Ls Piston Ring Gap Chart

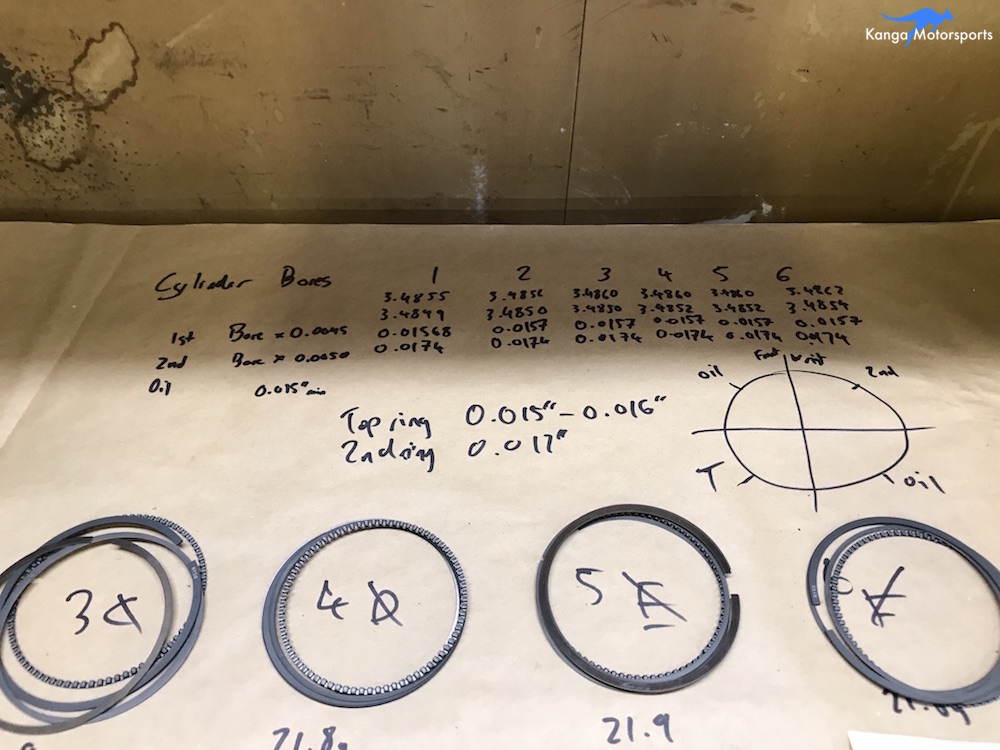

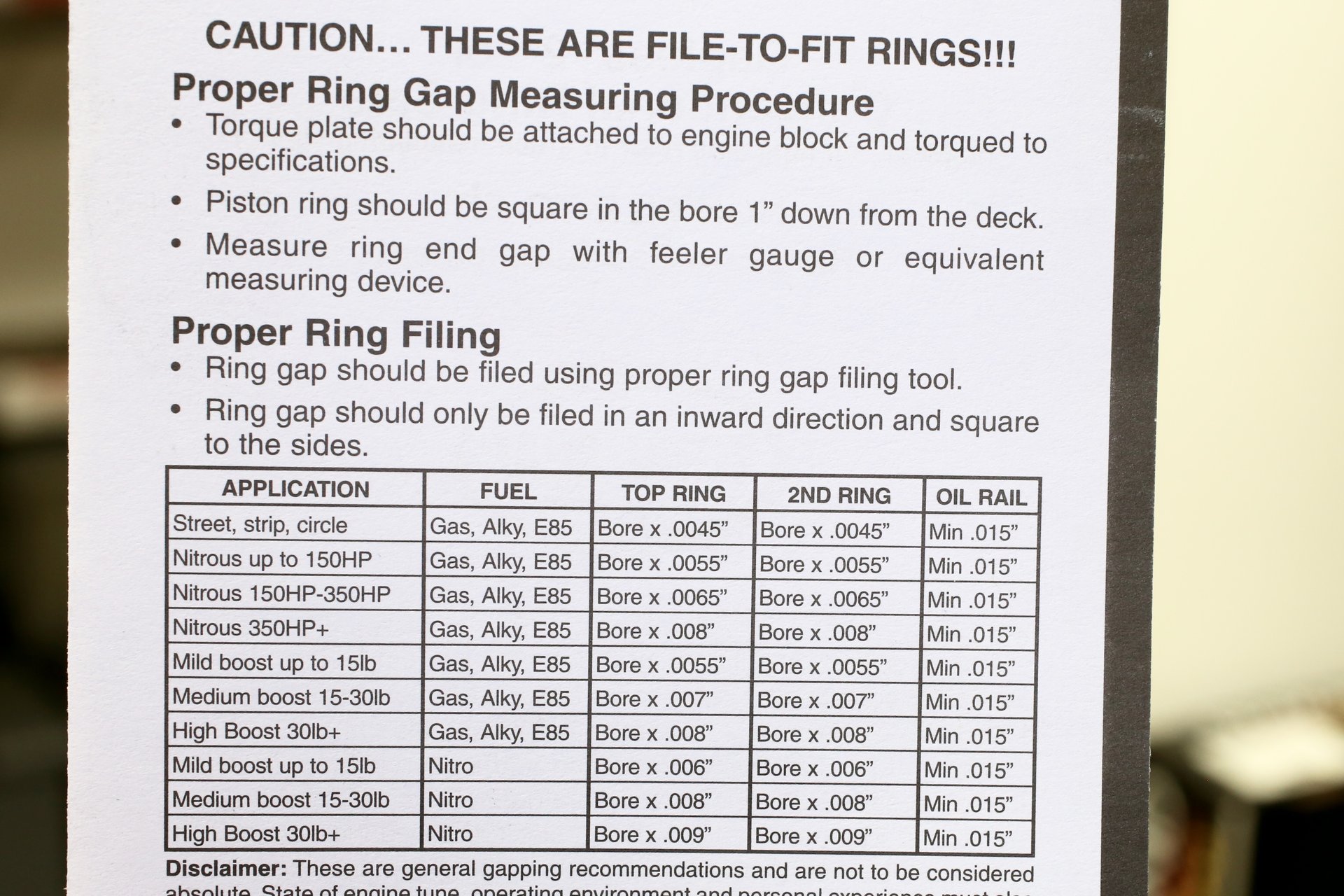

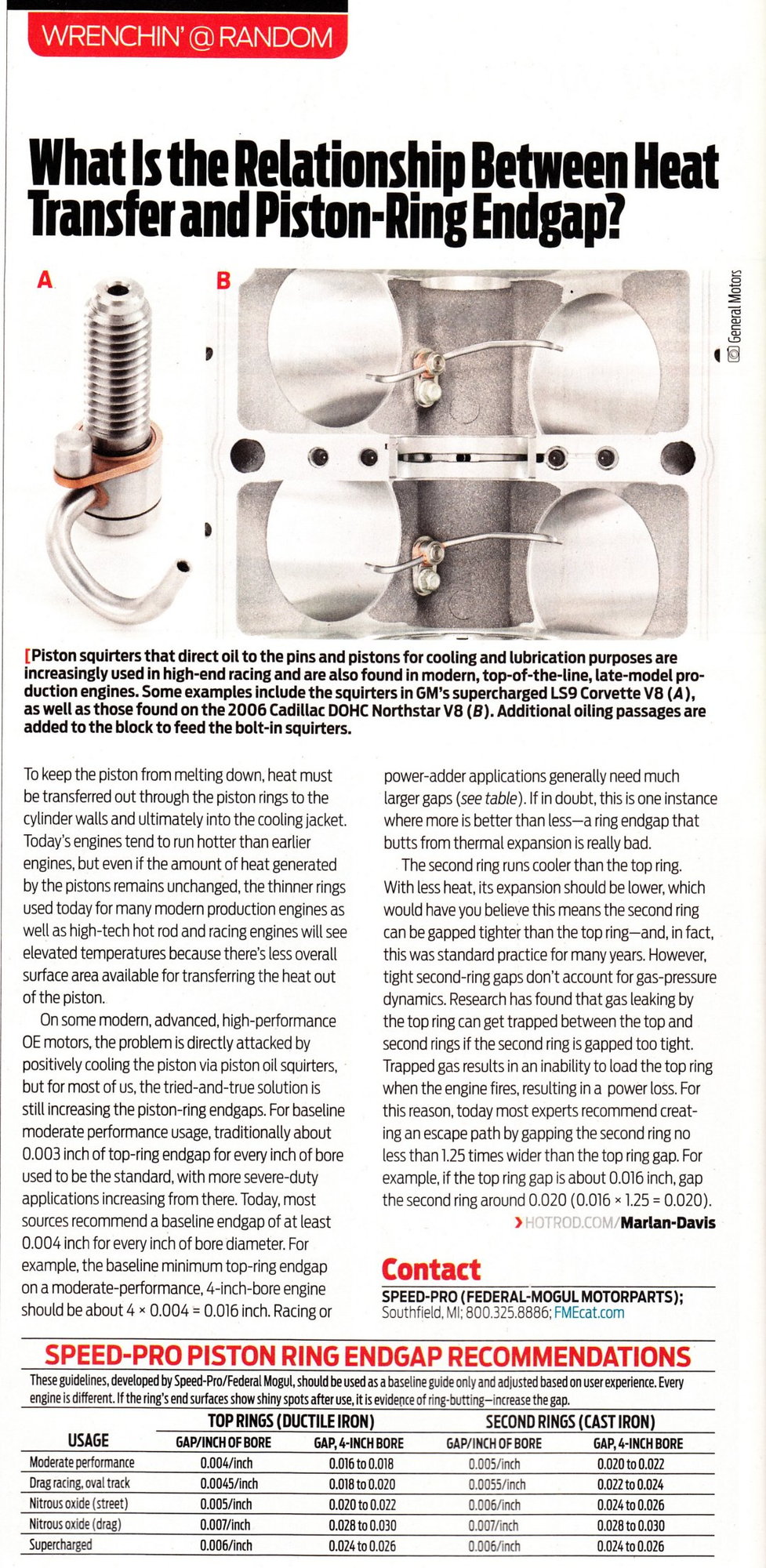

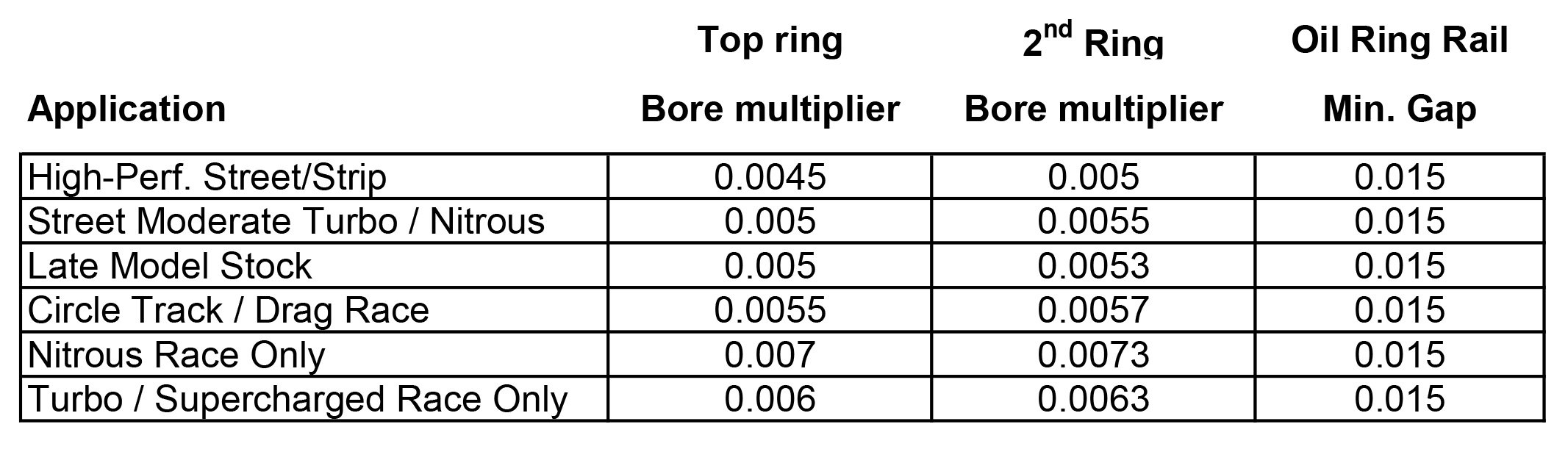

Ls Piston Ring Gap Chart - Do not measure the skirt over the coating. Web piston ring gap theory is critical to ensure that the top ring is not bypassing compression, but not expanding so much that the ends run into each other. Never use grease press fit, use rod heater. Install the lower steel ring, the ring end gap must be approximately 90° to 120° left from the expander edges. Web this means that once installed, they’re good to go. Web below is a chart which contains the recommended end gap factor. Web how much ring gap is recommended for a turbocharged 5.3 liter running 8 to 12 pounds of boost? Properly clocking piston rings when they are installed will keep things running and sealing as they should. Web the aera technical committee offers the following information regarding the piston to rod orientation on the general motors ls engine family. Web piston ring should be square in the bore 1 down from the deck. Final piston clearance should be based solely on the demands of your applicaion. I have a 98 z 5.7, i was looking to just freshen it up a bit. Install the lower steel ring, the ring end gap must be approximately 90° to 120° left from the expander edges. To use this chart, multiply the bore size by the ring. Measure the ring end gap with a feeler gauge or equivalent device. Web position clock ring gaps on piston to fi gure d. I started checking ring gaps, and i am getting.020 on my top and.019 on my second. Web je pistons ring end gap recommendations. These are based on different user applications. In this article, we’re going to explore how to select, measure, and adjust your ring end gaps to help achieve a reliable ring seal. What ever the motor came with. Measure the ring end gap with a feeler gauge or equivalent device. Web position clock ring gaps on piston to fi gure d. This bulletin provides guidance when assembling the. Web how much ring gap is recommended for a turbocharged 5.3 liter running 8 to 12 pounds of boost? Web this means that once installed, they’re good to go. What ever the motor came with. 442k views 3 years ago #d4a #boostschool. I lightly honed the cylinders just enough to break the glaze and cross hatch. 4.000” bore street engine with cast piston the top ring end gap factor is.004”, thus 4.000” x.004” =.016” minimum end gap. Final piston clearance should be based solely on the demands of your applicaion. Web the ring gap position on the piston is a critical thing to pay attention to when assembling an engine. 442k views 3 years ago #d4a. A proper ring gap fi ling tool must be used. I also tried a set of speed pro rings. 442k views 3 years ago #d4a #boostschool. Web the aera technical committee offers the following information regarding the piston to rod orientation on the general motors ls engine family. The following is a recommended gap chart for conventional (gap style) rings. This bulletin provides guidance when assembling the piston to the rod. Web piston ring should be square in the bore 1 down from the deck. Use high quality oil or supplied lube. Some second ring sets can be set slightly looser, but that depends on the ring configuration and the manufacturer specs. Do not use locks when press fitting the. Web piston ring should be square in the bore 1 down from the deck. Received 15 likes on 11 posts. Properly clocking piston rings when they are installed will keep things running and sealing as they should. Install the lower steel ring, the ring end gap must be approximately 90° to 120° left from the expander edges. The following is. What ever the motor came with. It’s critical that the gap in all three rings does not align to form a clear path between the crank case and the combustion chamber. To use this chart, multiply the bore size by the ring end gap factor to obtain the minimum end gap which should be achieved. Web this means that once. Final piston clearance should be based solely on the demands of your applicaion. Web to find the proper ring end gap, multiply your bore size by the ring end gap factor listed on the chart (i.e., street naturally aspirated 4.000” bore x.0065” gap factor =.026” total top ring end gap). Selection depends upon how your engine will be used. Web. Web position the expander ends in the desired orientation on the piston, an image of the recommended installation location is provided in the proper ring alignment section. 442k views 3 years ago #d4a #boostschool. Web the following chart indicates the specifications for compression ring gap as outlined by the sae (society of automotive engineers) as standards for the automotive piston ring manufacturers. Do not measure the skirt over the coating. Use high quality oil or supplied lube. Variables such as fuel type, altitude, outside temperature, humidity, tune up, application type and much more must be considered. Do not use locks when press fitting the pin. Selection depends upon how your engine will be used. Install the lower steel ring, the ring end gap must be approximately 90° to 120° left from the expander edges. Web je pistons ring end gap recommendations. What ever the motor came with. This bulletin provides guidance when assembling the piston to the rod. Web this means that once installed, they’re good to go. Web piston ring should be square in the bore 1 down from the deck. These are based on different user applications. Never use grease press fit, use rod heater.

Piston Ring Gap How Important Is It And How To Get Them Correct

How to FileFit and Install Piston Rings

Building a 5.3 LS Piston Ring GapReady to handle boost???? YouTube

PISTON RING GAP for future boost On LY6 Bored to 4.065 LS1TECH

Blueprint Series The How And Why Of Setting Piston Ring End Gap

ring gapping and basic piston ring info YOULL NEED Grumpys

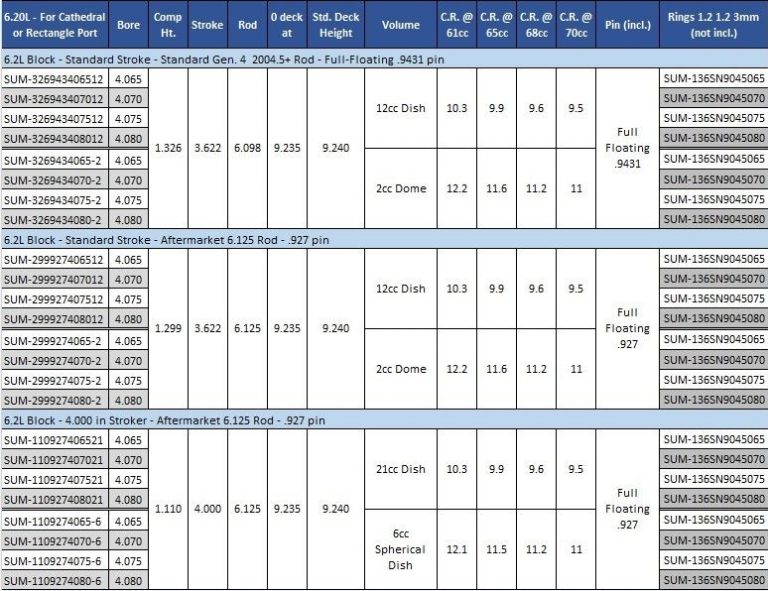

Pro LS Profile Summit Racing Makes Choosing a Piston for Your

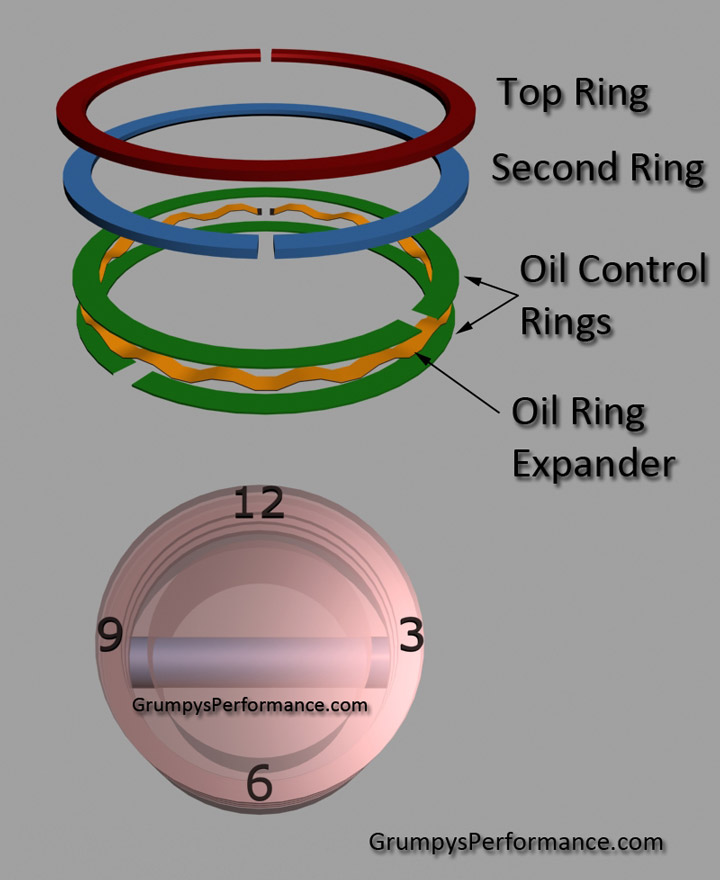

Ls Piston Ring Orientation

Piston ring gap chart. Greg Clark Flickr

How to gap LS 4.8 5.3 6.0 piston rings for boost! YouTube

The Following Is A Recommended Gap Chart For Conventional (Gap Style) Rings From Total Seal Piston Rings:

I Lightly Honed The Cylinders Just Enough To Break The Glaze And Cross Hatch.

If Your Casting Number Is Not Listed, Use The Rod Features For Orientation.

Web Position The Expander Ends In The Desired Orientation On The Piston, An Image Of The Recommended Installation Location Is Provided In The Proper Ring Alignment Section.

Related Post: