Knurling Patterns

Knurling Patterns - An internal knurling holder tool knurls up to a prescribed depth. It can enhance the appearance of customized items by creating unique patterns such as ridges and swirls on milled surfaces. Web knurling is a process used to create a pattern on the surface of a material by displacing or deforming the surface. The metal item is securely held in an upright position. Three common knurl patterns are: Top brandsdaily dealsunder $10buy it now available Diamond shapes are another popular knurling pattern. It's achieved by pressing a knurling tool against the workpiece, causing plastic deformation as the raised elements of the tool depress and deform the surface. Knurling serves to improve grip, facilitate. This is achieved by a rotating tool that impressions the desired pattern into the metal. It's achieved by pressing a knurling tool against the workpiece, causing plastic deformation as the raised elements of the tool depress and deform the surface. Knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. Web what is knurling? Web barbell knurling is the crosshatch pattern on the shaft of. Web unlock the secrets of knurling with our comprehensive guide! This is achieved by a rotating tool that impressions the desired pattern into the metal. Web however, the knurling patterns gradually become less defined, and defects like flattened areas and burrs begin to appear as the tool wears continuously. It can enhance the appearance of customized items by creating unique. Web knurling is a machining process that creates a patterned texture on a workpiece's surface, improving grip and aesthetics. Creating either type of pattern is relatively easy, especially using a lathe. To create a custom pattern, you can design the knurling wheel with the desired pattern using cad software, then have the wheel manufactured or machined. It is mostly performed. Web custom knurling patterns can be made using a cnc lathe or milling machine equipped with a knurling tool, designed to press a pattern onto a rotating workpiece. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Diamond shapes are another popular knurling pattern. Web knurling is a manufacturing. Web knurling tools produce straight, diagonal, or diamond patterns, having teeth of uniform pitch on cylindrical surfaces. Three common knurl patterns are: It can also be held. Web custom knurling patterns can be made using a cnc lathe or milling machine equipped with a knurling tool, designed to press a pattern onto a rotating workpiece. This process creates small ridges. This moving of the workpiece material creates the knurled pattern. Knurling is a finishing process in metalworking where grooves or patterns are formed on the surface of a finished part. Web knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. Web custom knurling patterns can be made using a. The metal item is securely held in an upright position. The type of pattern you create depends on the tool. The knurling process enhances the part’s durability and aesthetics while improving its grip. Knurling is done to increase the friction on a surface, and is typically performed on a lathe to cylindrical parts. Appeal, endurance, and traction than the initial. By using a tool with a specific pattern, manufacturing companies can achieve the same textured pattern on their products. Knurling uses the tool to displace material. It is mainly used for: This textured pattern, called a knurl, provides enhanced grip, facilitates rotational movement, and adds aesthetic value to the machined part. A knurled pattern is frequently used on plastic mold. Web knurling is a manufacturing process that deforms a workpiece, or a section of it, to achieve a rough patterned surface. Talented creatorsunique & vintage itemseveryday supplies Web knurling tools produce straight, diagonal, or diamond patterns, having teeth of uniform pitch on cylindrical surfaces. Generally, knurling patterns must have clear, definite lines and coherent depth. A diamond pattern may also. Web however, the knurling patterns gradually become less defined, and defects like flattened areas and burrs begin to appear as the tool wears continuously. Three common knurl patterns are: Web custom knurling patterns can be made using a cnc lathe or milling machine equipped with a knurling tool, designed to press a pattern onto a rotating workpiece. It can also. However, it would help to note that inadequate lubrication, incorrect tool. The knurling process enhances the part’s durability and aesthetics while improving its grip. Web barbell knurling is the crosshatch pattern on the shaft of olympic barbells that is intended to increase friction between your hands and the bar and thus improving grip. Generally, knurling patterns must have clear, definite lines and coherent depth. These patterns can consist of straight lines, angles, or interlocking designs. This process creates small ridges along the surface of the metal object so that it can be easily. This textured pattern, called a knurl, provides enhanced grip, facilitates rotational movement, and adds aesthetic value to the machined part. Hand knurling is ideal for small workpieces and simpler patterns, while machine knurling is suitable for larger and more complex components. Web what is knurling? Web custom knurling patterns can be made using a cnc lathe or milling machine equipped with a knurling tool, designed to press a pattern onto a rotating workpiece. Left/right with tips raised, spiral angle: Knurling uses the tool to displace material. A knurled pattern is frequently used on plastic mold casting to produce the impression of knurling in molded. It can enhance the appearance of customized items by creating unique patterns such as ridges and swirls on milled surfaces. A female diamond knurl creates protruded diamond patterns. Web knurling defined knurling is a manufacturing process that involves impressing a pattern of straight or diagonal lines onto a cylindrical or round surface.

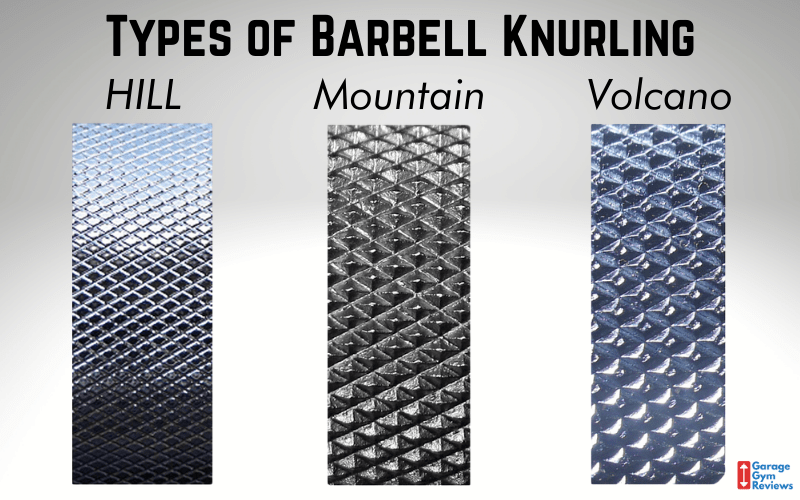

What is a knurl on a barbell? 3 Types of Knurling. MENSQUATS

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

Knurling.jpg (720×1200) Pattern design

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

The 3 Types of Barbell Knurling and What It Means for Your Grip

knurling operation? Purpose of knurling 5 knurl patterns knurling

The 3 Types of Barbell Knurling and What It Means for Your Grip

ArtStation Free Diamon / Knurling Pattern Alpha Material Brushes

What is Barbell Knurling and Why It Matters Garage Gym Reviews

Knurling Serves To Improve Grip, Facilitate.

A Great Example Of Knurling Is Seen On The Thimble Of Most Micrometers.

To Create A Custom Pattern, You Can Design The Knurling Wheel With The Desired Pattern Using Cad Software, Then Have The Wheel Manufactured Or Machined.

Different Patterns Require Various Knurling.

Related Post: