Moving Range Control Chart

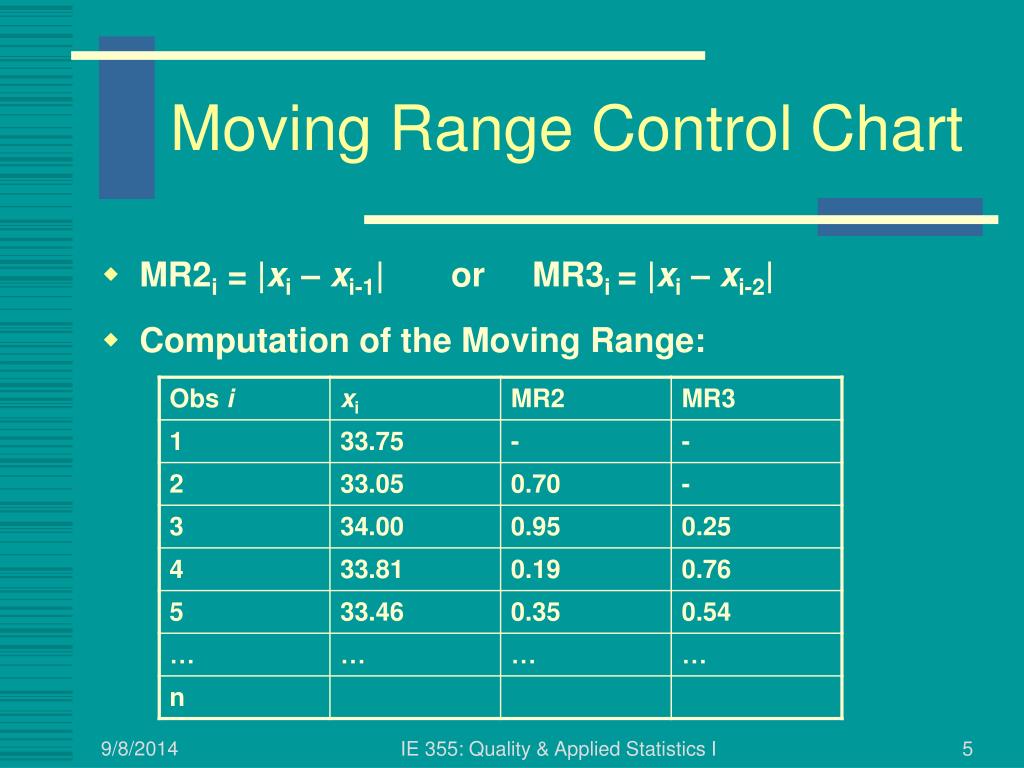

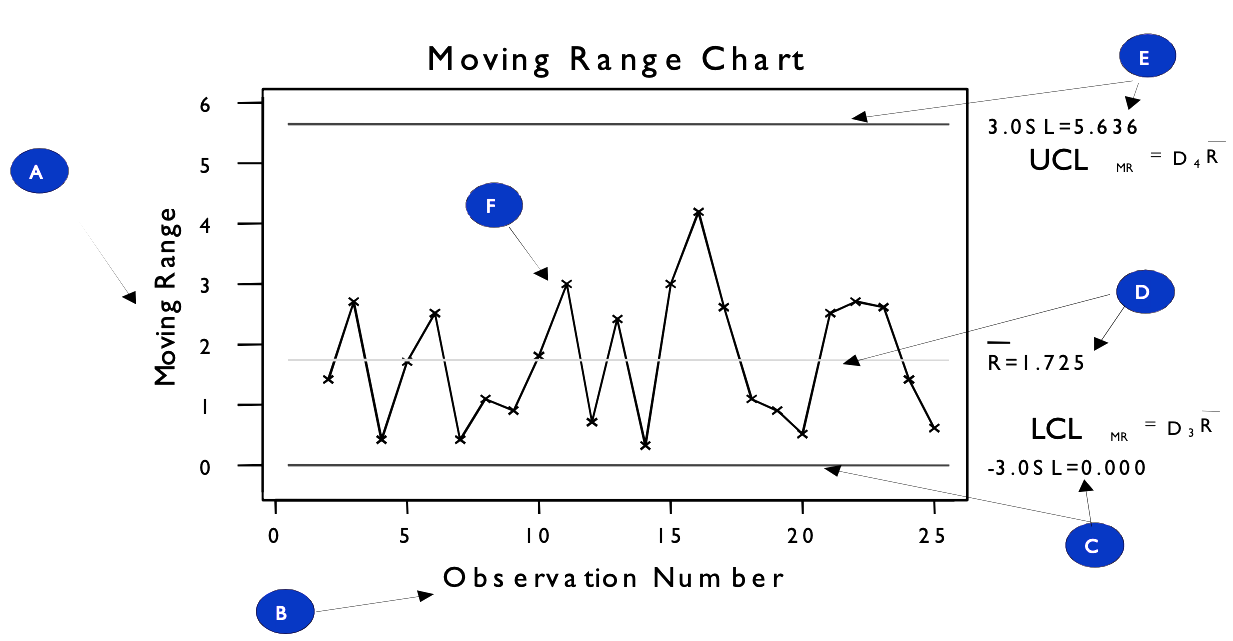

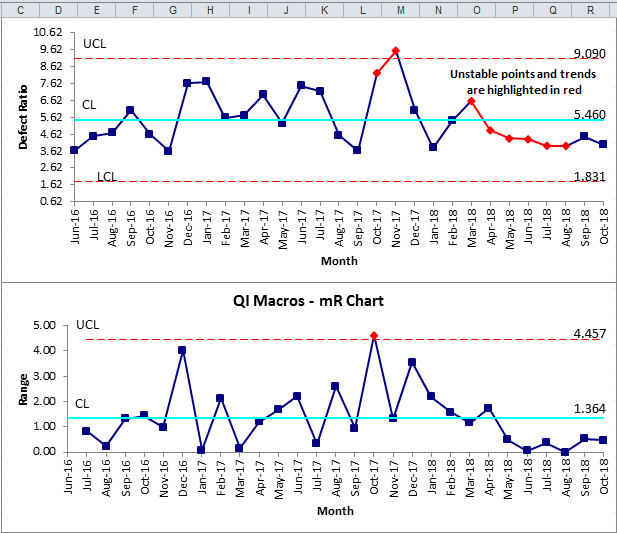

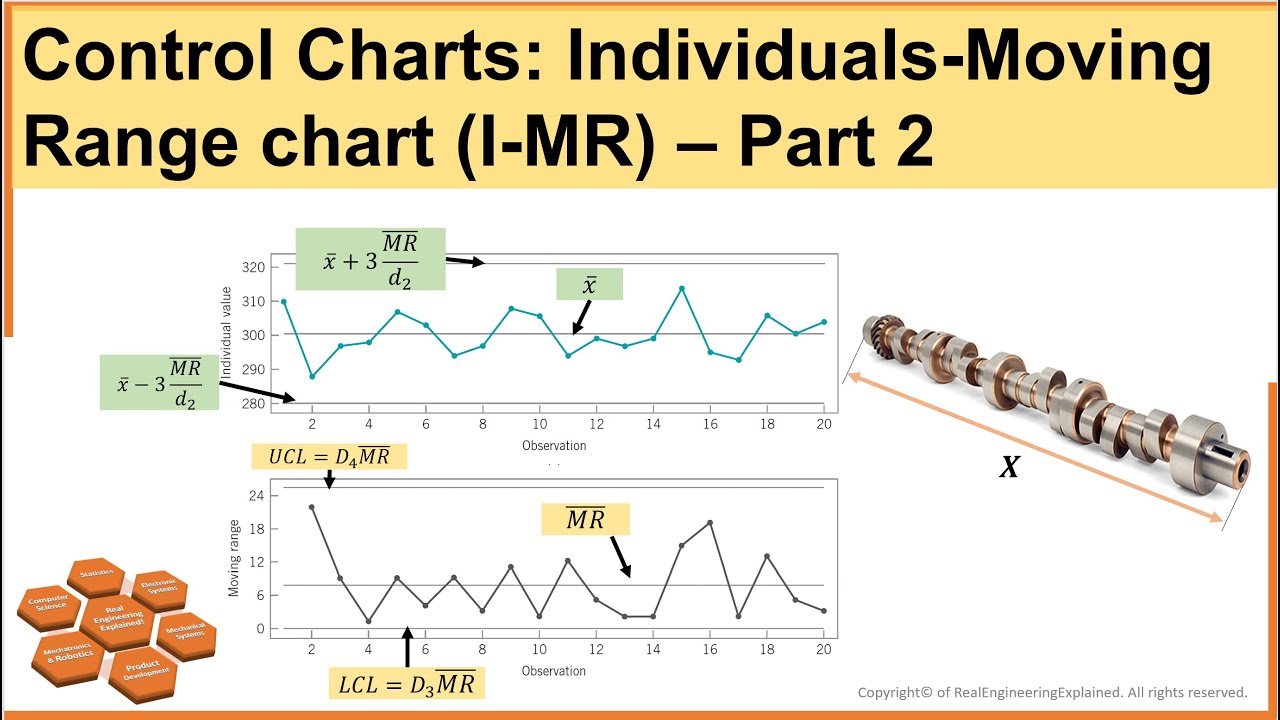

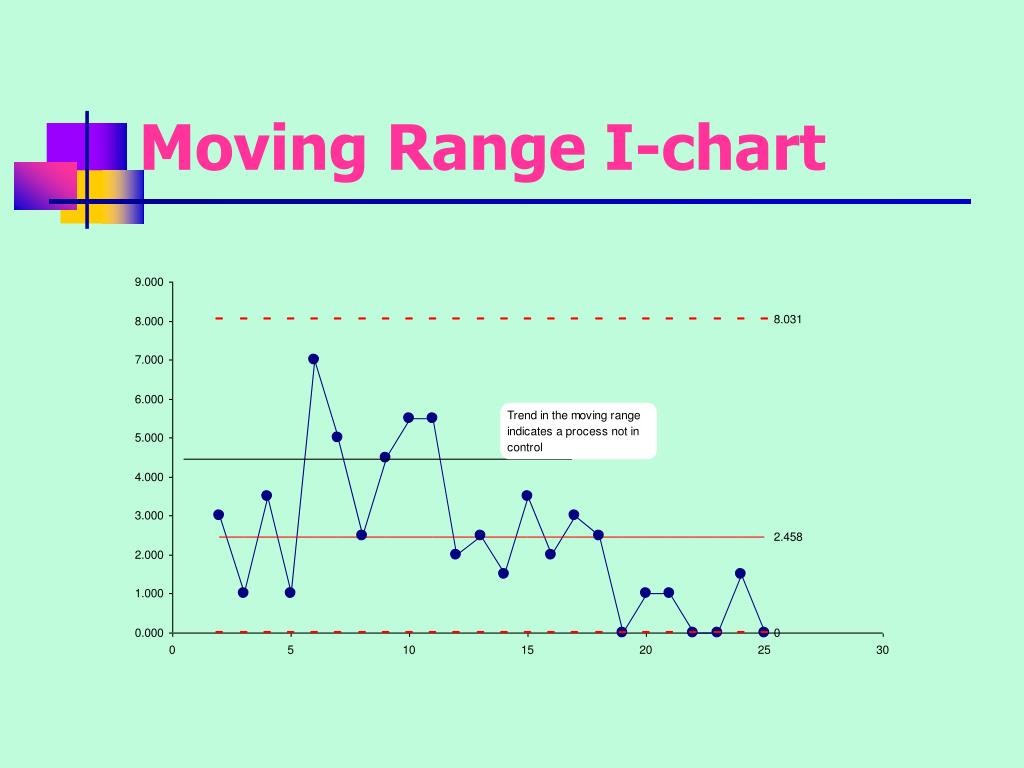

Moving Range Control Chart - The average moving range ( r) is used to calculate the control limits on the x chart. What control charts look like; They are particularly useful when data is collected one sample at a time, instead of in subgroups. Determine whether the process mean is in control. Web a moving range measures how variation changes over time when data are collected as individual measurements rather than in subgroups. Types of variable control charts. Special control charts for special applications; Web a control chart displays process data by time, along with upper and lower control limits that delineate the expected range of variation for the process. Brainstorm and conduct designed experiments to find those process elements that contribute to sporadic changes in. Determine whether the process variation is in control. The x chart where the individual values are plotted and the moving range (mr) chart where the range between consecutive values are plotted. Brainstorm and conduct designed experiments to find those process elements that contribute to sporadic changes in. Web all statistics and graphs for moving range chart. Web steps in constructing an individuals and moving range control chart. They. Web example of moving range chart. They are particularly useful when data is collected one sample at a time, instead of in subgroups. Web steps in constructing an individuals and moving range control chart. This was developed initially by walter shewart and hence the control charts are sometimes also referred to as shewart chart. If there are any, then the. Find definitions and interpretation guidance for every statistic and graph that is provided with the moving range chart. The average moving range ( r) is used to calculate the control limits on the x chart. Special control charts for special applications; The engineer measures the ph of 25 consecutive batches of detergent. 1) the ideal, 2) the threshold, 3) the. These limits let you know when unusual variability occurs. The center line is the average of all moving ranges. Web steps in constructing an individuals and moving range control chart. The control limits on the moving range chart, which are set at a distance of 3 standard deviations above and below the center line, show the amount of variation that. The format of the control charts is fully customizable. A quality engineer monitors the manufacture of liquid detergent and wants to assess whether the process is in control. The green line on each chart represents the mean, while the red lines show the upper and lower control limits. Key output includes the individuals chart, the moving range chart, and test. Determine whether the process variation is in control. Setting up a variables control chart; The engineer creates a moving range chart to monitor the detergent process. Determine whether the process mean is in control. Types of variable control charts. Find definitions and interpretation guidance for every statistic and graph that is provided with the moving range chart. Use this control chart to monitor process stability over time so that you can. Analogous to the shewhart control chart, one can plot both the data (which are the individuals) and the moving range. Learn more about these control charts online at. Web the individuals control chart is composed of two charts: If we collect individual measurements and need to plot the data on a control chart, or assess the capability of a process, we need a way to estimate the variation over time. Individuals control limits for an observation. Special control charts for special applications; Identify which points failed each test. Determine whether the process mean is in control. These limits let you know when unusual variability occurs. Web create individuals and moving range control charts to monitor the performance of a continuous variable over time. Setting up a variables control chart; Web the moving range is defined as m r i = | x i − x i − 1. Statistical formulas use historical records or sample data to calculate the control limits. The control limits on the moving range chart, which are set at a distance of 3 standard deviations above and below the center line, show the amount of variation that is expected in the moving ranges of the standardized data. Web methods and formulas for moving range. Types of variable control charts. Identify which points failed each test. The format of the control charts is fully customizable. Analogous to the shewhart control chart, one can plot both the data (which are the individuals) and the moving range. Web the moving range is defined as m r i = | x i − x i − 1 |, which is the absolute value of the first difference (e.g., the difference between two consecutive data points) of the data. The engineer creates a moving range chart to monitor the detergent process. They are particularly useful when data is collected one sample at a time, instead of in subgroups. If we collect individual measurements and need to plot the data on a control chart, or assess the capability of a process, we need a way to estimate the variation over time. An individuals chart is used when the nature of the process is such that it is difficult or impossible to group measurements into subgroups so an estimate of the process. Use this control chart to monitor process stability over time so that you can. Processes fall into one of four states: The averages and control limits are also part of the charts. 1) the ideal, 2) the threshold, 3) the brink of chaos and 4) the state of chaos (figure 1). The engineer measures the ph of 25 consecutive batches of detergent. These limits let you know when unusual variability occurs. Learn more about these control charts online at quality america!

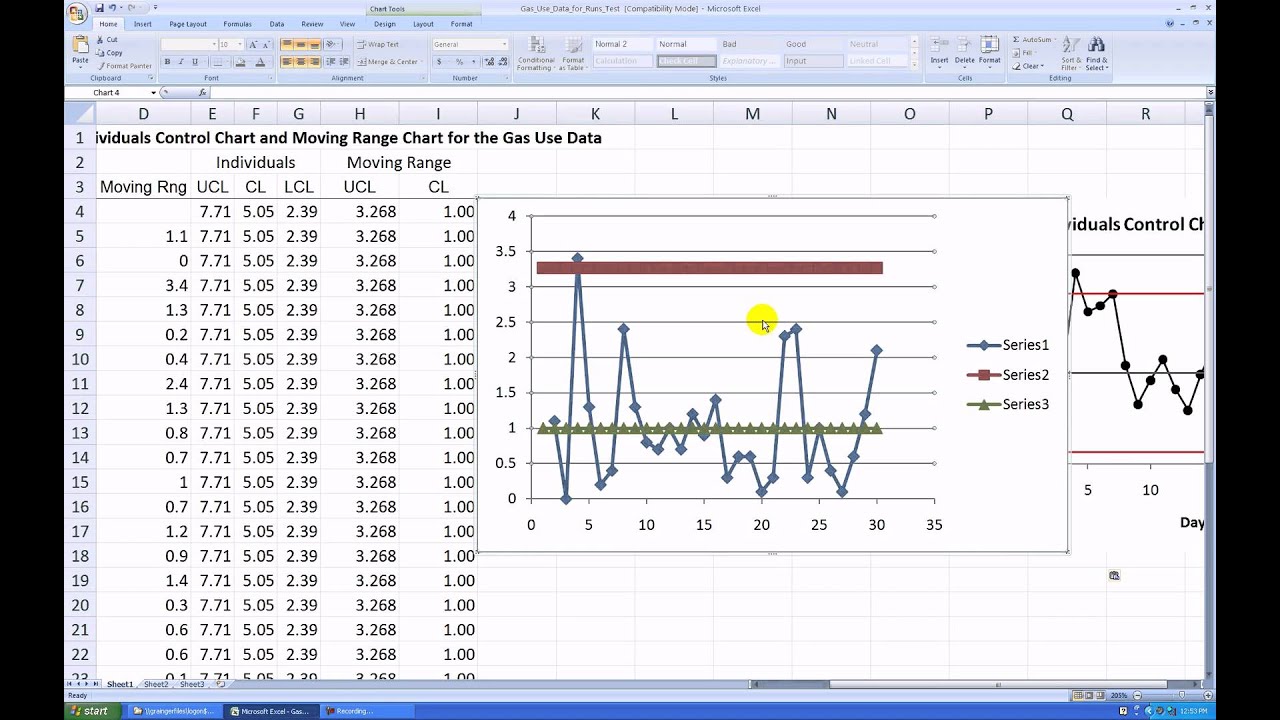

IMRR Chart in Excel Individual Within & Between

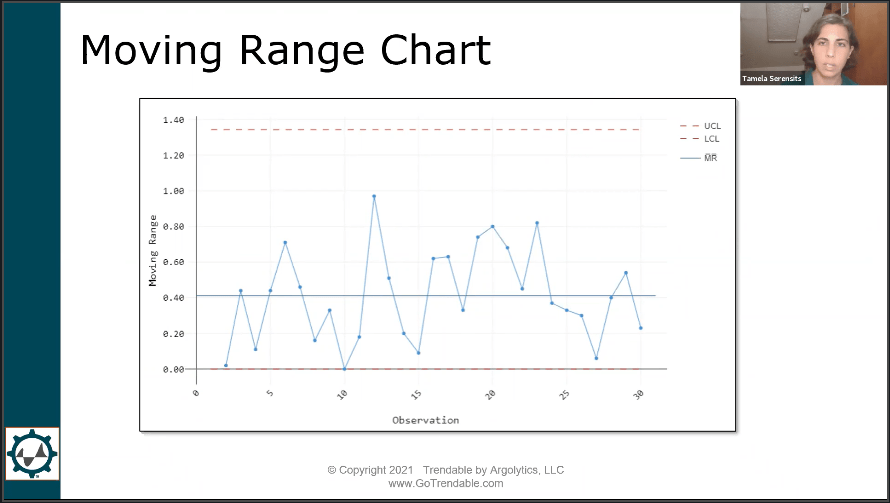

What is a Moving Range chart? TRENDABLE

How to Make a Moving Range Control Chart in MS Excel 2007 YouTube

PPT IENG 486 Lecture 17 PowerPoint Presentation, free download ID

Control Charts Enhancing Your Business Performance

Moving Range Charts IndividualX Chart Quality America

Individual Moving Range Chart ImR Chart XmR Chart

XmR Chart StepbyStep Guide by Hand and with R RBAR

Part 2 Control Charts Individual Moving Range (IMR) chart

PPT Statistical Quality Control PowerPoint Presentation, free

Web The Bottom Part Of The Graph Is A Moving Range (Mr) Chart, Which Plots Process Variation As Calculated From The Ranges Of Two Or More Successive Observations.

The Green Line On Each Chart Represents The Mean, While The Red Lines Show The Upper And Lower Control Limits.

Web A Moving Range Measures How Variation Changes Over Time When Data Are Collected As Individual Measurements Rather Than In Subgroups.

Web The Moving Range Chart Plots The Moving Ranges.

Related Post: