Paint Viscosity Chart

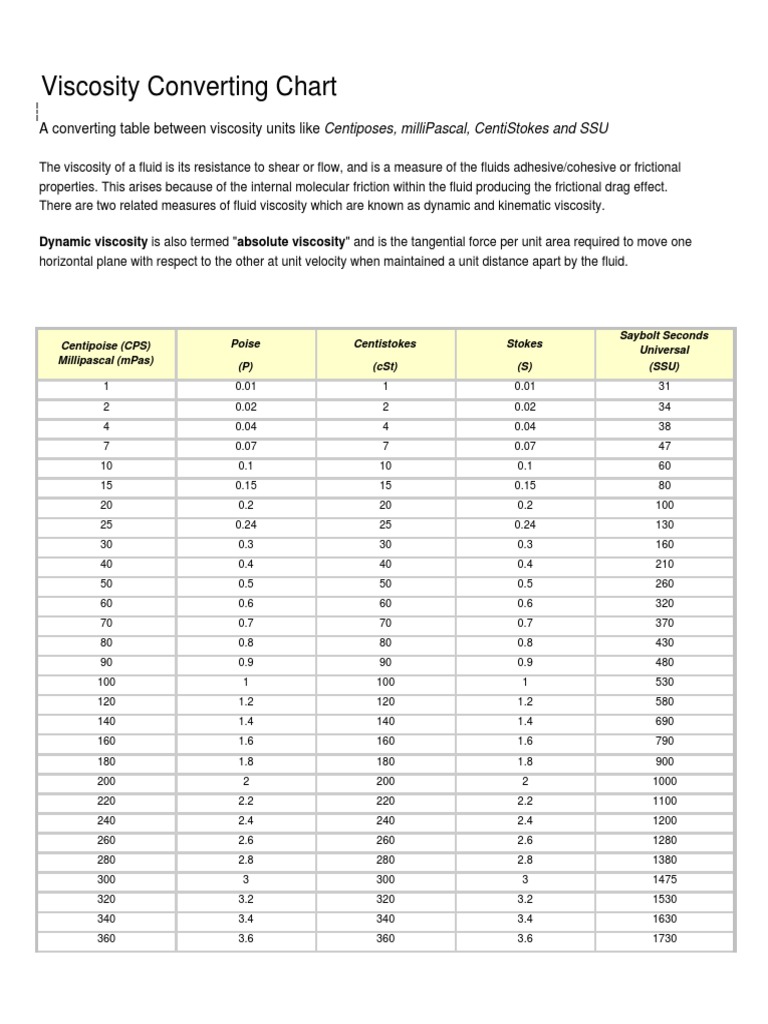

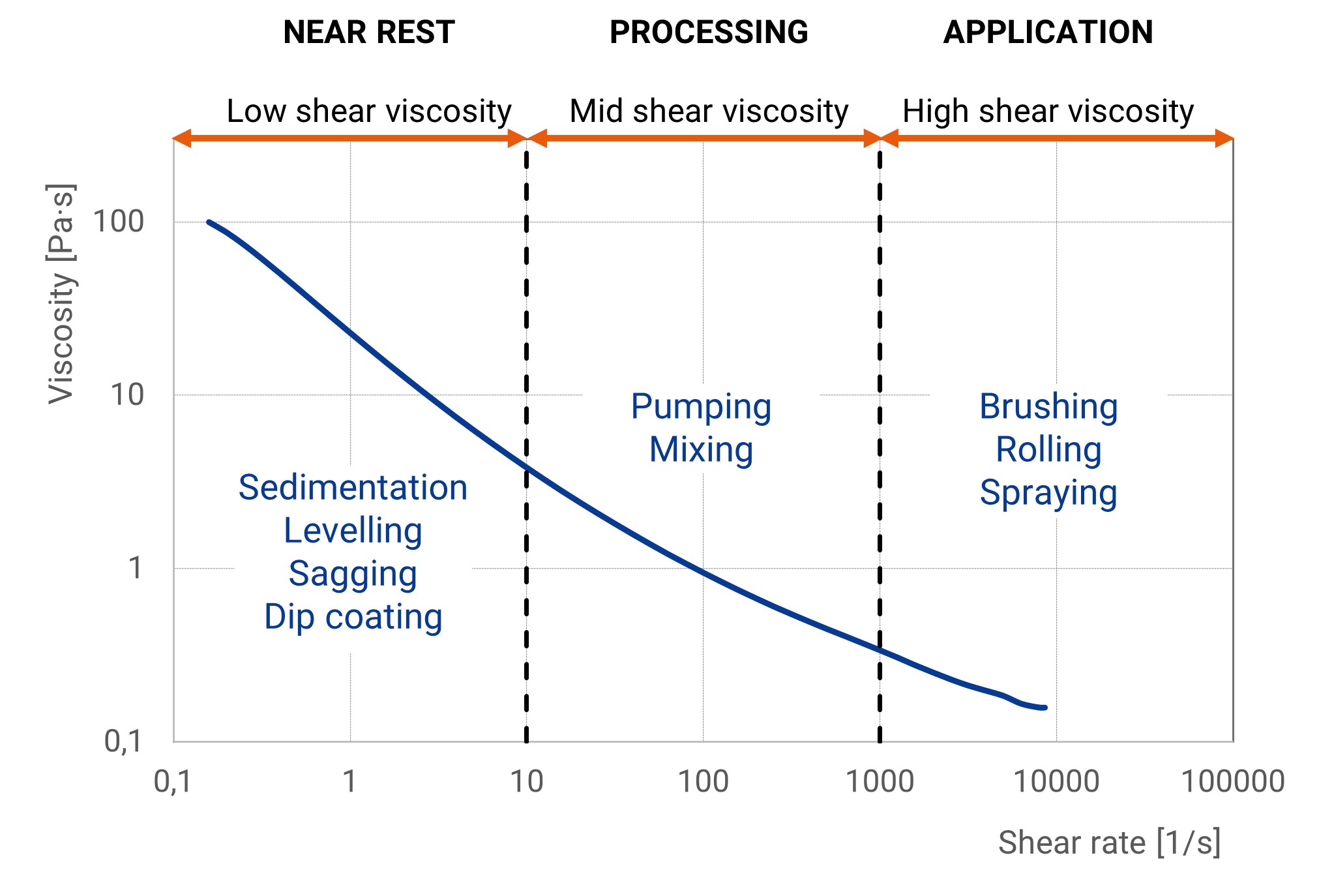

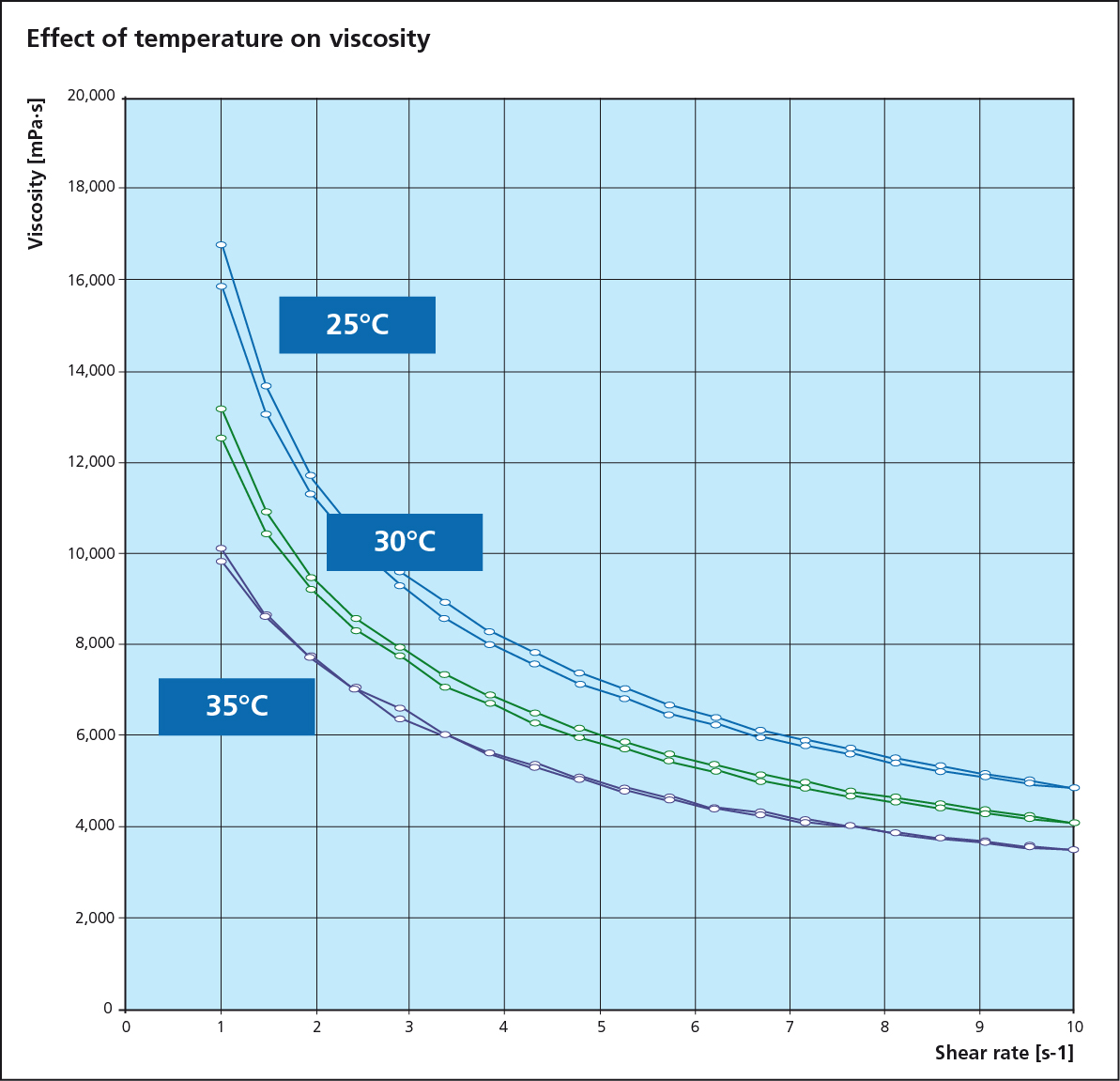

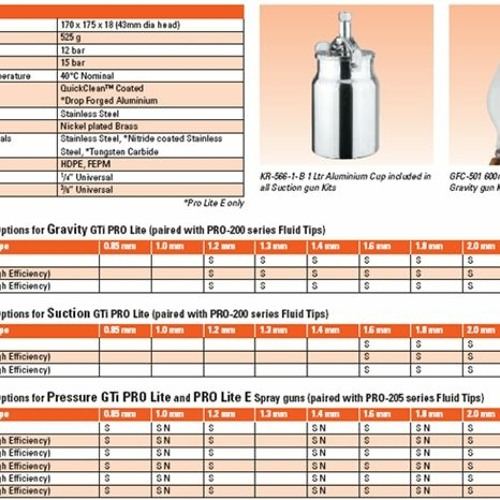

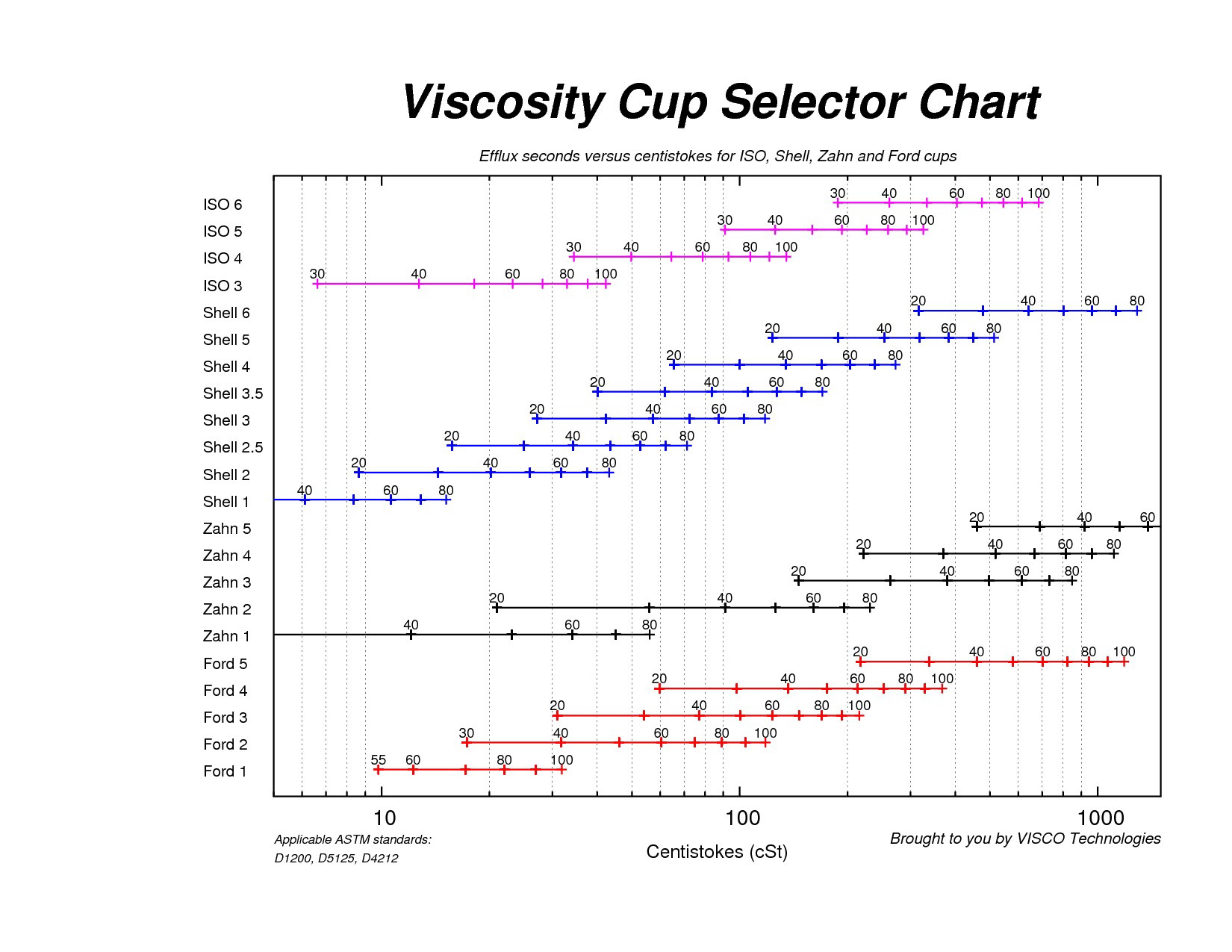

Paint Viscosity Chart - After measurement, you can determine if any thinning of material is needed. 2 different methods of paint viscosity measurement; Web 1 what is paint viscosity? Web how to check the viscosity of paint for spraying measure and adjust viscosity for spraying, paint viscosity is really important when you are spray painting. Kinematic viscosity measures the time it takes for a fixed volume of paint to flow through a capillary tube under the force of gravity. Web paint viscosity can be measured using two main methods: In general, the following measurements for dupont The spruce / meg macdonald. Web normally, viscosity would be measured at 25 ºc. Turned to solvent addition to adjust viscosity. In fact, we ask a great deal from paint formulators. How to thin latex paint for sprayers, brushes, or rollers. Web there are nine astm standards commonly used for measuring the viscosity of paint systems. Actual reduction will depend upon model turbine used, flow out properties of the coating and the final visual results of the sprayed work piece. If. The standards are governed by two subcommittees in astm committee d01 on paint and related coatings, materials and applications. Viscosity is the resistance of a fluid to movement or to a change of shape. In some applications, thicker paint is simply a better option. Always adjust viscosity for best results. Actual reduction will depend upon model turbine used, flow out. Article last updated on may 30, 2021. Web there is a rule of thumb in the paint industry that a viscosity of approximately 100 cps (1 p, 0.1 pa•s) provides acceptable spraying, brushing, or roll coating. In the sector of paints and related products, the most used tools are: The viscosity of paint is a key indicator of the paint’s. Kinematic viscosity and dynamic viscosity. Ford, zahn and gardner cup. Always adjust viscosity for best results. This is due to a thicker paint film, rather than a. Actual reduction will depend upon model turbine used, flow out properties of the coating and the final visual results of the sprayed work piece. Web check out the conversion chart below for recommendations on atomizing set sizes based on viscosity measurements. Testing the viscosity of a fluid, whether it’s a liquid or a gas, can show you how that sample will behave in certain circumstances. Experimentation is the best way to decide which setup works best. Suggestions on usage should be used as a. In fact, we ask a great deal from paint formulators. Web for optimum refinishing results, adjust viscosity by adding more basemaker, thinner or reducer to match the specific product’s label recommendation. Actual reduction will depend upon model turbine used, flow out properties of the coating and the final visual results of the sprayed work piece. Kinematic viscosity and dynamic viscosity.. Of all of the available viscosities, heavy body acrylics generally provide the best coverage. Article last updated on may 30, 2021. Experimentation is the best way to decide which setup works best. There are a number of devices that can measure viscosity. In the paints and coatings industry, flow properties of the final formulation hold a prime importance. Web the viscosity of paint, which is essentially a suspension of pigment and other ingredients, is a key performance parameter. In some applications, thicker paint is simply a better option. Article last updated on may 30, 2021. It is crucial for liquid products to undergo a viscosity measurement in incoming and outgoing qc. Kinematic viscosity measures the time it takes. Web there are nine astm standards commonly used for measuring the viscosity of paint systems. Actual reduction will depend upon model turbine used, flow out properties of the coating and the final visual results of the sprayed work piece. Seconds quoted are measured in a zahn #2 viscosity cup. An important measure of paint capability and durability. The standards are. Web manufacturers specify a viscosity at 77 degrees f. Web normally, viscosity would be measured at 25 ºc. Turned to solvent addition to adjust viscosity. This article will walk you through how to measure paint viscosity for spraying with an hvlp spray gun. Learn how to use a viscosity measuring cup and determine the optimal draining speed. Marcus paint company often provides viscosity/temperature conversion charts to assist operators online. Web there is a rule of thumb in the paint industry that a viscosity of approximately 100 cps (1 p, 0.1 pa•s) provides acceptable spraying, brushing, or roll coating. Web 1 what is paint viscosity? Web i am looking for a paint viscosity chart that will give me relative comparisons between a #2 ez zahn cup, a #3 ez zahn cup, and a #4 ford cup, with the ideal temperature of the paint being 77 degrees. Article last updated on may 30, 2021. 3 how to measure paint viscosity for spraying Web check out the conversion chart below for recommendations on atomizing set sizes based on viscosity measurements. These instructions pertain to the zahn viscosity cup. The spruce / meg macdonald. Each standard measures viscosity at the point of approximating the paint application process. Experimentation is the best way to decide which setup works best. Seconds quoted are measured in a zahn #2 viscosity cup. In the sector of paints and related products, the most used tools are: Kinematic viscosity and dynamic viscosity. Actual reduction will depend upon model turbine used, flow out properties of the coating and the final visual results of the sprayed work piece. Of all of the available viscosities, heavy body acrylics generally provide the best coverage.

ViscosityChart Engineered Solutions

Viscosity Converting Chart Viscosity Materials Science

How to test paint viscosity poleweek

Chart Viscosity PDF PDF

Paint Viscosity Chart

Viscosity Comparison Chart Hapco, Inc.

Paint Viscosity Chart

Stream Paint Viscosity Chart Pdf from Beibisaluomm Listen online for

Paint Viscosity Chart Pdf

Paint Viscosity Chart A Visual Reference of Charts Chart Master

This Is Due To A Thicker Paint Film, Rather Than A.

I Have Been Unsuccessful In My Attempts To Locate A Chart Using The Resources I Have Available To Me.

Web For Optimum Refinishing Results, Adjust Viscosity By Adding More Basemaker, Thinner Or Reducer To Match The Specific Product’s Label Recommendation.

It Is Crucial For Liquid Products To Undergo A Viscosity Measurement In Incoming And Outgoing Qc.

Related Post: