Mig Welding Gas Flow Rate Chart

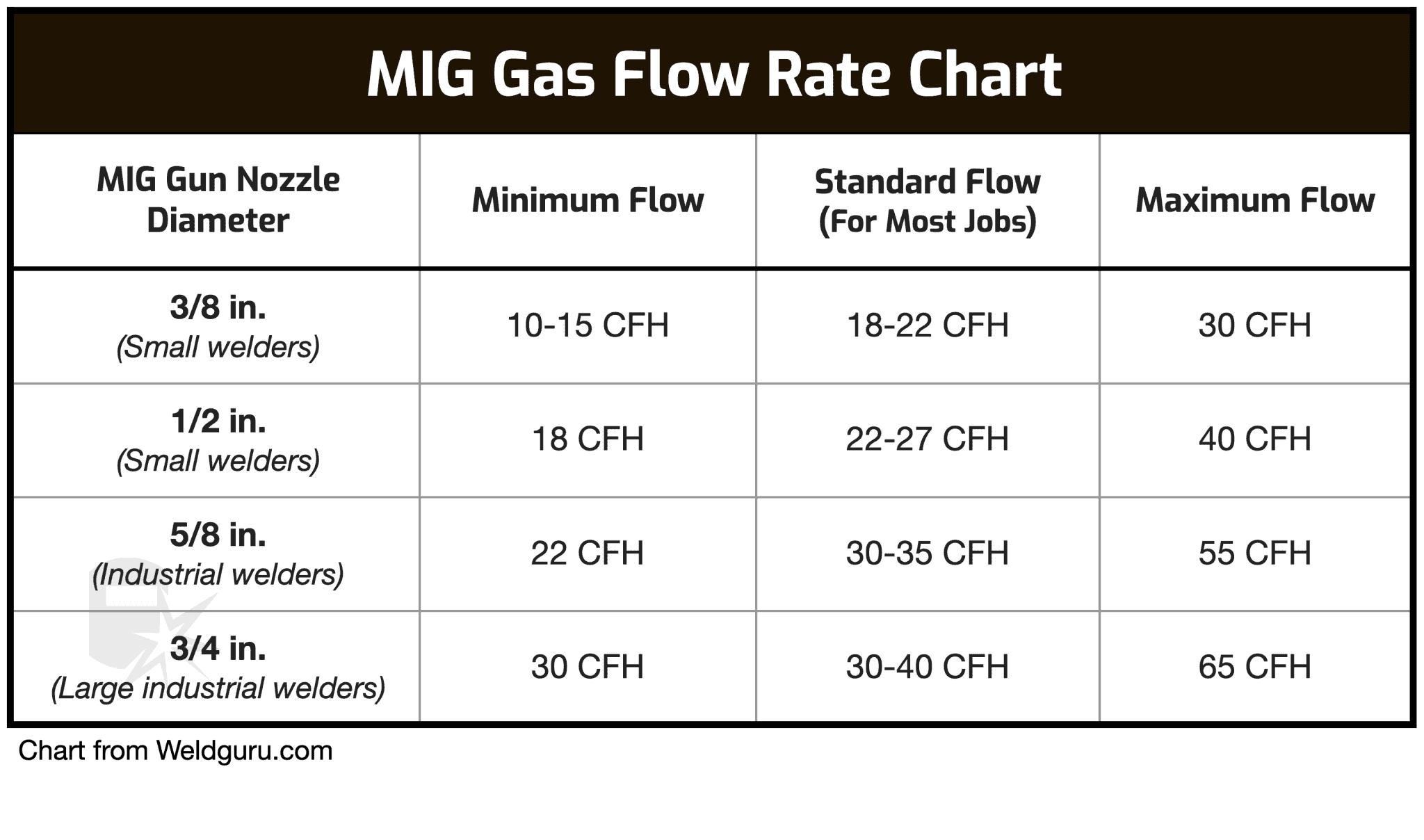

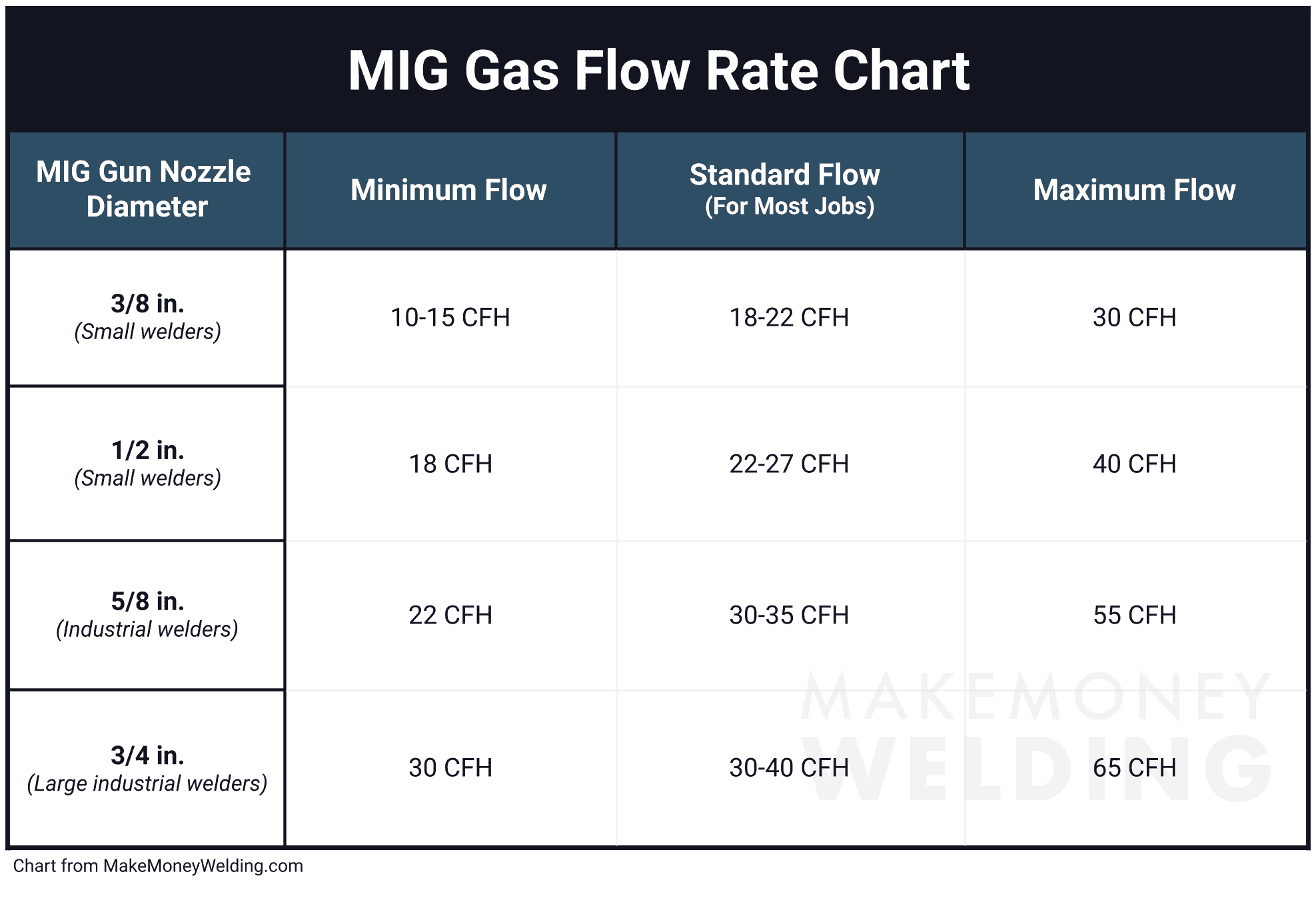

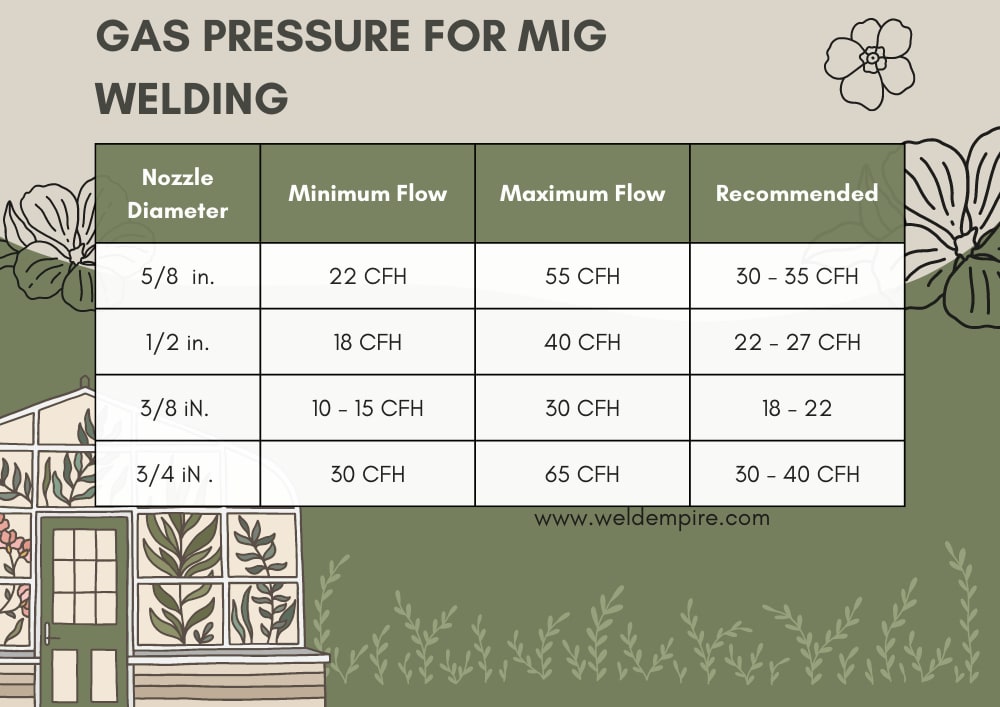

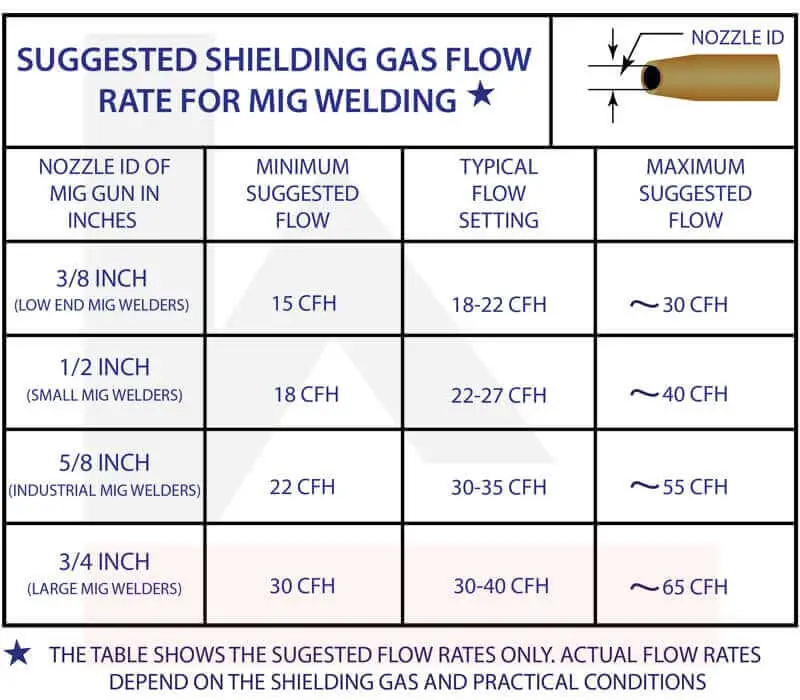

Mig Welding Gas Flow Rate Chart - Web the most common gas used for mig welding is a 75% argon, 25% co2 mixture. Helllooo how's every one doing over here. .125 inch = 125 amps. Web see the full mig180 welding chart here. The system is available for purchase on our web site. See the full mig250 welding chart here. Web best mig gas flow rates. But make sure to take into account the different variables while selecting the flow rate. The gas pressure in the hose going into a wire feeder/welder, while welding, typically varies from 3 to 8 psi. Hello all, i'm quite new to mig welding, and i'm currently doing a college course in it. The whole point of shielding gas. Your shielding gas choice significantly impacts the weld quality, arc behavior, productivity, and costs. Web the correct gas flow rate in mig welding ranges between 15 to 25 cfh. Web unlike oxyfuel welding and cutting, mig gas flow rates are very low. Web the flow rate, volume, and type of shielding gas determine transfer. The whole point of shielding gas. See web page with suggested flow rate chart. Determining the right flow rate involves a balance between too little and too much gas. Higher concentrations of helium or argon make for a hotter arc. For example, you may see helium blends used to weld thick aluminum. It’s measured in cubic feet per hour (cfh) and is one of the main mig welding settings for successful welds. Web the correct gas flow rate in mig welding ranges between 15 to 25 cfh. Web finally the gas type and gas flow rate help regulate the transfer type. This is an area that requires. The gas pressure in the. Web see the full mig180 welding chart here. Web finally the gas type and gas flow rate help regulate the transfer type. Work within wire operating limits. This shielding gas allows a stable arc, low spatter, and control over molten weld puddles. Helllooo how's every one doing over here. Web see the full mig180 welding chart here. If this is your first time using a mig welder, you need to familiarize yourself with three main settings. Higher concentrations of helium or argon make for a hotter arc. See the full mig250 welding chart here. See web page with suggested flow rate chart. This is an area that requires. The manual says to set it between 4 and 8 l/min. See causes for mig gas usage being over 3. Web the gas flow rate determines the amount of gas that goes through your torch to the weld, controlling the thickness of the weld bead. Be aware of the unit of measurement used in. But make sure to take into account the different variables while selecting the flow rate. Wa technology's gas saver system reduces the blast of shielding gas at each weld start. Is there some basic rule for the gas flow settings or not? In dip transfer mode a sound a bit like frying bacon should be heard. Setting the optimal flow. Web to figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. Web as a guideline, each.001 inch of material thickness requires 1 amp of output: The main goal of the gas setting is to provide enough gas to shield the. Using a pea shooter flow indicator to check the shielding gas flow rate at the nozzle is the most accurate method. With experience, learn to ‘tune’ the wire feed by listening to the sound of the weld. Is there some basic rule for the gas flow settings or not? Web the most common gas used for mig welding is a. This chart can help figure out what flow rate you need based on the size ( the welders ). ( fronius) (1) mains connection. With experience, learn to ‘tune’ the wire feed by listening to the sound of the weld. Web setting mig shielding gas flow rates. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination,. Work within wire operating limits. See web page with suggested flow rate chart. Determining the right flow rate involves a balance between too little and too much gas. Web the flow rate, volume, and type of shielding gas determine transfer type when combined with voltage and wire speed. Your shielding gas choice significantly impacts the weld quality, arc behavior, productivity, and costs. For example, you may see helium blends used to weld thick aluminum. ( fronius) (1) mains connection. I was wondering if you need to change the gas flow rate if you change the cup or does it always stay the same? Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. It’s measured in cubic feet per hour (cfh) and is one of the main mig welding settings for successful welds. If this is your first time using a mig welder, you need to familiarize yourself with three main settings. Is there some basic rule for the gas flow settings or not? The system is available for purchase on our web site. Have a question about converting cfh to psi? Helllooo how's every one doing over here. This reduces the blast of gas and cuts total gas use in half.

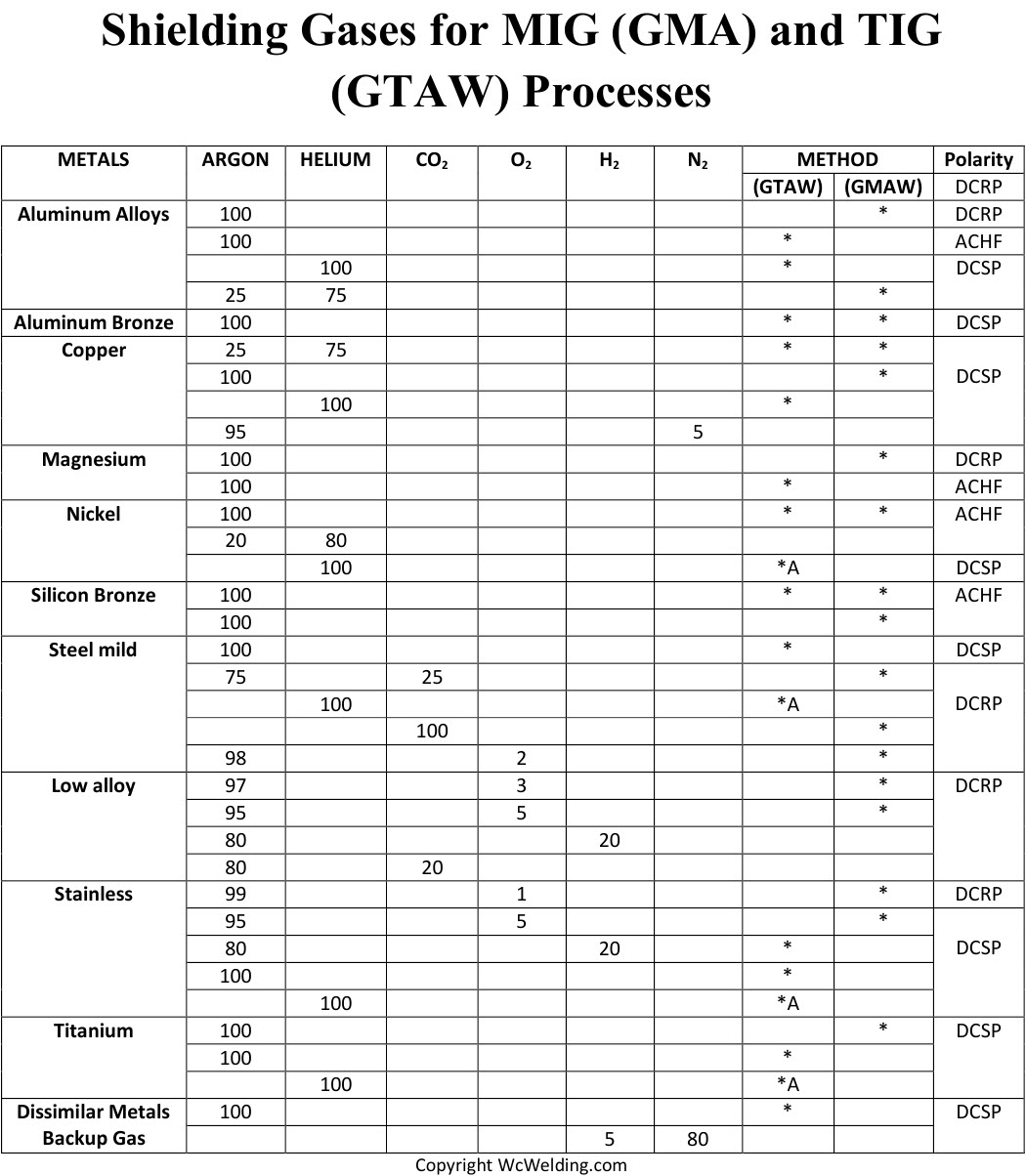

Shielding Gas Guide

MIG Welding Gas Pressure Settings (with Charts)

Mig Welding Gas Flow Rate Chart

MIG Welding Gas Pressure Settings

What Should Be the Gas Pressure for MIG Welding? Weld Empire

MIG Flow Rate Chart Welding Mechanical Engineering

How to Optimize MIG Welding Shielding Gas Pressure

Mig Welding Gas Flow Rate Chart Lpm

MIG Welding Gas Pressure Settings (with Charts)

MIG Flow Rate Chart Welding Gases

Whether There Is Any Uncontrollable Factors That May Disrupt The Gas Shield Around The Weld, Draught/Wind Being The Most Obvious.

Web The Joint Configuration.

With Experience, Learn To ‘Tune’ The Wire Feed By Listening To The Sound Of The Weld.

This Is An Area That Requires.

Related Post: