Pipe Bending Offset Chart

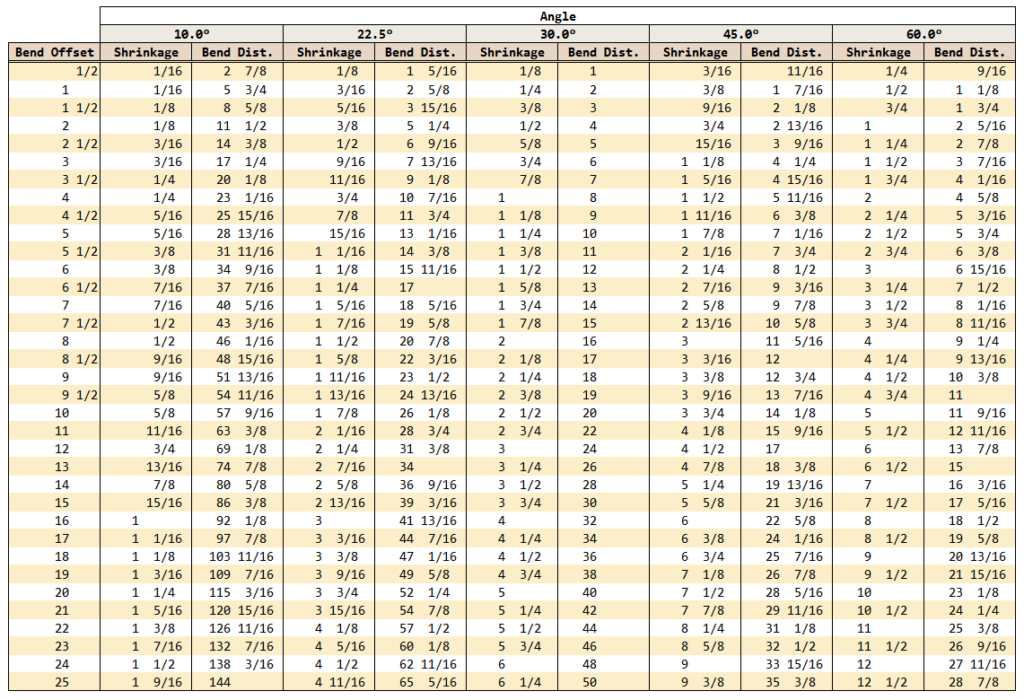

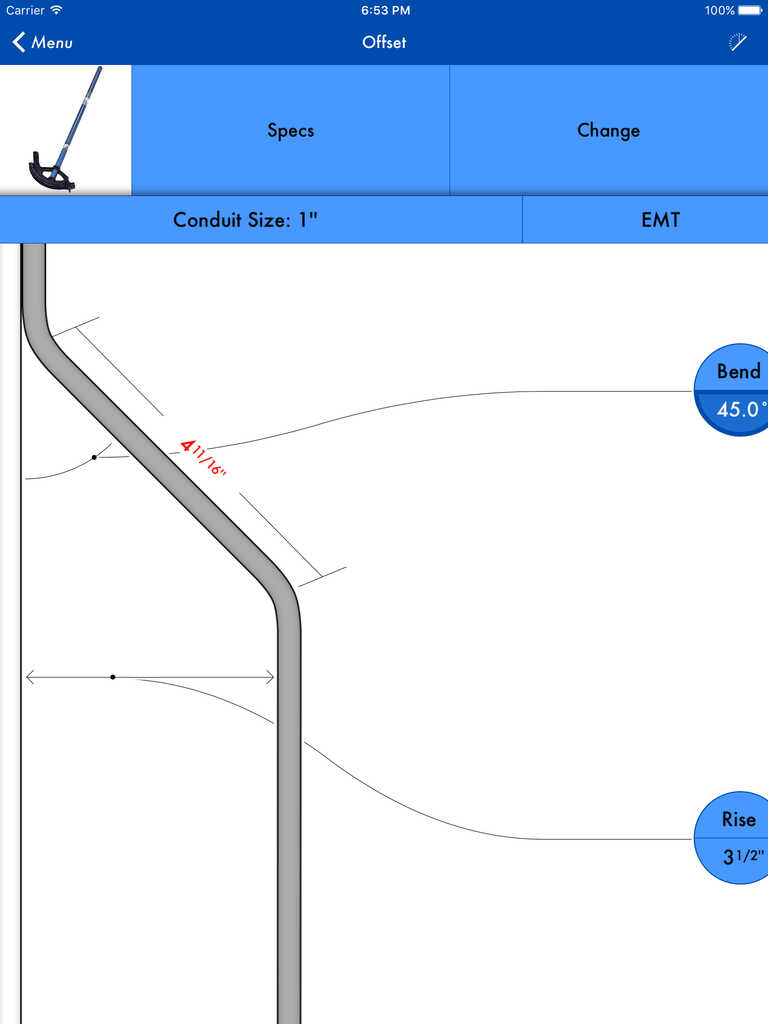

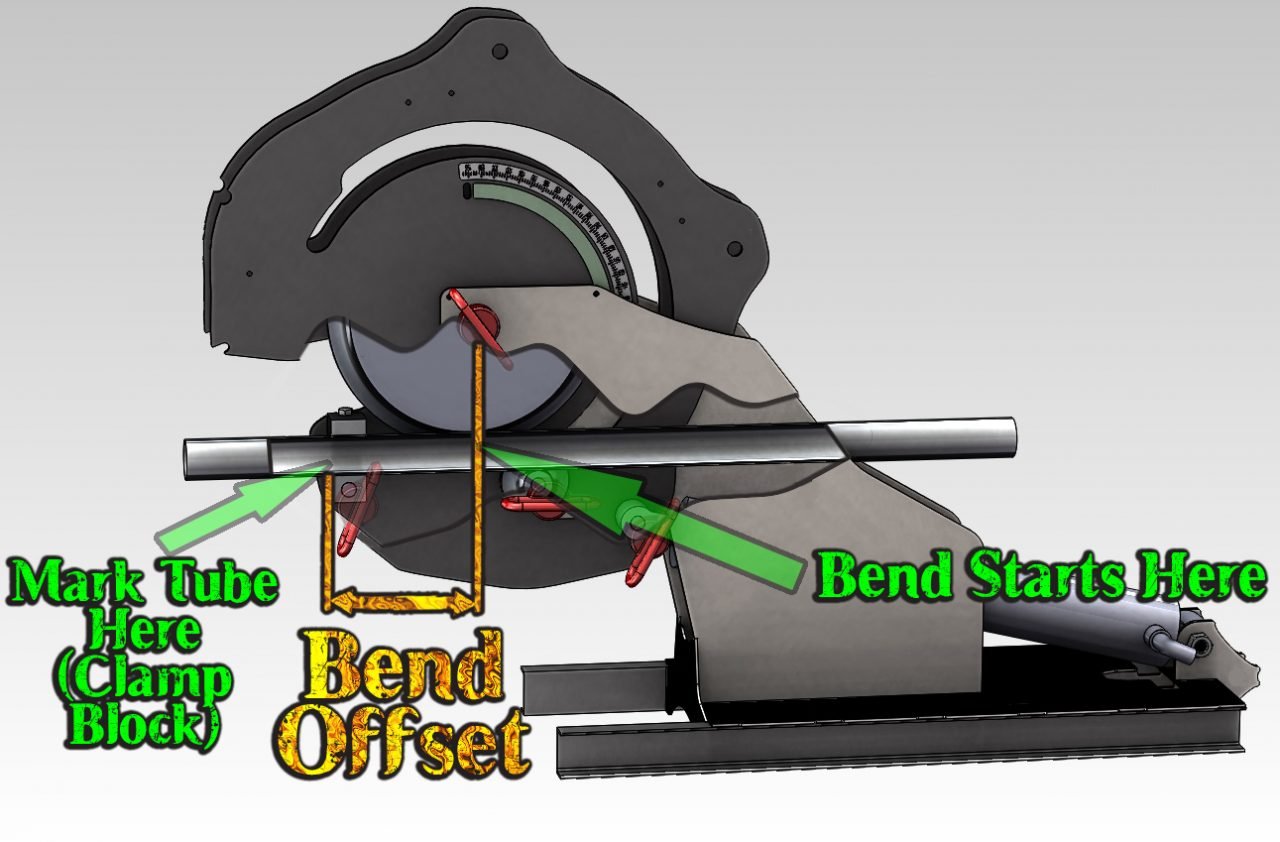

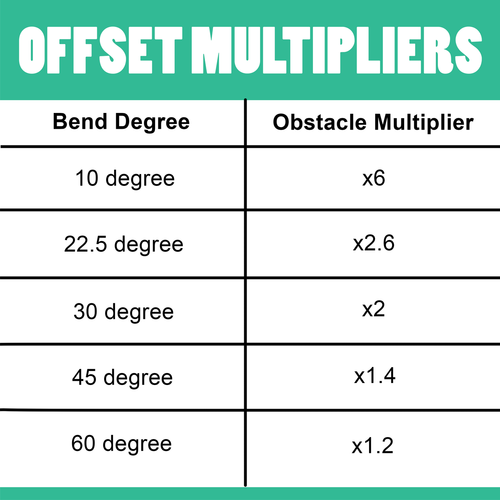

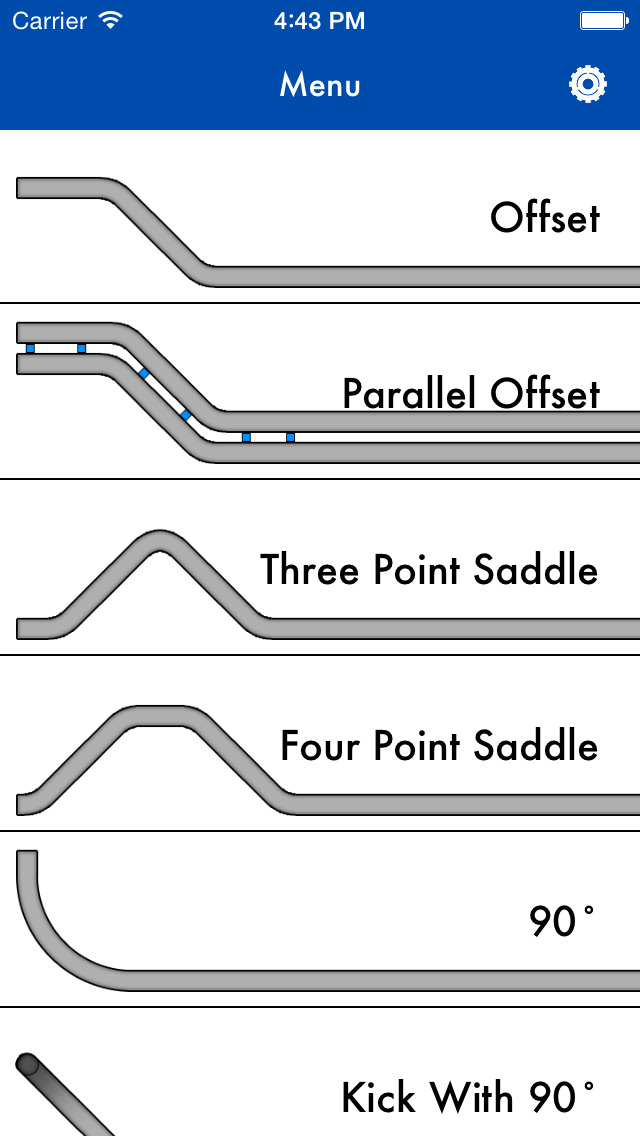

Pipe Bending Offset Chart - Find the distance between bends for a 15 inch offset using 25 degree bends. As an exercise, consider an offset of 12 using two 22º bends. The sine of 22º =.3846, and 1 /.3846 = 2.6, which is the familiar multiplier for a 22º offset. Dev length = 1.57 x 4” = 6.28”. The different pipe rolling offset formulas; Web a pipe bend is an offset or change in direction of the pipe from its original route. This value is the radius you obtain when bending with the die. We all know that pipelines run several kilometers of distance transporting oil, gas, or water from one point to another. Web you should memorize this number for the common bends of 10, 22, 30, and 45 degrees. Most bends other than 90° can be calculated using the geometry of a triangle. Find the distance between bends for a 15 inch offset using 25 degree bends. Master conduit bending techniques, , and calculations with our comprehensive cheat sheet. Locates the center of a saddle bend. Most bends other than 90° can be calculated using the geometry of a triangle. If bending at 10 degrees, the conduit will shrink 1/16 for every inch. Then, multiply the offset dimension (o) by the offset bend allowance (a). Making 90 degree (“l”) stub up bends. 3.1416 (2x2.2) = 13.823/360 = 0.0384. Once bends are made, check for accuracy and make any needed adjustments. Web you should memorize this number for the common bends of 10, 22, 30, and 45 degrees. The different pipe rolling offset formulas; To use this chart simply multiply the known side by the corresponding number to find the missing value. Obstacle height), rounded to the nearest 1/16 th of an inch. One of the most used offsets is the rolling offset therefore it's imperative. Distance between bends = 2.37 x 15 = 35.55 or 35 9/16. Keep in mind, when bending offsets, the conduit will shrink. To determine the length of offset, select the offset angle (e). Web this is the amount of straight conduit required to make the bend. To calculate clr of 35° bend. Most of these angles can achieve clearing the same obstacle, it just depends on how tight to the object you’d. Web an offset in 3 1/2 pipe, so it can be used where a 10º offset cannot. This value is the radius you obtain when bending with the die. To be used with stub, offset and outer marks of saddle bends. These values can be used as scale factors for other obstacle heights, which is exactly how the table in. Find the distance between bends for a 15 inch offset using 25 degree bends. Web a pipe bend is an offset or change in direction of the pipe from its original route. L = o × a use the offset calculation as the distance between the bend marks described in bend. To use this chart simply multiply the known side. Web there are multiple ways to bend an offset, and by ways i mean shapes. These numbers are also shown in the chart below. One of the most used offsets is the rolling offset therefore it's imperative. I'll cover each bend separately, and you should make sure you've understood and practiced each type before moving on to the next! A. Dev length = 1.57 x 4” = 6.28”. One of the most used offsets is the rolling offset therefore it's imperative. Web 3 basic conduit bends. Keep in mind, when bending offsets, the conduit will shrink. You can bend a 10, 22.5, 30, 45, and 60 degree offset with most standard benders. So, pipe bends are introduced to change the pipeline direction. Web the bend offset is the distance between the start of the bend and where you line up the tube in the machine. 48k views 4 years ago conduit bending. Master conduit bending techniques, , and calculations with our comprehensive cheat sheet. 0.0384 x 35 = 1.344” offset bend calculation. Bend 10° at each line. Obstacle height), rounded to the nearest 1/16 th of an inch. Developed length =.0175 x degree of bend x radius. These values can be used as scale factors for other obstacle heights, which is exactly how the table in figure 3 was generated. So, pipe bends are introduced to change the pipeline direction. 3.1416 (2x2.2) = 13.823/360 = 0.0384. To use this chart simply multiply the known side by the corresponding number to find the missing value. If you want to make a bend on a 4.5 radius die, and you want that bend to be 10 inches from the end of a piece of tube, mark a line on the tube 10 inches from the end. In this video i will show you how to measure for the rolling offset. A stub up or “l” conduit bend is kind of bend that creates a vertical bend in conduit that is in an “l” shape. Note that this can also be written as c = a * (1 / sine(22º)). Find the distance between bends for a 15 inch offset using 25 degree bends. The sine of 22º =.3846, and 1 /.3846 = 2.6, which is the familiar multiplier for a 22º offset. Many benders have the multiplier permanently stamped on the reverse side of the bender—a useful option for the beginning electrician. Web offset formula table angle of bend constant multiplier shrink per inch of offset 10° x 10° 6 1/16 =.063 22½° x 22½° 2.6 3/16 =.188 30° x 30° 2.0 1/4 =.250 45° x 45° 1.4 3/8 =.375 60° x 60° 1.2 1/2 =.500 offset formula table angle of bend constant multiplier shrink per inch of offset 45° x 45° 1.4 3/8 =.375 The different pipe rolling offset formulas; If bending at 10 degrees, the conduit will shrink 1/16 for every inch of rise. To calculate clr of 35° bend. Developed length =.0175 x degree of bend x radius. Web to calculate one degree of bend. Obstacle height), rounded to the nearest 1/16 th of an inch.

Conduit Bending Chart Pdf

Tube bending offset chart bxezip

pipe rolling offset formula / any degree pipe offset formula Fitter

Emt Offset Bending Chart

Tube and Pipe Bending 101 Rogue Fabrication

Emt Pipe Bending Chart Reviews Of Chart

Nec Conduit Bend Radius Chart In 2023 What You Need To Know

How To Bend Conduit change comin

Emt Pipe Bending Chart

Standard Pipe Bend Radius Chart

You Can Bend A 10, 22.5, 30, 45, And 60 Degree Offset With Most Standard Benders.

L = O × A Use The Offset Calculation As The Distance Between The Bend Marks Described In Bend.

So, Pipe Bends Are Introduced To Change The Pipeline Direction.

Making 90 Degree (“L”) Stub Up Bends.

Related Post: