Mig Voltage Chart

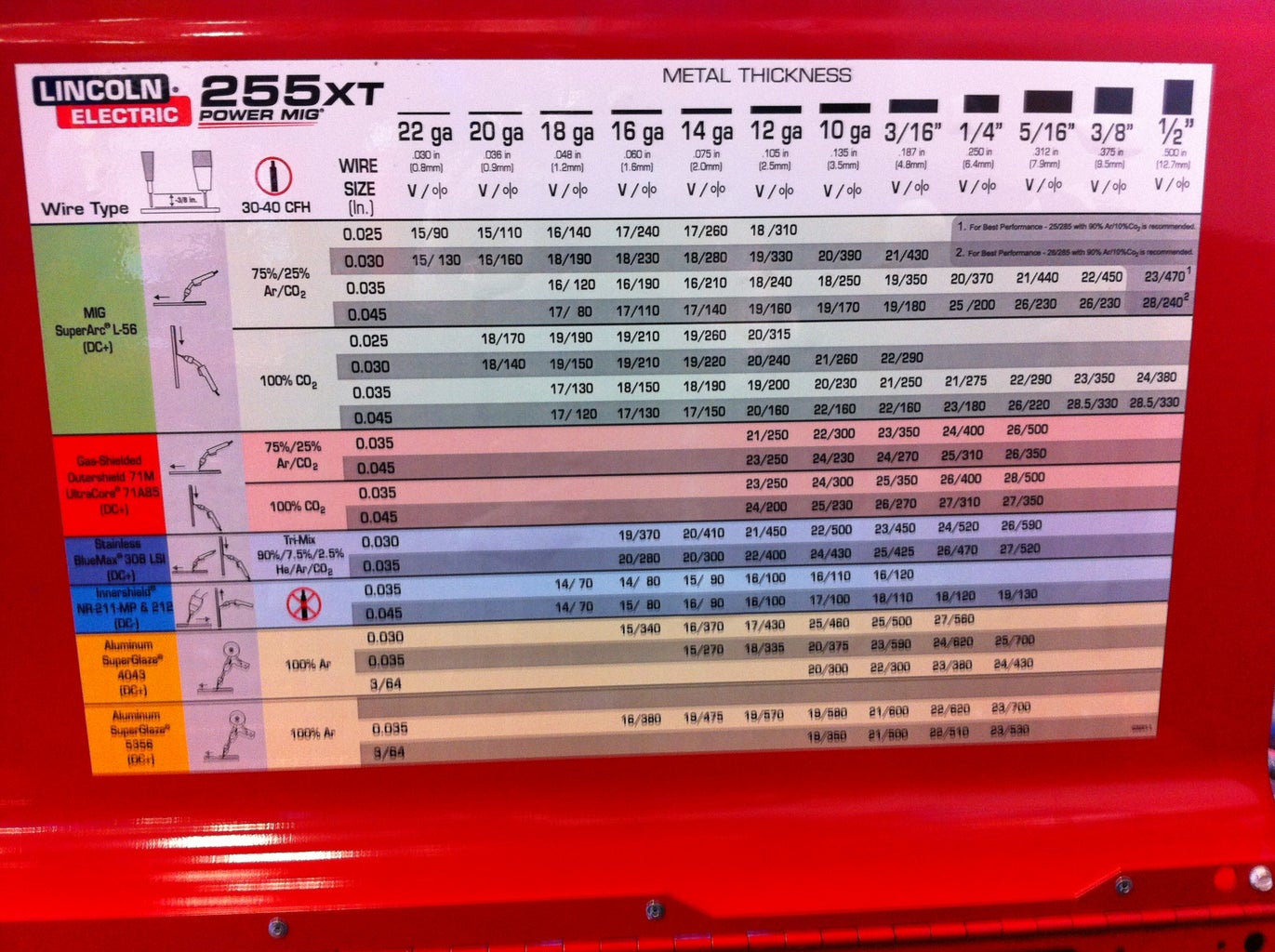

Mig Voltage Chart - For example, instruction manual or side door charts usually feature only guidelines. Web a mig welding wire speed chart offers insights into appropriate wire speeds for various material thicknesses and types in mig welding. Extend the electrode wire to ¼ or ½. If no chart, manual or specifications are available for setting the correct voltage, you can try this: The charts below provide a great starting place to help you as your try to decide what the right setting is for you. So, you can get a pretty good deal about the setup needed for your project and expect good results by using these wire speed and voltage settings. Web how do you set wire speed and voltage without a chart and on pretty much any mig welding machine? Set the gesstings around 30 cfh. As when welding other materials, getting the best results with thin materials depends on correct voltage, amperage and travel speed — along with other factors. In these charts, we will be comparing the appropriate voltage and wire speed needed for the job. So, you can get a pretty good deal about the setup needed for your project and expect good results by using these wire speed and voltage settings. Web the flux core mig welding wire speed and voltage chart offers precise guidance on optimal voltage and wire speed settings in mig welding. Before tackling any mig welding application, look at the. In this weeks video, i am showing a method for setting wire speed first based on the thickness being welded. Web mig welding wire speed & voltage chart. If no chart, manual or specifications are available for setting the correct voltage, you can try this: Web what material are you welding? Web a longer arc (more voltage) produces a flatter,. Web weld setting calculator app. As when welding other materials, getting the best results with thin materials depends on correct voltage, amperage and travel speed — along with other factors. This will be good for most jobs up to about ½”. In these charts, we will be comparing the appropriate voltage and wire speed needed for the job. Web the. Before tackling any mig welding application, look at the charts and tips below. However, you will need special wire if you plan to weld other metals, such as aluminum. Navigating the complexities of mig welding requires a deep understanding of its two pivotal parameters: This will be good for most jobs up to about ½”. Browse suggested weld parameter settings. This will be good for most jobs up to about ½”. In these charts, we will be comparing the appropriate voltage and wire speed needed for the job. Browse suggested weld parameter settings for stick welding, tig. There might be variations with the settings depending on the manufacturer. Web the flux core mig welding wire speed and voltage chart offers. If no chart, manual or specifications are available for setting the correct voltage, you can try this: Web a mig welding wire speed chart offers insights into appropriate wire speeds for various material thicknesses and types in mig welding. Plus, don’t miss my tips that make the task of mig welding aluminum not only achievable but also efficient. As when. However, you will need special wire if you plan to weld other metals, such as aluminum. If no chart, manual or specifications are available for setting the correct voltage, you can try this: There might be variations with the settings depending on the manufacturer. Web what material are you welding? Web there are various criteria to consider when setting your. Web a longer arc (more voltage) produces a flatter, wider bead. Web what material are you welding? Too much arc length makes a very flat bead and the undercut possibility. Stainless steel and aluminium amps chart. Web mig welding is also called as gas metal arc welding (gmaw) is a type of welding that is done using a continuously fed. Web mig welding wire speed & voltage chart. Voltage determines height and width of the bead. These settings determine the heat, wire deposition rate, and protection from atmospheric contamination, respectively,. Web the most important mig welder settings are voltage, wire feed speed, and shielding gas flow rate. Web the american welding society (aws) defines it as 3/16 inch or thinner. Web a mig welding wire speed and voltage chart provide essential settings based on material thickness and wire diameter. Web set the voltage. While one person welds on scrap metal, an assistant turns down the voltage until the arc starts stubbing into the workpiece. The charts below provide a great starting place to help you as your try to decide. Web there are various criteria to consider when setting your mig weld controls, including materials, metal thickness, shielding gas, electrode wires, and amperage. In these charts, we will be comparing the appropriate voltage and wire speed needed for the job. Below are the voltage settings for each of these metals. Stainless steel and aluminium amps chart. This will be good for most jobs up to about ½”. Plus, don’t miss my tips that make the task of mig welding aluminum not only achievable but also efficient. Web how do you set wire speed and voltage without a chart and on pretty much any mig welding machine? Web here is a chart that summarizes the mig welding amps according to the three most common types of metal and their thickness: Web a mig welding wire speed chart offers insights into appropriate wire speeds for various material thicknesses and types in mig welding. Voltage determines height and width of the bead. Web the flux core mig welding wire speed and voltage chart offers precise guidance on optimal voltage and wire speed settings in mig welding. Web what material are you welding? Web estimates the range of mild steel thicknesses you can weld with each setting on your mig welder. If no chart, manual or specifications are available for setting the correct voltage, you can try this: However, you will need special wire if you plan to weld other metals, such as aluminum. While one person welds on scrap metal, an assistant turns down the voltage until the arc starts stubbing into the workpiece.

Important MIG Welder Settings You Need to Know (with Chart)

242 MIG Settings Chart Metalworking Metals

Jasic MIG Inverter Welder Selection Guide Jasic Blog

Mig welder options, Old machine vs new MIG Welding Forum

Mig Welding Amps To Metal Thickness Chart

MIG Welder Voltage Selection 120 Volt or 240 Volt

How To MIG Weld Aluminum Beginners Guide (with Chart)

The parameter values for MIG welding Download Scientific Diagram

Lincoln Mig Welder Settings Chart

Basics of MIG Welding 17 Steps (with Pictures) Instructables

Web Weld Setting Calculator App.

So, You Can Get A Pretty Good Deal About The Setup Needed For Your Project And Expect Good Results By Using These Wire Speed And Voltage Settings.

Extend The Electrode Wire To ¼ Or ½.

To Get The Voltage Straight, You Should Follow The Manufacturer’s Recommendations.

Related Post: