Gear Patterns For Ring And Pinions

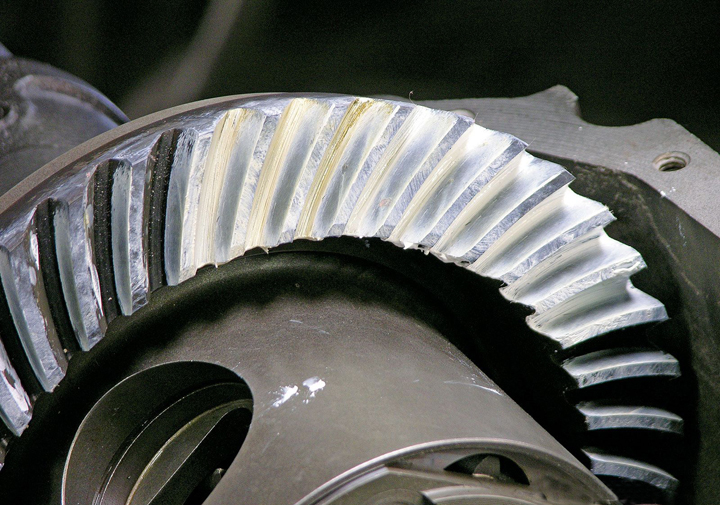

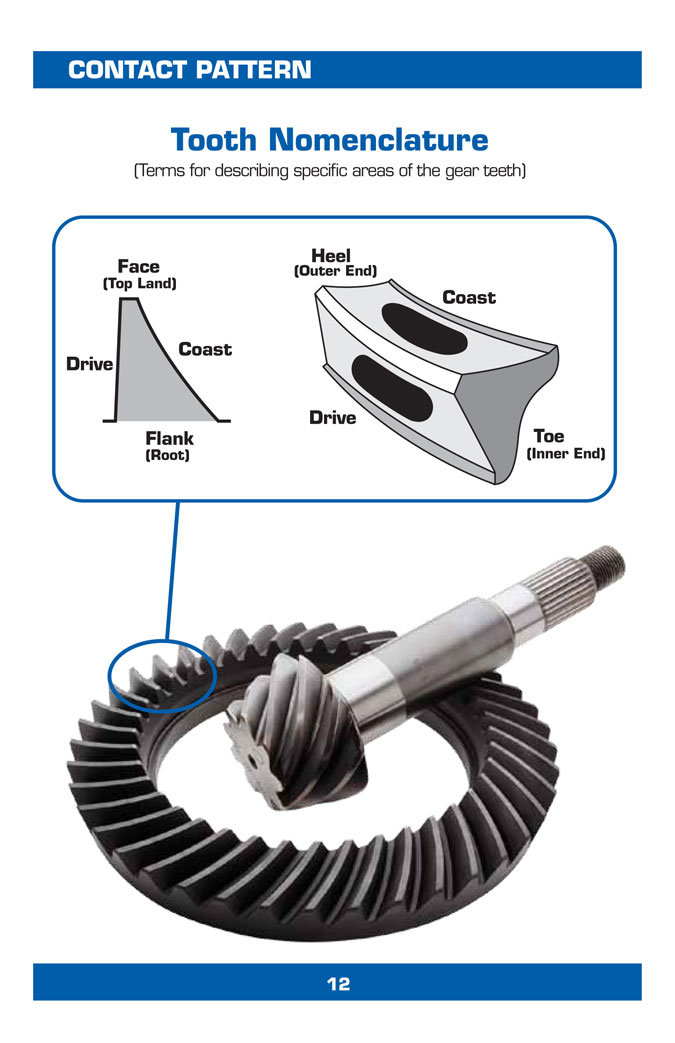

Gear Patterns For Ring And Pinions - Move the ring gear farther from the pinion gear to increase backlash. Web proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. Sent from my iphone using h.a.m.b. Coast pattern (concave side of gear) moves lower and toward the toe. You can check the pattern again after you get it set up and see. Web the pattern refers to how the ring gear and pinion gears mesh. Web here's how to achieve the best ring & pinion contact pattern , every time, in just 3 simple steps!reading contact patterns can be daunting when looking at th. Use gear marking compound to paint all of the ring gear teeth. Supply some drag on the ring gear while doing it. Drive pattern (convex side of gear) moves slightly lower and toward the toe. Used gears have wear on them and will not have the same type of pattern as new gears. Sequential graphic detail from too deep to to sha. Web closer to the ring gear. If your gear tooth pattern is too low, down towards the gear flank (root), you will need to decrease your pinion. You can check the pattern again. Web see how to set up a ring and pinion gear set. Drive pattern moves toward the top of the tooth (face contact) and toward the. The procedure involves changing the pinion position via shims in the carrier and repositioning the carrier. Web the pattern refers to how the ring gear and pinion gears mesh. Use shims to move the. Drive pattern (convex side of gear) moves slightly lower and toward the toe. Web closer to the ring gear. Use shims to move the ring gear farther from the pinion gear to increase backlash. Yukon provides highest quality drivetrain parts including differentials, axles, driveshafts, super joints and ring and pinion installation kits. (2) increasing backlash moves the ring gear away. The procedure involves changing the pinion position via shims in the carrier and repositioning the carrier. Web here's how to achieve the best ring & pinion contact pattern , every time, in just 3 simple steps!reading contact patterns can be daunting when looking at th. (2) increasing backlash moves the ring gear away from the pinion. Supply some drag on. Web closer to the ring gear. Use shims to move the ring gear closer to the pinion gear to decrease backlash. Timeline:0:00 introduction0:22 pinion gear examples 0:40 pinion bearing locations 0:48 oil splash shield and se. Once pinion depth has been set, a final backlash setting can be achieved by adjusting the location of the differential and ring gear. Begin. Load the ring gear and run a full contact pattern check. Shallow pinion position, with correct backlash, moves the pinion further from the ring gear. Web here's how to achieve the best ring & pinion contact pattern , every time, in just 3 simple steps!reading contact patterns can be daunting when looking at th. Sequential graphic detail from too deep. Web ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Coast pattern moves deeper on the tooth and toward the heel. Use gear marking compound to paint all of the ring gear teeth. This will help give you a nice clear pattern like this one. Shallow pinion position,. Use shims to move the ring gear farther from the pinion gear to increase backlash. Drive pattern moves toward the top of the tooth (face contact) and toward the. Sent from my iphone using h.a.m.b. Web improper gear spacing will lead to wear and damage to your gear set. Web this will move the drive side contact point down towards. Supply some drag on the ring gear while doing it. Once pinion depth has been set, a final backlash setting can be achieved by adjusting the location of the differential and ring gear. (2) increasing backlash moves the ring gear away from the pinion. Web closer to the ring gear. Ring gear tooth profile face hobbing face milling the toe. If the pattern is heavy on Web improper gear spacing will lead to wear and damage to your gear set. Rotate the ring gear several times by hand and inspect the ring gear teeth. You don’t need to go much, maybe 0.005” to start with, set backlash run a pattern, repeat as necessary. Begin by setting proper pinion bearing preload,. Rotate the ring gear several times by hand and inspect the ring gear teeth. Worn carrier or pinion bearings can create excessive play between the gears and produce an uneven wear pattern or chipping teeth. The coast side contact pattern will also move down towards the flank but out slightly towards the heel of the ring gear. Timeline:0:00 introduction0:22 pinion gear examples 0:40 pinion bearing locations 0:48 oil splash shield and se. Use shims to move the pinion closer to the ring gear to move the drive pattern deeper on the tooth (flank contact) and slightly toward the toe. Web here's how to achieve the best ring & pinion contact pattern , every time, in just 3 simple steps!reading contact patterns can be daunting when looking at th. Sent from my iphone using h.a.m.b. There is a process used when reassembling a differential that optimizes ring gear and pinion tooth contact. Web reading and interpreting gear patterns can be very confusing if they aren't obvious patterns. Coast pattern moves deeper on the tooth and toward the heel. If the differential was loose and it had about.014 backlash then i would just set the backlash to about.009 and get the bearings tight and hope for the best. Once pinion depth has been set, a final backlash setting can be achieved by adjusting the location of the differential and ring gear. This will help give you a nice clear pattern like this one. Incorrect backlash can lead to damaged gear. Web yes, move the pinion towards the center of the ring gear, the pattern should move in towards the toe or inside of the ring gear and towards the flank or down into the “valley” of the tooth. Load the ring gear and run a full contact pattern check.

How To Create & Read Ring Gear Patterns

Ring Gear And Pinion Pattern

How to Select the Optimal Ring and Pinion Gears for a Dana Rear

Ring Gear And Pinion Pattern

Pinion/ring gear wear pattern ?

Ring Gear And Pinion Pattern

Ring & Pinion Installation Instructions The Ranger Station

How to Read and Interpret Gear Patterns (Ring and Pinion) YouTube

The Easiest Way to Read Ring & Pinion Contact Patterns YouTube

Figure 83. Proper piniontodifferential ring gear tooth contact pattern.

Use Shims To Move The Ring Gear Closer To The Pinion Gear To Decrease Backlash.

Ensuring Peak Performance And Longevity.

Move The Ring Gear Farther From The Pinion Gear To Increase Backlash.

(2) Increasing Backlash Moves The Ring Gear Away From The Pinion.

Related Post: