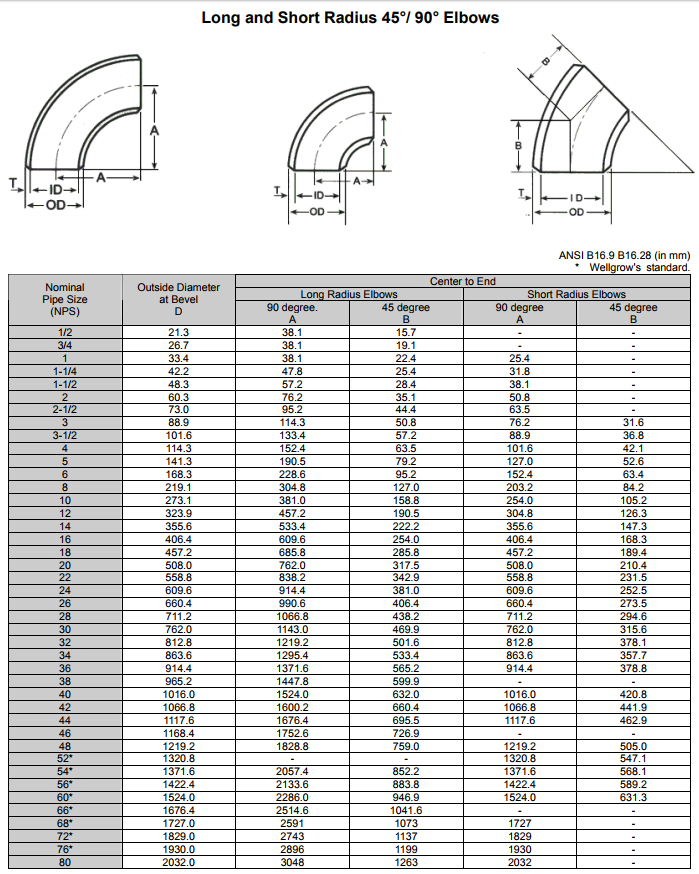

Pipe Fitting Takeoff Chart - The pipes leading to the left are to radiators on the lower floor, those to the right leading to floor above. • only use abs / cpvc / pvc pipe. The function of a 180° elbow is to change direction of flow through 180°. Web pipe schedule chart. Web blue book of fitter's welder's pattern and layout manual a111 chart type pipe sizes concentric reducers tap & drill sizes for american standard threaded national course bolt thread pipe dimensions wall thicknesses for steel pipe per schedule wall thicknesses for stainless pipe per schedule weld caps center to end dimensions for. T nibco manufactures nine general types of fittings: These fittings can be made of carbon, alloy or stainless steel and in nickel alloys in 150, 3000, 6000 and 9000 lb. Barbed insert fittings for polybutylene. Pipe schedule chart of pipe thickness free download pdf chart. Socket weld fittings are formed by either the drop forge or upset forging method. Length of thread also applies to plain fittings. Socket weld fittings are formed by either the drop forge or upset forging method. Web 10 pipe fitting charts fig. Web pipe and flange data weld fitting and steel flange data table of contents gruvlok tech. 7shows branch connections which may be concealed in floors. Overall length (includes elbows & gaps for welds) length of pipe. T nibco manufactures nine general types of fittings: It will be noted that the lower floor is favored by being taken from the run of the tee, as the water flo wing up the riser tends to continue. • only use abs / cpvc / pvc pipe. Web the. Socket weld fittings are formed by either the drop forge or upset forging method. Barbed insert fittings for polybutylene. The pipes leading to the left are to radiators on the lower floor, those to the right leading to floor above. All fittings shall be threaded with american national standard pipe threads (ansi/asme b1.20.1) and shall have taper threads, except wrought. • never test with or transport/store compressed air or gas in abs / cpvc / pvc pipe or fittings. Overall length (includes elbows & gaps for welds) length of pipe. Length of thread also applies to plain fittings. Web nominal size of pipe upper elevation lower elevation. Web weld fittings • dimensional specification nominal pipe size 90° elbow 45° elbow. Web pipe and flange data weld fitting and steel flange data table of contents gruvlok tech. • never test abs / cpvc / pvc pipe or fittings with compressed air or gas, or air over water boosters. When the fitting is pressed, the smart connecttm feature is closed, forming a permanent leak proof joint. Pipe outside to outside dimension. These. Overall length (includes elbows & gaps for welds) length of pipe. Web full reference for national pipe thread (npt): Web weld fittings • dimensional specification nominal pipe size 90° elbow 45° elbow tee caps long rad. 7shows branch connections which may be concealed in floors. • only use abs / cpvc / pvc pipe. They are forged solid and require. Length of thread also applies to plain fittings. I said gaskets are normally 1/4 but i ment 1/8th of a inch you see me write the corre. The function of a 180° elbow is to change direction of flow through 180°. 7shows branch connections which may be concealed in floors. • never test with or transport/store compressed air or gas in abs / cpvc / pvc pipe or fittings. Web the inside diameter at end shall be determined by circumferential measurement, and the tolerance refers to variations from nominal i.d. Bw elbows 180° lr & sr. Web cpvc / pvc pipe or fittings can result in explosive failures and cause. Web standard malleable pipe fittings class 150 pressure / temperature ratings general dimensions / in inches these dimensions apply to all standard malleable banded fittings, both straight and reducing. Pipe schedule chart of pipe thickness free download pdf chart. They are forged solid and require. • only use abs / cpvc / pvc pipe. Web nominal size of pipe upper. These fittings can be made of carbon, alloy or stainless steel and in nickel alloys in 150, 3000, 6000 and 9000 lb. Web the infrabuild pipe and fittings data charts brochure contains useful technical information and specifications for steel pipe and fittings. Calculate runs gaps for weldments are assumed to be 1/8 fitting class: Web pipe and flange data weld. Web the center to face distance for a long radius elbow, abbreviated lr always is 1.1/2 x nominal pipe size (nps) (1.1/2d), while the center to face distance for a short radius elbow, abbreviated sr even is to nominal pipe size. Web because of the accuracy of construc ion and design, copper plumbing is more efficient and less expensive. Socket weld fittings are formed by either the drop forge or upset forging method. Pipe schedule chart of pipe thickness free download pdf chart. Length of thread also applies to plain fittings. Web nominal size of pipe upper elevation lower elevation. Web the inside diameter at end shall be determined by circumferential measurement, and the tolerance refers to variations from nominal i.d. It will be noted that the lower floor is favored by being taken from the run of the tee, as the water flo wing up the riser tends to continue. The pipes leading to the left are to radiators on the lower floor, those to the right leading to floor above. Ward class 150 malleable iron fittings are. Web standard malleable pipe fittings class 150 pressure / temperature ratings general dimensions / in inches these dimensions apply to all standard malleable banded fittings, both straight and reducing. 7shows branch connections which may be concealed in floors. Elbow center dimensions long radius short radius 90° 45° degree. Web a back weld is applied to hold the pipe in the fitting. All fittings shall be threaded with american national standard pipe threads (ansi/asme b1.20.1) and shall have taper threads, except wrought couplings and wrought caps in sizes 1/8, 1/4, 3/8 and 1/2, which may have. Web the length of useful thread (b plus threads with fully formed roots and flat crests) shall not be less than l2 (effective length of external thread) required by american national standard for pipe threads (ansi/asme b1.20.1) thread fittings.

Threaded Pipe Fitting Takeoff Chart

Take Off Chart For Pipe Fittings

Piping Takeoff Spreadsheet Spreadsheet Softwar

Pipe Fitting Dimensions

Pipe Fitting Take Off Chart

Weld Fitting Take Off Chart

Weld Fitting Take Off Chart

pipe fittings dimension chart pipe schedule chart PDF download

Takeoff Chart Take Off For Threaded Pipe Fittings

Pvc Fitting Take Off Chart Call your pipe and fitting supplier.

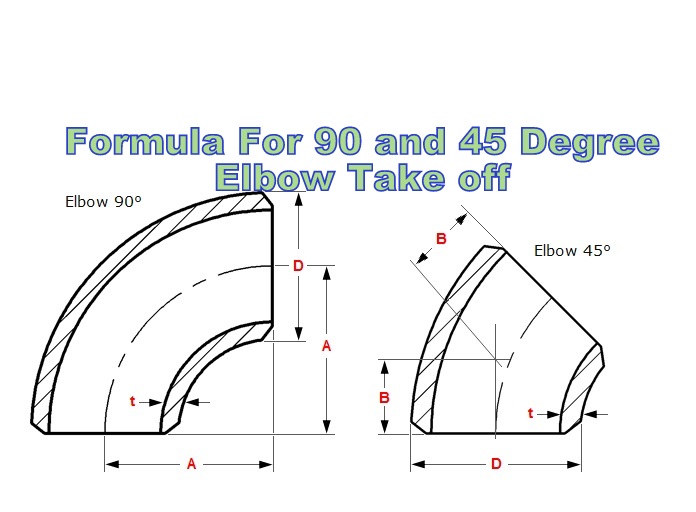

Piping Elbow Center Dimension Chart 90° 45°.

These Fittings Can Be Made Of Carbon, Alloy Or Stainless Steel And In Nickel Alloys In 150, 3000, 6000 And 9000 Lb.

Calculate Runs Gaps For Weldments Are Assumed To Be 1/8 Fitting Class:

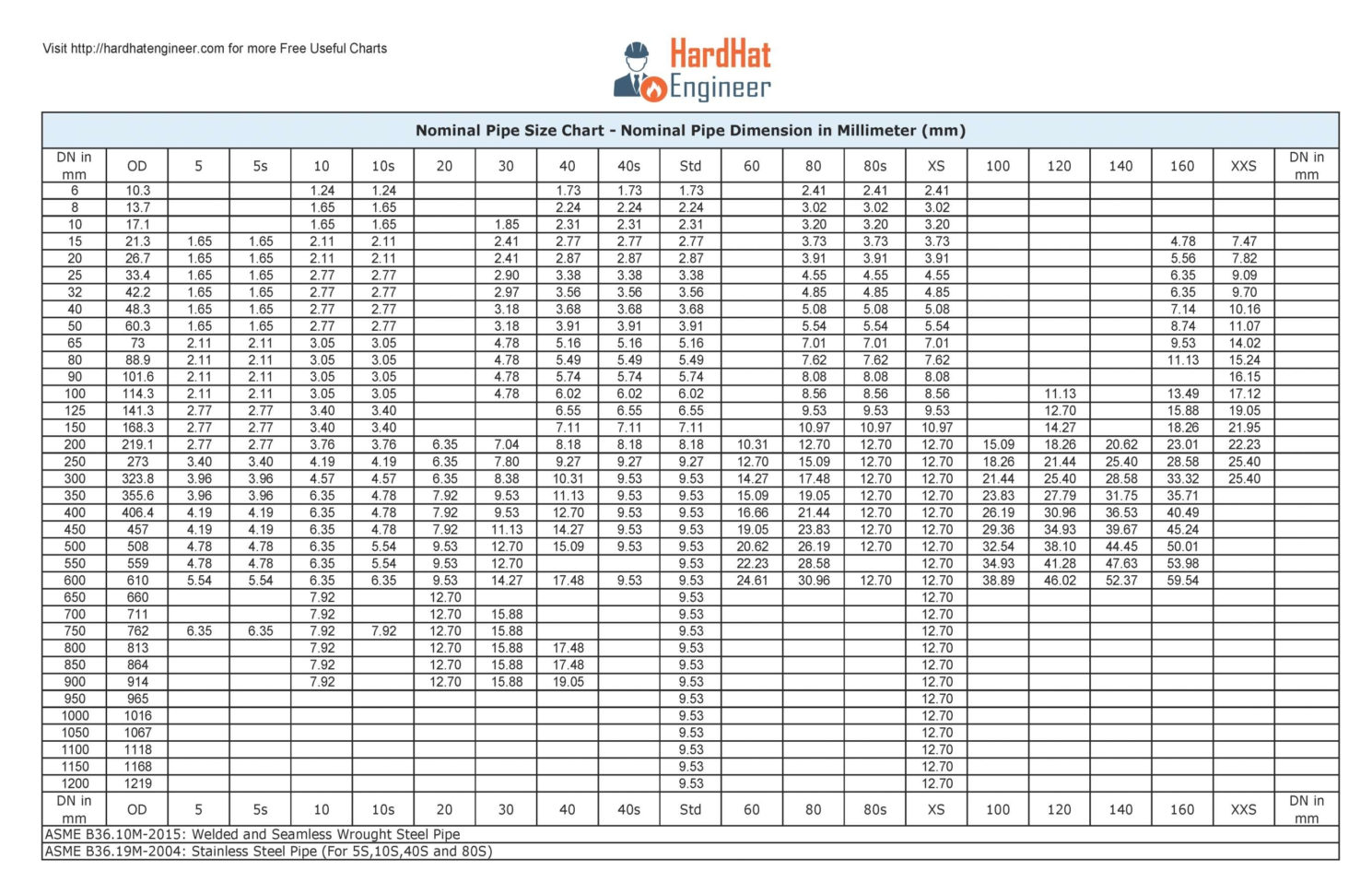

Web Pipe Schedule Chart.

Related Post: