Mcelroy Pipe Fusion Time Chart

Mcelroy Pipe Fusion Time Chart - Place the heater adapter between the pipe and the. This guide, now in its sixth. Web connect the fusion unit to the pipe. • wall thickness (dr) • pipe diameter • ambient temperature • pipe temperature. [1] • close the carriage. Web the tracstar® 900 fuses 12” ips (340mm) minimum to 36” od (900mm) maximum pipe. Web the integrity and versatility of the joining techniques used for polyethylene (pe) pipe allow the designer to take advantage of the performance benefits of pe in a wide variety of. • shift the selector valve down into the fusing position. Web mcelroy manufacturing, inc., is pleased to announce the release of the newest version of the polyethylene pipe fusion catalog and reference guide. Web the mccalc fusion pressure calculator is designed to help you quickly find the correct fusion pressure for your job. Web butt fusion welding machines can be used to allow precise control of factors, such as: This guide, now in its sixth. Web mcelroy’s datalogger® 5 system uses a handheld computer with a pressure sender to record information in the making of pipe fusion joints. • shift the selector valve down into the fusing position. All system components comply with. • wall thickness (dr) • pipe diameter • ambient temperature • pipe temperature. Web the mcelroy socket fusion tooling system is designed for socket fusion on 1/2 cts to 4 ips pipe. Web optimized cooling™ technology uses mcelroy’s advanced datalogger® software to calculate, in real time, the most appropriate cool times based on material. Web the tracstar® 900 fuses 12”. Web mcelroy manufacturing, inc., is pleased to announce the release of the newest version of the polyethylene pipe fusion catalog and reference guide. • shift the selector valve down into the fusing position. Web the mcelroy socket fusion tooling system is designed for socket fusion on 1/2 cts to 4 ips pipe. • wall thickness (dr) • pipe diameter •. Ensure that proper safety precautions were taken to reduce static electricity in. Web connect the fusion unit to the pipe. Web • use the mcelroy mccalc app to calculate the fusing pressure. This guide, now in its sixth. Place the heater adapter between the pipe and the. Web butt fusion welding machines can be used to allow precise control of factors, such as: Web the integrity and versatility of the joining techniques used for polyethylene (pe) pipe allow the designer to take advantage of the performance benefits of pe in a wide variety of. Web optimized cooling™ technology uses mcelroy’s advanced datalogger® software to calculate, in real. Web the tracstar® 900 fuses 12” ips (340mm) minimum to 36” od (900mm) maximum pipe. Web the mcelroy socket fusion tooling system is designed for socket fusion on 1/2 cts to 4 ips pipe. Web determine pressures (joining, heating, and fusion) for pipe size(s) per mcelroy chart. Mcelroy’s research to date has included pipe sizes between 6 and 24” od.. Web the tracstar® 900 fuses 12” ips (340mm) minimum to 36” od (900mm) maximum pipe. • shift the selector valve down into the fusing position. If fusing other thermoplastic pipe materials, refer to the pipe. Web optimized cooling™ technology uses mcelroy’s advanced datalogger® software to calculate, in real time, the most appropriate cool times based on material. Web the mccalc. Web butt fusion welding machines can be used to allow precise control of factors, such as: Web • use the mcelroy mccalc app to calculate the fusing pressure. All system components comply with astm standards. Mcelroy’s research to date has included pipe sizes between 6 and 24” od. • wall thickness (dr) • pipe diameter • ambient temperature • pipe. [1] • close the carriage. Web optimized cooling™ technology uses mcelroy’s advanced datalogger® software to calculate, in real time, the most appropriate cool times based on material. Ensure that proper safety precautions were taken to reduce static electricity in. Web the mcelroy socket fusion tooling system is designed for socket fusion on 1/2 cts to 4 ips pipe. Web fusion. Web the tracstar® 900 fuses 12” ips (340mm) minimum to 36” od (900mm) maximum pipe. Web optimized cooling™ technology uses mcelroy’s advanced datalogger® software to calculate, in real time, the most appropriate cool times based on material. Web the integrity and versatility of the joining techniques used for polyethylene (pe) pipe allow the designer to take advantage of the performance. [2] • when the pipe. Mcelroy’s research to date has included pipe sizes between 6 and 24” od. Web determine pressures (joining, heating, and fusion) for pipe size(s) per mcelroy chart. Web mcelroy manufacturing, inc., is pleased to announce the release of the newest version of the polyethylene pipe fusion catalog and reference guide. The 250 model fuses 2” ips (63mm) minimum. If fusing other thermoplastic pipe materials, refer to the pipe. [1] • close the carriage. To properly fuse pipe the fusion pressure must be adjusted so the pipe. Place the heater adapter between the pipe and the. Web the mcelroy socket fusion tooling system is designed for socket fusion on 1/2 cts to 4 ips pipe. • shift the selector valve down into the fusing position. Web the mccalc fusion pressure calculator is designed to help you quickly find the correct fusion pressure for your job. • wall thickness (dr) • pipe diameter • ambient temperature • pipe temperature. Web mcelroy’s datalogger® 5 system uses a handheld computer with a pressure sender to record information in the making of pipe fusion joints. Web connect the fusion unit to the pipe. Web butt fusion welding machines can be used to allow precise control of factors, such as:

McElroy Rolling 28 Fusion Machine

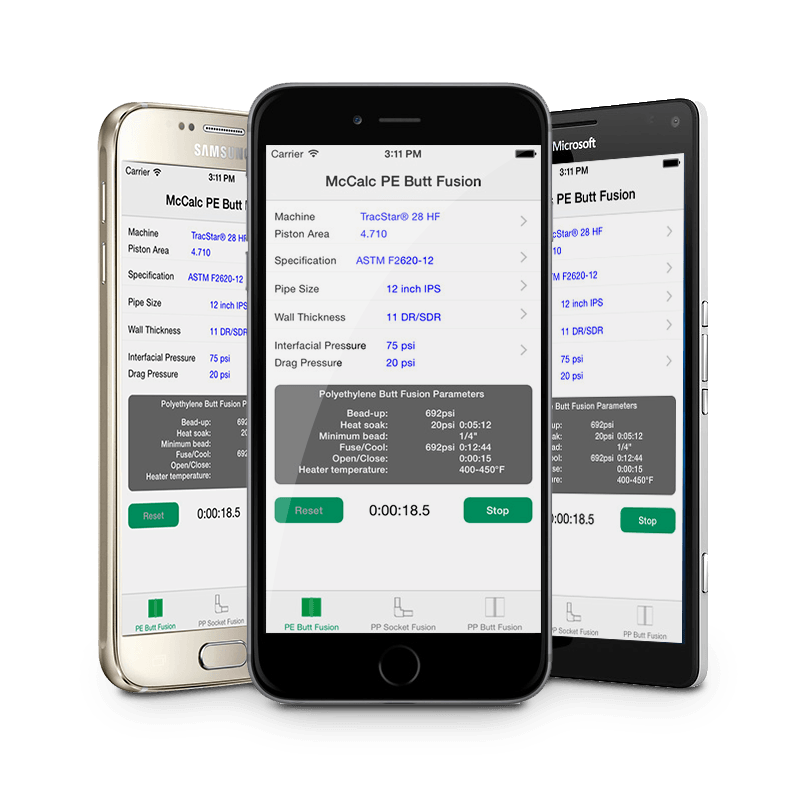

McElroy McCalc® Fusion Pressure Calculator

Patent US8128853 Fusion process for conduit Google Patents

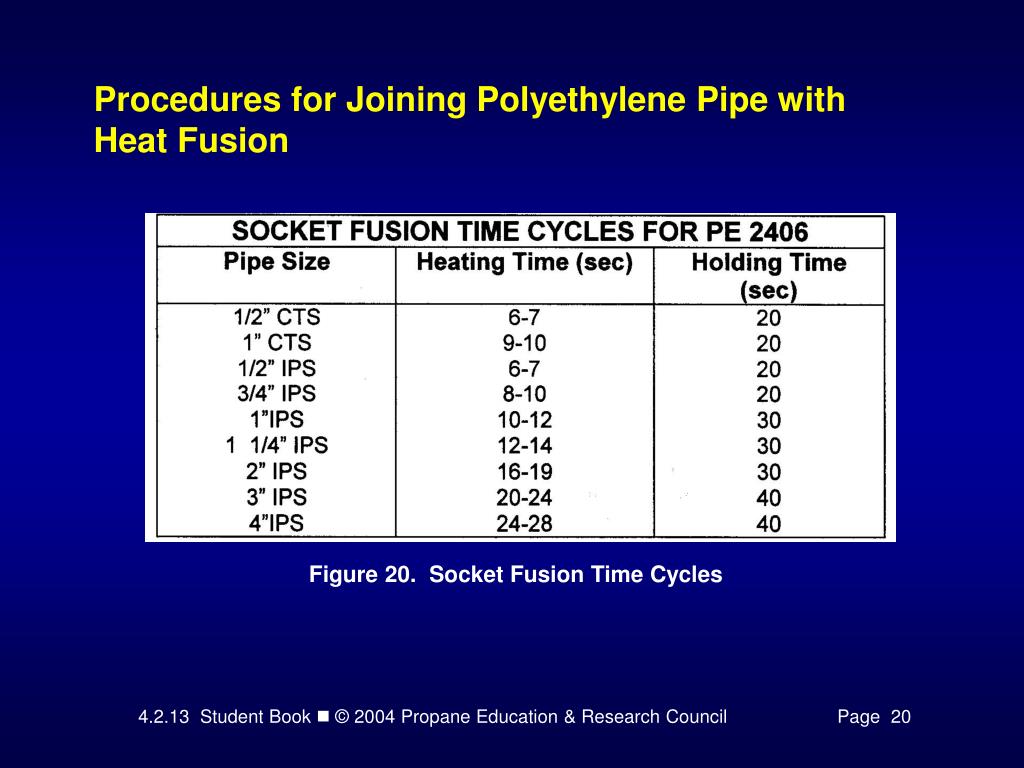

PPT 4.2.13 PowerPoint Presentation, free download ID479602

Mcelroy Pipe Fusion Time Chart

High Country Fusion HDPE Pipe DIPS Chart by FRED Issuu

Socket fusion made easy McElroy Press Room

Patent US20060071365 Fusion process for conduit Google Patents

Mcelroy Pipe Fusion Time Chart

McElroy Optimized Cooling

Web The Tracstar® 900 Fuses 12” Ips (340Mm) Minimum To 36” Od (900Mm) Maximum Pipe.

Web • Use The Mcelroy Mccalc App To Calculate The Fusing Pressure.

Web Optimized Cooling™ Technology Uses Mcelroy’s Advanced Datalogger® Software To Calculate, In Real Time, The Most Appropriate Cool Times Based On Material.

All System Components Comply With Astm Standards.

Related Post: