Pattern Making For Casting

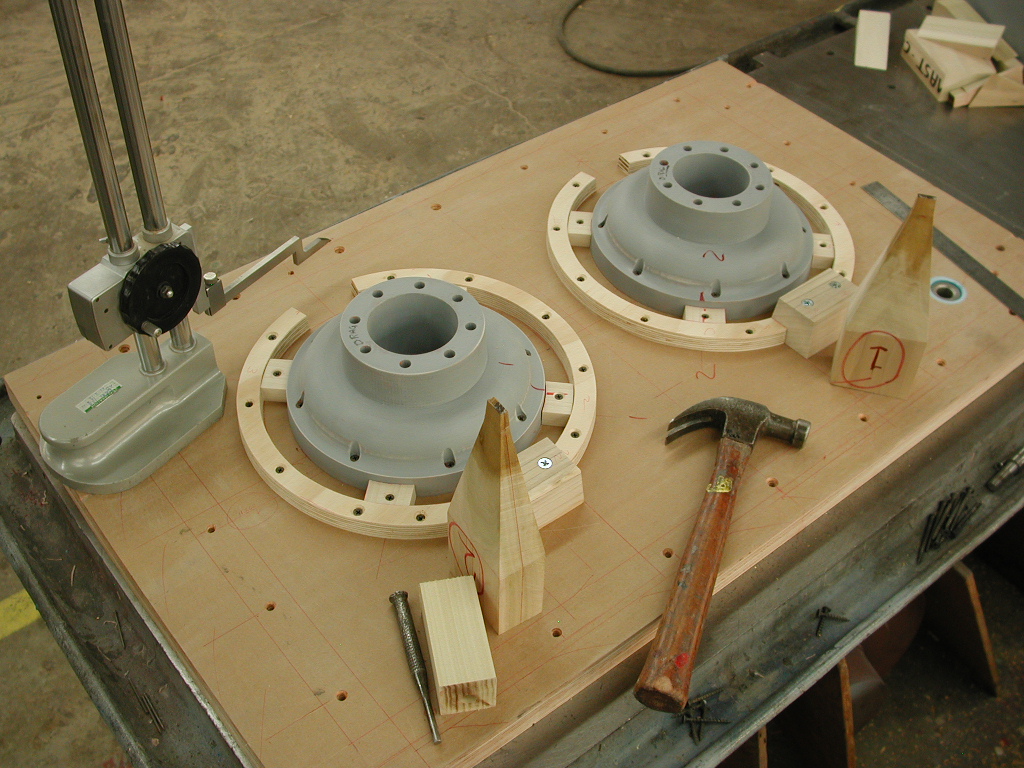

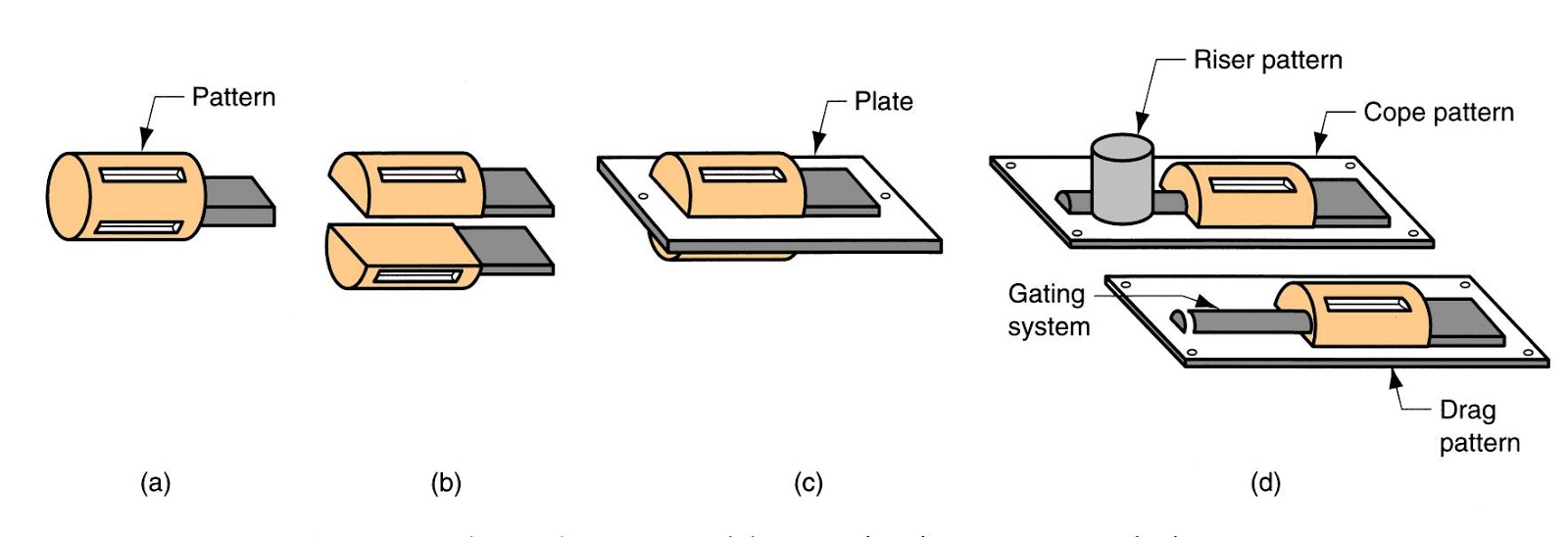

Pattern Making For Casting - It is the first step in the ductile iron casting process. These cast patterns are coated with a resin or ceramic aggregate, made of sand and a binder, which hardens into a shell. A number of viewers have asked for more details of pattern making. Consumable: types of pattern for investment casting. Web as the deciding factor in a specific casting process, patterns play a vital role in determining quality and perfection. The wooden pattern of the cylinder is. Web a pattern is a replica of the part to be produced by casting. Web patterns are used in foundry casting to create the mold into which molten metal is poured to create a casting. Web a wooden pattern is used to make an impression in the sand mold. Web some of the basics you need to know if you are going to make a pattern to have cast in metal at a foundry along with examples of patterns that i have in my c. At arnette, we specialize in providing high quality, precision, wood, plastic, and metal foundry patterns for the metal casting industry. Once the pattern has been used to form the sand mould cavity, the pattern is then removed, molten metal is then poured into the sand mould cavity to produce the casting. The wooden pattern of the cylinder is. Core making. Web in this article, we’ll explore 12 essential types of patterns employed in the casting process and delve into their respective applications. It describes the principles of the patternmaking techniques used to make expendable molds and for metal casting processes such as die casting and permanent mold casting. 65+ happy customer , all specialised and specific shapes foundry patterns for. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. Reusable: types of pattern in sand casting or plaster. Different types of patterns are used depending on the complexity of the shape of the casting and the casting process being used. More than decade experience in pattern making. Web a casting pattern is a. Web a pattern is a model used in foundries for casting, and patternmaking is the process and trade for producing patterns. Web a pattern is a replica of the part to be produced by casting. But we can divide them into two types: It is important to select a. For this reason, the casting pattern acts as an essential component. A silica sand core is place in the mold produce the cylinder bore in the casting. They can leave marks in many molds. Web a casting pattern is a reproduction of the desired final product to be cast. Our typical pattern maker can boast an average of 25 years experience in his profession. Web in casting, a pattern is a. This replica is used to provide the correct shape for a mold, forming the cavity molten metal is poured into and solidified in. Web a wooden pattern is used to make an impression in the sand mold. Navinkrishnaa is a specialised pattern maker. Web learn the types of metal casting, the different processes, and how to get started in this. Patterns play a crucial role in casting, serving as replicas or models that closely resemble the final product. Web some of the basics you need to know if you are going to make a pattern to have cast in metal at a foundry along with examples of patterns that i have in my c. What is foundry pattern making? Designing. Gate and runner are the two main components used in all kinds of patterns. It is the first step in the ductile iron casting process. Web patterns are used in foundry casting to create the mold into which molten metal is poured to create a casting. Web patternmaking ‘tricks’ for better castings. Web foundry pattern making is the process of. Web as the deciding factor in a specific casting process, patterns play a vital role in determining quality and perfection. The “pattern” is essentially a replica of the object about to be cast. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. Web complete casting, face casting, mass casting and gel coat patterns. It is important to select a. What is foundry pattern making? Web in this article, we’ll explore 12 essential types of patterns employed in the casting process and delve into their respective applications. The “pattern” is essentially a replica of the object about to be cast. Web in a holistic approach, the pattern in casting is the prominent object for. Web in a holistic approach, the pattern in casting is the prominent object for casting. For this reason, the casting pattern acts as an essential component that helps provide the final parts. Web foundry pattern service has the ability and experience to meet your unique pattern needs. Learn more on our blog. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. Patterns play a crucial role in casting, serving as replicas or models that closely resemble the final product. Casting patterns are specifically used to shape the casting mold, and hence the mold crates metal parts. 65+ happy customer , all specialised and specific shapes foundry patterns for cast iron , alloy steel. Web in casting, a pattern is a replica of the object to be cast, used to form the sand mould cavity into which molten metal is poured during the casting process. Consumable: types of pattern for investment casting. Web this video shows the complete making of a pattern for an essex turntable. Web in this article, we’ll explore 12 essential types of patterns employed in the casting process and delve into their respective applications. A silica sand core is place in the mold produce the cylinder bore in the casting. What is foundry pattern making? Web patterns are used in foundry casting to create the mold into which molten metal is poured to create a casting. More than decade experience in pattern making.

Casting Process Terminology Types Pattern Making Core Making

Patternmaking and Casting Pattern Making Patternmaking Castings

Pattern Types and Mold Cavity Animation in Casting Process by Shubham

Types of Pattern in Casting Process (Explained in Detail) PDF

Steel Casting Patternmaking US Casting Company

Types of patterns used in Casting Process Mechanical Engineering

11 Most Common Types of Patterns Used in Casting G For Games

Learn about patterns definition, classification and how to make pattern

Patterns and Cores Sand Casting. YouTube

Foundry Pattern Making Life of a Casting Reliance Foundry

It Describes The Principles Of The Patternmaking Techniques Used To Make Expendable Molds And For Metal Casting Processes Such As Die Casting And Permanent Mold Casting.

These Cast Patterns Are Coated With A Resin Or Ceramic Aggregate, Made Of Sand And A Binder, Which Hardens Into A Shell.

Web Foundry Pattern Making Is The Process Of Designing And Creating A Mold Pattern, Casting Pattern, Or Sand Casting Pattern If Sand Is The Material The Mold Is To Be Made From.

Web Patternmaking ‘Tricks’ For Better Castings.

Related Post: