Metal Nobility Chart

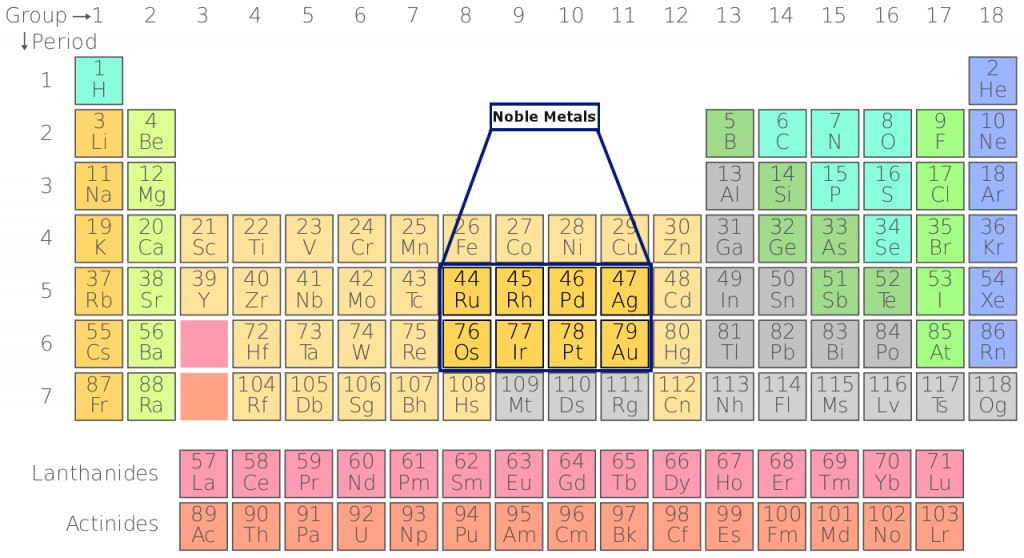

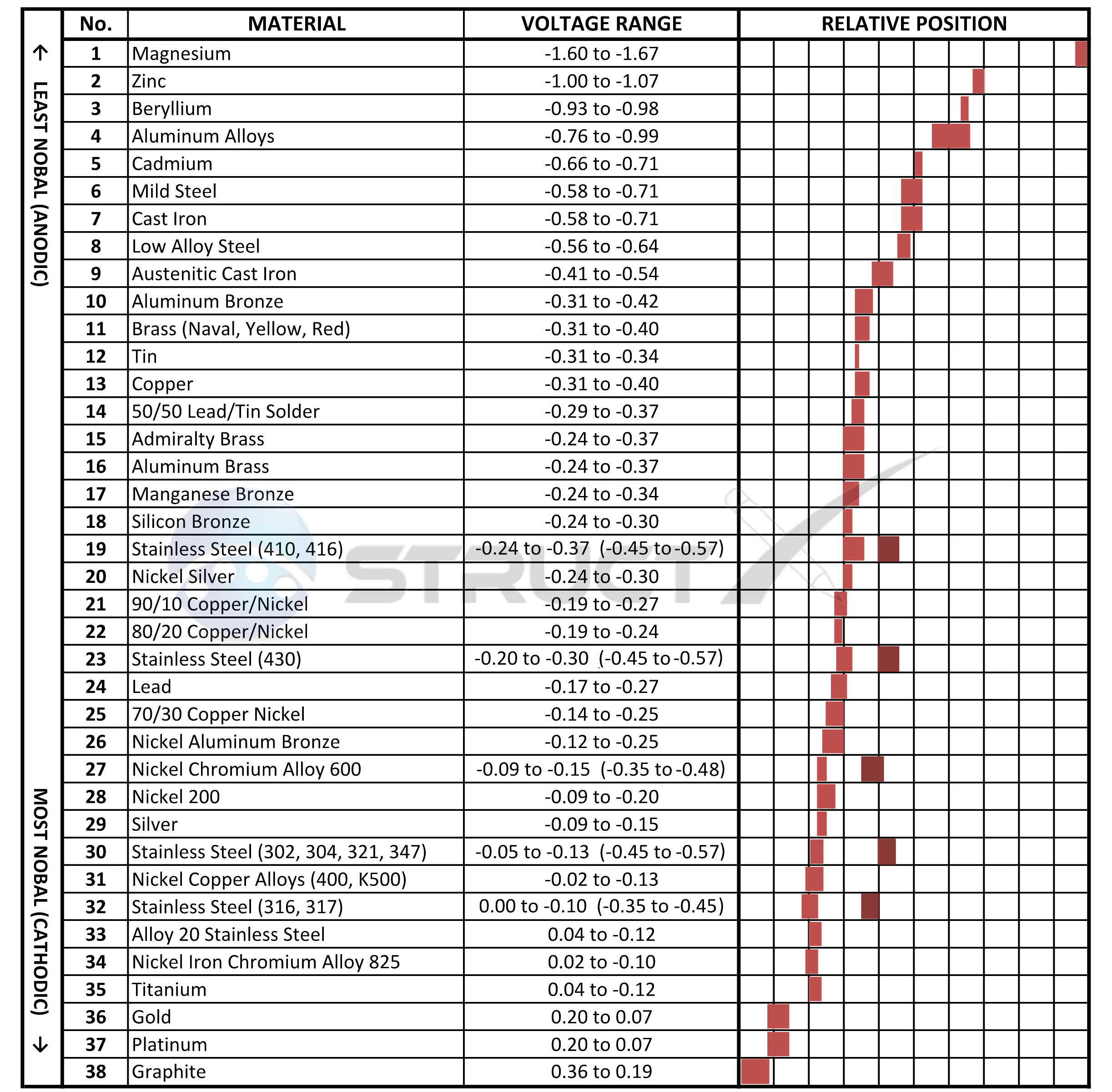

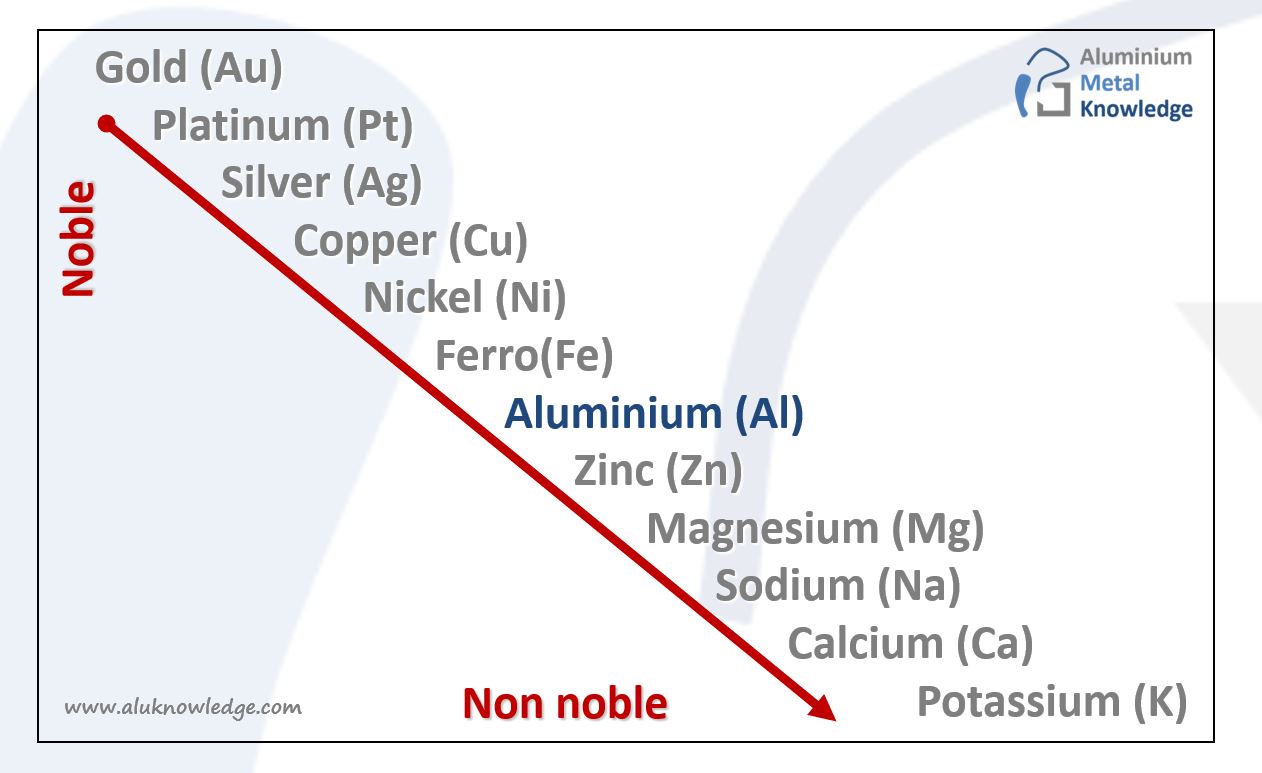

Metal Nobility Chart - The dissolution and removal of alloying elements from the cathode will cause pitting corrosion, hence the inclusion of the 'element electronegativity ' list in nobility. Web galvanic series, or nobility chart for dissimilar metals. Web below, we give a brief overview of galvanic corrosion and provide a galvanic corrosion chart to help fabricators and machinists avoid using the wrong metal combinations. Top listed metals/alloys are the least active (most noble) and proceeds down to the most active (anodic) metal/alloy. All dissimilar materials have the potential to react with each other when they are brought together in the presence of a catalyst. Web when dissimilar metals are connected — either by simple contact or by wiring — and they are immersed in water, a current will flow which can cause galvanic corrosion. Whilst electronegativity is not directly related to, or proportional to nobility it does give an indication as to their potential corrodibility. Web a noble metal is ordinarily regarded as a metallic chemical element that is generally resistant to corrosion and is usually found in nature in its raw form. Galvanic series chart — determine metal nobility and bimetallic corrosion. Web the following galvanic table lists metals in the order of their relative activity in seawater environment. When two metals are submerged in an electrolyte, while electrically connected, the less noble (base) will experience galvanic corrosion. Noble metals benefit from exceptional corrosion resistance and their (more or less) inert nature. Web below, we give a brief overview of galvanic corrosion and provide a galvanic corrosion chart to help fabricators and machinists avoid using the wrong metal combinations.. We also provide other helpful methods for avoiding galvanic corrosion. Web galvanic series relationships are useful as a guide for selecting metals to be joined, will help the selection of metals having minimal tendency to interact galvanically, or will indicate the need or degree of protection to be applied to lessen the expected potential interactions. Web metals are rated in. For example, noble metals that are higher up the galvanic scale retain their electrons better compared to base metals at the lower end of the scale when placed within the same environment. Web when dissimilar metals are connected — either by simple contact or by wiring — and they are immersed in water, a current will flow which can cause. Alloys with higher nobility are at the top, and metals that are less noble (or more base) are at the bottom. Whilst electronegativity is not directly related to, or proportional to nobility it does give an indication as to their potential corrodibility. It is important to remember that the tests that originally produced the tabulated values may not have identically. Web the different properties of noble metals are briefly discussed below: Whilst electronegativity is not directly related to, or proportional to nobility it does give an indication as to their potential corrodibility. A base metal such as aluminum loses more of its electrons than a noble metal such as stainless steel. The below diagram lists metals and alloys potential in. Type 410 stainless steel (passive) A base metal such as aluminum loses more of its electrons than a noble metal such as stainless steel. It is important to remember that the tests that originally produced the tabulated values may not have identically replicated the exact scenario in which they are intended to be used on site. The galvanic series can. Titanium (pass.) hastelloy c & c276 (passive), inconel 625 (pass.) The galvanic series can be used to determine which combinations need special protection and which of the metals will corrode. The rate of corrosion is determined by the electrolyte and the difference in nobility. Web galvanic series, or nobility chart for dissimilar metals. For example, noble metals that are higher. For example, noble metals that are higher up the galvanic scale retain their electrons better compared to base metals at the lower end of the scale when placed within the same environment. All dissimilar materials have the potential to react with each other when they are brought together in the presence of a catalyst. Galvanic series chart — determine metal. All dissimilar materials have the potential to react with each other when they are brought together in the presence of a catalyst. Alloys with higher nobility are at the top, and metals that are less noble (or more base) are at the bottom. Some texts list gold, silver and copper as the noble metals, excluding all others. Noble metals benefit. Usually noble metals are said to include ruthenium, rhodium, palladium, silver, osmium, iridium, platinum and gold. Web galvanic series diagram. Noble metals benefit from exceptional corrosion resistance and their (more or less) inert nature. Web galvanic series of metals and alloys. Web structx has provided material properties for some of the most commonly encountered structural materials encountered as a guide. Web the following galvanic table lists metals in the order of their relative activity in seawater environment. Type 410 stainless steel (passive) The rate of corrosion is determined by the electrolyte and the difference in nobility. With the galvanic series, metals are grouped according to electrical potential measured to a known reference. Type 316 stainless steel (passive) type 304 stainless steel (passive) monel 400. Web galvanic series, or nobility chart for dissimilar metals. All dissimilar materials have the potential to react with each other when they are brought together in the presence of a catalyst. When two metals are submerged in an electrolyte, while electrically connected, the less noble (base) will experience galvanic corrosion. (noble metals are those that are resistant to corrosion and oxidation.) when two metals are immersed in an electrolyte, while also being connected externally by a conductor, the less noble metal experiences galvanic corrosion. When two metals are submerged in an electrolyte, while also electrically connected by some external conductor, the less noble (base) will experience galvanic corrosion. Web the noble metals typically resist corrosion and oxidation in humid air. Titanium (pass.) hastelloy c & c276 (passive), inconel 625 (pass.) Web below, we give a brief overview of galvanic corrosion and provide a galvanic corrosion chart to help fabricators and machinists avoid using the wrong metal combinations. Web galvanic series diagram. Web in other words, when two different metals are in contact with each other in the presence of moisture, there will be a flow of current from one metal (the “anode”) to the other metal (the “cathode”), and one will be eaten away, or disintegrated, while. The galvanic series can be used to determine which combinations need special protection and which of the metals will corrode.

Printable periodic table of elements noble gases fulcclas

The Nobility of Common Metals

Galvanic Series, or Nobility Chart for Dissimilar Metals Fair Wind

Noble Metal Definition, List, Properties, And Examples

Galvanic Series (electrochemical series)

alloy Archieven Aluminium Metal Knowledge

Alkaline earth metals, Transition metal, Alkali metal

everyday chemistry Accelerated Oxidation Of Iron When Coating Breaks

What Are Noble Metals? Definition and List

Chemical Compatibility Table For Metals

Web Metals Listed On The Top Of The Chart (Anodic) Will Corrode Faster Than The Metals On The Bottom Of.

Some Texts List Gold, Silver And Copper As The Noble Metals, Excluding All Others.

Usually Noble Metals Are Said To Include Ruthenium, Rhodium, Palladium, Silver, Osmium, Iridium, Platinum And Gold.

Whilst Electronegativity Is Not Directly Related To, Or Proportional To Nobility It Does Give An Indication As To Their Potential Corrodibility.

Related Post: