Is Mig Or Tig Easier

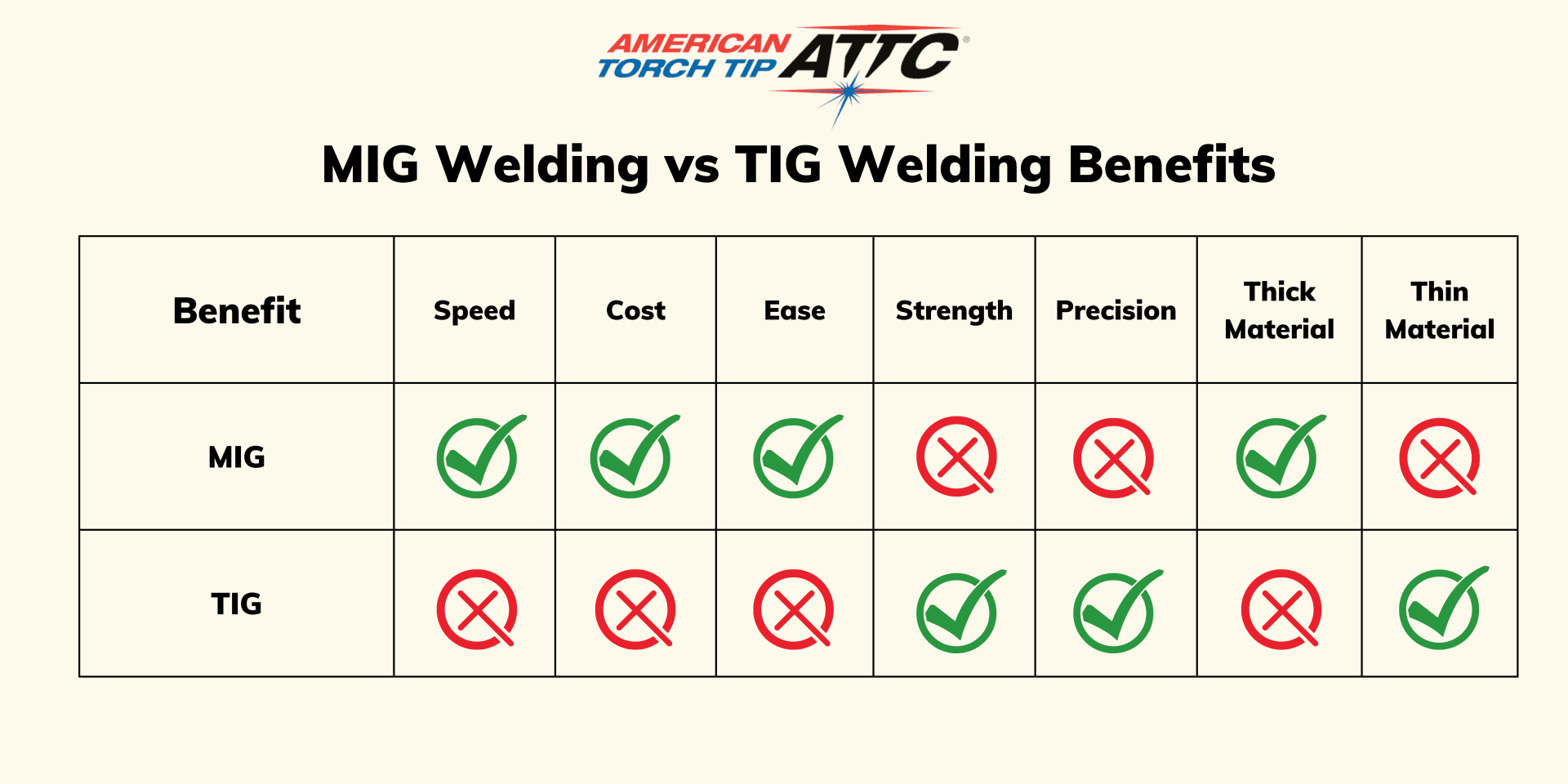

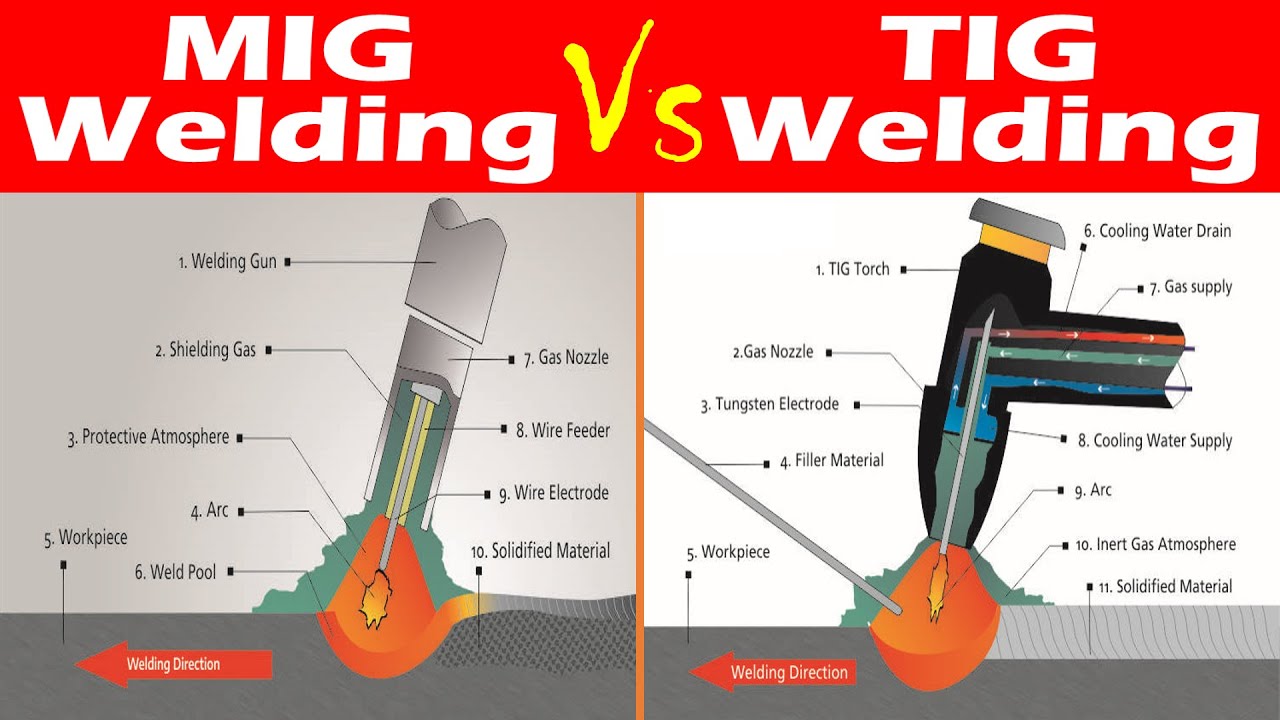

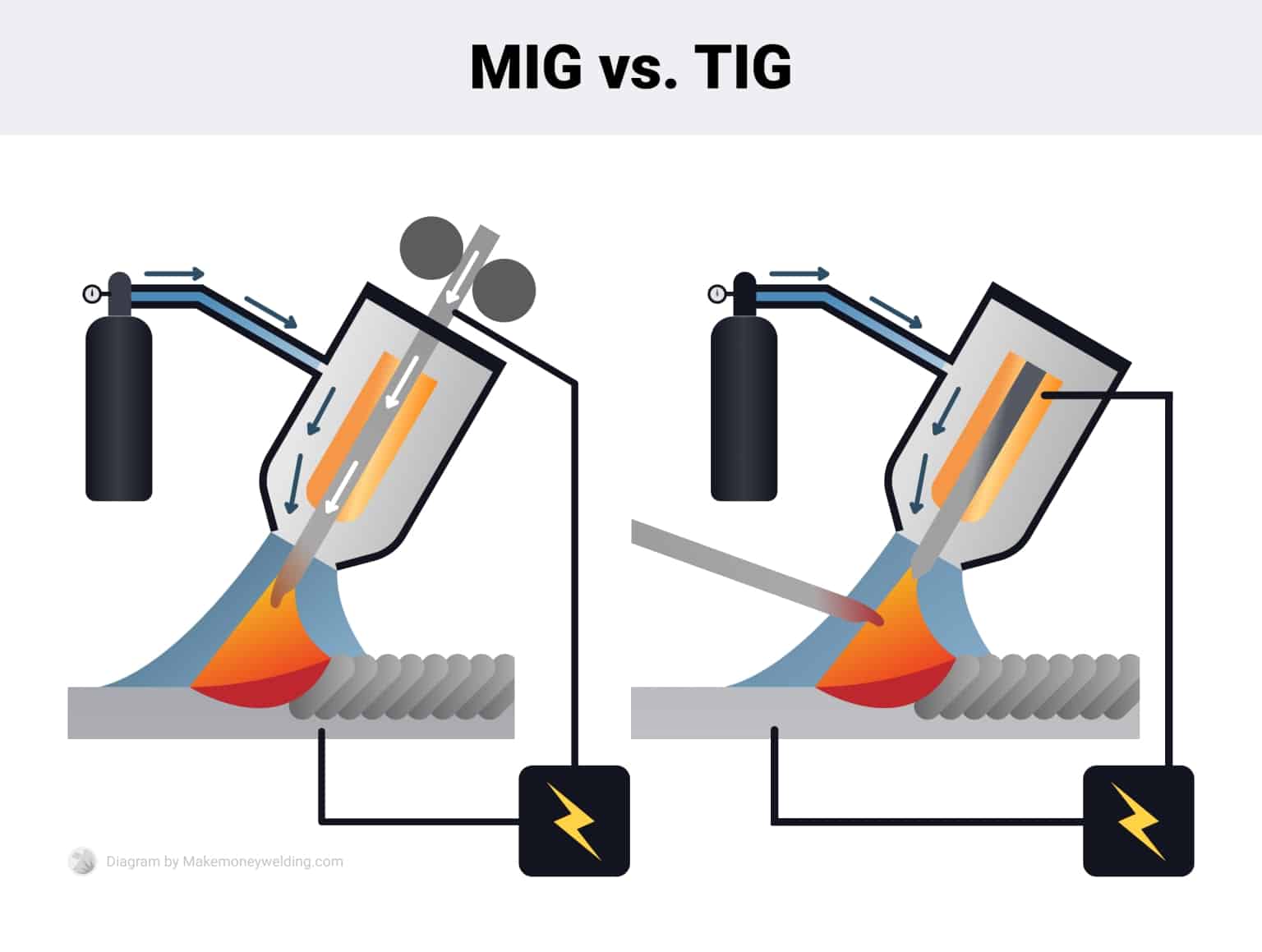

Is Mig Or Tig Easier - Mig welding is relatively easy to learn and use, making it a popular choice for both beginners and experienced welders. Mig welding is also easier to learn, making it easier to. The reason is that there is better operational. Web ease of use. Mig and tig at a glance. Web mig welding is faster than tig welding, creating shorter production times for welds and, subsequently, lower costs. If you’re working with delicate or thin. Web mig (metal inert gas) welding uses a consumable solid wire quickly fed into the welding pool, whereas tig (tungsten inert gas) welding uses a fixed electrode and a. The wire feed system simplifies the welding process, requiring. Web ease of use: Web the main difference between mig and tig welding is the electrode they use to create the arc. Mig welding is relatively easy to learn and use, making it a popular choice for both beginners and experienced welders. Embarking on the welding journey, it’s essential to grasp the. Web however, mig welding is the better process for welding thick metals,. In mig (metal inert gas) welding, the weld strength is generally considered to be good and suitable for a wide range of. Mig welding is relatively easy to learn and use, making it a popular choice for both beginners and experienced welders. If you’re working with delicate or thin. Mig welding is invariably considered the best type of welding for. Web however, mig welding is the better process for welding thick metals, while tig welding is better used for thin metals. Mig and tig at a glance. Embarking on the welding journey, it’s essential to grasp the. Web mig is a much easier process but the results aren’t quite to the same standard as tig. In mig (metal inert gas). The term mig (metal inert gas) refers to welding that uses a feed wire that constantly moves. Web because tig welding is more technically demanding, mig is easier to learn for beginners. You can weld in all types of positions. Web ease of use: Web mig welding is faster than tig welding, creating shorter production times for welds and, subsequently,. Embarking on the welding journey, it’s essential to grasp the. Web ease of use: The reason is that there is better operational. Web hitbox 140a mig welder gasless, 110v/220v dual voltage flux core welder flux mig/lift tig/stick 3 in 1 synergy mig welding machine with torch clamp. Mig and tig at a glance. Arc welding is the process of welding metals using heat generated by. Mig welding is invariably considered the best type of welding for beginners. Web hitbox 140a mig welder gasless, 110v/220v dual voltage flux core welder flux mig/lift tig/stick 3 in 1 synergy mig welding machine with torch clamp. Mig and tig at a glance. Mig welding is relatively easy. Mig uses a consumable solid wire that is machine fed to the weld,. Web mig welding, also known as gtaw (gas tungsten arc welding) is the technique of choice when joining thick metal objects, because of the extra mass added. The term mig (metal inert gas) refers to welding that uses a feed wire that constantly moves. If you’re working. Mig welding is also easier to learn, making it easier to. Web ease of use. The term mig (metal inert gas) refers to welding that uses a feed wire that constantly moves. Mig welding is relatively easy to learn and use, making it a popular choice for both beginners and experienced welders. Mig and tig welding both use an electric. Equipment is easy to clean. Web the main difference between mig and tig welding is the electrode they use to create the arc. Web mig weld strength is good, tig is better. Web mig welding is faster than tig welding, creating shorter production times for welds and, subsequently, lower costs. Web mig (metal inert gas) welding uses a consumable solid. Web the main difference between mig and tig is the way the arc is used. Web hitbox 140a mig welder gasless, 110v/220v dual voltage flux core welder flux mig/lift tig/stick 3 in 1 synergy mig welding machine with torch clamp. Mig welding is invariably considered the best type of welding for beginners. Web the main difference between mig and tig. Embarking on the welding journey, it’s essential to grasp the. In mig (metal inert gas) welding, the weld strength is generally considered to be good and suitable for a wide range of. Web ease of use: Equipment is easy to clean. Mig welding is relatively easy to learn and use, making it a popular choice for both beginners and experienced welders. Web however, mig welding is the better process for welding thick metals, while tig welding is better used for thin metals. The reason is that there is better operational. Web ease of use. Mig welding is invariably considered the best type of welding for beginners. Web hitbox 140a mig welder gasless, 110v/220v dual voltage flux core welder flux mig/lift tig/stick 3 in 1 synergy mig welding machine with torch clamp. Web mig welding is faster than tig welding, creating shorter production times for welds and, subsequently, lower costs. Web the main difference between mig and tig welding is the electrode they use to create the arc. Web mig welding, also known as gtaw (gas tungsten arc welding) is the technique of choice when joining thick metal objects, because of the extra mass added. Web mig weld strength is good, tig is better. Web because tig welding is more technically demanding, mig is easier to learn for beginners. Stick is useful for welding rusty metal or welding outside on the farm.

MIG vs TIG Welding Why a MIG Welder is More Efficient

MIG vs. TIG Welding Differences Which Is Better?

MIG vs TIG vs Stick Welding UNIMIG Welding Guides & Tutorials

Welding TIG vs MIG What's the Difference

TIG vs MIG Welding (Differences). Which Is Better & Why?

![Tig and Mig Welding The Real Differences Explained [PDF]](https://www.theengineerspost.com/wp-content/uploads/2018/12/Difference-Between-Tig-and-Mig-Welding.jpg)

Tig and Mig Welding The Real Differences Explained [PDF]

MIG VS TIG Welding Ultimate Guide Weldinguru

Differences between MIG Welding and TIG Welding. YouTube

MIG vs TIG Welding Types, Materials, and Applications A Guide

MIG vs. TIG Welding Differences Which Is Better?

Web Mig (Metal Inert Gas) Welding Uses A Consumable Solid Wire Quickly Fed Into The Welding Pool, Whereas Tig (Tungsten Inert Gas) Welding Uses A Fixed Electrode And A.

Arc Welding Is The Process Of Welding Metals Using Heat Generated By.

Web 30.06.2022 By Siim Sild.

The Term Mig (Metal Inert Gas) Refers To Welding That Uses A Feed Wire That Constantly Moves.

Related Post: