Laney P Chart

Laney P Chart - P charts evaluate process stability when counting the fraction defective (or in many healthcare applications, the fraction meeting. In subgroup sizes, enter total. > 5,000) and assumptions are not met. Web the laney p’ control chart is an exciting innovation in statistical process control (spc). To ensure that your results are valid, consider the following guidelines when you collect data, perform the analysis, and. Choose stat > control charts > attributes charts > laney p′. Minitab blog editor | 9/25/2012. A z value tells you the number of sample. Both charts monitor the proportion of defective items that are produced by your process. Web the laney p’ chart is produced by combining z values with the individuals control chart. (for more information, go to select tests for special causes for laney p' chart.) size of subgroup. Learn more about p charts. Web if a p or u control chart has control limits so narrow that almost every point is beyond the control limits, use a laney p' chart (p' is pronounced as p prime) or u' chart ( u. The laney p chart or p prime chart is an alternative to the standard p chart when over or. Laney p' chart in excel. A z value tells you the number of sample. Control charts , project tools , statistics , quality improvement. Web p' and u' (laney) control charts are attribute control charts that should be used when the. Laney p prime chart could be useful in the situations when process data have large subgroups. Web the laney p’ chart is produced by combining z values with the individuals control chart. Web if a p or u control chart has control limits so narrow that almost every point is beyond the control limits, use a laney p' chart (p'. To ensure that your results are valid, consider the following guidelines when you collect data, perform the analysis, and. Laney p' chart in excel. Choose stat > control charts > attributes charts > laney p′. Web in the control chart below, you can see a sample of our continuous integration metrics. However, if your data exhibit. Calculate the moving range of the z values. > 5,000) and assumptions are not met. Web the laney p’ control chart is an exciting innovation in statistical process control (spc). Web this historical control chart shows three stages of a process, which represent before, during, and after the implementation of a new procedure. Web this paper will discuss the performance. P chart format options in qi macros. Learn more about p charts. Laney p prime chart could be useful in the situations when process data have large subgroups. Web this paper will discuss the performance of p’ control chart based on graphic visualization and average run length (arl), then compare its performance with the conventional p. In addition, we analyze. (for more information, go to select tests for special causes for laney p' chart.) size of subgroup. To ensure that your results are valid, consider the following guidelines when you collect data, perform the analysis, and. Laney p prime chart could be useful in the situations when process data have large subgroups. Web the laney p′ control chart is a. Web the laney p' chart, however, corrects for overdispersion and shows that the process is actually in control. Learn more about p charts. In subgroup sizes, enter total. Web the laney p' chart is similar to a traditional p chart. Web the ability to visualize and control for these complex patterns of variation can offer profound insights into process behavior. Web when should you use a laney p' chart? Web if a p or u control chart has control limits so narrow that almost every point is beyond the control limits, use a laney p' chart (p' is pronounced as p prime) or u' chart ( u prime). Calculate the moving range of the z values. P charts evaluate process. Explained and laney’s contributions — isssp for lean six sigma. Web the ability to visualize and control for these complex patterns of variation can offer profound insights into process behavior and improvement opportunities. However, if your data exhibit. Web in the control chart below, you can see a sample of our continuous integration metrics. Web open the sample data, defectiverecords.mtw. Convert the p values to z values. The laney p chart or p prime chart is an alternative to the standard p chart when over or. Calculate the moving range of the z values. Web the laney p′ control chart is a new type of attribute control chart that can be applied in situations where the process exhibits either overdispersion or underdispersion. Minitab blog editor | 9/25/2012. Start creating these charts and diagrams in seconds using. Web watch this video to learn how to create a laney p' chart in excel using the qi macros spc software. Web this paper will discuss the performance of p’ control chart based on graphic visualization and average run length (arl), then compare its performance with the conventional p. Web data considerations for laney p' chart. > 5,000) and assumptions are not met. In addition, we analyze the. P chart format options in qi macros. (for more information, go to select tests for special causes for laney p' chart.) size of subgroup. Laney p' chart in excel. Laney p prime chart could be useful in the situations when process data have large subgroups. In addition, we analyze the.

Difference between Laney P charts and Traditional P ChartMinitab YouTube

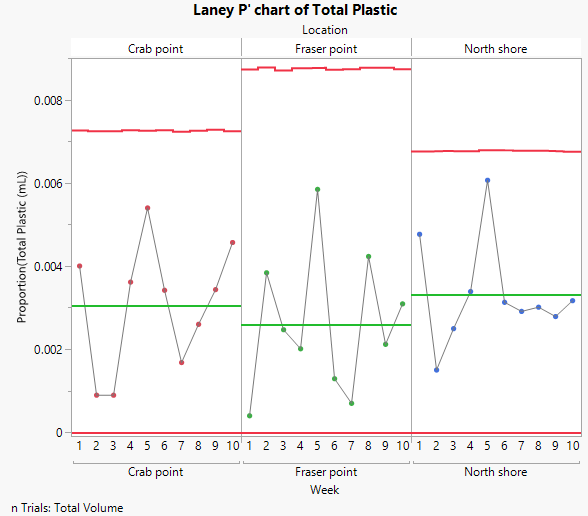

Example of a Laney P′ Chart

Laney P' Chart YouTube

(PDF) Evaluation of laney p’ chart performance

Laney P' U' control chart for overdispersionTao's Tips

Laney P' chart of LWBS rates rate by week. Download Scientific Diagram

Laney P' U' control chart for overdispersionTao's Tips

A New Control Chart Laney P’ Chart YouTube

Laney P' U' control chart for overdispersionTao's Tips

Laney P chart of the reject number. Download Scientific Diagram

However, If Your Data Exhibit.

Web This Historical Control Chart Shows Three Stages Of A Process, Which Represent Before, During, And After The Implementation Of A New Procedure.

Both Charts Monitor The Proportion Of Defective Items That Are Produced By Your Process.

A Z Value Tells You The Number Of Sample.

Related Post: