Mold Pattern

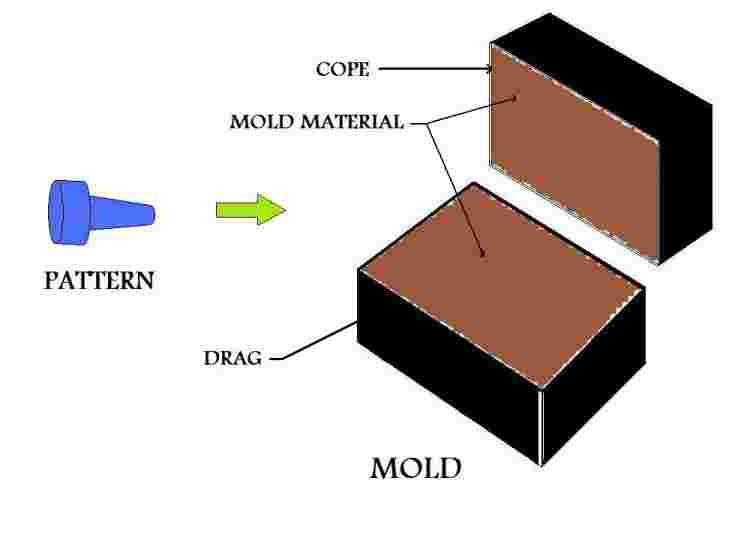

Mold Pattern - After the shell mold has completely cured, the cast. It consists of two or more parts that can be separated to facilitate the removal of the pattern from the mold. After removing the pattern from both molds, the next step involves preparing the mold for assembly. Read our guide to metal casting for details on each process. To cause mold to grow upon. There are different types of patterns in casting. We provide permanent molds, vacuum form molds , and precast refractory molds. Web what is the types of patterns in casting? according to wikipedia’s explanation, a pattern is a copy of the object to be cast. The pattern is placed in one half, and the other half is placed on top to enclose the pattern. The metal patterns are heated to temperatures ranging from 175 ºc to 370 ºc. A reusable pattern allows for higher production rates, while the disposable molds enable complex geometries to be cast. It consists of two or more parts that can be separated to facilitate the removal of the pattern from the mold. Web pattern and mold are two words that are often used interchangeably, but they have distinct meanings. The pattern is placed. It involves creating a precise wax replica, also known as a wax pattern, of the desired metal part. Web the heating phase and mold shell creation. So the pattern is very critical to the final part. It consists of two or more parts that can be separated to facilitate the removal of the pattern from the mold. In casting, a. Web in transitive terms the difference between pattern and mold is that pattern is to serve as an example for while mold is to cause to become moldy; The metal patterns are heated to temperatures ranging from 175 ºc to 370 ºc. Sand casting supports a variety of different metals and alloys. As a result, the mold pattern can be. In this order, pattern shapes molds, and molds make metal parts. Now it’s time to pour the molten metal into the mold cavity. Donut model from lesson 5: To cause mold to grow upon. Once the pattern is removed from the drag mold, the pattern in the cope mold should be removed in a similar fashion as outlined in the. So the pattern is very critical to the final part. Read our guide to metal casting for details on each process. Split patterns are employed for creating more complex shapes and larger production quantities. Web pattern (casting) the top and bottom halves of a sand casting mould showing the cavity prepared by patterns. This wax pattern is then used to. Cores to accommodate holes can be seen in the bottom half of the mould, which is called the drag. In casting, a pattern is a replica of the object to be cast, used to form the sand mould. Apply and solidify ceramic slurry on the mold pattern. Web casting is the process of pouring liquid metal into a mold, where. Web pattern and mold are two words that are often used interchangeably, but they have distinct meanings. Step #4) pour molten metal into mold cavity. Web the heating phase and mold shell creation. Next, place the pattern atop a “dump box” full of the sand and resin mixture. In this type, the mold cavity is created by the complete sweep. Web foundry pattern service has the ability and experience to meet your unique pattern needs. Next, place the pattern atop a “dump box” full of the sand and resin mixture. In this type, the mold cavity is created by the complete sweep of the pattern. Web sweep pattern is suitable when the casting is large and symmetrical about the axis. Web mold patterns, including sand casting patterns, come in a variety of styles for making simple or complex, solid or hollow objects. We serve a wide range of diverse customers and industries. Web pattern and mold are two words that are often used interchangeably, but they have distinct meanings. It is a template that is used to produce multiple copies. We provide permanent molds, vacuum form molds , and precast refractory molds. To cause mold to grow upon. Read our guide to metal casting for details on each process. Two or more halves of a mold, made of sand mixed with a bonding agent, are created. After removing the pattern from both molds, the next step involves preparing the mold. It consists of two or more parts that can be separated to facilitate the removal of the pattern from the mold. Web what is the types of patterns in casting? according to wikipedia’s explanation, a pattern is a copy of the object to be cast. To cause mold to grow upon. Web foundry pattern service has the ability and experience to meet your unique pattern needs. Web in transitive terms the difference between pattern and mold is that pattern is to serve as an example for while mold is to cause to become moldy; Different pattern styles may also be better suited to casting small or large items, a few or a great many items, symmetrical or asymmetrical castings. The casting process can produce everything from art pieces to engine parts. Before we dive into the world of mold making and casting, we need to have a quick chat about the object you choose to make a mold of, known as a model (for this class i will be using the word model, but it can also be referred to as a pattern). The pattern is placed in one half, and the other half is placed on top to enclose the pattern. When the mold pattern is placed inside sand, the sand takes its shape. In this type, the mold cavity is created by the complete sweep of the pattern. Web arnette pattern company has been providing high quality industrial molds since 1948. Patterns are a model for the object to be cast. Split patterns are employed for creating more complex shapes and larger production quantities. Lubricate the pattern with calcium stearate and then preheat it to between 175 ºc and 370 ºc. Apply and solidify ceramic slurry on the mold pattern.

Mold Pattern Free Stock Photo Public Domain Pictures

Premium Vector Mold pattern

for mechanical engineering expendable mold casting

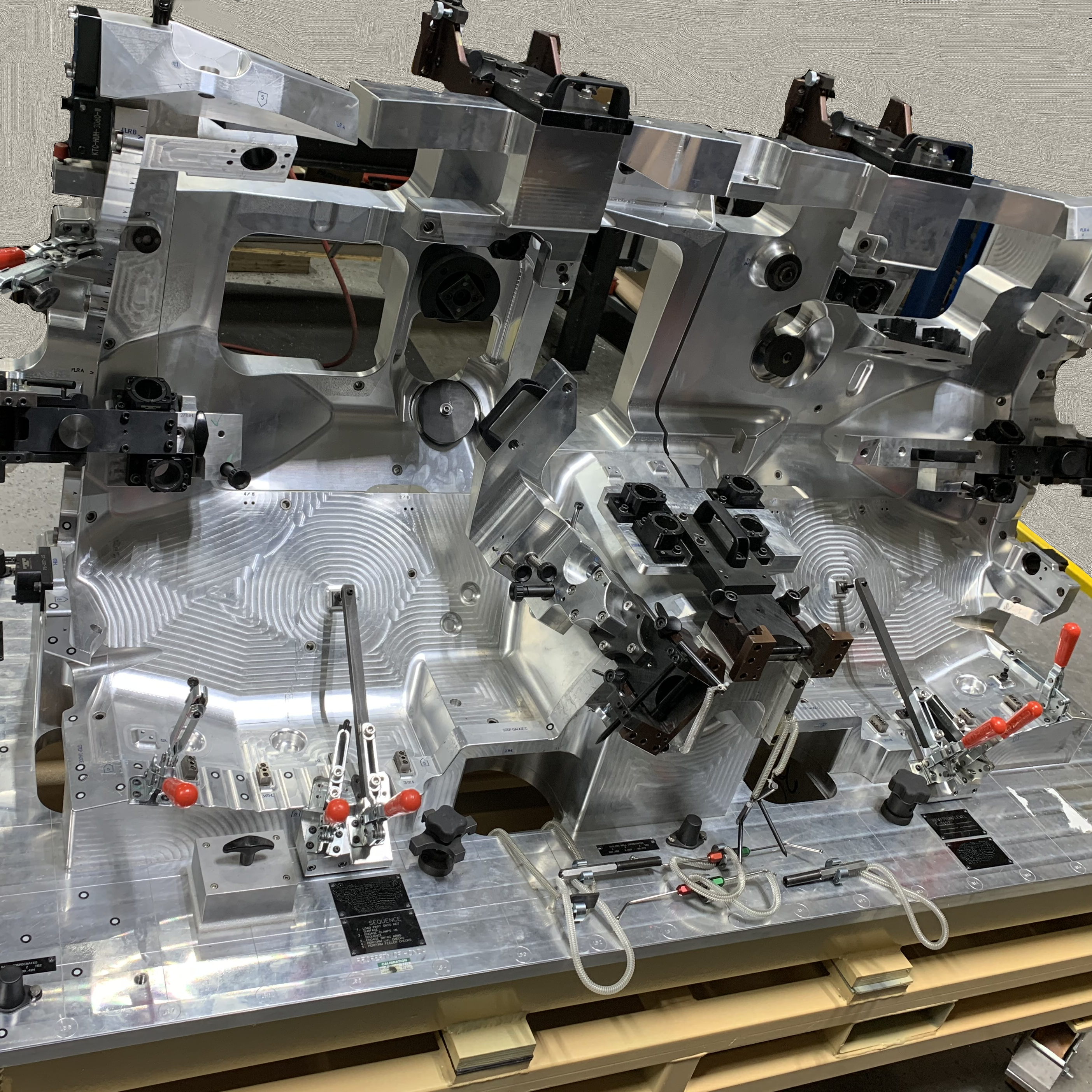

Home Aluminum Mold & Pattern

Home Aluminum Mold & Pattern

Pattern Types and Mold Cavity Animation in Casting Process by Shubham

Pattern of mold stock image. Image of medicine, mold, macro 8039297

file13 Aluminum Mold & Pattern

Mold Pattern Akshar Engineers

Premium Vector Mold pattern 8

Accurate Pattern Designs And Builds Plugs And Molds For Fiberglass Composite Laminating Customers In The Aerospace, Energy, Military, Transportation And Related Industries.

Sand Casting Supports A Variety Of Different Metals And Alloys.

We Provide Permanent Molds, Vacuum Form Molds , And Precast Refractory Molds.

Web A Replica Pattern Is Used To Create A Mold Out Of Rubber, Metal, Or Resin.

Related Post: