Machining Tolerances Chart

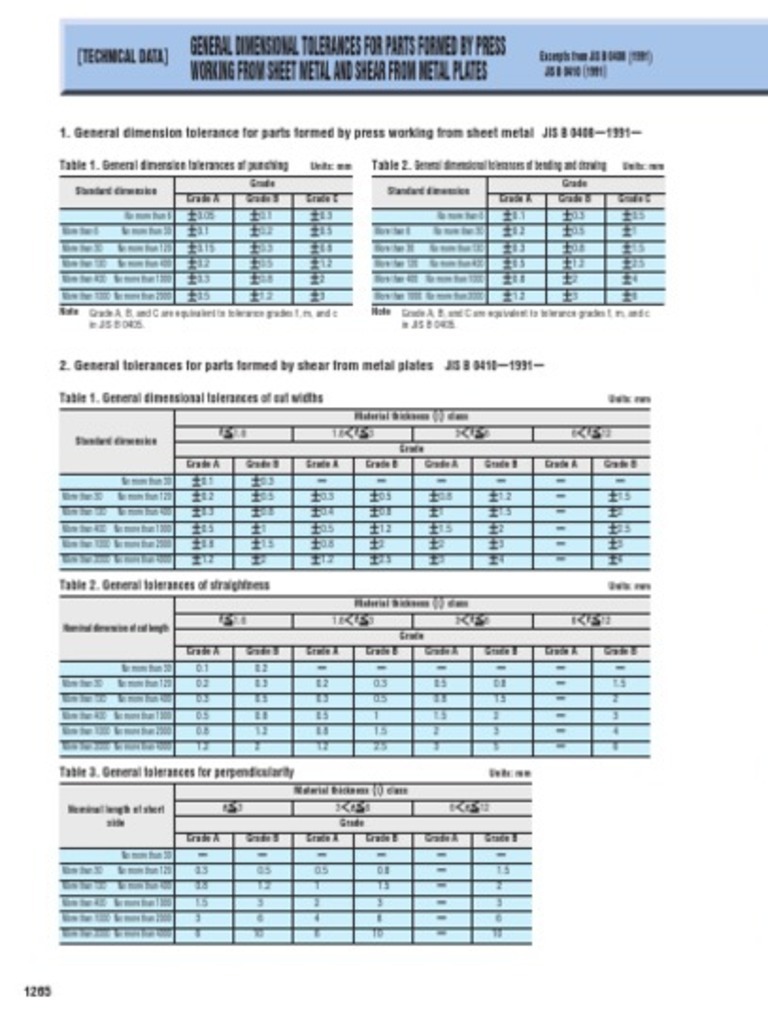

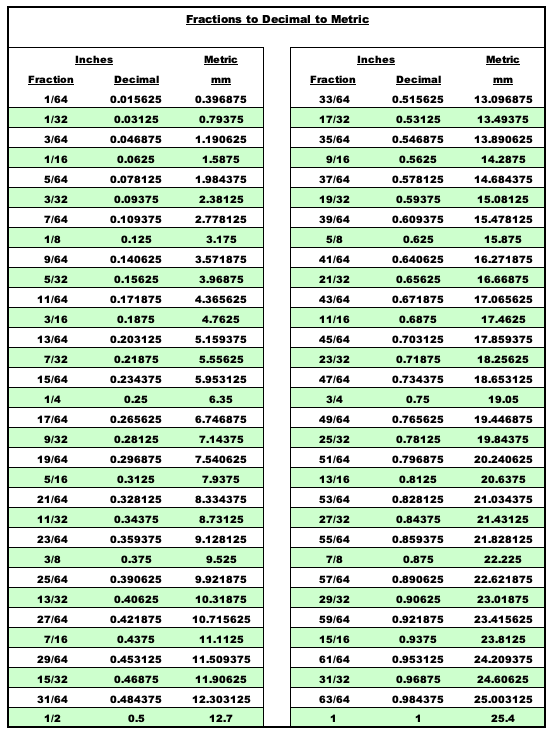

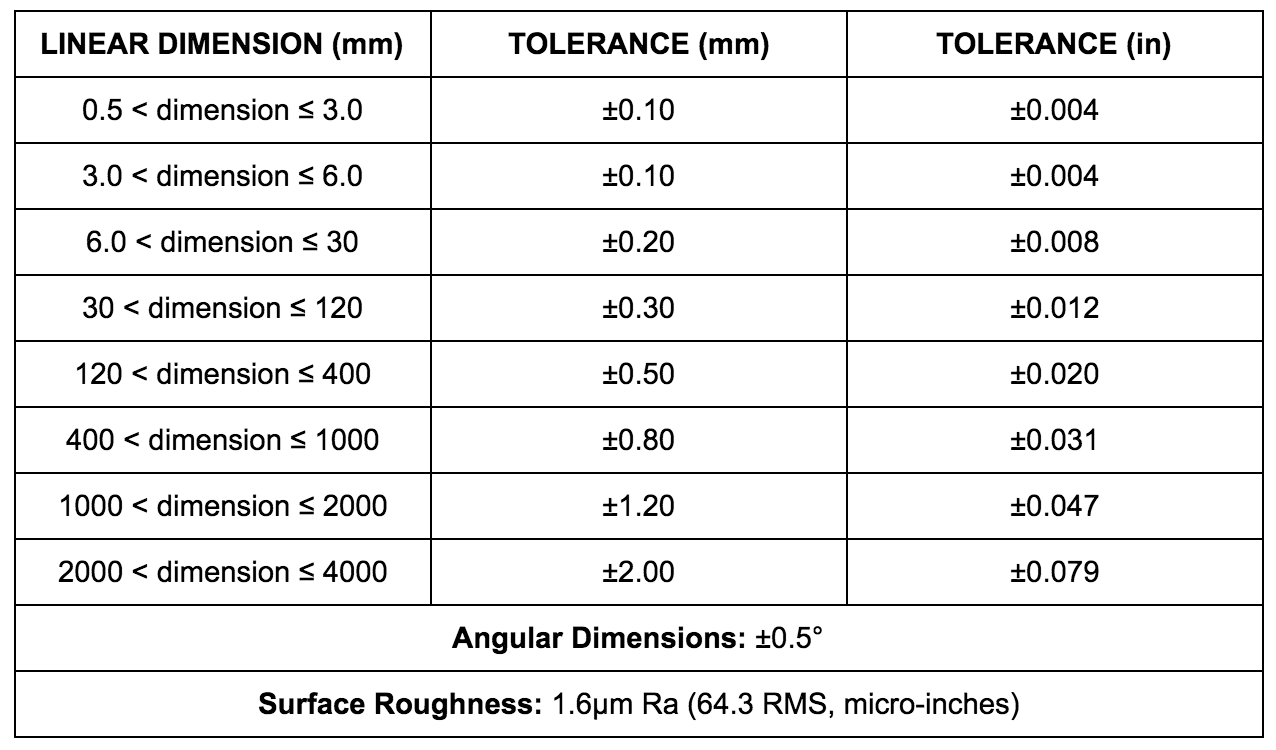

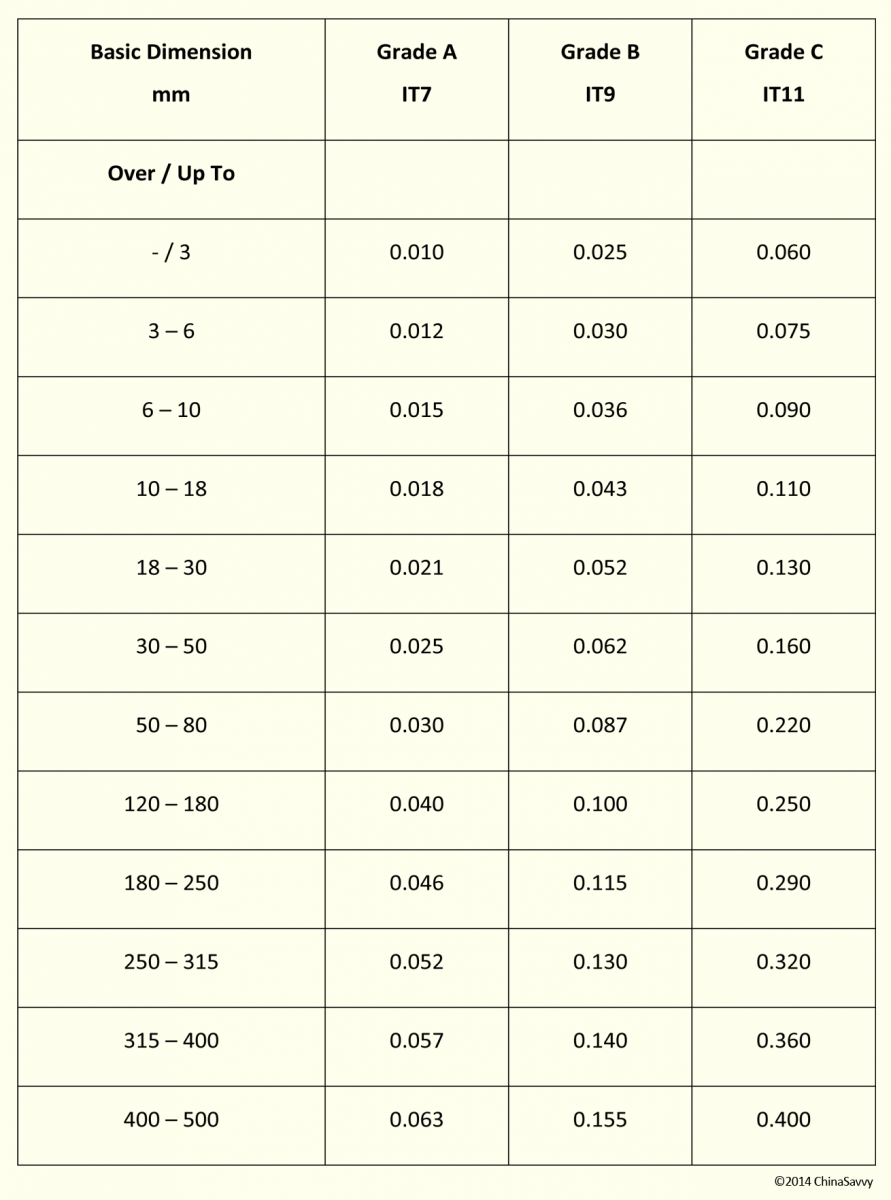

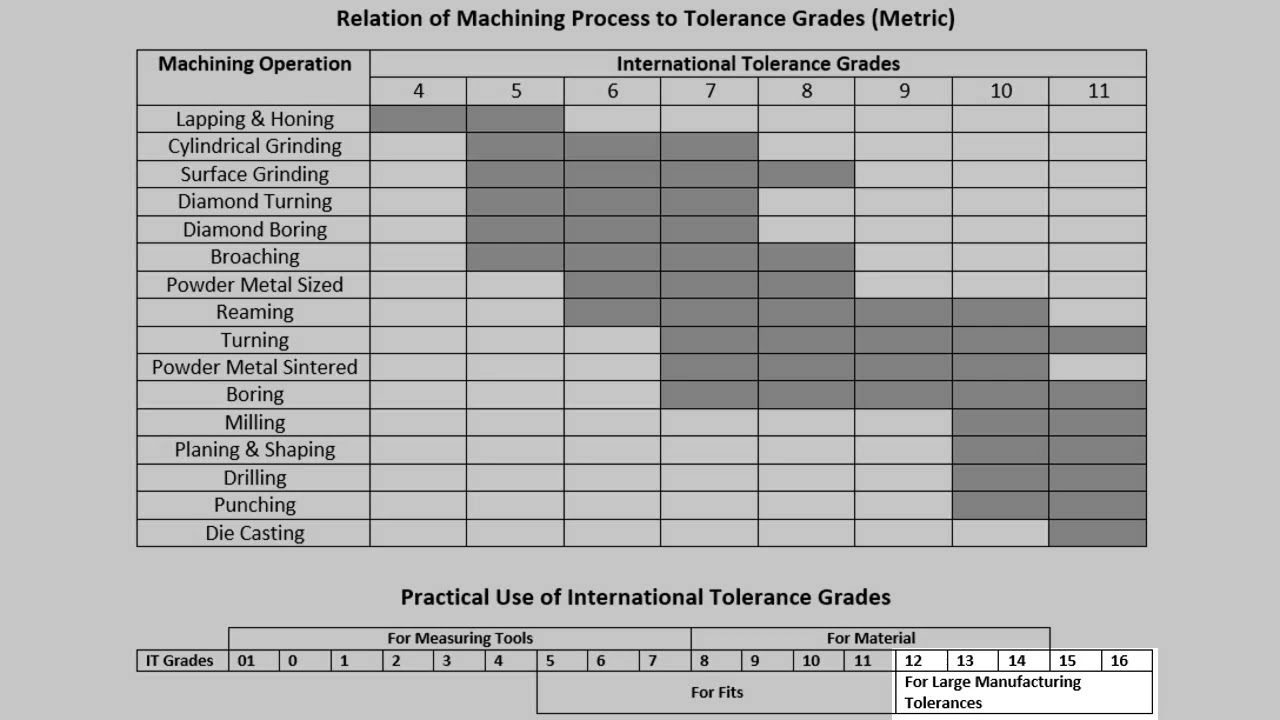

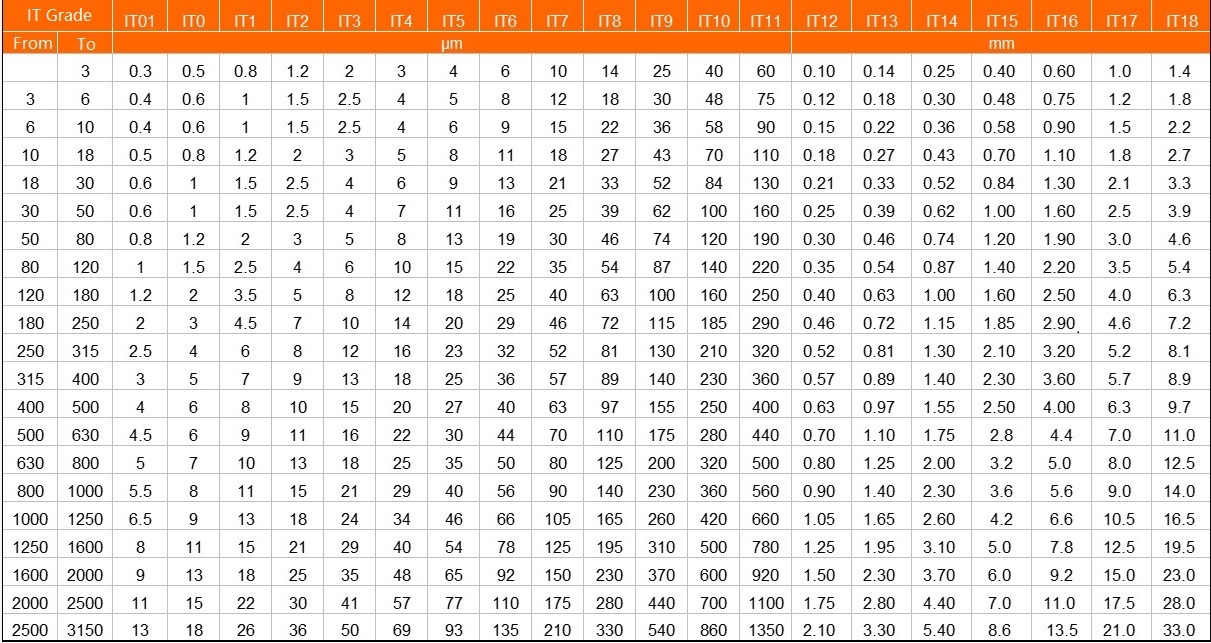

Machining Tolerances Chart - Web here’s a chart table showing the relative surface finish roughness of various manufacturing processes: The following engineering calculator will show the plus and minus tolerance for the specific iso 286 shaft tolerance data. Web these classes are arranged into a chart that separates the different tolerance limits as very coarse (v), coarse (c), medium (m), and fine (f). Web the following tolerance tables correspond to the different precision levels. The following links are to general tolerance table charts for standard shaft hole fits per mcdonald douglas design guide. Ansi b4.1 standard tolerances are indicated in the diagram below: Web mechanical tolerance chart data. The following engineering calculator will show the plus and minus tolerance for the specific iso 286 hole tolerance data. The following symbols are used for specifying geometrical characteristics on engineering drawings. External radius and chamfer heights. This part of the international tolerance standards has three tables with respect to ideas. Web the following are general geometrical tolerances per. Web mechanical tolerance standards charts. Web these classes are arranged into a chart that separates the different tolerance limits as very coarse (v), coarse (c), medium (m), and fine (f). The following links are to general tolerance table. Iso 2768 for the following: The following symbols are used for specifying geometrical characteristics on engineering drawings. Web the following are general geometrical tolerances per. Web here’s a chart table showing the relative surface finish roughness of various manufacturing processes: This part of the international tolerance standards has three tables with respect to ideas. The following engineering calculator will show the plus and minus tolerance for the specific iso 286 shaft tolerance data. Web the following are general geometrical tolerances per. Web these classes are arranged into a chart that separates the different tolerance limits as very coarse (v), coarse (c), medium (m), and fine (f). Web the following tolerance tables correspond to the. Web mechanical tolerance standards charts. The following links are to general tolerance table charts for standard shaft hole fits per mcdonald douglas design guide. Web which tolerance to choose? Web the following are general geometrical tolerances per. Iso metric tolerance zone limits and fits. Web cnc machining tolerance chart. Relative surface finish roughness of manufacturing. The following engineering calculator will show the plus and minus tolerance for the specific iso 286 shaft tolerance data. External radius and chamfer heights. Web this web page contains links to mechanical tolerance design manufacturing calculators and tables, gd&t, geometric dimensioning and tolerancing calculators, standard. Ansi b4.1 standard tolerances are indicated in the diagram below: The following engineering calculator will show the plus and minus tolerance for the specific iso 286 shaft tolerance data. The following links are to general tolerance table charts for standard shaft hole fits per mcdonald douglas design guide. Web the first provides the charts for the fundamental deviations (g, j,. A comprehensive guide for cnc machining. You can determine the tolerance class based on the production capacity of the manufacturer and the requirements of the parts to be. Web these classes are arranged into a chart that separates the different tolerance limits as very coarse (v), coarse (c), medium (m), and fine (f). Relative surface finish roughness of manufacturing. The. Web range of tolerance grades that various machine processes may produce under normal conditions: The following engineering calculator will show the plus and minus tolerance for the specific iso 286 shaft tolerance data. Web iso 2768 dimensional tolerance chart: Iso metric tolerance zone limits and fits. 1133 | published by vmt at sep 30 2021. Web the first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6, etc.) can be. Relative surface finish roughness of manufacturing. Web here’s a chart table showing the relative surface finish roughness of various manufacturing processes: Ansi b4.1 standard tolerances are. The following links are to general tolerance table charts for standard shaft hole fits per mcdonald douglas design guide. External radius and chamfer heights. You can determine the tolerance class based on the production capacity of the manufacturer and the requirements of the parts to be. Iso metric tolerance zone limits and fits. Web mechanical tolerance standards charts. Web the first provides the charts for the fundamental deviations (g, j, etc.) and tolerance grades (7, 8, 9, etc.), out of which the limits of the tolerance classes (h7, g6, etc.) can be. Web the following tolerance tables correspond to the different precision levels. These dimensions are standardized limits for. Web these classes are arranged into a chart that separates the different tolerance limits as very coarse (v), coarse (c), medium (m), and fine (f). Web mechanical tolerance chart data. The following engineering calculator will show the plus and minus tolerance for the specific iso 286 hole tolerance data. You can determine the tolerance class based on the production capacity of the manufacturer and the requirements of the parts to be. A comprehensive guide for cnc machining. Web range of tolerance grades that various machine processes may produce under normal conditions: Web this web page contains links to mechanical tolerance design manufacturing calculators and tables, gd&t, geometric dimensioning and tolerancing calculators, standard. The following symbols are used for specifying geometrical characteristics on engineering drawings. External radius and chamfer heights. Relative surface finish roughness of manufacturing. Web here’s a chart table showing the relative surface finish roughness of various manufacturing processes: Web the following are general geometrical tolerances per. This part of the international tolerance standards has three tables with respect to ideas.

Cnc Machining Tolerance Chart

Fictiv

Machining Tolerance Chart Catalog A Visual Reference of Charts Chart

Standard Machining Tolerance Engineering Tolerance Mechanical

Machining Tolerance Chart Catalog A Visual Reference of Charts Chart

ENGR1304 Machining Processes & Tolerances

Machining Tolerances Standard Machining Tolerances Am vrogue.co

Machining Tolerance Chart

Tolerance Grade for Different Machining Process

Machining Tolerance Chart

Web Cnc Machining Tolerance Chart.

Web Limits And Fits Are A Set Of Rules Regarding The Measurements And Tolerances Of Mating Machine Parts To Achieve The Best Working Conditions.

Iso Metric Tolerance Zone Limits And Fits.

Ansi B4.1 Standard Tolerances Are Indicated In The Diagram Below:

Related Post: