Oxy Acetylene Torch Pressure Chart

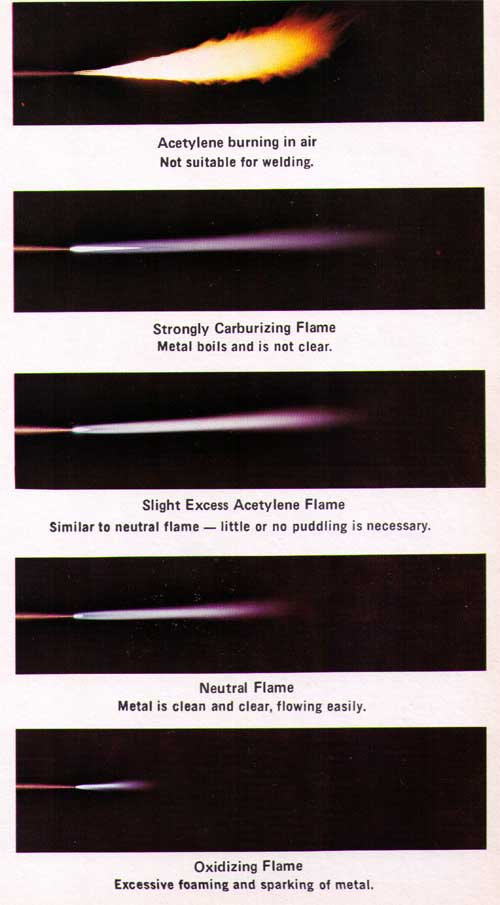

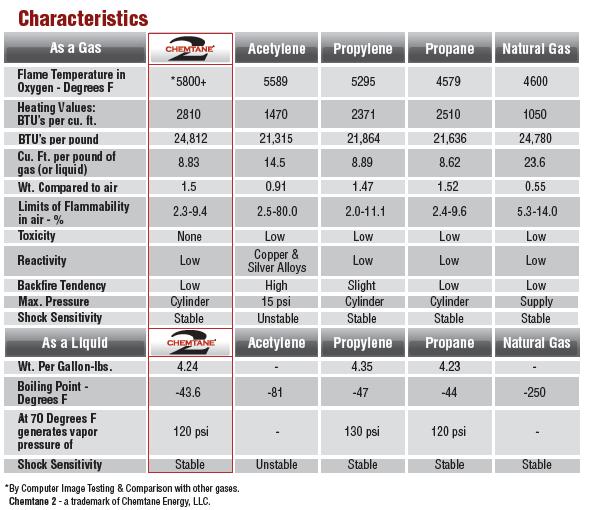

Oxy Acetylene Torch Pressure Chart - · depress oxygen lever and make necessary adjustments. Web the first step in setting up your oxy acetylene rosebud torch is to choose the right tip. Web adjust to the correct flame setting. The tip is angled at 20o. Hose for size 4 and larger. The third open valve in the torch is the first acetylene after that you can open the oxygen valve. Tables show approximate gas pressures for welding or cutting. Web · open oxygen valve and adjust to neutral flame. So, what is the proper way to handle an oxyacetylene torch? A larger tip will generate more heat, while a. Increase regulator pressures if longer hose or smaller i.d. ** to provide required flow, use 3/8 i.d. Web medium preheat tip with two milled flat sides. Proper adjustment of oxygen and acetylene pressures, as well as the cutting tip size, directly impact the efficiency and quality of the cutting process. Web as a welding torch, the basic operation of an. It combines oxygen and acetylene gases to form a superheated flame that melts and joins two pieces of metal. Web harris cutting tip charts. The third open valve in the torch is the first acetylene after that you can open the oxygen valve. If more than 100 ft (31 m) of hose is required, use 1/2 in. Oxy acetylene cutting. Hose for size 4 and larger. Web open regulator oxygen and acetylene, set until the pressure matches with what you want or for acetylene 5 to 7 psi and oxygen 7 to 10 psi. Web as a welding torch, the basic operation of an oxyacetylene unit is blending two gases, oxygen and acetylene, together in the right proportion to create. Tip size numbers vary among manufacturers, so orifice sizes are shown in number drill sizes. Torches with flashback arrestors require up to 25% more pressure as tip size increases (15 psi maximum acetylene pressure). Tables show approximate gas pressures for welding or cutting. This will be done starting with the cylinders and ending with the torch tip. ** for best. · close oxygen torch valve. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. The recommended setting is for the fuel gas adjustor to shall set at 10 psig and the oxygen regulator at 45 psig. So, what is the proper way to handle an oxyacetylene torch? Tip size numbers vary. This will be done starting with the cylinders and ending with the torch tip. Everyone in the hvac/r trade uses some type of torch to braze or solder alloys together. It combines oxygen and acetylene gases to form a superheated flame that melts and joins two pieces of metal. Web open regulator oxygen and acetylene, set until the pressure matches. Web open regulator oxygen and acetylene, set until the pressure matches with what you want or for acetylene 5 to 7 psi and oxygen 7 to 10 psi. Web · open oxygen valve and adjust to neutral flame. Flared cutting cavity that supplies low velocity oxygen for grooving, gouging and removing flawed welds. Hose for size 4 and larger. It. Web an oxy acetylene mixture burns the hottest, somewhere around 5800 degrees, and that's what this article will be about: This will be done starting with the cylinders and ending with the torch tip. Pieces of metal to the point. For additonal information refer to www.harrisproductsgroup.com. Everyone in the hvac/r trade uses some type of torch to braze or solder. If the torch/regulators and gases are done being used for a while, follow these procedures: Web · open oxygen valve and adjust to neutral flame. Web regulator pressures are for 50 ft (13 m) or less of 3/8 in. A larger tip will generate more heat, while a. Tables show approximate gas pressures for welding or cutting. Web regulator pressures are for 50 ft (13 m) or less of 3/8 in. It combines oxygen and acetylene gases to form a superheated flame that melts and joins two pieces of metal. The recommended setting is for the fuel gas regulator to be set at 10 psig and the oxygen regulator at 45 psig. If more than 100 ft. If more than 100 ft (31 m) of hose is required, use 1/2 in. If the torch/regulators and gases are done being used for a while, follow these procedures: Tables show approximate gas pressures for welding or cutting. Pieces of metal to the point. The tip is angled at 20o. Web adjust to the correct flame setting. Web as a welding torch, the basic operation of an oxyacetylene unit is blending two gases, oxygen and acetylene, together in the right proportion to create a proper size flame. Propane is not as expensive as acetylene and so many people gravitate to this type of fuel. Torches with flashback arrestors require up to 25% more pressure as tip size increases (15 psi maximum acetylene pressure). This will depend on the thickness of the metal you are welding, as well as the type of joint you are using. ** to provide required flow, use 3/8 i.d. Web the first step in setting up your oxy acetylene rosebud torch is to choose the right tip. ** for best results use appropriate capacity torches and 3/8 hose when using tip size 6 or larger. The third open valve in the torch is the first acetylene after that you can open the oxygen valve. Web harris cutting tip charts. The recommended setting is for the fuel gas regulator to be set at 10 psig and the oxygen regulator at 45 psig.

Oxy Acetylene Torch Tip Chart

Goneryl scheme Eliot oxygen and acetylene pressure settings

oxygen and acetylene pressure settings

Doclib 8051 DocLib 4680 Victor Acetylene Cutting Tip Chart

Oxyacetylene Torch Settings Chart

Oxyacetylene Torch Settings Chart

oxygen and acetylene pressure settings

Oxyacetylene Torch Settings Chart

Oxy Acetylene Settings Chart

Oxyacetylene Torch Settings Chart

It Is An Intricate Process That Requires A Great Degree Of Skill, Focus And Patience, But Don’t Be Discouraged.

The Flame Is Used To Melt Two.

For Additonal Information Refer To Www.harrisproductsgroup.com.

· Depress Oxygen Lever And Make Necessary Adjustments.

Related Post: