Metal Casting Patterns

Metal Casting Patterns - Web pattern (casting) the top and bottom halves of a sand casting mould showing the cavity prepared by patterns. Once the sand is packed tight, the pattern can be removed and the cast will. The sand casting process involves using a furnace, metal, pattern, and sand mold. Web ceramic mold casting; This is known as metal sand casting. A pattern is an object that resembles the shape of a cast object and is used to create a mold cavity, which later hardens and forms a cast object according to the shape of the pattern when molten metal is poured. Web investment casting or lost wax casting is a way of casting metal using an expendable pattern and mold: Web the casting pattern design of the gating and riser patterns plays a crucial role in achieving sound castings. Web patternmaking is the initial and critical step in the metal casting process. The gates are used to combine the different patterns, and runners are. The sand casting process involves using a furnace, metal, pattern, and sand mold. A pattern is a replica of the final product that will be cast, designed to include allowances for shrinkage of the metal during cooling and solidification. A pattern is an object that resembles the shape of a cast object and is used to create a mold cavity,. A pattern is an object that resembles the shape of a cast object and is used to create a mold cavity, which later hardens and forms a cast object according to the shape of the pattern when molten metal is poured. A pattern is a replica of the final product that will be cast, designed to include allowances for shrinkage. This shell is then dried, stripped, and joined to form a cavity for pouring molten metal. Web shell molding, also referred to as shell mold casting, is a precise casting process suitable for alloy steel and has six main steps. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. This is to allow. Carlos vasto, president of gf. Web a replica pattern is used to create a mold out of rubber, metal, or resin. Metal casting patterns can be made from. During the process of solidification, a mold must have been designed to suitably place the appropriate sized risers to supply the molten metal into casting. Green sand, or molding sand, is packed. The process begins with the creation of a foam pattern, which serves as a replica of the desired metal part. Due to this, these patterns are less prone. Carlos vasto, president of gf. The shape is determined by the mold cavity, but something needs to shape the mold—that’s where the pattern comes in. Gate pattern can consist of one or. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. It begins with creating a metal pattern, usually from iron or steel, which determines the shape of the finished casting. Patterns are a fundamental part of the casting process, ensuring that the end products are produced with the desired dimensions and quality. If casting. Web shell molding, also referred to as shell mold casting, is a precise casting process suitable for alloy steel and has six main steps. After the shell mold has completely cured, the cast. The casting process can produce everything from art pieces to engine parts. Web molding is a multistep process that will form a cast around the pattern using. Due to this, these patterns are less prone. In casting, a mold is contained in a frame called a flask. This optimization minimizes the defects and ensures consistent quality production of sound castings. Gate pattern can consist of one or more patterns into a pattern molding pattern. Web this kind of casting pattern is widely used in metal casting like. At arnette, we specialize in providing high quality, precision, wood, plastic, and metal foundry patterns for the metal casting industry. The casting process can produce everything from art pieces to engine parts. Web shell molding, also referred to as shell mold casting, is a precise casting process suitable for alloy steel and has six main steps. Carlos vasto, president of. Web casting is the process of pouring liquid metal into a mold, where it cools and solidifies. The pattern engineer also has a responsibility of determining. The sand casting process involves using a furnace, metal, pattern, and sand mold. This shell is then dried, stripped, and joined to form a cavity for pouring molten metal. Web shell molding, also referred. The basic steps involved in making castings are patternmaking, molding, melting and pouring, cooling, shakeout and cleaning, heat treating, and inspection. Our typical pattern maker can boast an average of 25 years experience in his profession. Web making a pattern, also known as an object with a shape like the desired product, is the first step in the metal casting process. Web molding is a multistep process that will form a cast around the pattern using molding sand. Web the casting pattern designer has to observe the flow of steel into the mold to avoid turbulent flow and producing rapid fill. This is known as metal sand casting. If casting patterns ensure precisely positioned and designed gating systems, it can optimize the metal flow. It is the most extensively and widely used types of casting process. In casting, a mold is contained in a frame called a flask. The pattern can be made from various materials, including wood, plastic, or metal, depending on the complexity of. From this mold, a pattern is cast from a material that can melt or evaporate—typically wax. Web a thin mold is made around a heated metal pattern as part of the precision casting process known as shell molding. This can be achieved using various methods, including cutting, molding, or 3d printing. Patterns are larger than the final product and may look somewhat distorted, too. During the lost wax casting process, a pattern is made from. Cnc machining is often used to create metal casting patterns.

Metal Casting at Home Part 35 Pattern Making Start to Finish YouTube

Large Metal Casting Patterns Produced 33 Faster BigRep Industrial 3D

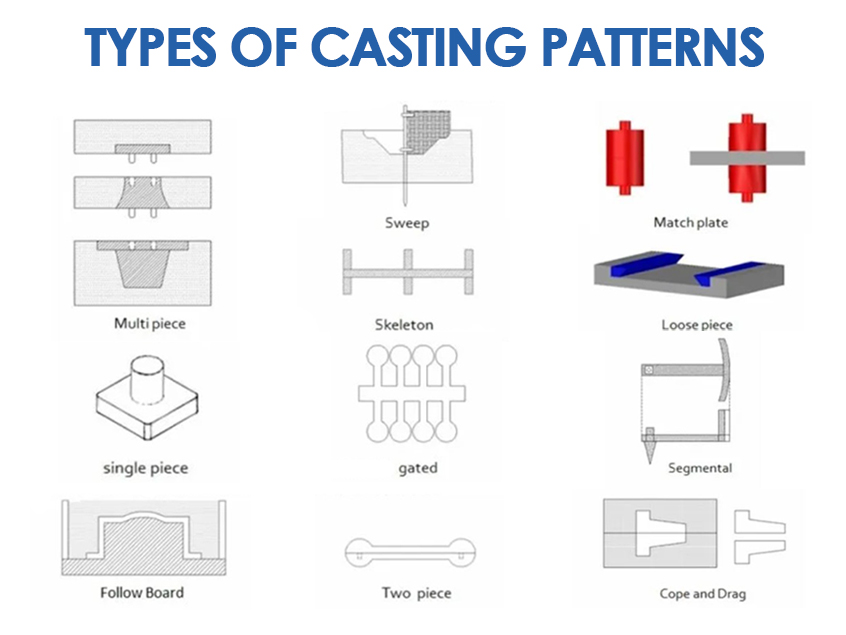

Types of Patterns in Casting Process Mechanical Booster

11 Most Common Types of Patterns Used in Casting G For Games

Metal Casting With Single Sided Patterns.... Two Ways YouTube

handverker sand casting using a 3d print as a pattern for casting in

Casting Patterns Functions, Material, Types, Allowances, Disadvantages

Types of Pattern in Casting Process (Explained in Detail) PDF

An Introduction to Metal Casting Process Stanford Advanced Materials

Casting Patterns and Patternmaking Metal Casting Blog

Web Some Of The Basics You Need To Know If You Are Going To Make A Pattern To Have Cast In Metal At A Foundry Along With Examples Of Patterns That I Have In My C.

The Process Begins With The Creation Of A Foam Pattern, Which Serves As A Replica Of The Desired Metal Part.

It Begins With Creating A Metal Pattern, Usually From Iron Or Steel, Which Determines The Shape Of The Finished Casting.

Reasons For This Are The Various Design Considerations That Affect Whether The Pattern Creates A Mold That Will, In Turn, Create A Product Of Acceptable.

Related Post: