Oxy Fuel Cutting Tip Chart

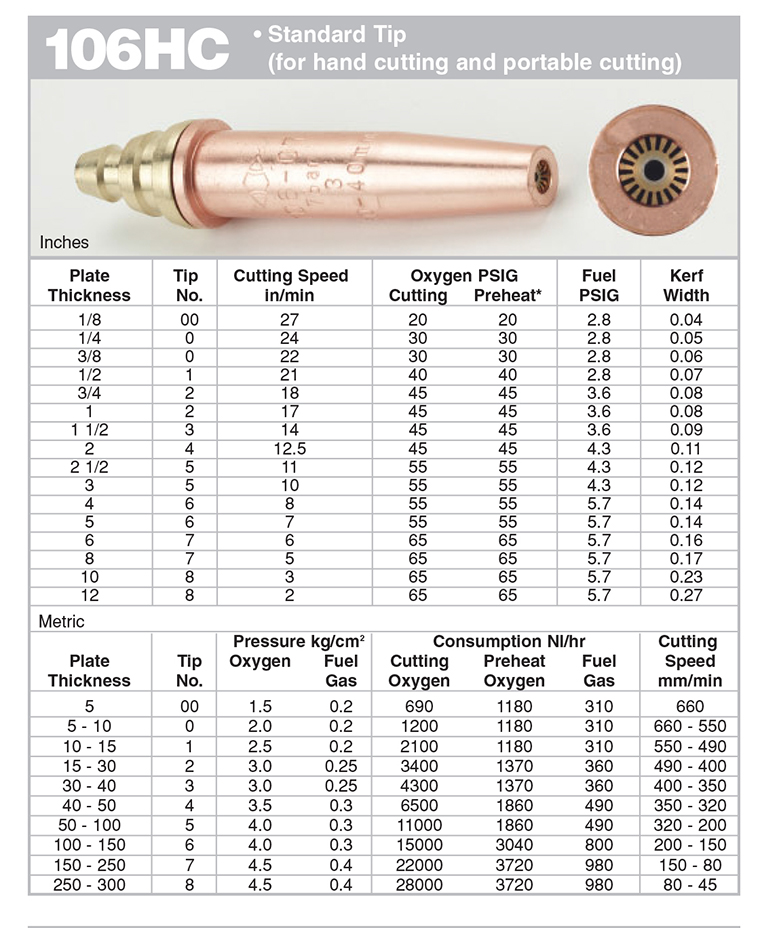

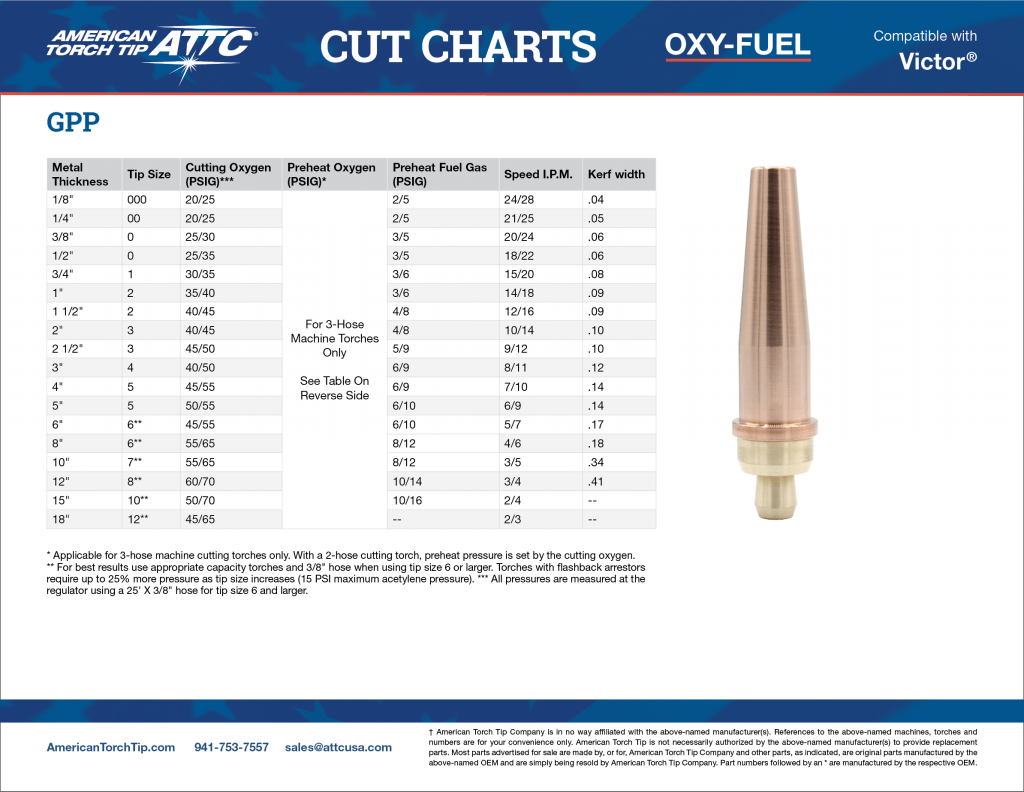

Oxy Fuel Cutting Tip Chart - Oxyfuel cutting equipment, supplies and gases are available from linde. *minimum of one 350 cu. Cutting oxygen cutting oxygen pressure consumption mpa (m2/h) 0.60. Click here to see harris charts to. When pure oxygen is added to a flame of acetylene, propane, or other hydrocarbons, the flame temperature is greatly increased. Web hand cutting operating chart. Two piece propylene cutting tip used in hand held cutting applications. Cutting tips, designed differently for each fuel gas, optimize the delivery of oxygen and gas. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. The thickness of the steel to be cut ; Oxygen fuel cutting is the use of oxygen gas combined with other combustible gasses to melt and cut through steel. Two piece propylene cutting tip used in hand held cutting applications. Two piece propane/natural gas cutting tip for hand held cutting applications. 24k views 1 year ago oxy fuel safety. *minimum of one 350 cu. Cutting tips, designed differently for each fuel gas, optimize the delivery of oxygen and gas. Pay attention to the details in the manufacturer's tip charts. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. 24k views 1 year ago oxy fuel safety. Oxygen fuel cutting is the use of oxygen gas. Cutting oxygen hole diameter mm. Cutting tips, designed differently for each fuel gas, optimize the delivery of oxygen and gas. Oxyfuel cutting equipment, supplies and gases are available from linde. * 3/8 outside diameter (od) minimum hose requirement. It will save you valuable time and money. Web below are 2 charts on choosing the correct tip.because not all manufacturers use the same numbering system, the first tip chart shows the hole size you need for the metal thickness you want to cut. * 3/8 outside diameter (od) minimum hose requirement. Web conversely, you will have to cut your 1 plate slower wasting more gas if your. Two piece propane/natural gas cutting tip for hand held cutting applications. Cutting oxygen hole diameter mm. Over decades, there have been many advances in the welding industry. *minimum of one 350 cu. Oxyfuel cutting is regarded as one of the most important production processes in the entire metal industry. It makes up 21% of the air we breathe. Web below are 2 charts on choosing the correct tip.because not all manufacturers use the same numbering system, the first tip chart shows the hole size you need for the metal thickness you want to cut. The thickness of the steel to be cut ; The following are several, but not. Type cutting bore (cylindrical bore or high speed/divergent bore) preheat gas to be used When pure oxygen is added to a flame of acetylene, propane, or other hydrocarbons, the flame temperature is greatly increased. 24k views 1 year ago oxy fuel safety. Web conversely, you will have to cut your 1 plate slower wasting more gas if your tip is. Cutting oxygen hole diameter mm. 24k views 1 year ago oxy fuel safety. *minimum of one 350 cu. Oxyfuel cutting is regarded as one of the most important production processes in the entire metal industry. It will save you valuable time and money. Click here to see harris charts to. Oxyfuel cutting is regarded as one of the most important production processes in the entire metal industry. Two piece propane/natural gas cutting tip for hand held cutting applications. Pay attention to the details in the manufacturer's tip charts. The following are several, but not all, factors to be considered. When pure oxygen is added to a flame of acetylene, propane, or other hydrocarbons, the flame temperature is greatly increased. Type cutting bore (cylindrical bore or high speed/divergent bore) preheat gas to be used ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Pay attention to the details in the manufacturer's. Cutting oxygen hole diameter mm. It makes up 21% of the air we breathe. The following are several, but not all, factors to be considered. It will save you valuable time and money. 24k views 1 year ago oxy fuel safety. *minimum of one 350 cu. Type cutting bore (cylindrical bore or high speed/divergent bore) preheat gas to be used ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. Oxyfuel cutting equipment, supplies and gases are available from linde. Over decades, there have been many advances in the welding industry. Oxygen fuel cutting is the use of oxygen gas combined with other combustible gasses to melt and cut through steel. Oxyfuel cutting is regarded as one of the most important production processes in the entire metal industry. Oxygen is an abundant gas in nature. Cutting tips, designed differently for each fuel gas, optimize the delivery of oxygen and gas. Web below are 2 charts on choosing the correct tip.because not all manufacturers use the same numbering system, the first tip chart shows the hole size you need for the metal thickness you want to cut. Pay attention to the details in the manufacturer's tip charts.

Oxy Acetylene Torch Tip Chart

Welding, Brazing Tip w/ Gas Mixer Style W1 ArcZone

SÜA Oxy/Acetylene Cutting Tips Replacement for 6290 Select Qtty and

Oxy Acetylene Victor Welding Tip Chart

Oxy Acetylene Cutting Tip Size Chart

CNC OxyFuel Cutting Tables AKS Cutting Systems

Victor GPP / MTHP Cut Chart American Torch Tip

Oxy Fuel Tip Seat Guide American Torch Tip

Harris 6290 Cut Chart American Torch Tip

What Materials Can Oxy Fuel Cut

Two Piece Propylene Cutting Tip Used In Hand Held Cutting Applications.

The Thickness Of The Steel To Be Cut ;

Web Hand Cutting Operating Chart.

Click Here To See Harris Charts To.

Related Post: